Page 1

RLM R6+ Performer

Owners manual

R9010270

R5976816/03

02/06/2006

Page 2

Barco nv Events

aan 5, B-8520 Kuurne

Noordl

Phone: +32 56.36.89.70

Fax: +32 56.36.88.24

sales.events@barco.com

E-mail:

Visit us at the web: www.barco.com

Printed in Taiwan

Page 3

Changes

Barco provides this manual ’as is’ without warranty of any kind, either expressed or implied, including but not limited to the implied warranties or merchantability and fitness for a particular purpose. Barco may make improvements and/or changes to the product(s) and/or the

program(s) described in this publication at any time without notice.

This publication could contain technical inaccuracies or typographical errors. Changes are periodically made to the information in this

publication; these changes are incorporated in new editions of this publication.

Copyright ©

All rights reserved. No part of this document may be copied, reproduced or translated. It shall not otherwise be recorded, transmitted or

stored in a retrieval system without the prior written consent of Barco.

Guarantee and Compensation

Barco provides a guarantee relating to perfect manufacturing as part of the legally stipulated terms of guarantee. On rece

must immediately inspect all delivered goods for damage incurred during transport, as well as for material and manufacturing faults Barco

must be informed immediately in writing of any complaints.

The period of guarantee begins on the date of transfer of risks, in the case of special systems and software on the date of commissioning,

at latest 30 days after the transfer of risks. In the event of justified notice of complaint, Barco can repair the fault or provide a replacement

at its own discretion within an appropriate period. If this measure proves to be impossible or unsuccessful, the purchaser can demand a

reduction in the purchase price or cancellation of the contract. All other claims, in particular those relating to compensation for direct or

indirect damage, and also damage attributed to the operation of software as well as to other services provided by Barco, being a component

of the system or independent service, will be deemed invalid provided the damage is not proven to be attributed to the absence of properties

guaranteed in writing or due to the intent or gross negligence or part of Barco.

If the purchaser or a third party carries out modifications or repairs on goo

in particular if the systems are commissioned operated incorrectly or if, after the transfer of risks, the goods are subject to influences not

agreed upon in the contract, all guarantee claims of the purchaser will be rendered invalid. Not included in the guarantee coverage are

system failures which are attributed to programs or special electroni

well as normal maintenance are not subject to the guarantee provided by Barco either.

The environmental conditions as well as the servicing and maintenance regulations specified in the this manual must be complied with by

the customer.

ds delivered by Barco, or if the goods are handled incorrectly,

c circuitry provided by the purchaser, e.g. interfaces. Normal wear as

ipt, the purchaser

Trademarks

Brand and product names mentioned in this manual may be trade

All brand and product names mentioned in this manual serve as comments or examples and are not to be understood as advertising for

the products or their manufactures.

marks, registered trademarks or copyrights of their respective holders.

Page 4

Page 5

Table of contents

TABLE OF CONTENTS

1. Packaging and Dimensions ...................................................................................... 5

1.1 Boxcontent........................................................................................................................... 5

1.2 Projector Packaging.................................................................................................................. 5

1.3 Dimensions ........................................................................................................................... 7

2. Installation Guidelines............................................................................................11

2.1 General .............................................................................................................................. 11

2.2 Projector Configuration..............................................................................................................12

2.3 Lenses . ..............................................................................................................................14

2.3.1 Lenses. . ... ....................................................................................................................14

2.3.2 Lens formulas .. ...............................................................................................................15

2.3.3 Lens installation ...............................................................................................................15

2.3.4 Cleaning the lens . ............................................................................................................ 16

2.4 BatteryInsertion inthe Remote Control ............................................................................................ 16

2.5 Stackingprojectors .................................................................................................................. 17

2.6 Riggingpointsand accessories.....................................................................................................19

2.6.1 Overview ...................................................................................................................... 19

2.6.2 Mounting the clamps.. . . ...................................................................................................... 19

3. Connections ........................................................................................................21

3.1 Power connection ...................................................................................................................21

3.2 Input Source Connections...........................................................................................................22

3.2.1 Input section...................................................................................................................22

3.2.2 Input facilities. . ................................................................................................................ 22

3.3 5-Cable input . . . ..................................................................................................................... 23

3.4 Composite Video Input .............................................................................................................. 25

3.5 S-Video input . . ... ...................................................................................................................26

3.6 Digital Visual Interface (DVI) input .................................................................................................. 27

3.7 Computer input (RGB analog) . . ....................................................................................................29

3.8 SDIorHDSDIinput..................................................................................................................29

3.9 Communication connection . ... . ....................................................................................................30

3.9.1 RS232 IN connection . ... ..................................................................................................... 30

3.9.2 Wirelessreceiver.............................................................................................................. 31

3.10 Extended configuration . . ............................................................................................................32

3.10.1 Introduction....................................................................................................................32

3.10.2 5-cable extended configuration. .. ............................................................................................32

3.10.3 S-Video extended configuration . . ............................................................................................33

3.10.4 Summarizing..................................................................................................................34

4. Getting Started.....................................................................................................35

4.1 Terminology overview ...............................................................................................................35

4.2 Switching on .........................................................................................................................37

4.3 Lamp runtime ........................................................................................................................ 38

4.4 Switching to standby . ...............................................................................................................38

4.5 Switching off .........................................................................................................................39

4.6 Temperature error DMD .............................................................................................................39

4.7 Using theRCU....................................................................................................................... 39

4.8 Projector address . ...................................................................................................................41

4.8.1 Address setting ............................................................................................................... 41

4.8.2 Displaying andProgramming addresses into theRCU......................................................................42

4.9 Controlling the projector.............................................................................................................42

4.10 Quick lensadjustment...............................................................................................................44

4.10.1 Lens Adjustment via Control Buttons on Projector . ... ...................................................................... 44

4.10.2 Lens Adjustment via Menu Bar ... ............................................................................................ 44

4.10.3 Direct Lens Adjustment (RCU) . . .............................................................................................45

4.11 Digital Zoom ......................................................................................................................... 45

4.12 Quick Picture inPicture selection...................................................................................................46

5. Getting used with the menu structure.........................................................................47

5.1 Howtostartup the menus..........................................................................................................47

5.2 Using themenu......................................................................................................................47

5.3 Using theDialogboxes..............................................................................................................48

5.4 Using the menus via the built-in LCD panel . . . .....................................................................................49

6. Source selection...................................................................................................51

6.1 Source Selection overview..........................................................................................................51

6.2 Theuse of icons .....................................................................................................................51

6.3 Source selection.....................................................................................................................51

6.4 Selecting a datasource on the 5-cable input....................................................................................... 52

6.5 Composite Video ....................................................................................................................53

6.6 S-Video selection .................................................................................................................... 53

6.7 TheVideo Selector ..................................................................................................................54

R5976816 RLM R6+ PERFORMER 02/06/2006

1

Page 6

Table of contents

7. General Menu ......................................................................................................57

7.1 General Menu overview ............................................................................................................. 57

7.2 Pause ................................................................................................................................57

7.3 Freeze ...............................................................................................................................57

7.4 Standby Timer . ... ...................................................................................................................58

7.5 Identification .........................................................................................................................59

8. Image Menu ........................................................................................................61

8.1 Image menu overview...............................................................................................................62

8.2 Settings .............................................................................................................................. 63

8.2.1 Contrast....................................................................................................................... 63

8.2.2 Brightness.....................................................................................................................64

8.2.3 Color...........................................................................................................................65

8.2.4 Tint (hue) . . .................................................................................................................... 65

8.2.5 Sharpness.....................................................................................................................66

8.2.6 Gamma........................................................................................................................ 67

8.2.7 Phase..........................................................................................................................67

8.2.8 Noise reduction ............................................................................................................... 68

8.3 Aspect ratio ..........................................................................................................................69

8.4 Show native resolution ..............................................................................................................72

8.5 Keystone correction ................................................................................................................. 73

8.6 Color Temperature................................................................................................................... 74

8.7 Color space.......................................................................................................................... 77

8.8 Filmmode detection..................................................................................................................80

8.9 Blanking.............................................................................................................................. 81

8.10 InputBalance........................................................................................................................83

8.10.1 Introduction to Input Balance ................................................................................................. 83

8.10.2 Adjusting theinputbalance...................................................................................................85

8.10.3 Input balance for YPrPb signals ..............................................................................................87

8.11 AGC on Video ....................................................................................................................... 88

8.12 ManualGainControl ................................................................................................................ 89

9. Tools Menu .........................................................................................................91

9.1 Overview of theTools menu......................................................................................................... 91

9.2 Introduction to PiP ................................................................................................................... 91

9.3 PiPselect............................................................................................................................ 93

9.4 PiP add window. .. ...................................................................................................................94

9.5 PiP remove window . . ...............................................................................................................95

9.6 PiPlayout............................................................................................................................ 96

9.6.1 PiP Save ......................................................................................................................96

9.6.2 PiP rename layout . ...........................................................................................................97

9.6.3 PiP deletelayout..............................................................................................................98

9.7 PiPAdjust............................................................................................................................98

10. Signal menu...................................................................................................... 101

10.1 Overview of the Signal menu. . . ....................................................................................................101

10.2 Switching mode.....................................................................................................................101

10.3 OutputFrame rate..................................................................................................................103

10.4 Background .........................................................................................................................104

11. Lamps Menu...................................................................................................... 105

11.1 Overview of the Lamps menu......................................................................................................105

11.2 Runtimes............................................................................................................................105

11.3 Mode................................................................................................................................106

11.4 Economic ON/OFF . ................................................................................................................107

11.5 Runtime warning....................................................................................................................107

12. Image Files Menu................................................................................................ 109

12.1 Overview ofthe Image Files Menu.................................................................................................109

12.2 Introduction to image files ..........................................................................................................109

12.3 Load file .............................................................................................................................110

12.4 File selection........................................................................................................................111

12.5 AutoImage.......................................................................................................................... 111

12.6 Editfile ..............................................................................................................................112

12.6.1 Editing a file..................................................................................................................112

12.6.2 Correct fileparameters ......................................................................................................113

12.6.3 Advanced video settings.....................................................................................................113

12.6.4 Advanced Data settings .....................................................................................................114

12.7 Rename file.........................................................................................................................115

12.8 Copy ................................................................................................................................116

12.9 Delete ...............................................................................................................................116

12.10Automaticload......................................................................................................................117

12.11 Zoom-Focus ........................................................................................................................118

13. Display Setup .................................................................................................... 119

13.1 Startup screen ......................................................................................................................119

13.2 TextBox .............................................................................................................................119

2

R5976816 RLM R6+ PERFORMER 02/06/2006

Page 7

Table of contents

13.3 Menubar position ..................................................................................................................120

13.4 Status barposition..................................................................................................................121

13.5 Sliderbox position...................................................................................................................122

13.6 AutoImage Setup ..................................................................................................................122

13.7 Scenergix . .........................................................................................................................124

13.7.1 Introduction...................................................................................................................124

13.7.2 Preparations..................................................................................................................124

13.7.3 ScenergiX overlap zone (horizontal scenergix) . ............................................................................125

13.7.4 ScenergiX overlap zone(verticalscenergix)................................................................................126

13.7.5 ScenergiX borderadjustment ...............................................................................................126

13.7.6 Black level ofthe images ....................................................................................................128

14. Installation menu ................................................................................................ 131

14.1 Lens adjustments . ..................................................................................................................131

14.2 Projector address . ..................................................................................................................132

14.3 Orientation ..........................................................................................................................134

14.4 Language . . .........................................................................................................................134

14.5 Quickaccess keys..................................................................................................................135

14.6 RS baudrate ........................................................................................................................136

14.7 RS mode............................................................................................................................136

14.8 Automaticstartup...................................................................................................................137

14.9 Security .............................................................................................................................138

15. Service ............................................................................................................ 141

15.1 Version Table .......................................................................................................................141

15.2 Lamps andPower supply ..........................................................................................................141

15.3 Board Identification ... ..............................................................................................................142

15.4 Diagnostics .........................................................................................................................143

15.4.1 I²C Diagnostics...............................................................................................................143

15.4.2 Lamps and powersupply....................................................................................................144

15.5 Formatterfirmware .................................................................................................................145

15.6 Formatterreset .....................................................................................................................145

16. Adjustment menu (check up) ................................................................................. 147

16.1 Internalpatterns ....................................................................................................................147

16.2 Convergence ... . . ..................................................................................................................148

16.3 More.. ...............................................................................................................................148

A. Standard Image Files............................................................................................. 149

A.1 Tableoverview......................................................................................................................149

B. Maintenance of the Projector................................................................................... 151

B.1 Air Filters............................................................................................................................151

C. Specifications ..................................................................................................... 153

C.1 RLM R6+ Performer specifications ................................................................................................153

Glossary............................................................................................................... 155

Index.................................................................................................................... 157

R5976816 RLM R6+ PERFORMER 02/06/2006 3

Page 8

Table of contents

4 R5976816 RLM R6+ PERFORMER 02/06/2006

Page 9

1. PACKAGING AND DIMENSIONS

Overview

• Box content

• Projector Packaging

• Dimensions

1.1 Box content

CEE7

European power plug to connect the power cord to the wall outlet.

ANSI 73.11

American power plug to connect the power cord to the wall outlet.

Content

• 1 RLM R6+ Performer projector (weight ± 30 kg or 67 lbs)

• 1 remote control unit RCU + 2 batteries.

• 2 power cables with outlet plug type CEE7 and ANSI 73.11.

