Page 1

EVENTS

SLM R12+

R9010170

OWNER’S MANUAL

09022004 R5976654/00

Page 2

Barco nv Events

aan 5, B-8520 Kuurne

Noordl

Phone: +32 56.36.89.70

Fax: +32 56.36.88.24

events@barco.com

E-mail:

Visit us at the web: www.barco.com

Printed in Belgium

Page 3

Changes

Barco provides this manual ’as is’ without warranty of any kind, either expressed or implied, including but not limited to the implied warranties or merchantability and fitness for a particular purpose. Barco may make improvements and/or changes to the product(s) and/or the

program(s) described in this publication at any time without notice.

This publication could contain technical inaccuracies or typographical errors. Changes are periodically made to the information in this

publication; these changes are incorporated in new editions of this publication.

Copyright ©

All rights reserved. No part of this document may be copied, reproduced or translated. It shall not otherwise be recorded, transmitted or

stored in a retrieval system without the prior written consent of Barco.

Federal Communications Commission (FCC Statement)

This equipment has been tested and found to comply with the limits for a class A digital device, pursuant to Part 15 of the FCC r

These limits are designed to provide reasonable protection against harmful interference when the equipment is operated in a commercial

environment. This equipment generates, uses, and can radiate radio frequency energy and, if not installed and used in accordance with

the instruction manual, may cause harmful interference to radio communications. Operation of t

cause harmful interference, in which case the user will be responsible for correcting any interference.

his equipment in a residential area may

ules.

Trademarks

Brand and product names mentioned in this manual may be trademarks, registered trademarks or copyrights of their respective holders.

All brand and product names mentioned in this manual serve as comments or examples and are not to be understood as advertising for

the products or their manufactures.

Page 4

Page 5

Table of contents

TABLE OF CONTENTS

1. Safety Instructions.................................................................................................. 5

1.1 Warnings ................................................................................................................................ 5

1.2 FCC statement .......................................................................................................................... 5

1.3 Note ..................................................................................................................................... 5

2. Packaging and Dimensions ....................................................................................... 7

2.1 Projector Packaging .................................................................................................................... 7

2.2 Box Content............................................................................................................................. 7

2.3 LensPackaging......................................................................................................................... 7

2.4 Projector Case.......................................................................................................................... 8

3. Installation Guidelines.............................................................................................. 9

3.1 General . . . ............................................................................................................................... 9

3.2 Configuration...........................................................................................................................10

3.3 Safety Areaaroundprojector..........................................................................................................13

3.4 Re-adjusting thelamppositionin the lamp casing....................................................................................14

3.5 Lenses..................................................................................................................................15

3.5.1 Lenses . ..........................................................................................................................16

3.5.2 Lens selection ...................................................................................................................16

3.5.3 Lens formulas ...................................................................................................................16

3.5.4 Lens Installation .. ...............................................................................................................17

3.5.5 Cleaning the lens . ...............................................................................................................17

3.6 BatteryInstallation inthe RCU ........................................................................................................18

3.7 Stacking Projectors ....................................................................................................................18

3.8 Riggingpoints and Accessories.......................................................................................................21

4. Connections.........................................................................................................23

4.1 Power connection .. . ...................................................................................................................23

4.2 Switching on............................................................................................................................23

4.3 Switching to standby ...................................................................................................................25

4.4 Switching off............................................................................................................................25

4.5 Input Source Connections . . ...........................................................................................................25

4.5.1 Input Facilities ...................................................................................................................25

4.5.2 Inputs via RCVDS05 . ...........................................................................................................25

4.5.3 Input module insertion...........................................................................................................26

4.5.4 Fixedslot (slot1 & 2)............................................................................................................27

4.5.5 Serial Digital Input (slot3 & 4)..................................................................................................28

4.5.6 HD SDI Digital input (slot 3 & 4) ................................................................................................29

4.5.7 Digital Video Decoder Input. ....................................................................................................30

4.6 Communication Connections .. .. . .....................................................................................................32

4.6.1 RS232 (RS422) Connection ....................................................................................................32

4.6.2 Communication withperipherals................................................................................................32

4.6.3 Network connection . . ...........................................................................................................32

5. Getting Started......................................................................................................35

5.1 RCU & Local keypad...................................................................................................................35

5.2 Terminology overview..................................................................................................................35

5.3 Operating the projector ................................................................................................................36

5.3.1 Switching on.....................................................................................................................36

5.3.2 Switching to standby . ...........................................................................................................37

5.3.3 Switching off.....................................................................................................................37

5.3.4 Temperature errorDMD.........................................................................................................37

5.4 Quick Set UpAdjustments.............................................................................................................38

5.4.1 Quick Language Change. . . . ....................................................................................................38

5.4.2 Quick Lens Adjustment.. . . . . ....................................................................................................38

5.4.3 QuickOn Screen Colorchange.................................................................................................39

5.5 Using the RCU .........................................................................................................................40

5.6 Projector Address......................................................................................................................42

5.6.1 Controlling the projector.........................................................................................................42

5.6.2 Displaying and Programming addresses.......................................................................................43

5.7 Controlling the Projector...............................................................................................................43

6. Start up of the Adjustment mode................................................................................45

6.1 Start up.................................................................................................................................45

6.2 Password...............................................................................................................................45

6.3 Menus onLocal LCD Display..........................................................................................................46

7. Random Access Adjustment Mode .............................................................................47

7.1 Overview Flow .........................................................................................................................47

7.2 PictureServices........................................................................................................................48

7.2.1 File annotation...................................................................................................................48

7.2.2 Possiblefile manipulations......................................................................................................48

7.2.3 Startup ..........................................................................................................................49

R5976654 SLM R12+ 09022004

1

Page 6

Table of contents

7.2.4 Load file..........................................................................................................................49

7.2.5 Edit File..........................................................................................................................50

7.2.5.1 Start up....................................................................................................................50

7.2.5.2 Changing the settings ....................................................................................................51

7.2.5.3 Correctvalue..............................................................................................................51

7.2.6 Rename..........................................................................................................................54

7.2.7 Copy .............................................................................................................................55

7.2.8 Delete............................................................................................................................55

7.2.9 File Options......................................................................................................................56

7.3 PictureTuning..........................................................................................................................57

7.3.1 Startup ..........................................................................................................................57

7.3.2 ColorTemperature...............................................................................................................57

7.3.3 Gamma..........................................................................................................................58

7.3.4 ColorSpace .....................................................................................................................58

7.3.5 Noise Reduction. . ...............................................................................................................59

7.3.6 Input Balance. ...................................................................................................................60

7.3.6.1 Input Balance for RGB input signals .....................................................................................60

7.3.6.2 Input Balance for YUV signals . . . . . . .....................................................................................61

7.3.6.3 Returning tothe factory defaults.........................................................................................62

7.3.6.4 Black balance for digital source ..........................................................................................62

7.4 Geometry...............................................................................................................................62

7.4.1 Introduction ......................................................................................................................62

7.4.2 Geometrystartup ...............................................................................................................63

7.4.3 Shift..............................................................................................................................63

7.4.4 Size ..............................................................................................................................64

7.4.5 Side Keystone...................................................................................................................65

7.4.6 Blanking..........................................................................................................................66

7.4.7 Aspect Ratio.....................................................................................................................67

7.4.8 GeometryOptions ...............................................................................................................68

7.5 ScenergiX ..............................................................................................................................68

7.5.1 Orderinformation................................................................................................................69

7.5.2 Introduction ......................................................................................................................69

7.5.3 Preparations.....................................................................................................................70

7.5.4 Scenergix........................................................................................................................70

7.5.5 ScenergiX overlap zone(horizontalscenergix) ................................................................................70

7.5.6 ScenergiX overlap zone(vertical scenergix) ...................................................................................71

7.5.7 ScenergiX size adjustment......................................................................................................72

7.5.8 Adjusting the blacklevelof the images.........................................................................................74

7.6 PictureinPicture (PiP).................................................................................................................75

7.6.1 Introduction toPiP...............................................................................................................75

7.6.2 Picture in Picture activation.....................................................................................................76

7.6.3 Picture in Picture source ........................................................................................................76

7.6.4 Position of Picture in Picture window . . . . . . .....................................................................................76

7.6.5 Set upof the QuickSelection...................................................................................................77

7.7 Save Changes . . .. . . ...................................................................................................................77

8. Installation Mode ...................................................................................................79

8.1 Start upoftheInstallationmode.......................................................................................................79

8.2 Input Slots..............................................................................................................................79

8.3 800 peripheral ..........................................................................................................................81

8.3.1 Definingthe output module oftheRCVDS05...................................................................................81

8.3.2 Definingthe InfraredCommunication protocol.................................................................................81

8.4 Source Switching.......................................................................................................................82

8.5 No Signal...............................................................................................................................82

8.5.1 Changing the Background Color................................................................................................83

8.5.2 Changing the Shutdown Setting ................................................................................................83

8.5.3 Changing the Shutdown Time . . ................................................................................................83

8.6 Contrast Enhancement . ...............................................................................................................84

8.7 Convergence...........................................................................................................................85

8.8 Configuration...........................................................................................................................85

8.9 LensAdjustment .......................................................................................................................86

8.10QuickAccess Keys ....................................................................................................................87

8.11OSD....................................................................................................................................88

8.11.1Color Settings ...................................................................................................................88

8.11.2Menu Position...................................................................................................................88

8.12InternalPatterns.......................................................................................................................88

9. Service Mode........................................................................................................91

9.1 Built-up .................................................................................................................................91

9.2 Start up.................................................................................................................................91

9.3 Identification............................................................................................................................91

9.4 Password...............................................................................................................................92

9.4.1 Change Password...............................................................................................................92

9.4.2 Access Control List..............................................................................................................93

9.5 Changing Language ...................................................................................................................95

9.6 Change Projector Address. ............................................................................................................95

2

R5976654 SLM R12+ 09022004

Page 7

Table of contents

9.7 Serial Communication .................................................................................................................96

9.7.1 StartUpof the Serial Communication ..........................................................................................96

9.7.2 Baud rate Setting................................................................................................................97

9.7.3 Setting up the Interface Standard. . . ............................................................................................97

9.7.4 RS422Termination..............................................................................................................98

9.8 NetworkConfiguration .................................................................................................................98

9.9 Lamp ...................................................................................................................................99

9.10Dimming ..............................................................................................................................102

9.11BARCO Logo .........................................................................................................................102

9.12Add-Ins................................................................................................................................103

9.13Preset Input Balance . . . ..............................................................................................................103

9.14AdvancedProcessing ................................................................................................................104

9.14.1Minimum Delay.................................................................................................................104

9.15Diagnosis .............................................................................................................................105

9.15.1How to start up the Diagnosis? ................................................................................................105

2

C Diagnoses..................................................................................................................105

9.15.2I

9.15.3DMD............................................................................................................................106

9.15.4SMPS...........................................................................................................................106

9.15.5LPS (lamp power supply) .. . ...................................................................................................106

9.15.6Voltages ........................................................................................................................107

10.Programmable Function Keys ................................................................................. 109

10.1FunctionKeys.........................................................................................................................109

A. Standard Source set up Files....................................................................................111

A.1Tableoverview ........................................................................................................................111

B. Cleaning the dust filters ......................................................................................... 115

B.1Dust filter onthefront side............................................................................................................115

B.2Dust filter ontheback side ...........................................................................................................118

B.3Dust filter onthebottom side .........................................................................................................119

C. Troubleshooting .................................................................................................. 121

C.1Error codes............................................................................................................................121

Glossary ............................................................................................................... 123

Index.................................................................................................................... 125

R5976654 SLM R12+ 09022004 3

Page 8

Table of contents

4 R5976654 SLM R12+ 09022004

Page 9

1. Safety Instructions

1. SAFETY INSTRUCTIONS

1.1 Warnings

To prevent personnel injury

The customer should never attempt to disassemble the lamp casing or to dispose of the lamp casing other than by returning it to

BARCO.

To prevent injuries and physical damage, always read this manual and all labels on the system before connecting to the

or adjusting the projector.

To prevent injuries, take note of the weight of the projector. Minimum 2 persons are needed to carry the projector.

NEVER look into the lens ! Due to the high luminance damage to the eye can happen.

Before attempting to remove the projector’s cover, you must turn off the projector and disconnect from the wall outlet.

When performing set up work at a ceiling mounted projector, to prevent injury caused by falling obje

out area.

Consult a professional structural engineer prior to suspending the ceiling mount from a structure not intended for that use. Always

ensure the working load limit of the structure supporting the projector.

The power input at the projector side is considered as the disconnect device. When me

some parts inside, always disconnect the power cord at the projector side.

ntioned to switch of the projector, to access

cts or the system, set out a keep

wall outlet,

To prevent projector damage

If the Air Filters are not regularly replaced, the air flow inside the projector could be disrupted, causing overheating. Overheating

may lead to the projector shutting down during operation.

In order to ensure that correct airflow is maintained, and that the proj

it should always be operated with all of it’s covers in place.

Ensure that nothing can be spilled on, or dropped inside the projector. If this does happen, switch off and unplug the mains supply

immediately. Do not operate the projector again until it has been checked by qualified service personnel.

The projector must always be mounted in a manner which ensures free flo

hot air exhausted from its cooling system. Heat sensitive materials should not be placed in the path of the exhausted air.

Special care should be used when DLP projectors are used in the same room as performant laser equipment. Direct or indirect

hitting of a laser beam on to the lens can severely damage the Digital Mirror Devices (TM) in which case there is a loss of warranty

ector complies with Electromagnetic Compatibility requirements,

w of air into its air inlets and unimpeded evacuation of the

To prevent battery explosion

Danger of explosion if battery is incorrectly replaced.

Replace only with the same or equivalent type recommended by the manufacturer.

Dispose of used batteries according to the manufacturer’s instructions.

1.2 FCC statement

Federal Communication Commission (FCC Statement)

This equipment has been tested and found to comply with the limits for a class A digital device, pursuant to Part 15 of the FCC

rules. These limits are designed to provide reasonable protection against harmful interference when the equipment is operated in a

commercial environment. This equipment generates, uses, and can radiate radio frequency energy and, if not installed and used in

accordance with the instruction manual, may cause harmful interference to radio communications. Operation of this equipment in a

residential area may cause harmful interference, in which case the user will be responsible for correcting any interference.

1.3 Note

Definitions

Definition Qualified service technicians or Qualified technicians : Persons having appropriate technical training and experience necessary to be aware of hazards to which they are exposed in performing a task and of measures to minimize the danger to themselves

or other persons.

R5976654 SLM R12+ 09022004 5

Page 10

1. Safety Instructions

Extra Safety manual

Read also safety instructions in separate manual (R5976125).

6

R5976654 SLM R12+ 09022004

Page 11

2. Packaging and Dimensions

2. PACKAGING AND DIMENSIONS

Overview

• Projector Packaging

• Box Content

• Lens Packaging

• Projector Case

2.1 Projector Packaging

Way of Packaging

The projector is packed in a carton box. To provide protection during transportation, the projector is surrounded with foam. The

package is secured with banding and fastening clips.

To unpack

1. Release the fastening clips.

2. Remove the banding. Handle as shown in the drawing. (image 2-1)

3. Take the projector out of its shipping carton and place it on a table.

PULL

TO OPE

Image 2-1

Save the original shipping carton and packing material, they will be necessary if you ever have to ship your

projector. For maximum protection, repack your projector as it was originally packed at the factory.

Never transport the projector with the lens mounted on it !

Always remove the lens before transporting the projector.

2.2 Box Content

Content

• 1 projector SLM R12+ (weight ± 56 kg or 123.5 lbs)

• 1 remote control unit RCU + 1 battery.

• 1 European and 1 American power cable.

• 1 Terminator for linked CLO

• 1 owners manual

• 1 safety manual

2.3 Lens Packaging

Way of Packaging

Lenses are supplied as an individual item.

R5976654 SLM R12+ 09022004

7

Page 12

2. Packaging and Dimensions

They are packed in a carton.