• 1 owners manual

• 1 safety manual

1. Packaging and Dimensions

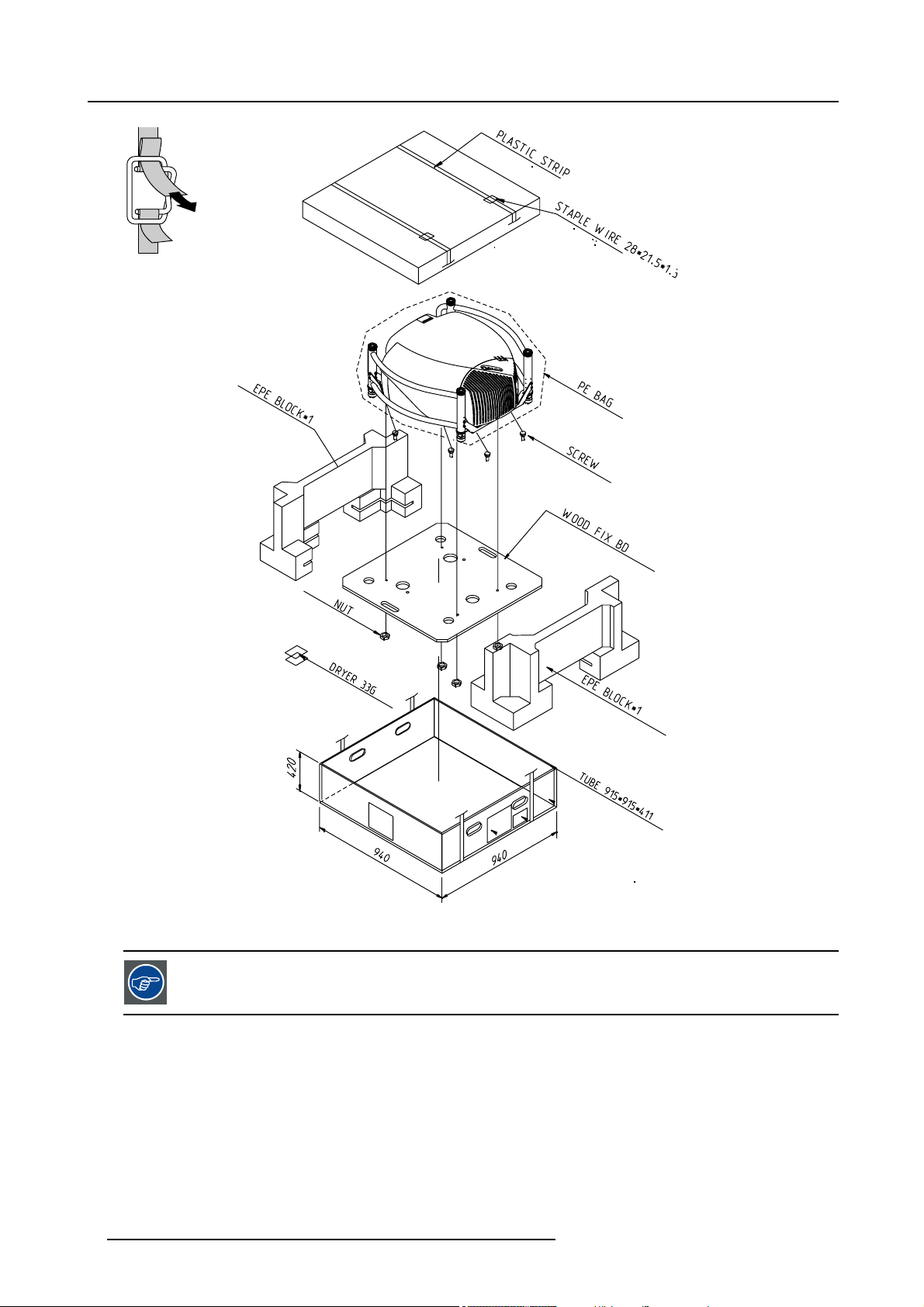

1.2 Projector Packaging

Way of Packaging

The projector is packed in a carton box. To provide protection during transportation, the projector is surrounded with foam. The

package is secured with banding and fastening clips.

To unpack

1. Is your projector packed with a fastening clips?

If yes, release the fastening clips (image 1-1)

If no, go to step 3

2. Remove the banding. Handle as shown in the drawing and continue with step 4.

3. Cut the binding ribbons.

4. Take the projector out of its shipping carton and place it on a table. (image 1-2)

R5976816 RLM R6+ PERFORMER 02/06/2006

5

Page 10

1. Packaging and Dimensions

PULL

TO OPE

Image 1-1

Image 1-2

Projector packaging

Save the original shipping carton and packing material, they will be necessary if you ever have to ship your

projector. For maximum protection, repack your projector as it was originally packed at the factory.

6 R5976816 RLM R6+ PERFORMER 02/06/2006

Page 11

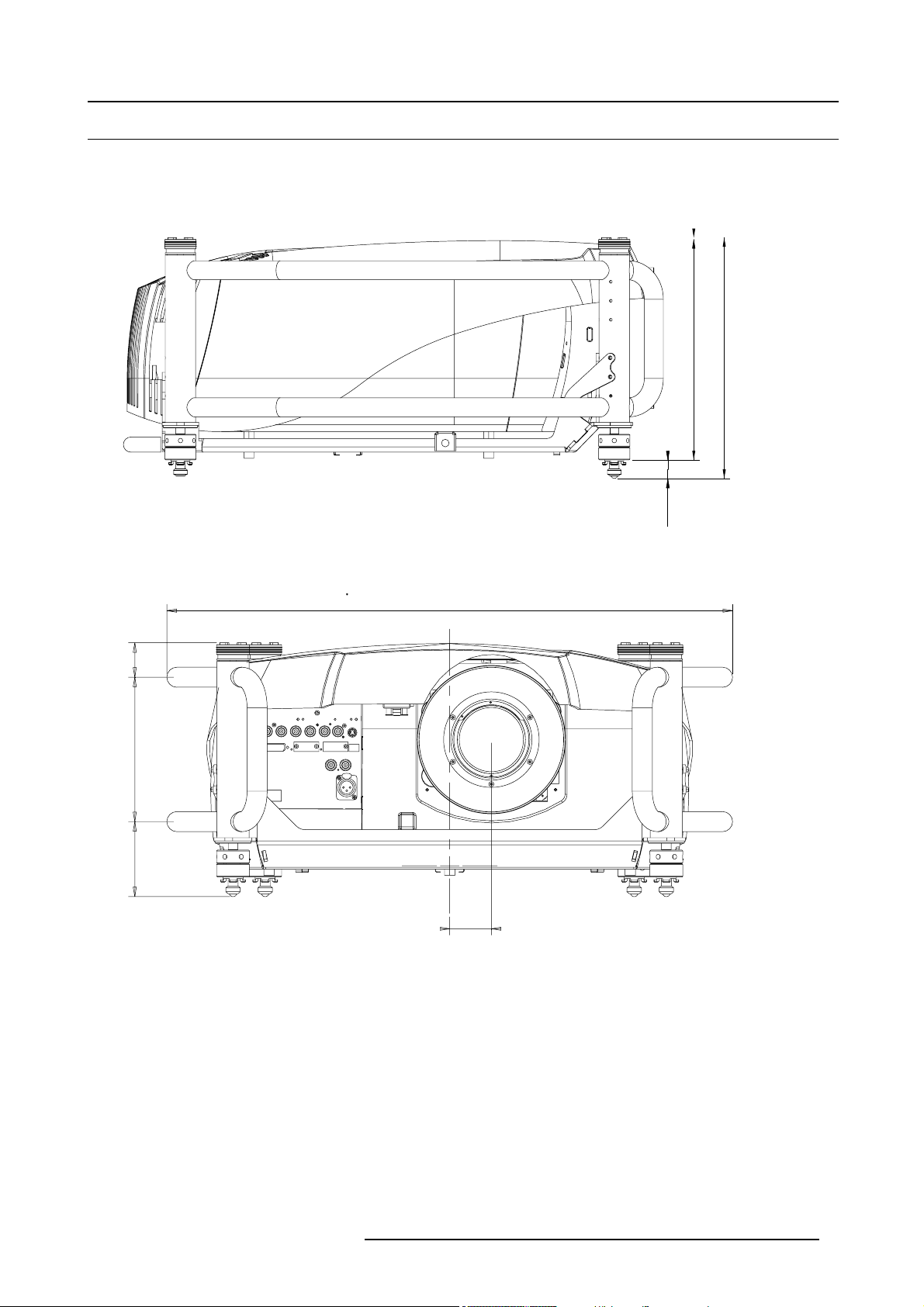

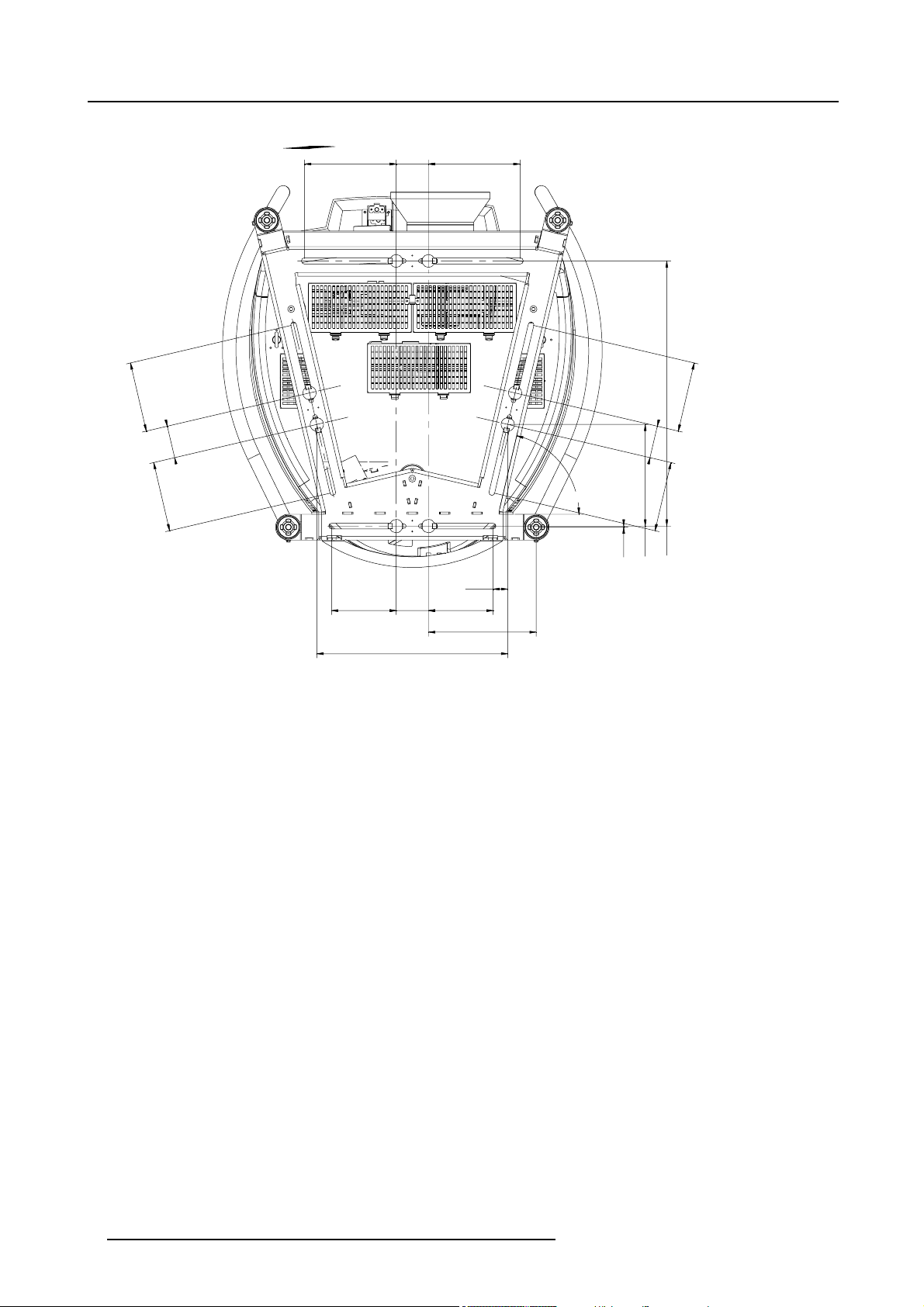

1.3 Dimensions

12 461

[

]

[

]

Side view

Image 1-3

Side view

1. Packaging and Dimensions

,091

2,3

[]

316,5

11,406

289,7

[]

]

4,5

,965

Front view

43

[1.69]

180

[7.09]

93.5

[3.68]

Image 1-4

Front view

705

[27.76]

51.9

2.04

R5976816 RLM R6+ PERFORMER 02/06/2006 7

Page 12

1. Packaging and Dimensions

[13.96]

Bottom view

[

5

1

3

.

1

0

2

]

[

2

.

3

[

5

.

1

2

]

Image 1-5

Bottom view

170

[6.69]

6

0

6

]

1

3

0

120

[4.72]60[2.36]

60

[2.36]

354.5

170

[6.69]

[1.07]

120

[4.72]

27.2

200

[7.87]

76.8°

2

0

6

188.8

[0.079]

]

6

3

.

2

[

0

3

1

5

[

492.4

[7.43]

0

3

1

]

2

1

.

[19.39]

]

2

1

.