2.4 Projector Case

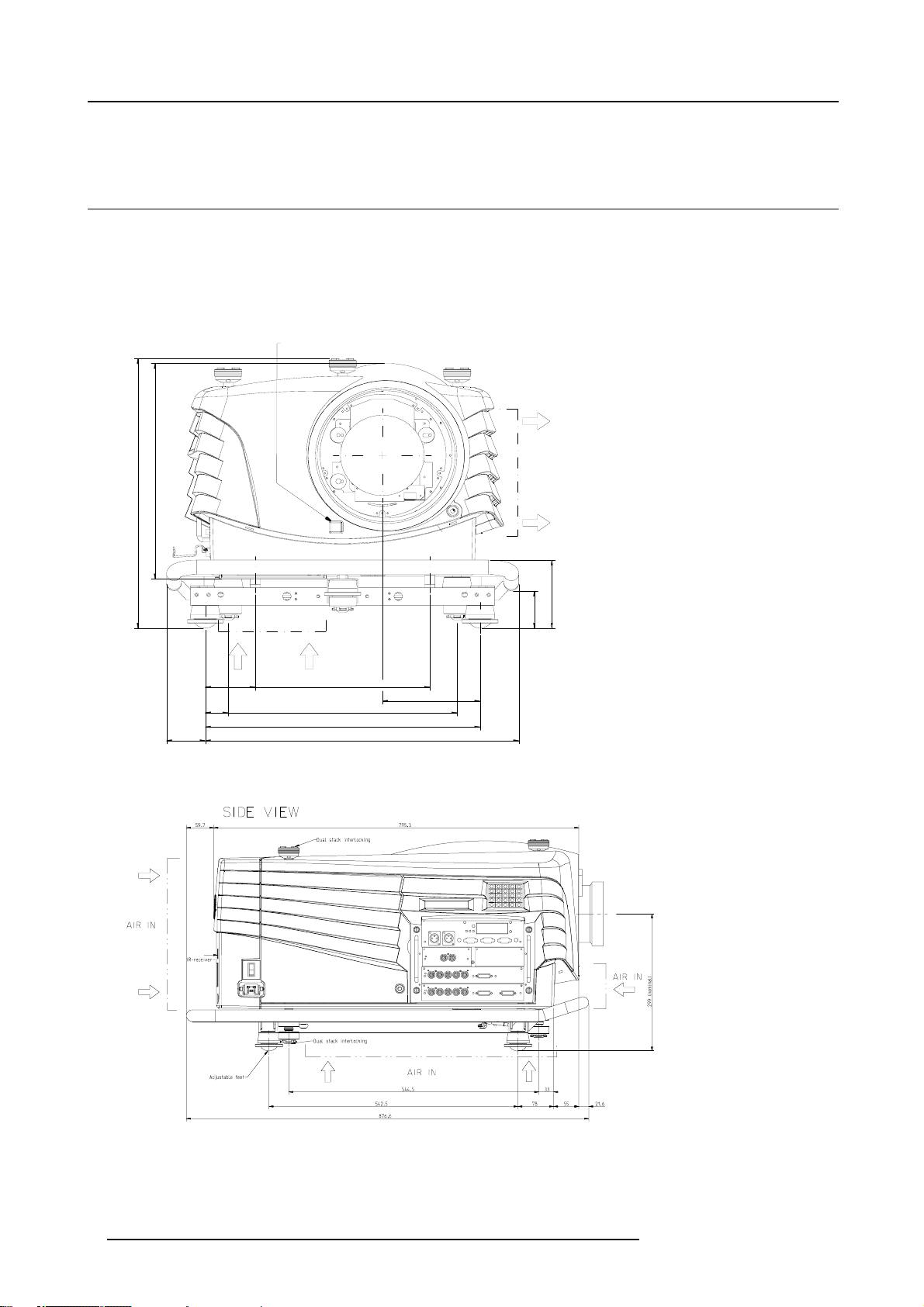

Dimensions

The dimensions are given in mm

25.4mm = 1 inch

IR-receiver

FRONT VIEW

372,7

466

0 456

64,5 520,5

Image 2-2

Front view dimensions

AIR IN

83 373

38 418

AIR OUT

118

64,5

162

Image 2-3

Side view dimensio ns

8 R5976654 SLM R12+ 09022004

Page 13

3. INSTALLATION GUIDELINES

Never use the projector when turned with the inputs downwards.

The engines are non sealed versions.

3.1 General

Before installing the projector, read first the safety instructions.

Ambient Temperature Conditions.

Careful consideration of things such as image size, ambient light level, project

the optimum use of the projection system.

Max. ambient temperature : 40°C or 104 °F

Min. ambient temperature : 10 °C or 50 °F

The projector will not operate if ambient air temperature falls outside this range (10°C- 40°C or 50°F-104°F).

Storage temperature: -35°C to +65°C (-31°F to 149°F)

or placement and type of screen to use are critical to

3. Installation Guidelines

Humidity Conditions

Storage: 0 to 98 % RH Non-condensing

Operation: 0 to 95 % RH Non-condensing

Harmful Environmental Contamination Precaution

Environment

Do not install the projection system in a site near heat sources such as radiators or air ducts, or in a place subject to direct sunlight,

excessive dust or humidity. Be aware that room heat rises t

excessive.

o the ceiling; check that temperature near the installation site is not

Environment condition check

A projector must always be mounted in a manner which ensures the free flow of clean air into the projectors ventilation inlets. For

installations in environments where the projector is subject to airborne contaminants such as that produced by smoke machines or

similar (these deposit a thin layer of greasy residue upon the projectors internal optics and imaging electronic surfaces, degrading

performance), then it is highly advisable and desirable to have this contamination removed prior to it reaching the projectors clean

air supply. Devices or structures to extract or shield contaminated air well away from the projector are a prerequisite, if this is not a

feasible solution then measures to relocate the projector to a clean air environment should be considered.

Only ever use the manufacturer’s recommended cleaning kit which has been specifically designed for cleaning optical parts, never

use industrial strength cleaners on the projector’s optics as these will degrade optical coatings and damage sensitive optoelectronics

components. Failure to take suitable precau

inants will culminate in extensive and irreversible ingrained optical damage. At this stage cleaning of the internal optical units will

be non-effective and impracticable. Damage of this nature is under no circumstances covered under the manufacturer’s warranty

and may deem the warranty null and void

repair. It is the clients responsibility to ensure at all times that the projector is protected from the harmful effects of hostile airborne

particles in the environment of the projector. The manufacturer reserves the right to refuse repair if a projector has been subject to

wantful neglect, abandon or improp

er use.

tions to protect the projector from the effects of persistent and prolonged air contam-

. In such a case the client shall be held solely responsible for all costs incurred during any

R5976654 SLM R12+ 09022004

9

Page 14

3. Installation Guidelines

Special Care for Laser Beams

Special care should be used when DLP projectors are used in the same room as performant laser equipment. Direct or indirect hitting

of a laser beam on to the lens can severely damage the Digital MicroMirror Devices™ in which case there is a loss of warranty

Which screen type ?

There are two major categories of screens used for projection equipment. Those used for front projected images and those for rear

projection applications.

Screens are rated by how much light they reflect (or transmit in the case of rear projection systems) given a determined amount

of light projected toward them. The ‘GAIN’ of a screen is the term used. Front and rear screens are both rated in terms of gain.

The gain of screens range from a white matte screen with a gain of 1 (x1) to a brushed aluminized screen with a gain of 10 (x10)

or more. The choice between higher and lower gain screens is largely a matter of personal preference and another consideration

called the Viewing angle. In considering the type of screen to choose, determine where the viewers will be located and go for the

highest gain screen possible. A high gain screen will provide a brighter picture but reduce the viewing angle. For more information

about screens, contact your local screen supplier.

What image size? How big should the image be?

The projector is designed for projecting an image size : min 1.00m (3.3ft) to max 15 m (49.2ft) (depending on the ambient light

conditions), with an aspect ratio of 4 to 3.

3.2 Configuration

Which configuration can be used?

The projector can be installed to project images in four different configurations:

• Front/table

• Rear/table

• Front/ceiling

• Rear/ceiling

10

R5976654 SLM R12+ 09022004

Page 15

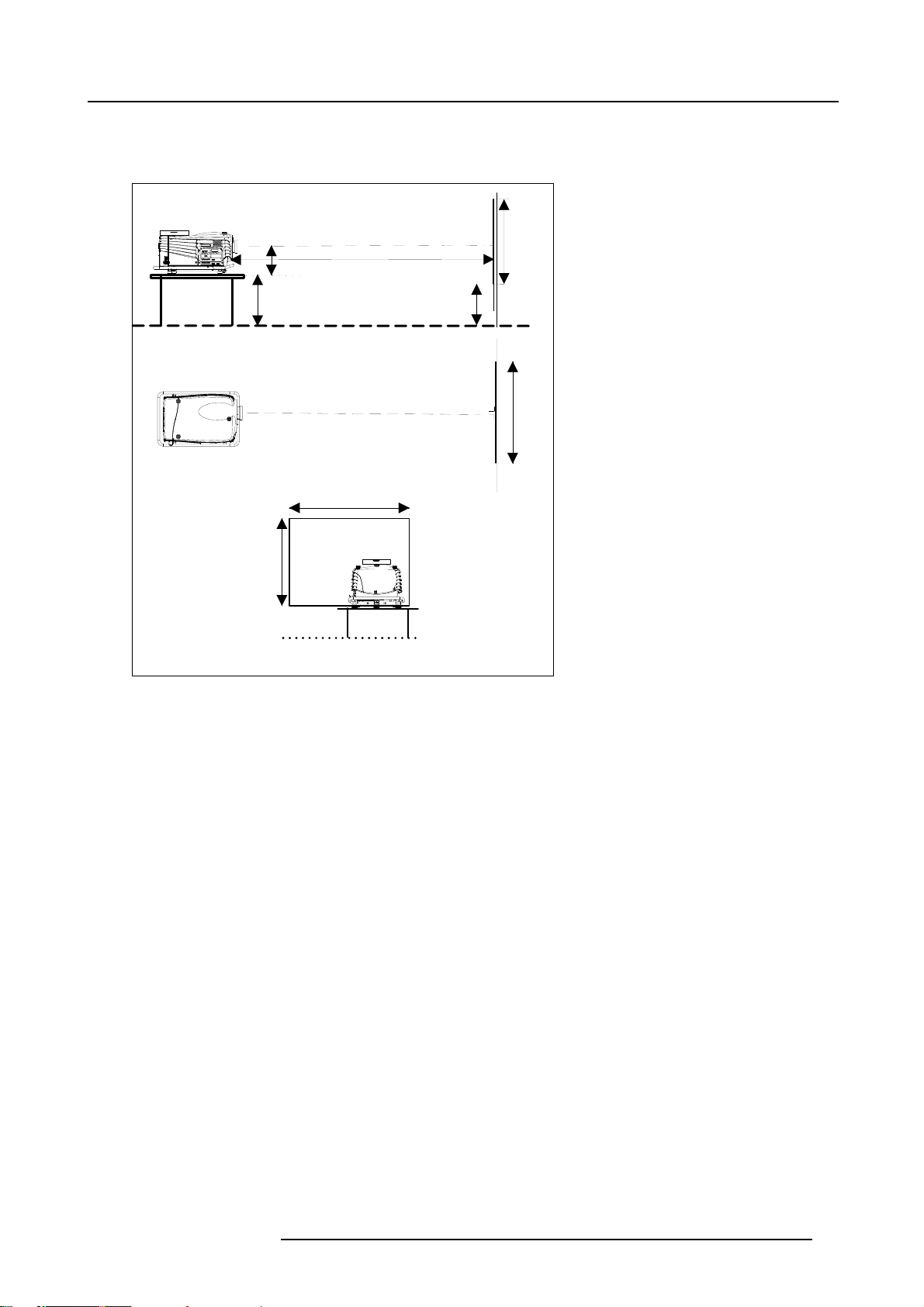

Positioning the projector

Table mounted, front projection

Table/Top side facing ceiling

Projector

A

SIDE VIEW

Optical axis projection lens

PD

Screen

3. Installation Guidelines

SH

Image 3-1

Table mounted configuration

CD

CD = SH/2 + B - A

SH

B

Floor

SW

Screen

TOP VIEW

SW

Floor

BACK VIEW

R5976654 SLM R12+ 09022004 11

Page 16

3. Installation Guidelines

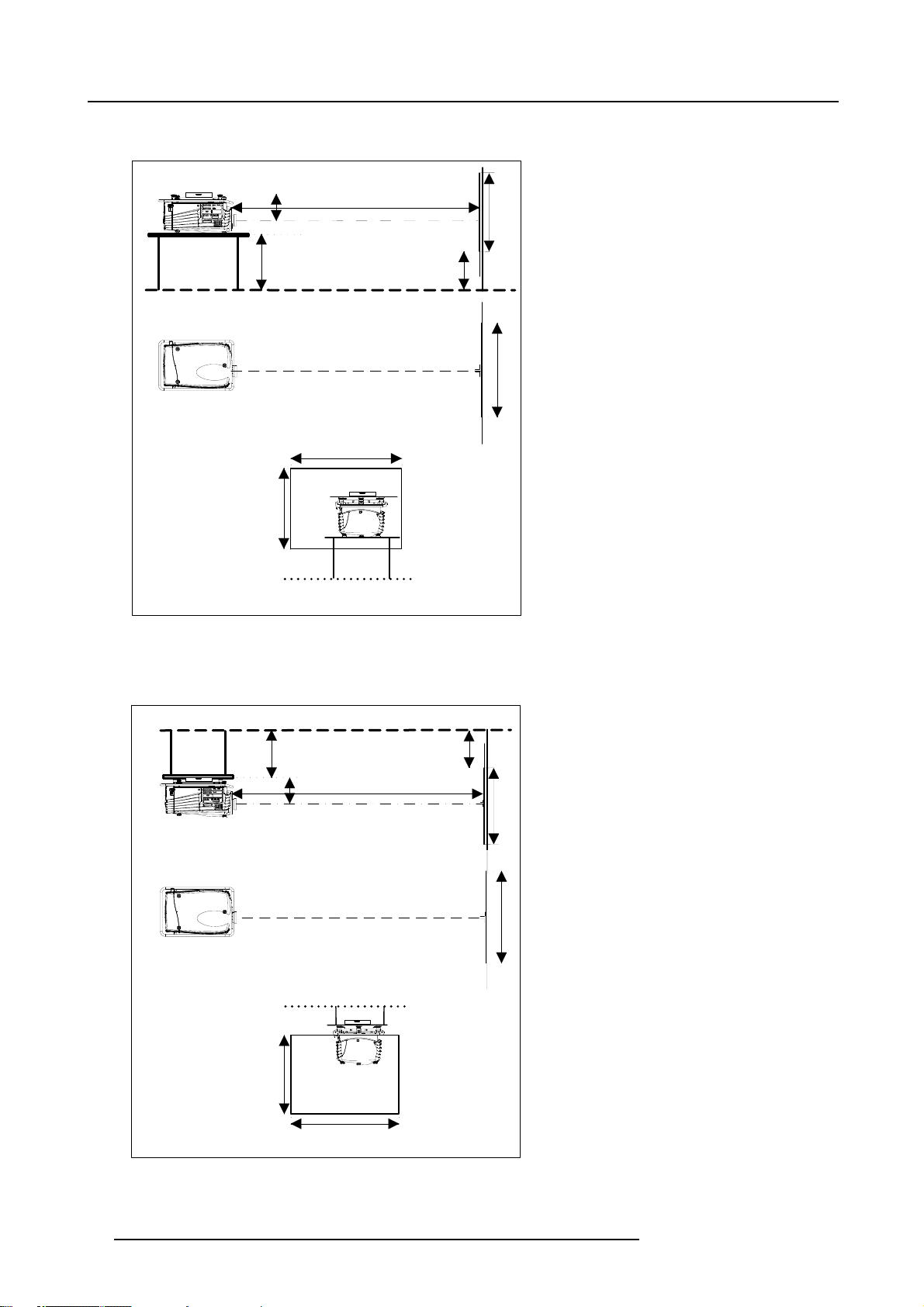

Table mounted, front projection, second way.