5

[

8 R5976816 RLM R6+ PERFORMER 02/06/2006

Page 13

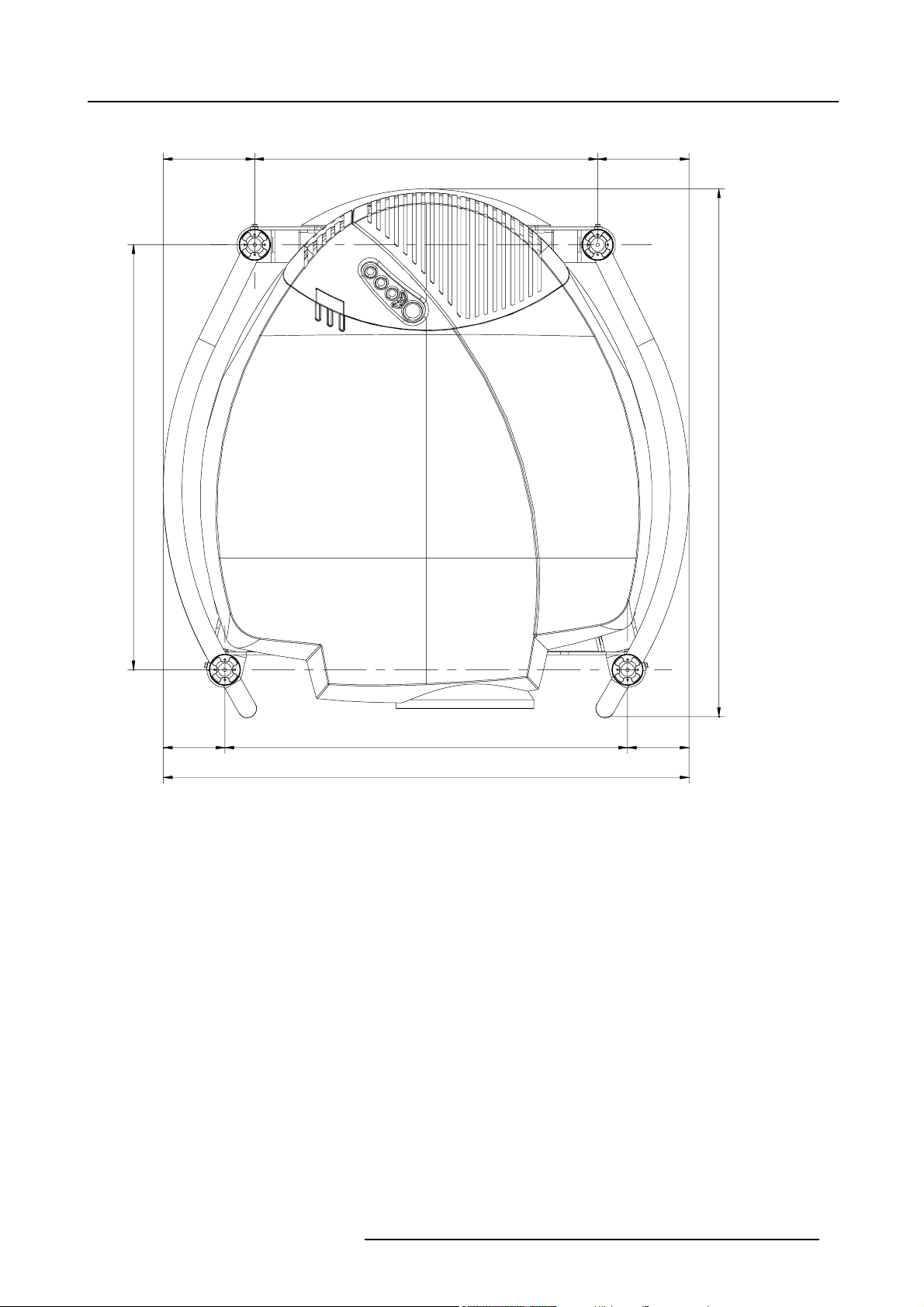

Top view

460

[27 87]

122.5

[4.82]

[18.11]

1. Packaging and Dimensions

122.5

[4.82]

570

[22.44]

Image 1-6

To p v ie w

82.5

[3.25]

705

540

[21.26]

82.5

[3.25]

707.8

R5976816 RLM R6+ PERFORMER 02/06/2006 9

Page 14

1. Packaging and Dimensions

10 R5976816 RLM R6+ PERFORMER 02/06/2006

Page 15

2. INSTALLATION GUIDELINES

Overview

• General

• Projector Configuration

• Lenses

• Battery Insertion in the Remote Control

• Stacking projectors

• Rigging points and accessories

WARNING: Before installing the projector, read first the safety instructions.

2.1 General

WARNING: Before installing the projector, read first the safety instructions.

2. Installation Guidelines

Ambient Temperature Conditions.

Careful consideration of things such as image size, ambient light level, projector placement and type of screen to use are critical to

the optimum use of the projection system.

Max. ambient temperature : 35°C or 95 °F

Min. ambient temperature : 10 °C or 50 °F

The projector will not operate if ambient air temperature falls outside this range (10°C- 35°C or 50°F-95°F).

Storage temperature: -35°C to +65°C (-31°F to 149°F)

Humidity Conditions

Storage: 0 to 98 % RH Non-condensing

Operation: 0 to 95 % RH Non-condensing

CAUTION: Harmful Environmental Contamination Precaution

Environment

Do not install the projection system in a site near heat sources such

excessive dust or humidity. Be aware that room heat rises to the ceiling; check that temperature near the installation site is not

excessive.

as radiators or air ducts, or in a place subject to direct sunlight,

Environment condition check

A projector must always be mounted in a manner which ensures the free flow of clean air into the projectors ventilation inlets. For

installations in environments where the projector is subject to airborne contaminants such as that produced by smoke machines or

similar (these deposit a thin layer of greasy residue upon the projectors internal optics and imaging electronic surfaces, degrading

performance), then it is highly advisable and desirable to have this contamination removed prior to it reaching the projectors clean

air supply. Devices or structures to extract or shield contaminated air well away from the projector are a prerequisite, if this is not a

feasible solution then measures to relocate the projector to a clean air environment should be considered.

Only ever use the manufacturer’s recommended cleaning kit which has been specifically designed for cleaning optical parts, never

use industrial strength cleaners on the project

components. Failure to take suitable precautions to protect the projector from the effects of persistent and prolonged air contaminants will culminate in extensive and irreversible ingrained optical damage. At this stage cleaning of the internal optical units will

be non-effective and impracticable. Damage

and may deem the warranty null and void. In such a case the client shall be held solely responsible for all costs incurred during any

repair. It is the clients responsibility to ensure at all times that the projector is protected from the harmful effects of hostile airborne

particles in the environment of the projec

wantful neglect, abandon or improper use.

or’s optics as these will degrade optical coatings and damage sensitive optoelectronics

of this nature is under no circumstances covered under the manufacturer’s warranty

tor. The manufacturer reserves the right to refuse repair if a projector has been subject to

R5976816 RLM R6+ PERFORMER 02/06/2006

11

Page 16

2. Installation Guidelines

Special Care for Laser Beams

Special care should be used when DLP projectors are used in the same room as performant laser equipment. Direct or indirect hitting

of a laser beam on to the lens can severely damage the Digital MicroMirror Devices™ in which case there is a loss of warranty

Which screen type ?

There are two major categories of screens used for projection equipment. Those used for front projected images and those for rear

projection applications.

Screens are rated by how much light they reflect (or transmit in the case of rear projection systems) given a determined amount

of light projected toward them. The ‘GAIN’ of a screen is the term used. Front and rear screens are both rated in terms of gain.

The gain of screens range from a white matte screen with a gain of 1 (x1) to a brushed aluminized screen with a gain of 10 (x10)

or more. The choice between higher and lower gain screens is largely a matter of personal preference and another consideration

called the Viewing angle. In considering the type of screen to choose, determine where the viewers will be located and go for the

highest gain screen possible. A high gain screen will provide a brighter picture but reduce the viewing angle. For more information

about screens, contact your local screen supplier.

What image size? How big should the image be?

The projector is designed for projecting an image size : min 1.00m (3.3ft) to max 15 m (49.2ft) (depending on the ambient light

conditions), with an aspect ratio of 4 to 3.

2.2 Projector Configuration

Which configuration can be used?

The projector can be installed to project images in four different configurations:

• Front/table

• Rear/table

• Front/ceiling

• Rear/ceiling

Positioning the projector

The projector should be installed perpendicular with the screen on a distance PD and water leveled in both directions. The mounting

positions in the following images are shown for a nominal lens position.

12

R5976816 RLM R6+ PERFORMER 02/06/2006

Page 17

2. Installation Guidelines

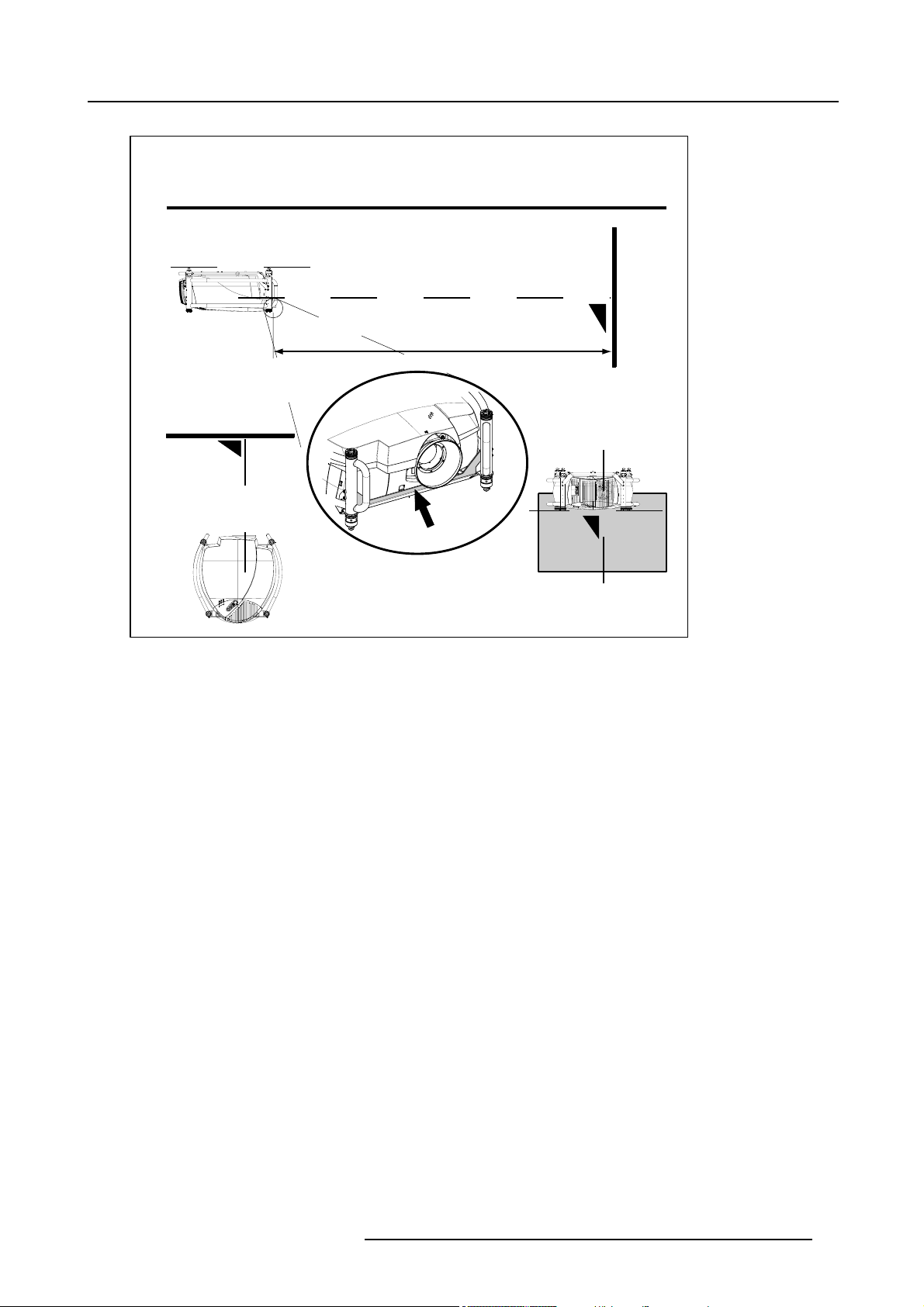

A

PD

B

Image 2-1

Front-Ceiling configuration

A Side view

B Top view

CBackview

PD Distance projector - screen

C

PD

R5976816 RLM R6+ PERFORMER 02/06/2006

13

Page 18

2. Installation Guidelines

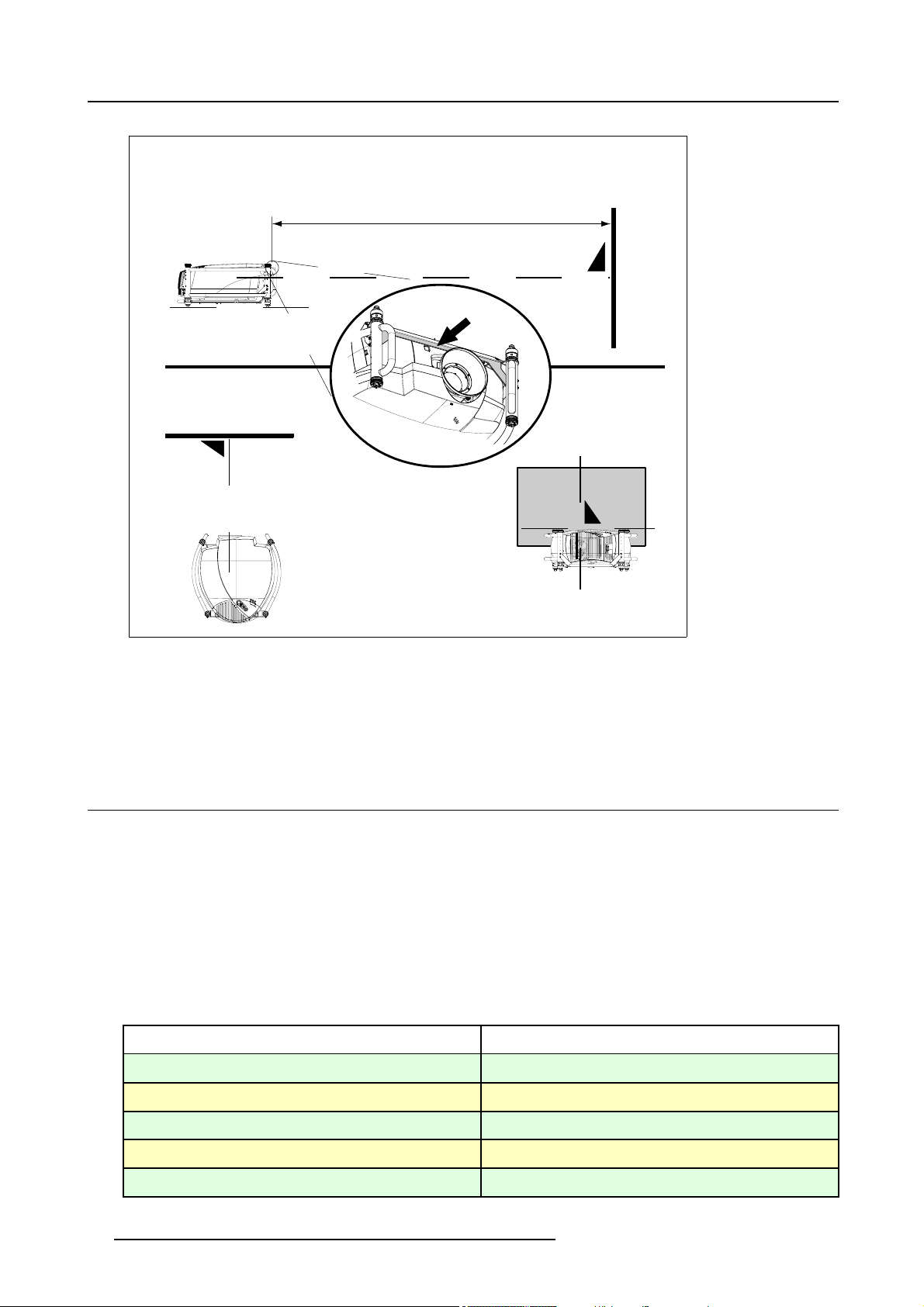

A

PD

PD

Image 2-2

Front-Table configuratio n

A Side view

B Top view

CBackview

PD Distance projector - screen

2.3 Lenses

Overview

• Lenses

• Lens formulas

• Lens installation

• Cleaning the lens

B

C

2.3.1 Lenses

Available lenses

TLD HB lenses:

Lenses

TLD HB (0.8)

TLD HB (1.6 - 2)

TLD HB (2 - 2.8)

TLD HB (2.8 - 5)

TLD HB (5 - 8)

14 R5976816 RLM R6+ PERFORMER 02/06/2006

Order number

R9842040

R9842060

R9842080

R9842100

9642120

R

Page 19

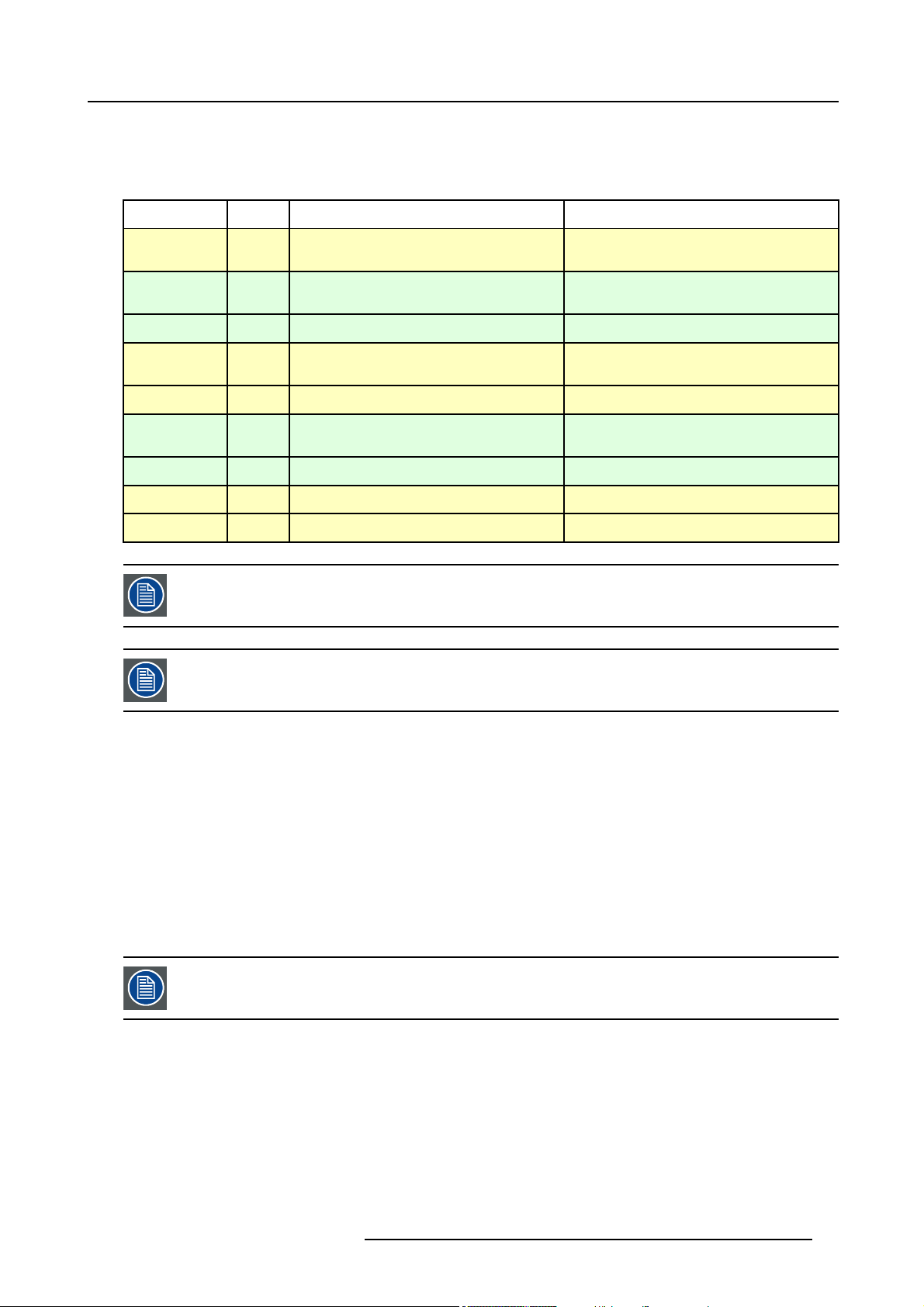

2.3.2 Lens formulas

Formulas

For TLD HB lenses :

2. Installation Guidelines

Metric Formulas (meter) Inch formulas (inch)

TLD HB (0.8 :

1)

TLD HB (1.6 -

2)

TLD HB (2 -

2.8)

TLD HB (2.8 -

5)

TLD HB (5 - 8)

The formulas for TLD HB lenses are also valid for TLD lenses with the same range.

The light output if TLD HB lenses is higher than the light output of TLD lenses. The contrast ratio is higher for

TLD lenses than for TLD HB lenses.

Wide

Te le

Wide

Te le

Wide

Te le

Wide

Te le

PD = 0.77 x SW + 0.07 PD = 0.77 x SW + 2.76

PD = 1.47 x SW - 0.07 PD = 1.47 x SW - 2.76

PD = 1.85 x SW - 0.11 PD = 1.85 x SW - 4.33

PD = 1.85 x SW - 0.14 PD = 1.85 x SW - 5.51

PD = 2.62 x SW - 0.21 PD = 2.62 x SW - 8.27

PD = 2.58 x SW - 0.14 PD = 2.58 x SW - 5.51

PD = 4.71 x SW - 0.35 PD = 4.71 x SW + 13.78

PD = 4.52 x SW + 0.01 PD = 4.52 x SW + 0.39

PD = 7.53 x SW - 0.26 PD = 7.53 x SW - 10.24

Lens shift

For table mounted projector:

Shift left 50%

Shift right 50%

Shift down 10%

Shift up 95%

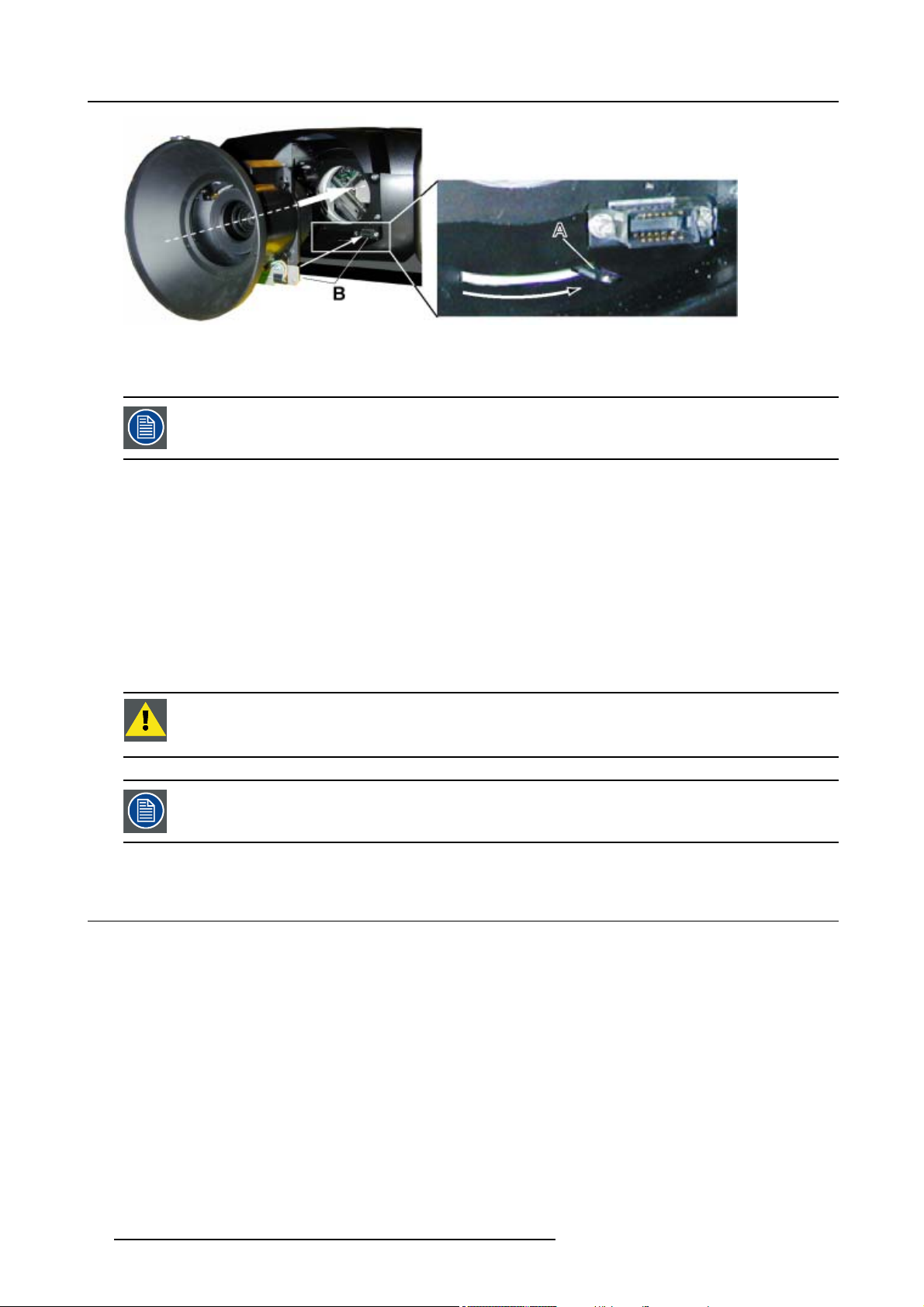

2.3.3 Lens installation

The default lens is standard mounted on the projector when it arrives on your location.

How to replace with another lens?

Follow the next procedure:

1. Move the handle (A) of the lens anchor system to the left and take out the lens.

2. Take the new lens assembly out of its packing material and remove the lens caps on both sides.

3. Push the lens, motors at the top, in the lens block gap horizontally, lining up the motor connector on the lens with the connector

on the lens block (B). (image 2-3)

Caution: On a table mounted projector, hold the projector when pushing the lens into the lens block to avoid sliding off from

4. Move the handle (A) of the lens anchor system to the right (front view, table mount) to lock the lens.

the table.

R5976816 RLM R6+ PERFORMER 02/06/2006

15

Page 20

2. Installation Guidelines

Image 2-3

2.3.4 Cleaning the lens

To minimize the possibility of damage to optical coatings, or scratches to lens surfaces, we have developed

recommendations for clean. FIRST, we recommend you try to remove any material from the lens by blowing

it off with clean, dry deionized air. DO NOT use any liquid to clean the lenses.

Necessary tools

To ra ys e eTMcloth (delivered together with the lens kit). Order number : R379058.