Table/Top side facing floor

Projector

A

SIDE VIEW

Optical axis projection lens

PD

Screen

SH

CD

CD = SH/2 + B + A - 554mm

SH

Image 3-2

Table mounted configuration up side down

Ceiling mounted, front projection

Ceiling/Top side facing floor

CD

B

Floor

SW

Screen

TOP VIEW

SW

Floor

BACK VIEW

Ceiling

B

Projector

Image 3-3

Ceiling mounted projector

A

CD = SH/2 + B - A

SH

PD

Optical axis projection lens

SIDE VIEW

CEILING VIEW

Ceiling

SW

BACK VIEW

SH

Screen

SW

Screen

12 R5976654 SLM R12+ 09022004

Page 17

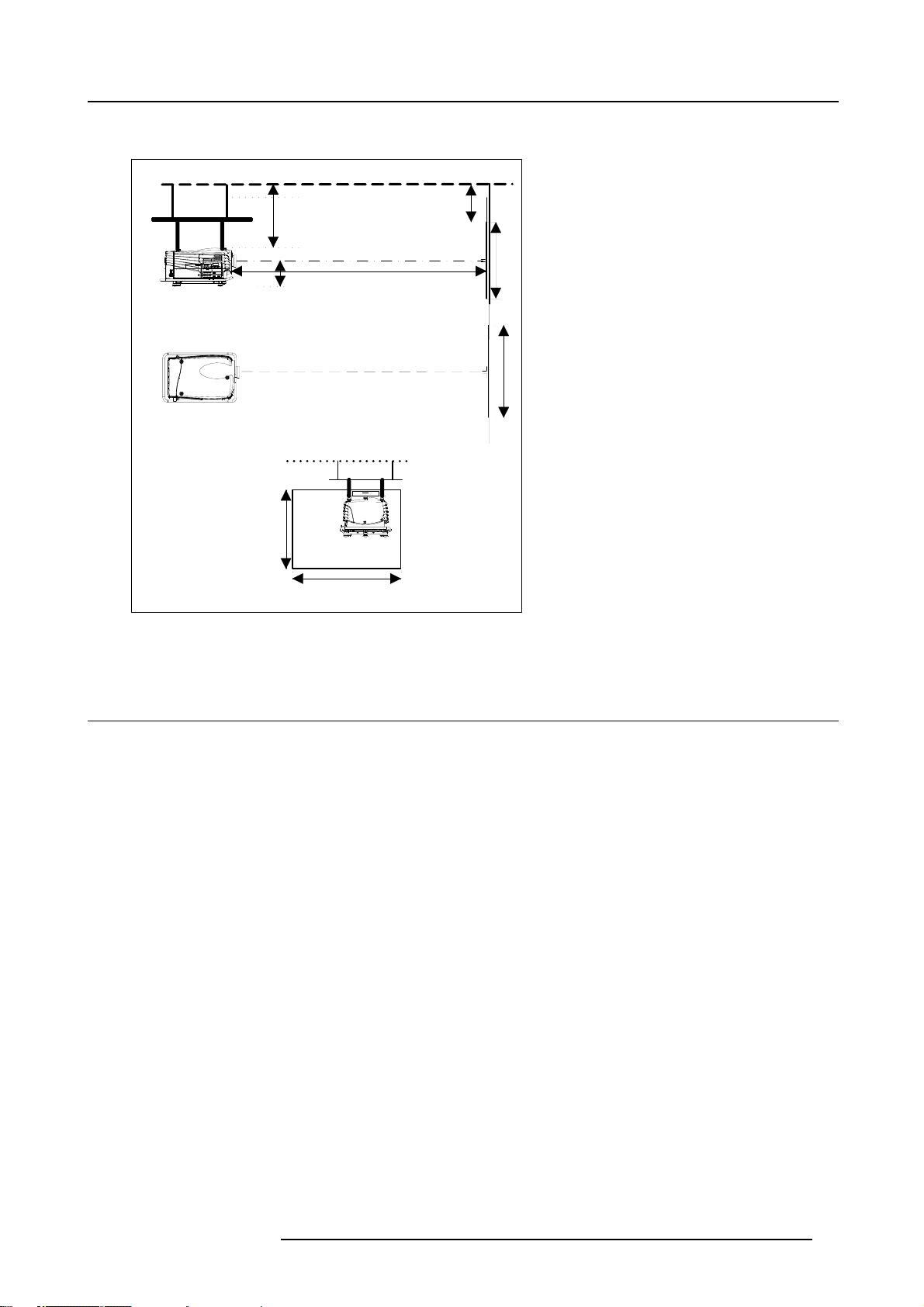

Ceiling mounted, front projection, second way.

Ceiling/Top side facing ceiling

Ceiling

3. Installation Guidelines

Projector

Image 3-4

Ceiling mounted projector

CD

A

CD = SH/2 + B + A - 554mm

Ceiling

SH

Optical axis projection lens

PD

SIDE VIEW

CEILING VIEW

SW

BACK VIEW

B

Screen

SH

SW

Screen

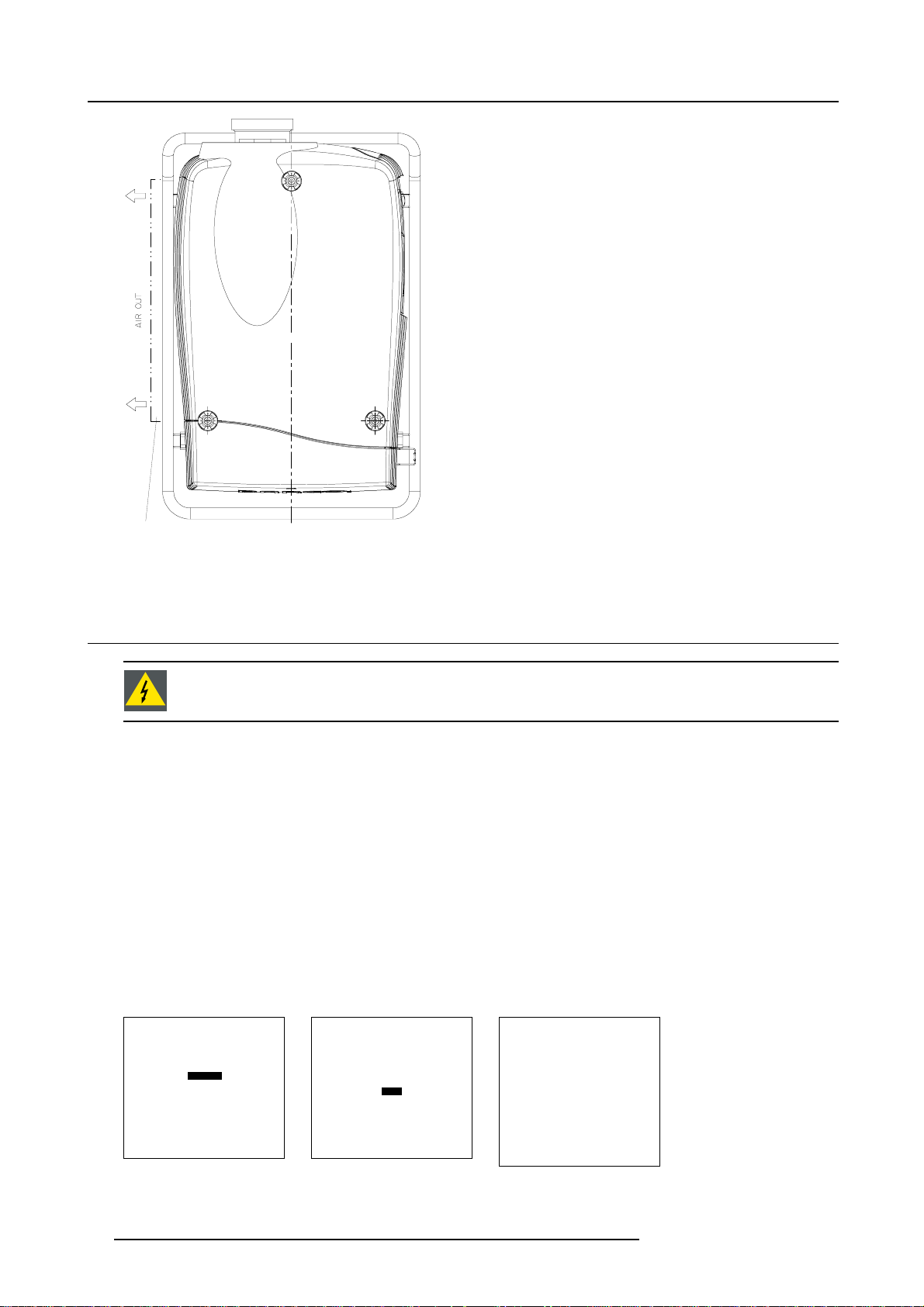

3.3 Safety Area around projector

Safety area

Make sure the projector is located so that the air inlets and outlets for the cooling system are not obstructed. Leave a safety area A

of about 1 meter on the left and the right side of the projector.

R5976654 SLM R12+ 09022004

13

Page 18

3. Installation Guidelines

A

Image 3-5

Safety a rea around th e projector

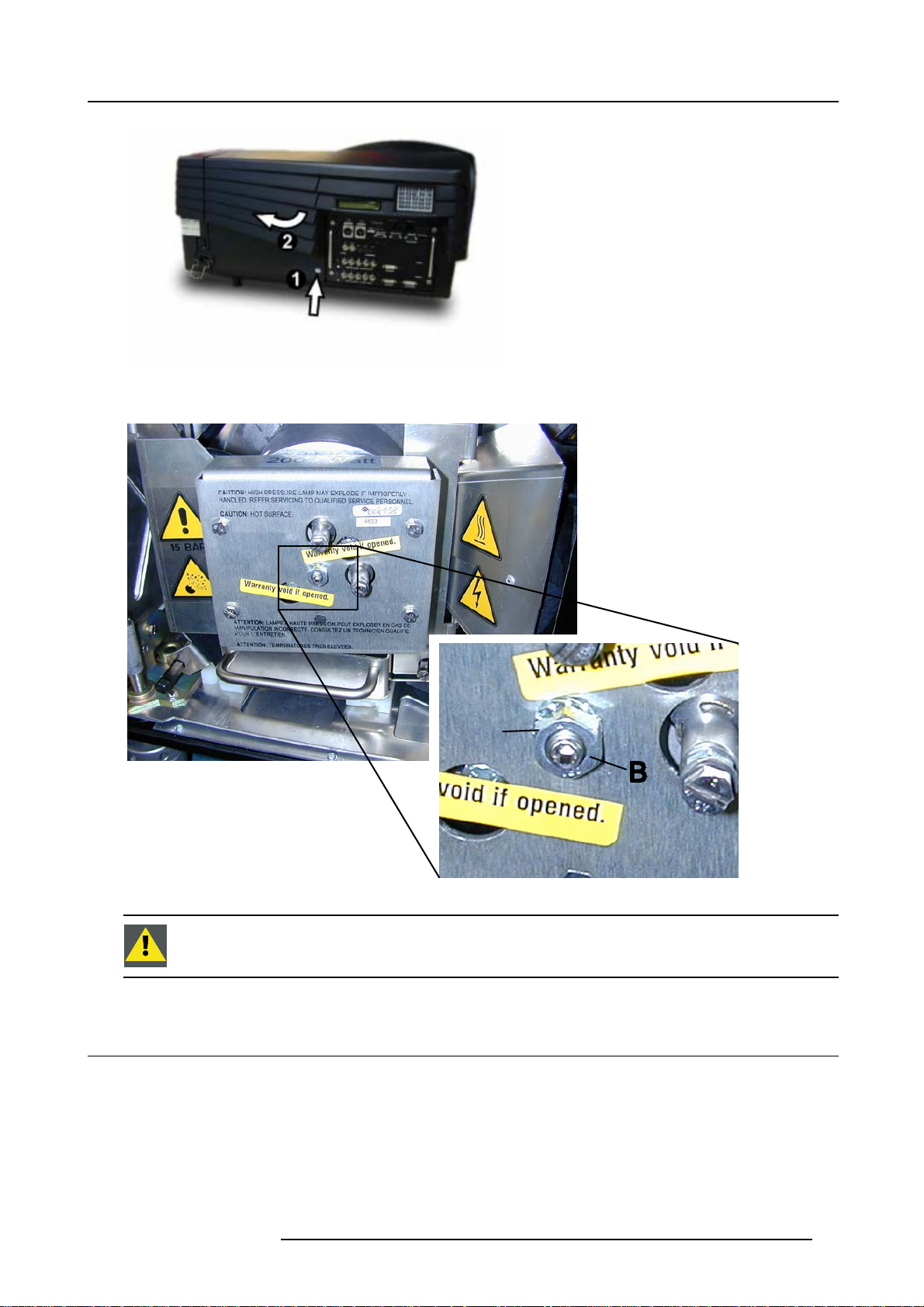

3.4 Re-adjusting the lamp position in the lamp casing

As the projector has to be opened, this procedure has to be performed by qualified service technician.

Why

With higher run times, the light output of the lamp will decrease, which results in a lower light output on the screen. This light output

decrease can be compensated by readjusting the position of the lamp.

How to readjust.

1. On the side of the inputs, turn the retaining bolt a quarter counter clockwise.

2. Flip the cover to the left side and take off. (image 3-6)

3. Start up the adjustment mode and select Service. (menu 3-1)

4. Select Lamp. The Z-axis indication (lamp menu in service mode) will be helpful while turning screw B . (menu 3-2)

5. Loosen the nut A (image 3-7)on the back of th

6. Adjust the screw B (image 3-7)with an Allen key by turning a little clockwise until the maximum light output is reached (the maximum value of the Z-AXIS indication on the lamp menu).

7. Fasten the nut on the back of the lamp casing to secure this position (nutdriver 10).

ADJUSTMENT MODE

Select a path from below :

RANDOM ACCESS

Menu 3-1

INSTALLATION

SERVICE

Select with ↑ or ↓

then <ENTER>

<EXIT> to return

CHANGE PROJ. ADDRESS

SERIAL COMMUNICATION

Select with ↑ or ↓

Menu 3-2

e lamp casing (nutdriver 10).

SERVICE

IDENTIFICATION

CHANGE PASSWORD

CHANGE LANGUAGE

NETWORK

LAMP

DIMMING

MORE...

then <ENTER>

<EXIT> to return

LAMP

Constant Light output [OFF]

Mode [NORMAL]

Serial number : R101111

Article number : R9840xxx

Run time : 10 hours

Remaining run time : 490

Menu 3-3

hours

Number of strikes : 10

Z_AXIS : 100

Select with ↑ or ↓

then <ENTER>

<EXIT> to return.

14 R5976654 SLM R12+ 09022004

Page 19

Image 3-6

Lamp adjustment access

3. Installation Guidelines

Image 3-7

3.5 Lenses

Overview

• Lenses

• Lens selection

• Lens formulas

• Lens Installation

• Cleaning the lens

A

Never turn the other screws ! These are factory aligned.

R5976654 SLM R12+ 09022004

15

Page 20

3. Installation Guidelines

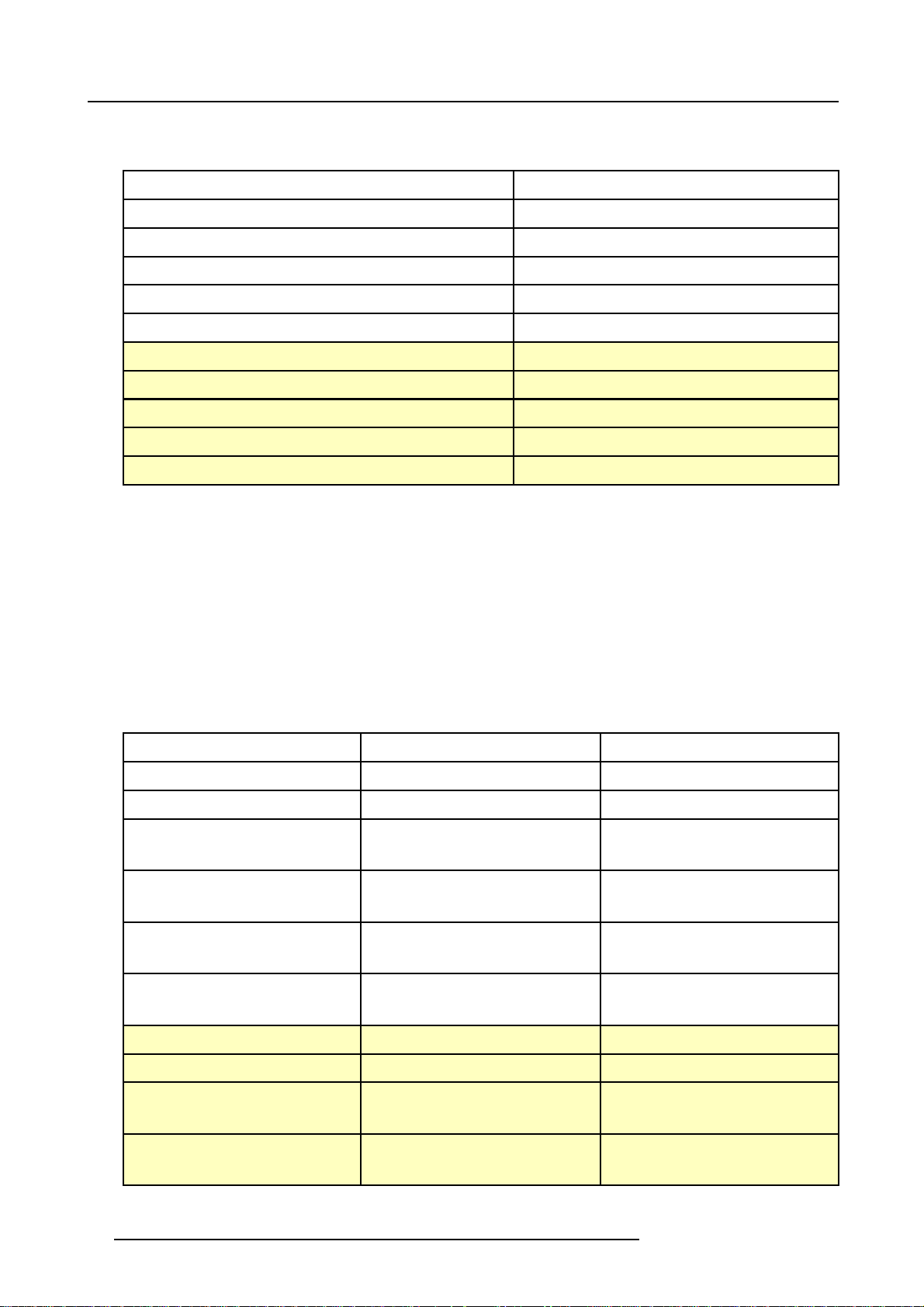

3.5.1 Lenses

Available lenses

TLD(1.6–2.0:1)

TLD(2.0–2.8:1)

TLD(2.8–5.0:1)

TLD(1.2:1)

TLD(0.8:1)

TLD(5.0–8.0:1)

TLD HB(0.8:1)

TLD HB(1.6–2.0:1)

TLD HB(2.0–2.8:1)

TLD HB(2.8–5.0:1)

TLD HB(5.0–8.0:1)

R9840670

R9840680

R9840690

R9840770

R9840900

R9840910

R9842040

R9842060

R9842080

R9842100

R9842120

3.5.2 Lens selection

How to select ?

1. Determine the required screen width.

2. Determine the approximate position of the project

screen distance (PD).