Howtocleanthelens?

Proceed as follow :

1. Always wipe lenses with a CLEAN Toraysee

2. Always wipe lenses in a single direction.

Warning: D o not wipe back and forwards across the lens surface as this tends to grind dirt into the coating.

3. Do not leave cleaning cloth in either an open room or lab coat pocket, as doing so can contaminate the cloth.

4. If smears occur when cleaning lenses, replace the cloth. Smears are the f

CAUTION: Do not use fabric softener when washing the cleaning cloth or so

cloth.

Do not use liquid cleaners on the cloth as doing so will contaminate the cloth.

Other lenses can also be cleaned safely with this TorayseeTMcloth.

TM

cloth.

irst indication of a dirty cloth.

ftener sheets when drying the

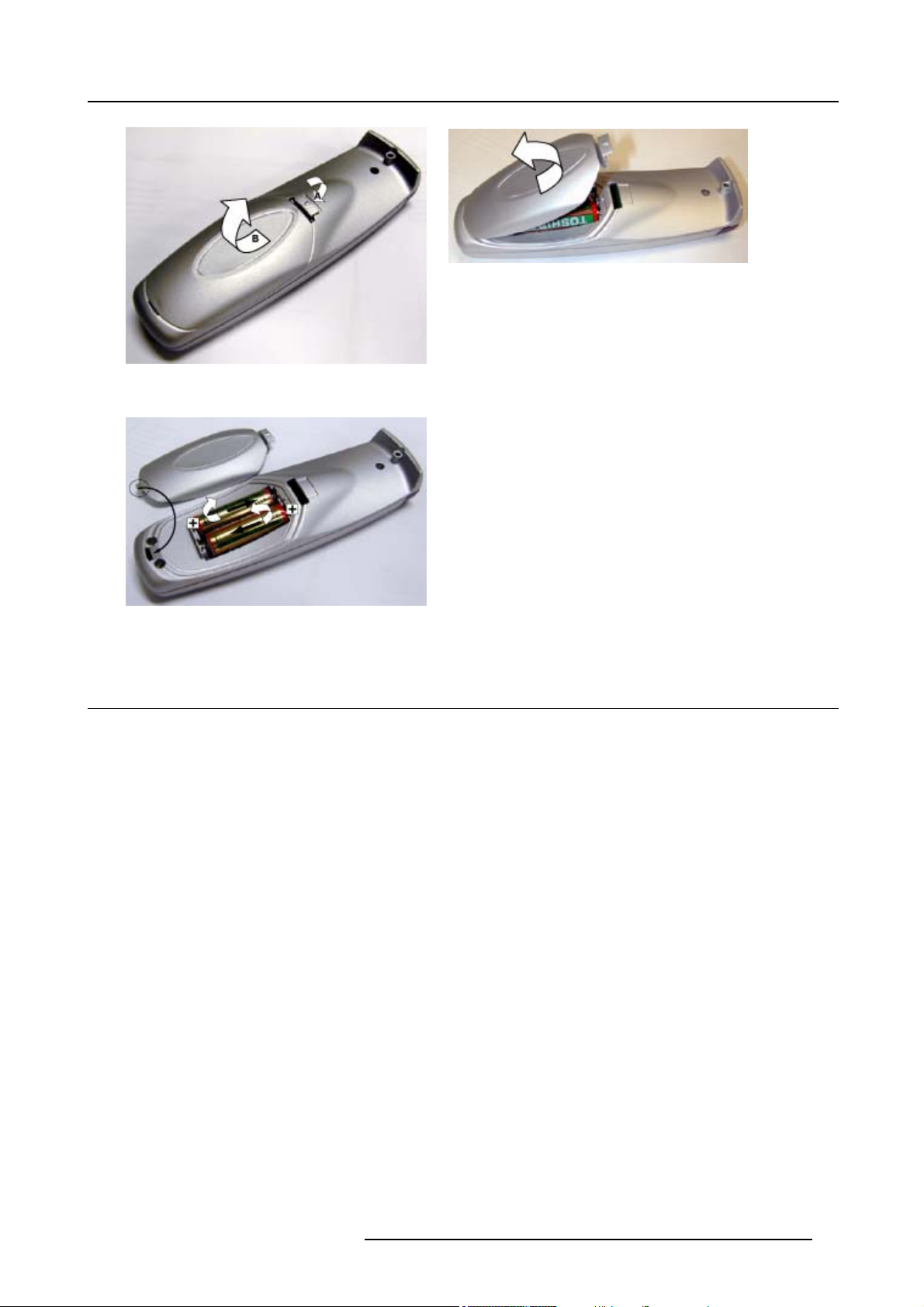

2.4 Battery Insertion in the Remote Control

Where to find the batteries

The batteries are not placed in the remote control to avoid remote control operation in its package, resulting in a shorter battery life

time.

How to install the batteries

1. Push the cover tab (A) with the fingernail a little backwards and pull upwards the cover top (B). (image 2-4)

2. Slide the cover forwards to remove. (image 2-5)

3. Push the battery body towards the spring and lift it up to remove. (image 2-6)

4. Insert two AA size batteries, making sure the polarities match the + and – marks inside the battery compartment (image 2-6).

5. Insert the lower tab of the battery cover in the gap at the bottom of the remote control, and press the cover until it clicks in place

(image 2-5).

16

R5976816 RLM R6+ PERFORMER 02/06/2006

Page 21

Image 2-4

Battery cover unlock

Image 2-5

Battery cover removal

2. Installation Guidelines

Image 2-6

Battery removal

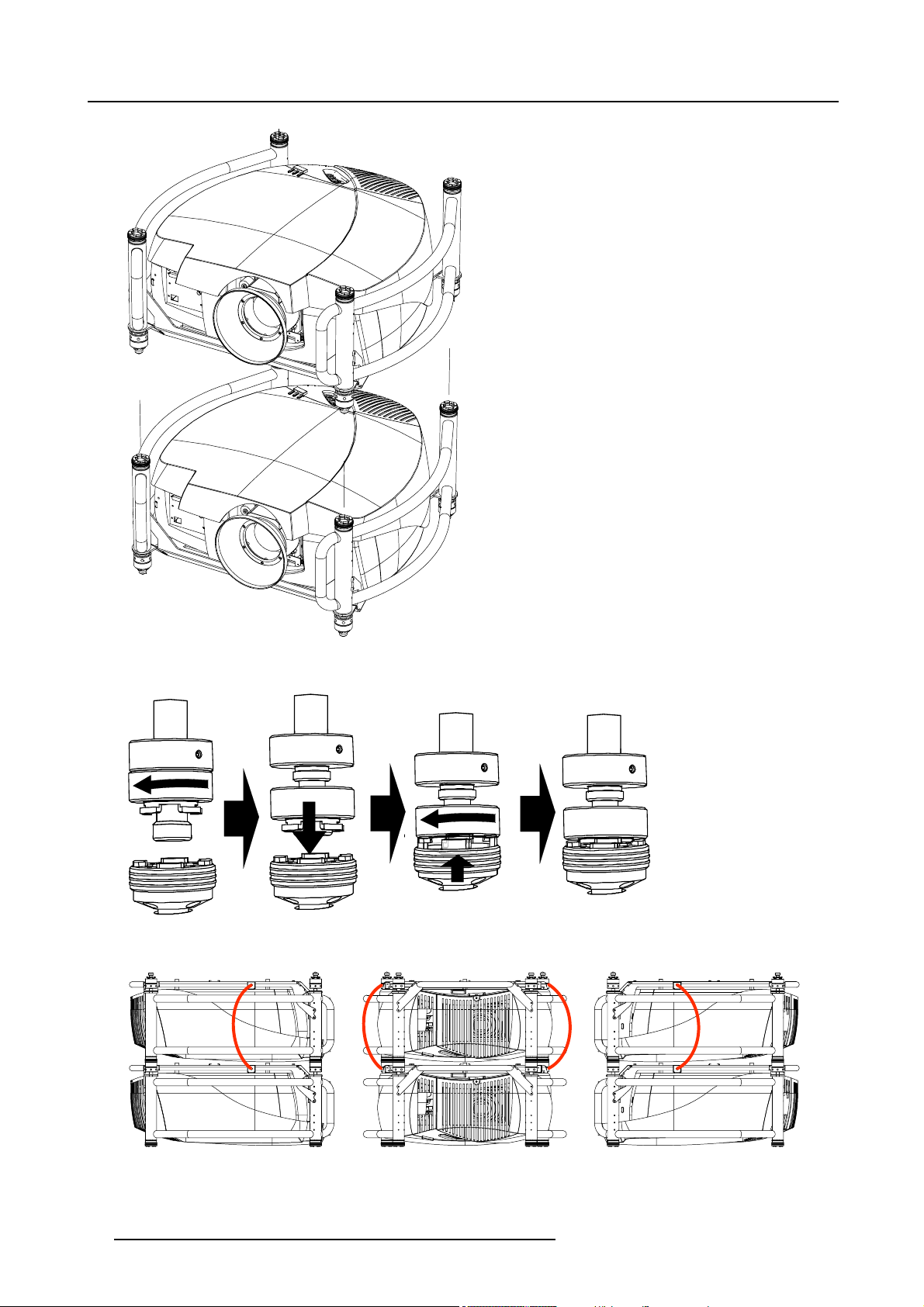

2.5 Stacking projectors

What is possible?

to 2 projectors can be stacked on each other without using extra tools or accessories.

Up

ow to stack?

H

Handle as follow:

the second projector on the first one so that base plate of the second projector matches with the rigging socket of the first

1. Put

projector. (image 2-7)

2. Turn the rigging sockets of the second projector counter clockwise until they are free to move up and down. (image 2-8)

3. Secure the projectors on each other by bringing the free part of the second projector into the socket of the first projector and turn

uarter clockwise while pushing downwards until it clicks in.

aq

4. For ceiling mounted configurations, mount a security cable between the lowest projector and the upper projector. (image 2-9)

Warning: Be sure the safe working loud of the used security cables and connectors are enough to support one projector. Refer

to the supplier of the security cable for safety details.

R5976816 RLM R6+ PERFORMER 02/06/2006

17

Page 22

2. Installation Guidelines

Image 2-7

Stacking two projectors

Image 2-8

Closing the rigging sockets

Image 2-9

Mounting the securi

ty chain

18 R5976816 RLM R6+ PERFORMER 02/06/2006

Page 23

2. Installation Guidelines

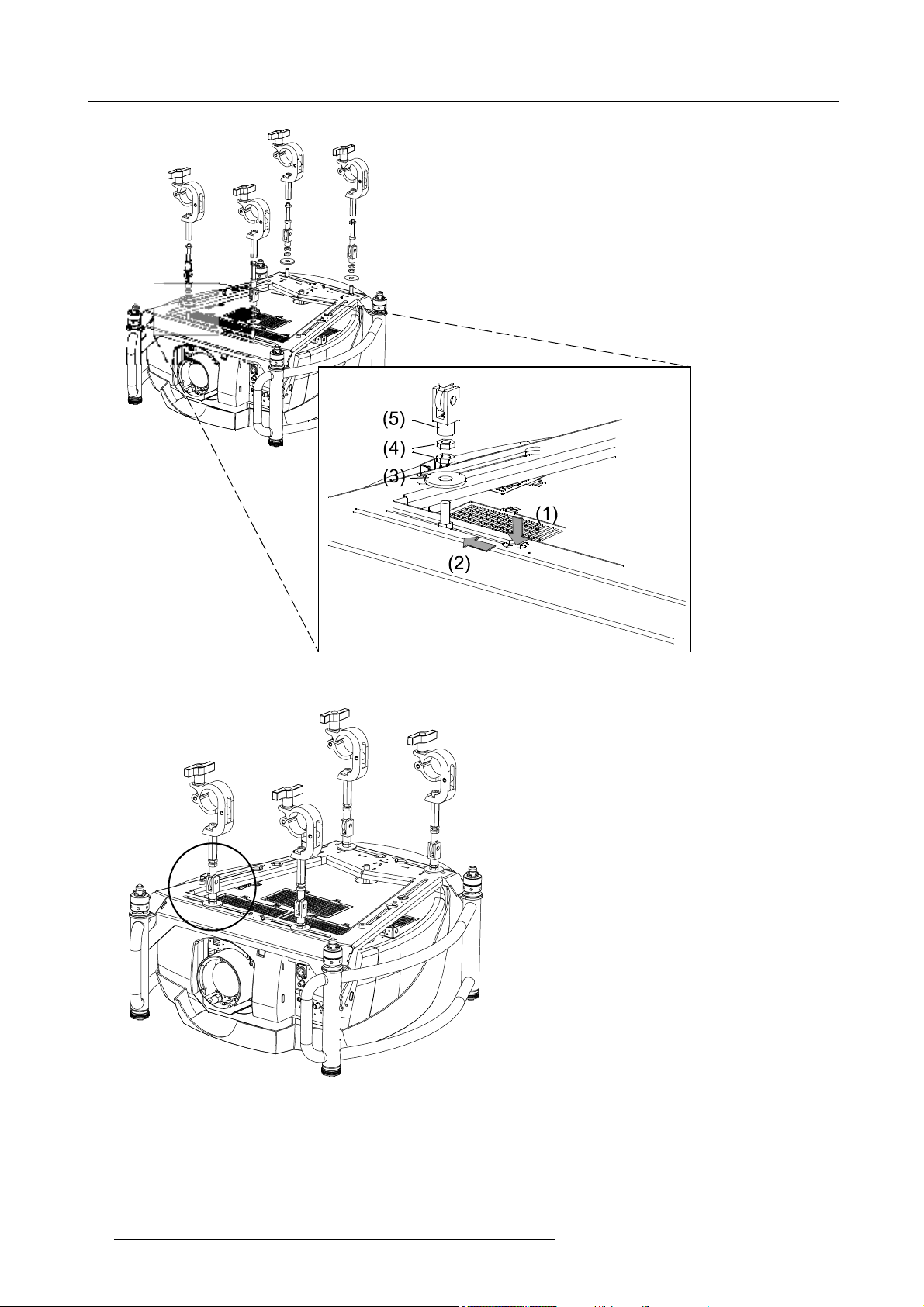

2.6 Rigging points and accessories

2.6.1 Overview

Clamps

Slots are made in the carry handle frame for easy inserting the overlockers and for easy adjusting the clamps position so that this

position matches with the rigging points.