3. Use the lens formulas to find the best corresponding PD with regard to the measured projector-screen distance for the required

screen width.

or in the projection room with regard to the screen and measure the projector-

3.5.3 Lens formulas

Formulas

Metric formulas (meter) Inch formulas (inch)

TLD(0.8:1) PD=0.85xSW-0.05 PD=0.85SW-1.97

TLD(1.2:1) PD=1.22xSW-0.01 PD=1.22xSW-0.39

TLD(1.6–2.0:1) PD

TLD(2.0–2.8:1) PD

TLD(2.8–5.0:1) PD

TLD(5.0–8.0:1) PD

TLD HB(0.8:1) PD=0.85xSW-0.05 PD=0.85SW-1.97

TLD HB(1.2:1) PD=1.22xSW-0.01 PD=1.22xSW-0.39

TLD HB(1.6–2.0:1) PD

=1.62xSW-0.09

min

PD

=2.03xSW-0.13

max

=2.03xSW-0.17

min

PD

=2.88xSW-0.24

max

=2.84xSW-0.16

min

=5.18xSW-0.38

PD

max

=4.97xSW-0.01

min

=8.28xSW-0.29

PD

max

=1.62xSW-0.09

min

=2.03xSW-0.13

PD

max

PD

PD

PD

PD

PD

PD

PD

PD

PD

PD

=1.62xSW-3.54

min

=2.03xSW-5.12

max

=2.03xSW-6.69

min

=2.88xSW-9.45

max

=2.84xSW-6.30

min

=5.18xSW-14.96

max

=4.97xSW-0.39

min

=8.28xSW-11.42

max

=1.62xSW-3.54

min

=2.03xSW-5.12

max

TLD HB(2.0–2.8:1) PD

=2.03xSW-0.17

min

=2.88xSW-0.24

PD

max

PD

=2.03xSW-6.69

min

=2.88xSW-9.45

PD

max

16 R5976654 SLM R12+ 09022004

Page 21

3. Installation Guidelines

Metric formulas (meter) Inch formulas (inch)

TLD HB(2.8–5.0:1) PD

TLD HB(5.0–8.0:1) PD

=2.84xSW-0.16

min

=5.18xSW-0.38

PD

max

=4.97xSW-0.01

min

=8.28xSW-0.29

PD

max

PD

=2.84xSW-6.30

min

=5.18xSW-14.96

PD

max

PD

=4.97xSW-0.39

min

=8.28xSW-11.42

PD

max

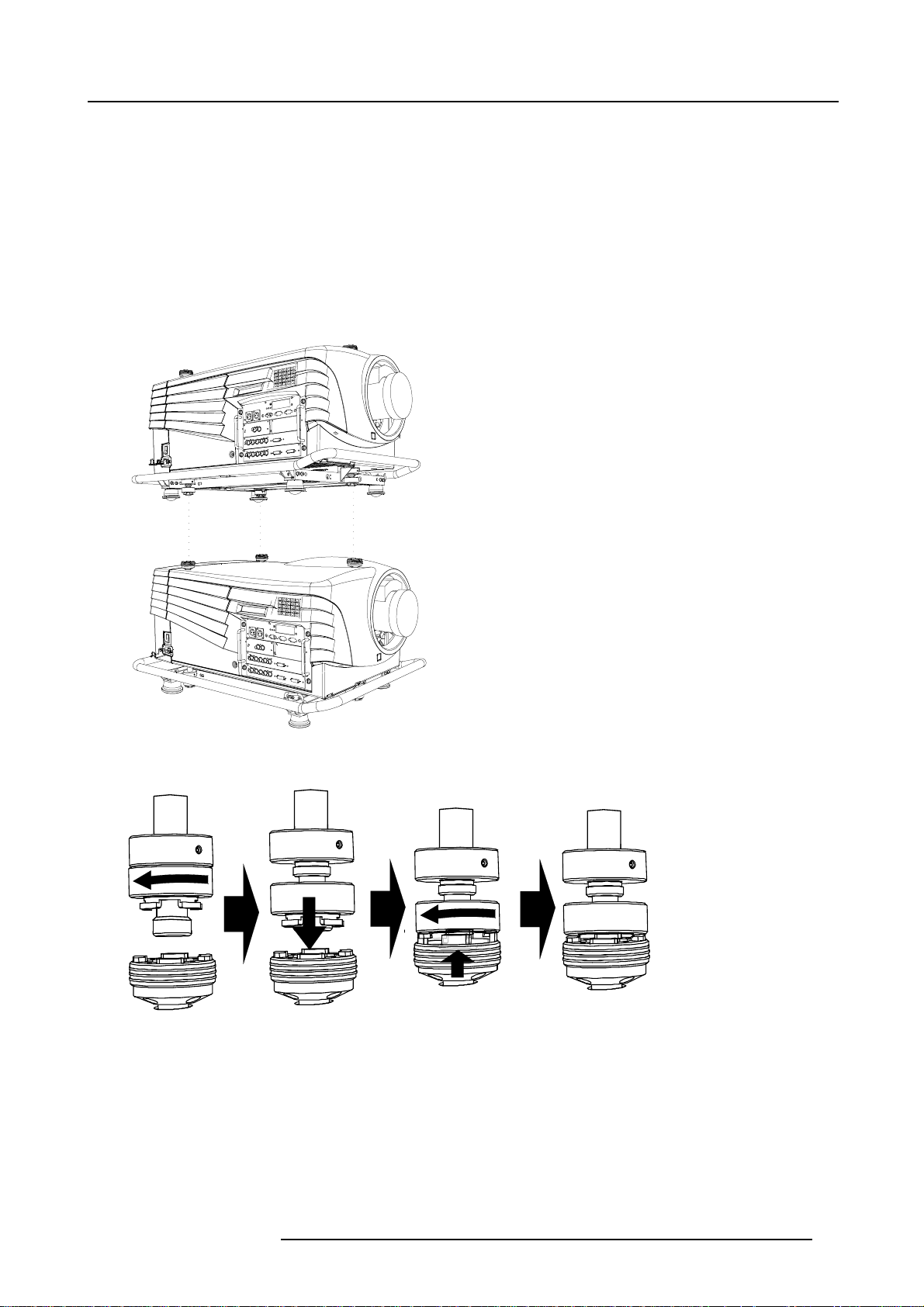

3.5.4 Lens Installation

How to install ?

Follow the next procedure:

1. Remove the foam rubber in the opening of the lens holder.

2. Take the lens assembly out of its packing material a

3. Move the handle (A) of the lens anchor system to the right. (image 3-8)

4. Push the lens, motors at the top, in the lens block gap horizontally, lining up the motor connector on the lens with the connector

on the lens block (B), until the lens clicks in the lens anchor system. (image 3-9)

Caution: On a table mounted projector, hold the projector whe

the table.

nd remove the lens caps on both sides.

n pushing the lens into the lens block to avoid sliding off from

Image 3-9

Mounted Lens

Image 3-8

Lens installat

ion

3.5.5 Cleaning the lens

To minimize the possibility of damaging the optical coating or scratching exposed lens surface, we have developed recommendations for cleaning the lens. FIRST, we recommend you try to remove any material from

the lens by blowing it off with clean, dry deionized air. DO NOT use any liquid to clean the lenses.

Necessary tools

To ra ys e eTMcloth (delivered together with the lens kit). Order number : R379058.

Howtocleanthelens?

Proceed as follow :

TM

1. Always wipe lenses with a CLEAN Toraysee

2. Always wipe lenses in a single direction.

Warning: Do not wipe back and forwards across the lens surface as this tends to grind dirt into the coating.

3. Do not leave cleaning cloth in either an open room or lab coat pocket, as doing so can contaminate the cloth.

4. If smears occur when cleaning lenses, replace the cloth. Smears are the first indication of a dirty cloth.

cloth.

R5976654 SLM R12+ 09022004

17

Page 22

3. Installation Guidelines

Do not use fabric softener when washing the cleaning cloth or softener sheets when drying the cloth.

Do not use liquid cleaners on the cloth as doing so will contaminate the cloth.

Other lenses can also be cleaned safely with this TorayseeTMcloth.