Consult a professional structural engineer prior to suspending the ceiling mount from a structure not intended for that use. Always

ensure the working load limit of the structure supporting the projector.

WARNING: When mounting the projector to the ceiling or to a rigging system, always mount security chains.

Complete documentation

For a complete documentation consult manual R5976746.

2.6.2 Mounting the clamps

Necessary tools

Wrench 17 mm

Steps to be taken

1. Insert the mushroom head square neck bolt into the mounting hole (1). (image 2-10)

2. Slide the bolt into the groove until the exact position is reached (2).

3. Slide a washer on the bolt (3).

4. Secure with a first nut (4).

5. Turn a second nut on the bolt (5).

6. Turn the movable connecting-piece almost fully onto the bolt. Stops with a sma

second nut so that the movable connecting-piece is still turnable (5).

7. Turn now the connecting-piece into the direction of the lens and secure this position by turning up the second nut. (image 2-11)

8. Turn the clamp on the movable connecting-piece.

ll distance between the clamp assembly and the

R5976816 RLM R6+ PERFORMER 02/06/2006

19

Page 24

2. Installation Guidelines

Image 2-10

Mounting the clamps fixation

Image 2-11

Mounting the rigging clamp

20 R5976816 RLM R6+ PERFORMER 02/06/2006

Page 25

3. Connections

3. CONNECTIONS

Overview

• Power connection

• Input Source Connections

• 5-Cable input

• Composite Video Input

• S-Video input

• Digital Visual Interface (DVI) input

• Computer input (RGB analog)

• SDI or HDSDI input

• Communication connection

• Extended configuration

3.1 Power connection

AC power (mains) cord connection

Use the supplied power cord to connect your projector to the wall outlet.

Plug the female power connector into the male connector at the back of the projector. Fixate the power plug with the power cord

clamp.

The power input is auto-ranging from 90 to 240 VAC.

Image 3-1

Power connection

1 Power input

2 Power cord clamp

3 ON/OFF switch

Fuses

For continued protection against fire hazard :

2

3

1

• refer replacement to qualified service personnel

• ask to replace with the same type of fuse.

R5976816 RLM R6+ PERFORMER 02/06/2006

21

Page 26

3. Connections

3.2 Input Source Connections

Overview

• Input section

• Input facilities

3.2.1 Input section

Input Layers

The input section is divided in layers, each of them regrouping several inputs, this architecture allows the input section to be upgraded

at any time with an optional analog or digital layer.

1. Layer 1: analog layer containing analog data and video inputs.

2. Layer 2: a hybrid layer containing 2 digital and 1 analog input.

3. Layer 3 : (HD)SDI and interconnection.

4. Layer 4 : is interconnection layer, with XLR connection and an optional Ethernet connection.

3.2.2 Input facilities

overview

• 5–cable input

- component video (PR/Y/PB)

-RGBS

• composite video

•S-Video

• Digital Visual Input (DVI)

• Computer (analog RGB)

• Serial Digital Input or High Definition Serial Digital Input with loop through connection

22

R5976816 RLM R6+ PERFORMER 02/06/2006

Page 27

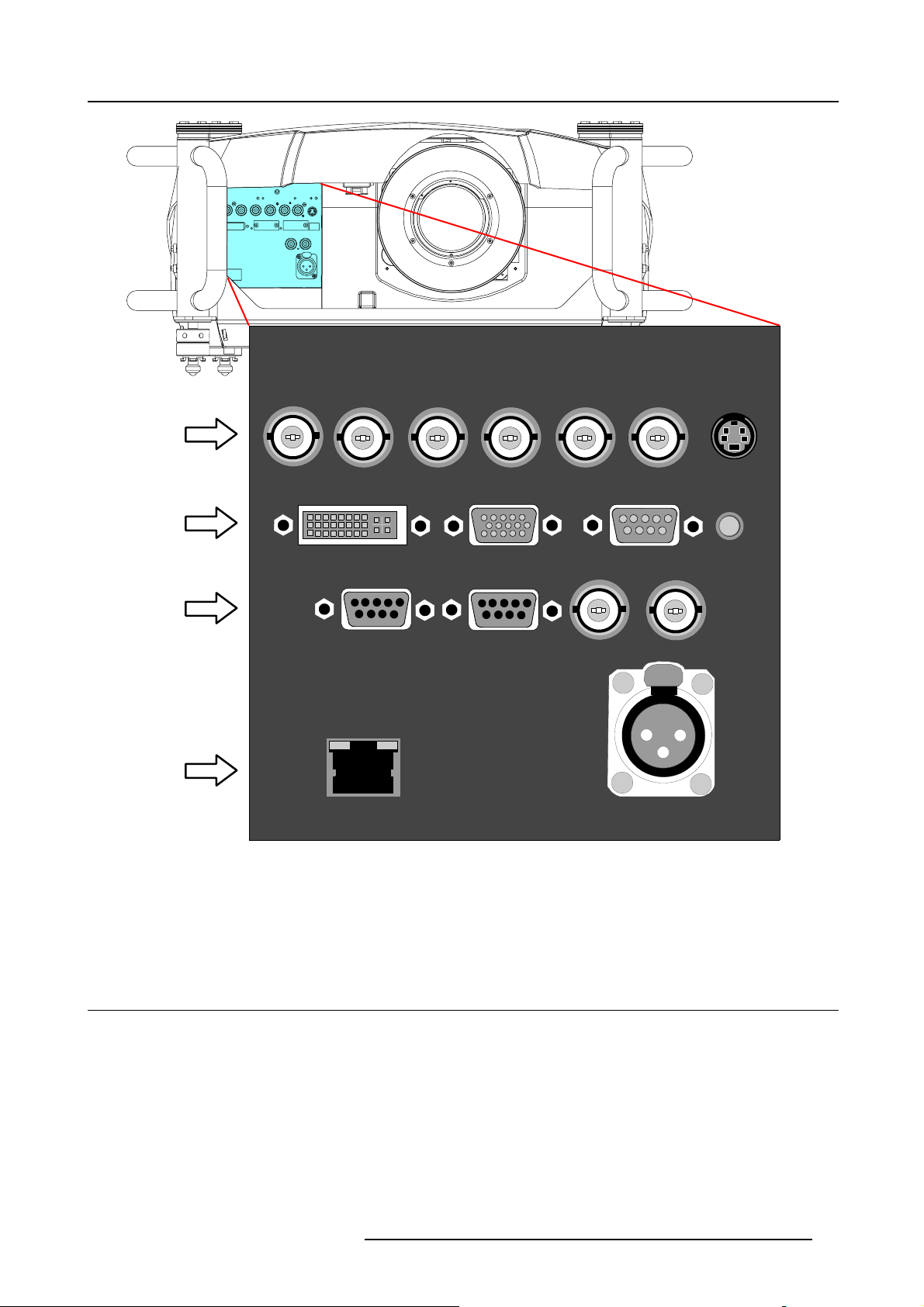

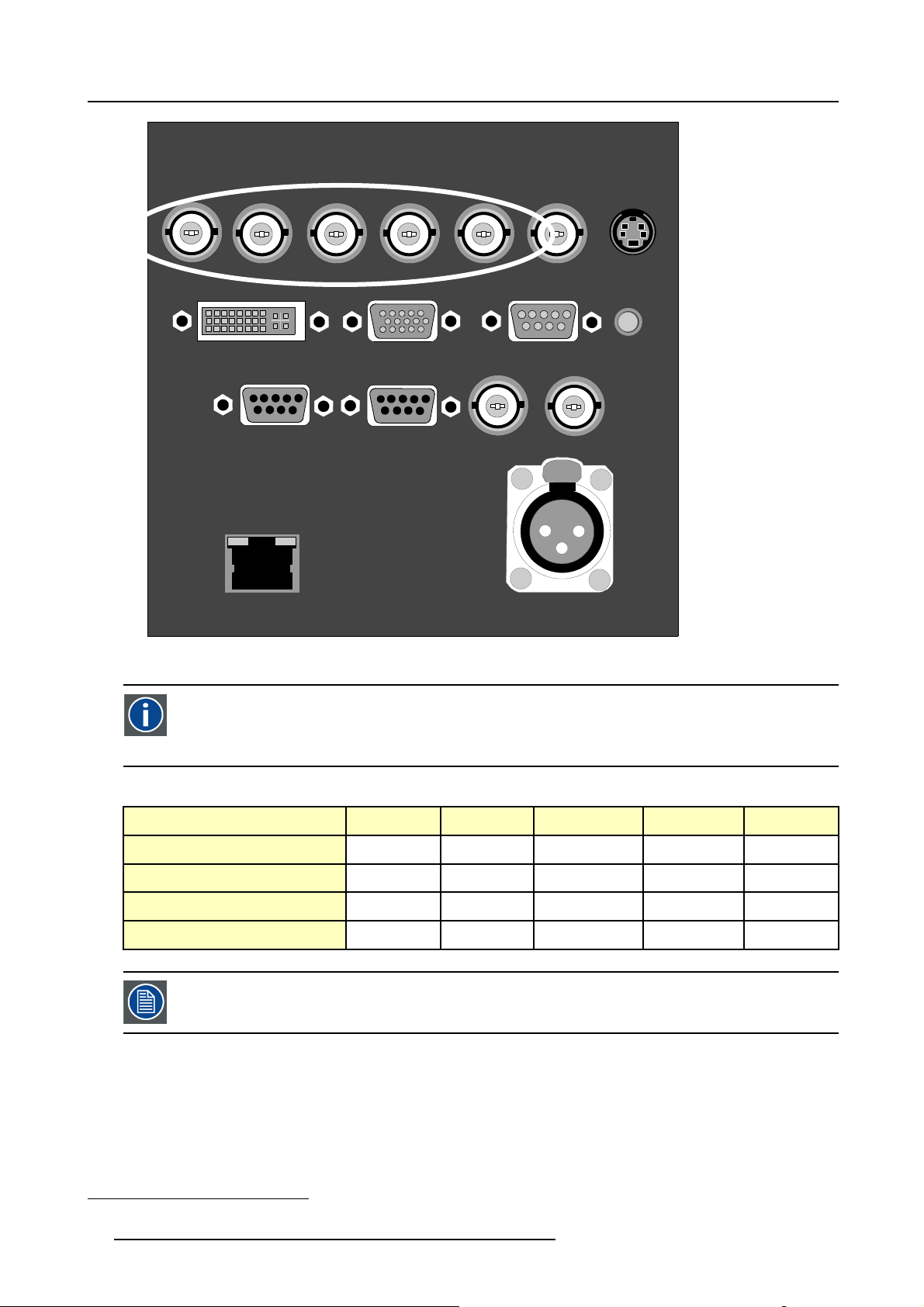

L1

3. Connections

R/PR

G/Y B/PB Hs/Cs Vs VIDEO

L2

DVI ANALOG RGB RS 232/422 IN

L3

POWER WIRELESS

RECEIVER

RS 232/422

OUT

L4

10 BASE-T

Image 3-2

Input facilities

L1 Layer 1 = RGBHV + Composite Video + S-Video

L2 Layer 2 = DVI + Computer + RS232IN + RC (wired remote control)

L3 Layer 3 = (HD)SDI in and out + RS232OUT + Power wireless receiver

L4 Layer 4 = Two way hardwired remote + Ethernet

S-VIDEO

(HD)SDI IN(HD)SDI OUT

PUSH

2

1

3

TWO WAY

HARDWIRED REMOTE

R.C.

3.3 5-Cable input

Input specifications

The 5-cable input sec

0.7 Vpp ± 3dB

75 Ω terminated

R5976816 RLM R6+ PERFORMER 02/06/2006

tion is made of 5 BNC input terminals.

23

Page 28

3. Connections

Image 3-3

5-cable input

R/PR

POWER WIRELESS

G/Y B/PB Hs/Cs Vs VIDEO

DVI ANALOG RGB RS 232/422 IN

(HD)SDI IN(HD)SDI OUT

PUSH

2

TWO WAY

RECEIVER

10 BASE-T

RS 232/422

OUT

S-VIDEO

R.C.

1

3

HARDWIRED REMOTE

Component Video

In Component Video the term component describes a number (3) of elements that are needed to make up the video

picture, these components are R-Y/Y/B-Y. A co

needed for the color picture in a single channel of information

mposite video signal on the other hand contains all the information

Which signals can be connected ?

Signals/Input BNC

RGBHV

1

RGsB

1

RGBS

Component

Beside the standard RGB, component and sync signals, the extended mode of the 5 Cable input makes pro-

ssing of additional signals possible.

ce

R

R

R

R

PR Y PB

G

G

G

s

G

B H V

B H V

B

B

- -

S

- -

-

How to select a source on the 5 cable input ?

ess 1 on the RCU

1. Pr

Note: Another way for selecting this input is via Source on the local keypad or via the Menu

1. data or video

24 R5976816 RLM R6+ PERFORMER 02/06/2006

Page 29

3. Connections

Component Video signals (PR/Y/PB)

Some interfaces use progressive output signals with a double line frequency of 32 kHz. The video decoder

used for the video signals is not appropriate for these signals since it can only handle 15 kHz signals. This

signal has therefore to be internally redirected, this is done in the Sourceselection menu by selecting Dataon

BNC’s instead of Component video and by selecting Pr/Y/Pb in the advanced settings of the Image file menu.

3.4 Composite Video Input

Input specifications

The Composite video input section is made of 1 BNC input terminal. Connect Composite video signals from a VCR, OFF air si

decoder, etc..

1.0 Vpp ± 3dB

75 Ω terminated

No loop through

gnal

R/PR

G/Y B/PB Hs/Cs Vs VIDEO

DVI ANALOG RGB RS 232/422 IN

POWER WIRELESS

RECEIVER

RS 232/422

OUT

10 BASE-T

Image 3-4

Composite Video indica tion

How to select a Composite Video Input ?

1. Press 3 on the RCU

Note: Another way for selecting this i

nput is via Source on the local keyp ad or via the Menu.

S-VIDEO

(HD)SDI IN(HD)SDI OUT

PUSH

2

1

3

TWO WAY

HARDWIRED REMOTE

R.C.

The projector allows the inpu

the 5 cable input in extended configuration. Press 3 to browse through the possible video sources.

R5976816 RLM R6+ PERFORMER 02/06/2006 25

t of more composite video signals (up to 7 composite video signals) when using

Page 30

3. Connections

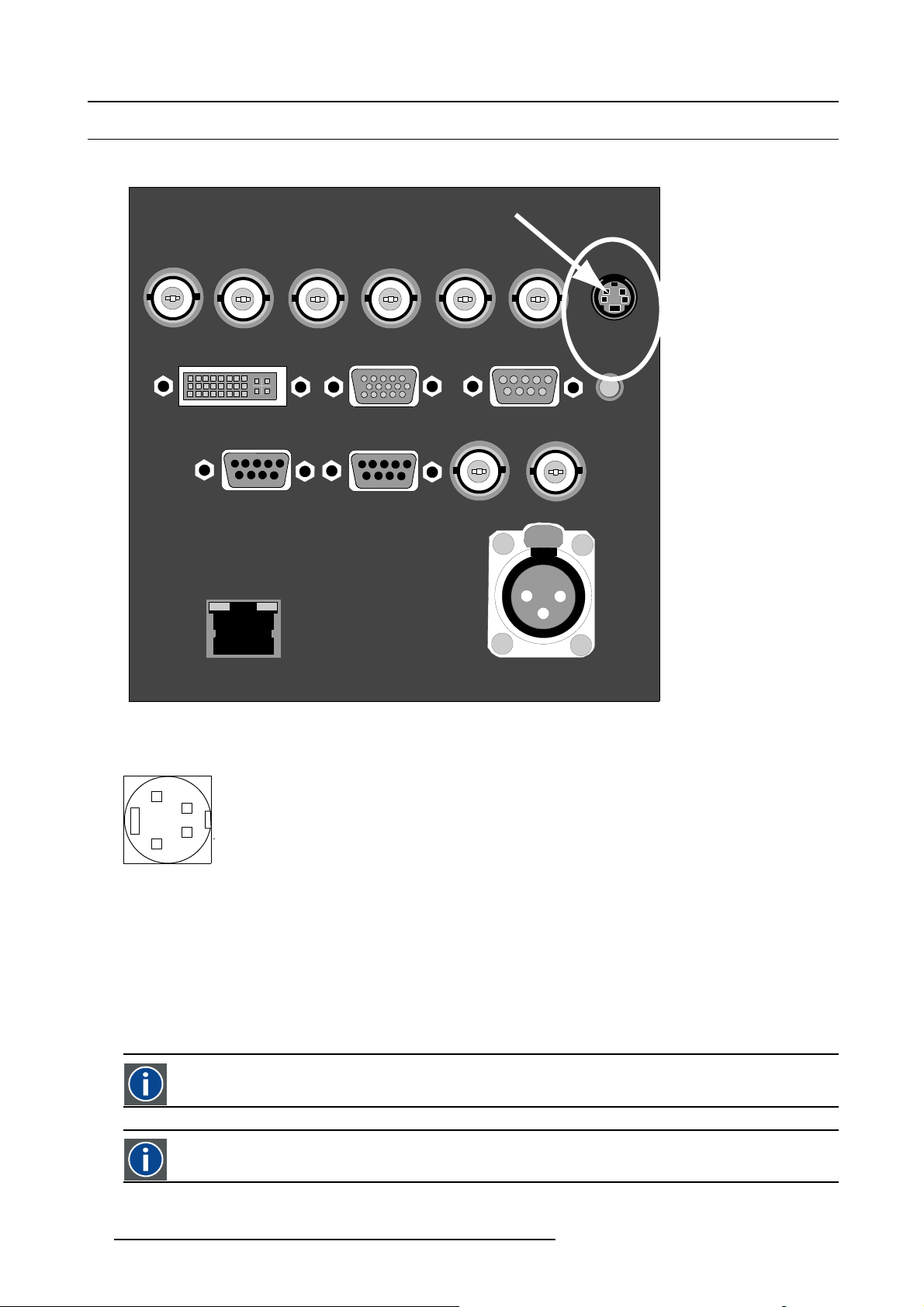

3.5 S-Video input

Input specification

R/PR

G/Y B/PB Hs/Cs Vs VIDEO

DVI ANALOG RGB RS 232/422 IN

POWER WIRELESS

RS 232/422

RECEIVER

10 BASE-T

Image 3-5

S-Video indication

Pin configuration 4 pin connector

OUT

S-VIDEO

(HD)SDI IN(HD)SDI OUT

PUSH

2

1

3

TWO WAY

HARDWIRED REMOTE

R.C.

2

4

3

1

Image 3-6

For S-Video

pin 1 : earth (ground) luminance pin 1 : earth (ground) video Y

pin 2 : earth (ground) chrominance pin 2 : earth (ground) video C

pin 3 : luminance signal (Y) 1Vpp ±3dB

pin 4 : chrominance signal (C) 300mVpp pin 4 : video C signal

Chrominance

The color component of a video signal that includes information about tint and saturation.

Luminance

The component of a video signal that includes information about its brightness.

26 R5976816 RLM R6+ PERFORMER 02/06/2006

For Video

pin 3 : video Y signal

Page 31

Which signal can be connected ?

Standard S-Video (S-VHS) with separate Y (luma) and C (chroma) signals.

InextendedmodealsoCompositevideocanbeconnectedtotheS-Videoplug.

How to select the S-Video input ?

1. Press 4 on the RCU

Note: Another way for selecting this input is via Source on the local keypad or via the Menu.

The projector allows the input of more S-Video signals (up to 3 S-Video signals) via the S-Video extended

configuration.

3.6 Digital Visual Interface (DVI) input

DVI

Digital Visual Interface is a display interface developed in response to the proliferation of digital flat panel displays.

The digital video connectivity standard that was developed by DDWG (Digital Display Work Group). This connection

standard offers two different connectors: one with 24 pins that handles digital video signals only, and one with 29 pins

that handles both digital and analog video. This standard uses TMDS (Transition Minimized Differential Signal) from

Silicon Image and DDC (Display Data Channel) from VESA (Video Electronics Standards Association).

DVI can be single or dual link.

3. Connections

Input specifications

Single link DVI

Differential input voltage: 200 mV - 800 mV

R5976816 RLM R6+ PERFORMER 02/06/2006

27

Page 32

3. Connections

R/PR

G/Y B/PB Hs/Cs Vs VIDEO

DVI ANALOG RGB RS 232/422 IN

POWER WIRELESS

RECEIVER

RS 232/422

OUT

10 BASE-T

Image 3-7

DVI indication. DVI-I type connector analog link

(4 pins at the right side of the connector) not supported.

Pin assignment for the DVI connector.

Pin 1

TMDS DATA2-

S-VIDEO

(HD)SDI IN(HD)SDI OUT

PUSH

2

1

3

TWO WAY

HARDWIRED REMOTE

Pin 13

R.C.

TMDS DATA3+

Pin 2

Pin 3

Pin 4

Pin 5

Pin 6

Pin 7

Pin 8 Not connected Pin 20

Pin 9

Pin 10

Pin 11

Pin 12

TMDS DATA2+

TMDS DATA2/4 Shield

TMDS DATA4-

TMDS DATA4+

DDC Clock

DDC Data

TMDS DATA1-

TMDS DATA1+

TMDS DATA1/3 Shield

TMDS DATA3-

Pin14 +5Power

Pin 15

Pin 16 Hot Plug Detect

Pin 17

Pin 18

Pin 19

Pin 21

Pin 22

Pin 23

Pin 24

How to select the DVI Input ?

1. Press 5 on

Note: Another way for selecting this input is via Source on the local keypad or via the Menu.

the RCU

Ground (for +5V)

TMDS DATA0-

TMDS DATA0+

TMDS DATA0/5 Shield

TMDS DATA5-

TMDS DATA5+

TMDS Clock Shield

TMDS Clock+

TMDS Clock-

28

R5976816 RLM R6+ PERFORMER 02/06/2006

Page 33

3.7 Computer input (RGB analog)

Input specification

TTL sync input : U

RGB input = 0.7 V

min

pp

=2.0V

±3dB

3. Connections

R/PR

G/Y B/PB Hs/Cs Vs VIDEO

DVI ANALOG RGB RS 232/422 IN

POWER WIRELESS

RECEIVER

10 BASE-T

Image 3-8

Analog input

What can be connected ?

•RGBHV

•RG

B

S

RS 232/422

OUT

S-VIDEO

(HD)SDI IN(HD)SDI OUT

PUSH

2

1

3

TWO WAY

HARDWIRED REMOTE

R.C.

CompositesynconlypossibleonGreen

How to select a computer input ?

1. Press 2 on the RCU

Note: Another way for selecting this input is via Source on the local keypad or via the Menu.

3.8 SDI or HDSDI input

SDI

Serial Digital Interface

R5976816 RLM R6+ PERFORMER 02/06/2006 29

Page 34

3. Connections

Input specifications

(HD)SDI input : BNC

(HD)SDI output : BNC (= loop through)

typical : 0.8 Vpp

75Ω terminated

output impedance: 75Ω

R/PR

G/Y B/PB Hs/Cs Vs VIDEO

DVI ANALOG RGB RS 232/422 IN

POWER WIRELESS

RS 232/422

RECEIVER

10 BASE-T

Image 3-9

(HD)SDI input

How to select the (HD)SDI input

1. Press 7 on the RCU

Note: Another way for selecting this input is via

(HD)SDI IN(HD)SDI OUT

OUT

PUSH

2

1

3

TWO WAY

HARDWIRED REMOTE

Source on the local keypad or via t he Menu.

S-VIDEO

R.C.

3.9 Communication connection

Overview

• RS232 IN connection

• Wireless receiver

3.9.1 RS232 IN connection

What can be connected to the RS232

The RS232 IN connection allows the projector to communicate with a computer e.g. IBM PC or Apple Macintosh.

30

/422 IN connection ?

R5976816 RLM R6+ PERFORMER 02/06/2006

Page 35

3. Connections

R/PR

G/Y B/PB Hs/Cs Vs VIDEO

DVI ANALOG RGB RS 232/422 IN

POWER WIRELESS

RECEIVER

RS 232/422

OUT

(b)

10 BASE-T

Image 3-10

Applications of the RS232/422 connection

Remote control:

S-VIDEO

(HD)SDI IN(HD)SDI OUT

PUSH

2

1

3

TWO WAY

HARDWIRED REMOTE

R.C.

(a)

• easy adjustment of projector via IBM PC (or compatible) or MAC connection.

• address range from 0 to 255.

• allow storage of multiple projector configurations and set ups.

• wide range of control possibilities.

Data communication: sending data to the projector or copying the data from the projector to the computer.

What can be connected to the RS232/422 OUT connection ?

The output is a loop through output for RS232/422 signal and can be connected to the RS232/422 IN of the next projector.

To set up the baud rate of the projector, see chapter Installation menu, RS baudrate.

3.9.2 Wireless receiver

What can be connected ?

The optional wireless receiver for the optional rugged remote control can be connected to the Power wireless receiver output and

to the RS232/422 IN. With these tools, it is possible to control the projector from a distance without using cables.

R5976816 RLM R6+ PERFORMER 02/06/2006

31

Page 36

3. Connections

R/PR

DVI ANALOG RGB RS 232/422 IN

POWER WIRELESS

RECEIVER

10 BASE-T

Image 3-11

Wireless receiver connection

G/Y B/PB Hs/Cs Vs VIDEO

RS 232/422

OUT

(HD)SDI IN(HD)SDI OUT

PUSH

2

3

TWO WAY

HARDWIRED REMOTE

S-VIDEO

R.C.

1

3.10 Extended configuration

Overview

• Introduction

• 5-cable extended configuration

• S-Video extended configuration

• Summarizing

3.10.1 Introduction

What can be done ?

The extended configuration allows to connect multiple equal source types to the inputs and allow switching between this wide range

of input signals.

3.10.2 5-cable extended configuration

What can be done ?

Beside the standard RGB, composite & sync signals, the extended capabilities of the 5-cable inputs make treatment of additional

signals possible:

• a composite video signal may be connected to 4 of the 5 BNC’s (beside the standard video BNC input)

• a S-Video signal can be connected

32

R5976816 RLM R6+ PERFORMER 02/06/2006

Page 37

Inputs

3. Connections

R

Signals

RGBHV

RGSB

RGBS

Component

S-Video

R

R

R

PR Y PB

- - - -

S-Video C

Composite VIDEO

Composite

Composite

Composite

Composite

Table 3-4

Extended configuration of the 5-cable input: the first column gives the possible signals, and the first row the 5 cable input connectors (+ the standard Video BNC).

-

- -

- - - -

- - - - -

G

G

G

S

G

-

- - - - -

VIDEO

B H V

B H V

B

B

- - -

S

- -

- - -

C

Y

- - -

- - - -

VIDEO

- - -

VIDEO

How to set up the 5-cable extended configuration ?

1. Connect the video or S-video source to the desired BNC connector

Note: In some cases an adapter cable is required (image 3-12, image 3-13, image 3-14)

VIDEO

-

Y

VIDEO

R/PR

G/Y B/PB Hs/Cs Vs VIDEO

Chroma

S-Video 2

Image 3-12

Connecting an S-Video signal on the Vs &

S-VIDEO

Luma

Video BNC

R/PR

G/Y B/PB Hs/Cs Vs VIDEO

Chroma Luma

S-Video 3

Image 3-13

Connecting an S-Video signal on the R&B

S-VIDEO

BNC

R/PR

G/Y B/PB Hs/Cs Vs VIDEO S-VIDEO

Video R Video G

Image 3-14

Connecting composite Video signals on the 5-cable input

Video B

Video VS Video

Multiple video signals can not be visualized simultaneously since there is only one decoder.

3.10.3 S-Video extended configuration

What can be done ?

Beside the standard luminance (Y) and chrominance (C) signals, the advanced capabilities of the S-Video input make treatment of

additional signals possible:

• 2 composite video signal may be connected.

Inputs

Y

C

Signals

S-Video

Composite Video

Composite Video

Table 3-5

Extended configuration of the S-Video input: the first column gives the possible signals, and the first row the S-Video inputs pins.

Y

Video

-

C

-

Video

R5976816 RLM R6+ PERFORMER 02/06/2006 33

Page 38

3. Connections

How to set up the S-Video extended configuration ?

1. Connect the video sources to the desired connector (image 3-15)

Note: An a dapter cable is required

R/PR

G/Y B/PB Hs/Cs Vs VIDEO

S-VIDEO

Video Y

Video C

Image 3-15

Connecting 2 composite Video signals to the S-Video connector

Luma

Chroma

Multiple video signals can not be visualized simultaneously since there is only one decoder.

3.10.4 Summarizing

Composite video signals

A composite video signal can be entered via 7 different inputs, which gives you 7 different video signals (optional video input not

included).

1. Video R : via 1st BNC

2. Video G : via 2nd BNC

3. Video B : via 3rd BNC

4. Video VS : via 5th BNC

5. Video : via the standard composite video BNC input

6. Video Y : via S-Video input

7. Video C : via S-Video input

Key 3 on the RCU allows to browse through the active video inputs, each hit moves to the next active video input. The first hit on

key 3 selects the last selected video input.

S-Video signals

An S-Video source can be connected in 3 different ways, through 3 different inputs.

1. S-Video 1: via the standard S-Video input

th

2. S-Video 2 : via the 5

3. S-Video 3 : via the 1st and the 3rd BNC

Key 4 on the RCU allows to browse through the active S-Video inputs, each hit moves to the next active video input. The first hit on

key 4 selects the last selected video input.

BNC and the standard Composite Video input

34

R5976816 RLM R6+ PERFORMER 02/06/2006

Page 39

4. GETTING STARTED

Overview

• Terminology overview

• Switching on

• Lamp runtime

• Switching to standby

• Switching off

• Temperature error DMD

•UsingtheRCU

• Projector address

• Controlling the projector

• Quick lens adjustment

• Digital Zoom

• Quick Picture in Picture selection

4.1 Terminology overview

Overview

The following table gives an overview of the different functionalities of the keys.

4. Getting Started

R5976816 RLM R6+ PERFORMER 02/06/2006

35

Page 40

4. Getting Started

19

1

F2

F1

F3

21

20

2

MENU

BACK

3

4

PIP

DIGI

ZOOM

PHASE

TINT

COLOR

BRIGHTN

CONTR

ENTER

5

LOGO

TEXT

PAUSE

AUTO IMAGE

6

7

0

8

9

9

SDI

SB-PC

8

7

DVI

6

5

VIDEO S-VID EO

3

4

PC

RGB

2

1

18

17

16

15

14

13

12

LENS

SHIFT

VOL

11

10

Image 4-1

LENS

ZOOM

LENS

FOCUS

No. Key name Description

1 Function keys

user programmable keys with funct

2 MENU Menu key, to enter or exit the Tool ba

3 Address key

(recessed key), to enter the address of the projector (between 0 and 9). Press the recessed

address key with a pencil, followed by pressing one digit button between 0 and 9.

4

LOGO key allows to recall the stored Logo (not

5

PAU SE to stop projection for a short time, press ’PAUSE’. The image disappears but full power is

retained for immediate restarting.

6

STBY standby button, to start projecto

r when the power switch is switched on and to switch off the

projector without switching off the power switch.

Attention : Switching to Standby. When the projector is running and you want to

go to standby, press the standby key for 2 seconds.

ions for direct access.

r menu.

in PiP mode)

7

TEXT to des-activate or activate the on screen dialog boxes and menus.

8

AUTOIMAGE Auto image, to center the image

ontheactiveDMDsurface.

9 Digit buttons direct input selection.

9b

SOURCE button this button allows to switch through the active (scanned) inputs

36 R5976816 RLM R6+ PERFORMER 02/06/2006

Page 41

No. Key name Description

4. Getting Started

10 Lens control

11

VOL Used as lens shift left - right.

12 Picture controls use these buttons to obtain the desired picture analog level.

13

DIGI ZOOM allows a digital Zoom of a part of the image

14 FREEZE

15 PIP

16 ENTER

17

Cursor keys Cursor Keys on RCU or on the local keypad : to make menu selections or to access the

18

BACK to leave the selected menu or item (go upwards to previous menu).

19

EFFECTS

20

PIP ADJUST allows to select a PiP window and change its configuration on screen

21

RC operating indication lights up when a button on the remote control is pressed. (This is a visual indicator to

22 IR receiver IR receiver

use these buttons to obtain the desired ZOOM, SHIFT, FOCUS.

press to freeze the projected image.

allows to activate the PICTURE IN PICTURE mode

to confirm an adjustment or selection in the MENU.

On the local keypad and the RCU, the ENTER button additionally accesses the PIP

window re-size function

menu bar.

not yet implemented

check the operation of the remote control)

Green

Led 1 IR acknowledgement

Led 2 Hardware error

Led 3

Cool down sequence: flickers 60 seconds

after switching to standby

4.2 Switching on

How to switch on.

1. Press the power switch to switch on the projector.

- When ’0’ is pushed in, the projector is switched off.

- When ’1’ is pushed in, the projector is switched on

The projector starts in standby mode, LED1 is red.

Starting image projection.

1. Press Standby key once on the local keypad or on the remote control.

Note: It may take about 60 seconds before ima

ware initialization,...).

Note: If the Security mode is enabled, a text box will be displayed for PIN code entry, see Security setting in the Installation

menu

Note: If Identification screen is on, the I

ge projection, i.e. no projection until the completion of several operations (soft-

dentification screen will be displayed during start up.

Red

Standby

rescue program (software error)

CAUTION: Pushing the standby key

displayed.

R5976816 RLM R6+ PERFORMER 02/06/2006 37

too long, might cause the projector to shut down right after an image is

Page 42

4. Getting Started

4.3 Lamp runtime

x

To generalize for the different projector types, x refers here to the maximum run time of the lamp. The maximum run

time is given in the specifications.

Lamp runtime indication while running

Independently of the lamp mode, when the total runtime of an active lamp (lamp 1 for example) is (x -30) hours or more, a warning

message will be displayed.

WARNING !!!

LAMP 1: 1471 hrs

LAMP 2: 1400 hrs

Image 4-2

warning message

This warning message will be repeated at the next start up. Press BACK or MENU to remove the message.

The total lifetime of the lamp (single lamp) for a safe operation is x hours max., do not use it longer. Alwa

type of lamp. Call a Barco authorized service technician for lamp replacement.

Lamp management when the lamp runtime is reached in the different lamp modes is indicated in the next image.

ysreplacewithasame

A

Lamp Status

ON

OFF

Lamp 1

X(Lamp Take Over)

X-30 (WARNING)

Lamp 2

Runtime(hrs)

2X (ALERT)

2X-30 (WARNING)

B

Lamp Status

ON

OFF

Image 4-3

Lamp runtime management

A Single lamp mode

B Dual lamp mode

x Maximum lamp runtime

In single mode, a lamp switch will be executed as far as the second lamp has not reached its maximum runtime.

WARNING: Using a lamp for more than x hours is dangerous as the lamp could explode.

The lamp runtime reset as well as the lamp replacement can only be done by a Barco authorized technician.

Lamp 1 +Lamp 2

Runtime(hrs)

X (ALERT)

X-30 (WARNING)

4.4 Switching to standby

Howtoswitchtostandby?

1. Press Standby to switch the projector to standby.

38

R5976816 RLM R6+ PERFORMER 02/06/2006

Page 43

4. Getting Started

Switching to Standby. When the projector is running and you want to go to standby, press the standby key for

2 seconds until the message ’Saving data, please wait’ is displayed. Do not press any longer on the standby

key otherwise the projector will restart.

4.5 Switching off

How to switch off the projector?

1. Press first Standby.

2. Let cool down the projector until the fans stop blowing, at least 15 min.

3. Switch off the projector with the power switch.

4.6 Temperature error DMD

Overview

When the temperature of one of the DMD is too low or too high the projector will be switched automatically to standby. Before

switching to standby, the following message appears for 3 seconds on the screen : ’DMD out of operating temperature range.

Automatic shutdown is activated.’.

Ambient temperature range within the operating temperature range of the DMD is situated : +10°C and +40°C.

4.7 Using the RCU

Pointing to a reflective screen

1. Point the front of the RCU to the reflective screen surface. (image 4-4

IR Sensor (C)

Remote Control (A)

Image 4-4

Pointing RCU to the screen

A Remote control

BScreen

C IR sensor

F

1

A

D

J

9

7

5

3

0

1

4

T

P

F

A

R

2

B

U

E

A

S

B

E

S

L

S

E

8

6

2

F

3

B

T

F

B

A

E

4

R

S

C

C

P

H

O

V

X

O

L

H

O

T

T

A

I

A

G

I

N

A

R

N

L

T

L

S

T

O

N

H

C

T

P

R

E

N

R

E

N

E

E

N

X

F

T

5

I

T

E

R

Screen (B)

When using the remote control, make sure you are within the effective operating distance.

The operating distance may be up to 15 m (50ft).

)

The remote control unit will not function properly if strong light strikes the sensor window or if there are

obstacles between the remote control and the IR sensor.

R5976816 RLM R6+ PERFORMER 02/06/2006 39

Page 44

4. Getting Started

Hardwired Remote input

1. Plug one end of the remote cable in the connector on the bottom of the RCU. (image 4-5)

2. Plug the other end in the connector in the front panel of the projector labelled RC.

Specifications of the RC input

=9V

-U

in

-I

=80mA

max

• Internal IR receivers can be disabled:

o

mono jack : on plug in of the jack

o

stereo jack : on plug in or using an external switch bringing the right channel (B) to ground level. (image 4-6)

Image 4-5

Hardwired remote control

D

BC

A

2

3

1

1

2

Image 4-6

Stereo jack pin configuration

A tip: Left channel

B ring: right channel

C screen: common (GND)

Dexternalswitch

1Stereojack

2 Mono jack

The Remote connection uses a standard two wire cable terminated on each end with a 3.5 mm male

(mono/stereo) phone jack.

This cable

is not delivered but is available in most electronic or audio shops.

Directly to one of the IR sensors

1. When using

The remote control unit will no function properly if strong light strikes the sensor window or if there are obstacles between the

remote control unit and the projector IR sensor. (image 4-7)

the wireless remote control, make sure you are within the effective operating distance (30m, 100ft in a straight line).

40

R5976816 RLM R6+ PERFORMER 02/06/2006

Page 45

4. Getting Started

IR Sensor (C)

IR Sensor on Front (A)

45° 45°

F

1

F

2

A

D

F

3

F

2

F

4

F

5

F

1

A

D

J

X

E

T

I

T

R

E

E

N

S

U

T

E

T

X

P

A

E

A

S

E

P

H

9

0

S

H

R

A

P

N

7

8

T

T

N

I

6

5

C

L

O

O

R

3

4

B

R

I

G

N

H

T

2

1

C

O

T

N

R

E

B

T

LEB

N

A

R

C

L

E

A

B

A

S

S

V

O

L

Image 4-7

Remote control to IR sensor

J

F

3

F

4

P

A

U

F

S

5

E

9

0

E

X

I

T

7

T

5

E

E

X

N

T

T

8

E

R

3

4

P

H

6

A

S

1

E

S

H

A

R

P

N

T

2

N

I

T

T

R

E

C

B

O

L

L

E

O

R

B

B

R

A

I

S

G

S

H

T

N

C

O

N

T

R

B

A

L

A

N

C

E

V

O

L

F

1

F

2

F

3

A

D

F

J

4

F

5

E

X

I

T

P

A

U

S

E

E

N

T

E

R

T

E

X

T

9

0

P

H

A

S

7

E

8

S

H

A

R

P

5

N

6

T

N