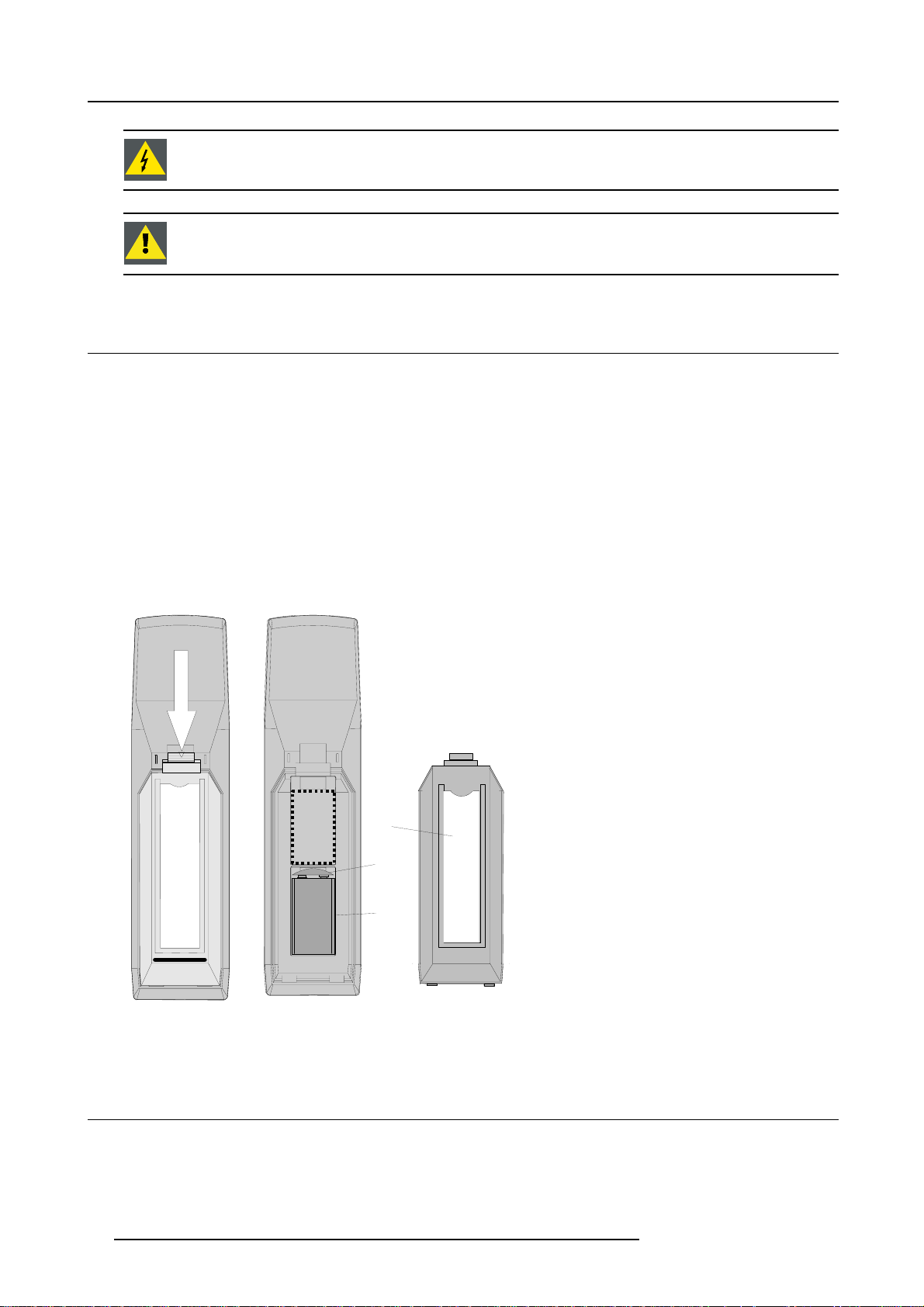

3.6 Battery Installation in the RCU

How is the battery delivered ?

A battery (not yet installed to save the battery life time) is delivered inside the plastic bag with the power cord.

How to install ?

1. Remove the battery cover on the backside of the remote control by pushing the indicated handle a little towards the bottom of

the RCU. (image 3-10)

2. Lift up the top side of the cover at the same time.image 3-10

3. Insert the new 9 V battery (type E-block or equivalent) in the lower compartment.

4. Connect the battery (B) to the contact plate (A). (image 3-11)

5. Insert the battery into the lower compartment and put the cover back.

6. Insert a overview card (C) in the back side.image 3-11

C

A

B

Image 3-10

Opening the battery cover of

the RCU

Image 3-11

Mounting the battery into the RCU

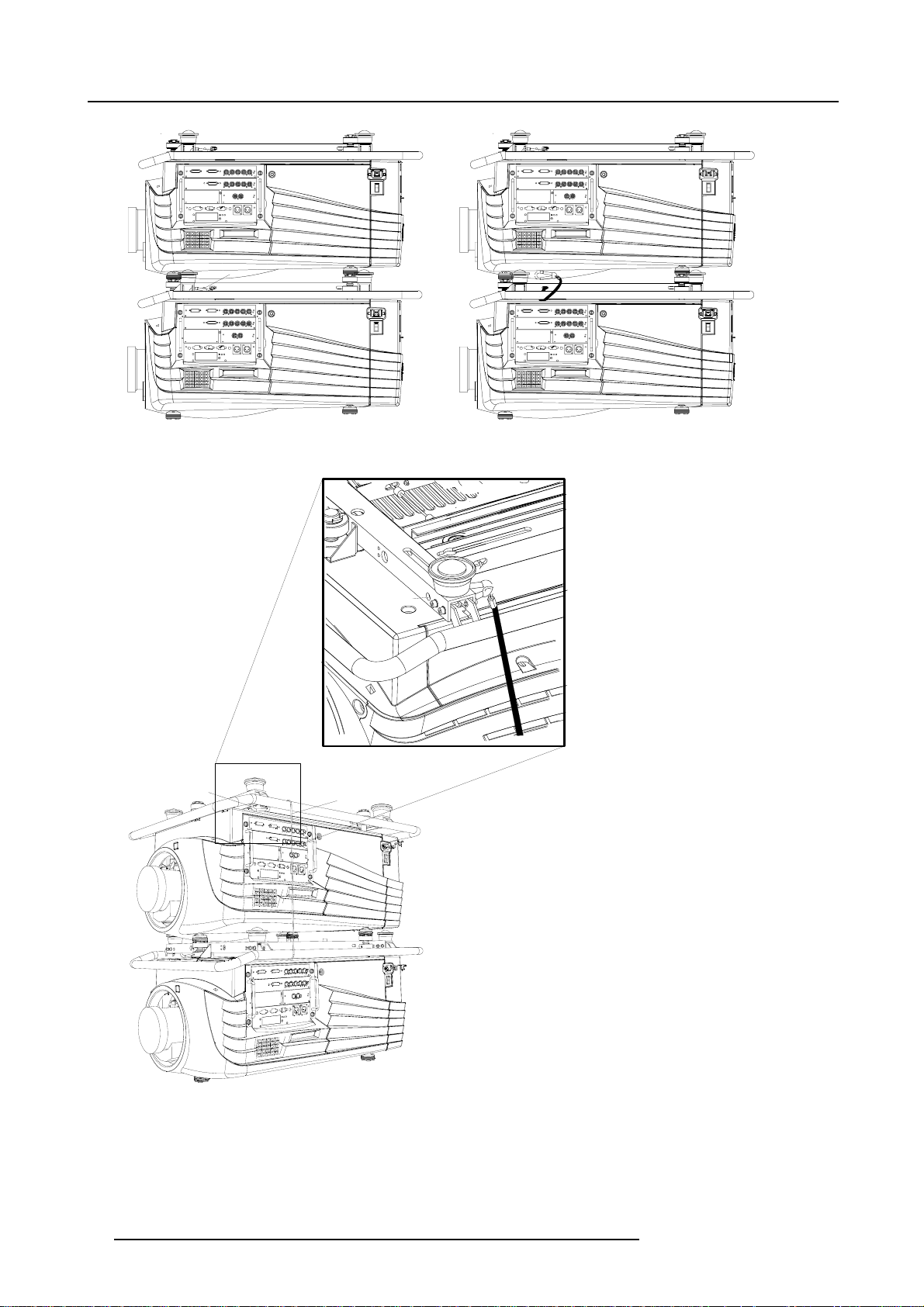

3.7 Stacking Projectors

What is possible?

Up to 3 projectors can be stacked on each other without using extra tools or accessories.

18

R5976654 SLM R12+ 09022004

Page 23

3. Installation Guidelines

How to stack?

Handle as follow:

1. Put the second projector on the first one so that base plate of the second projector matches with the rigging socket of the first

projector. (image 3-12)

2. Turn the rigging sockets of the second projector counter clockwise until they are free to move up and down. (image 3-13)

3. Secure the projectors on each other by bringing the free part of the second projector into the socket of the first projector and turn

a quarter clockwise while pushing downwards until it clicks in.

4. For ceiling mounted configurations, pull on the hook (A) with the cable of the lowest projector. (image 3-14)

5. Guide hook and cable around the carry handle and guide it around the carry handle of the upper projector. (image 3-15)

6. Hook it in the foreseen hole B in the base plate of the upper projector. (image 3-16)

Image 3-12

Stacking two projectors

Image 3-13

Closing the rigging sockets

R5976654 SLM R12+ 09022004 19

Page 24

3. Installation Guidelines

A

Image 3-14

Mounting the security chain

B

Image 3-15

Mounting the security hook

B

C

Image 3-16

Mounting the security hook (detail)

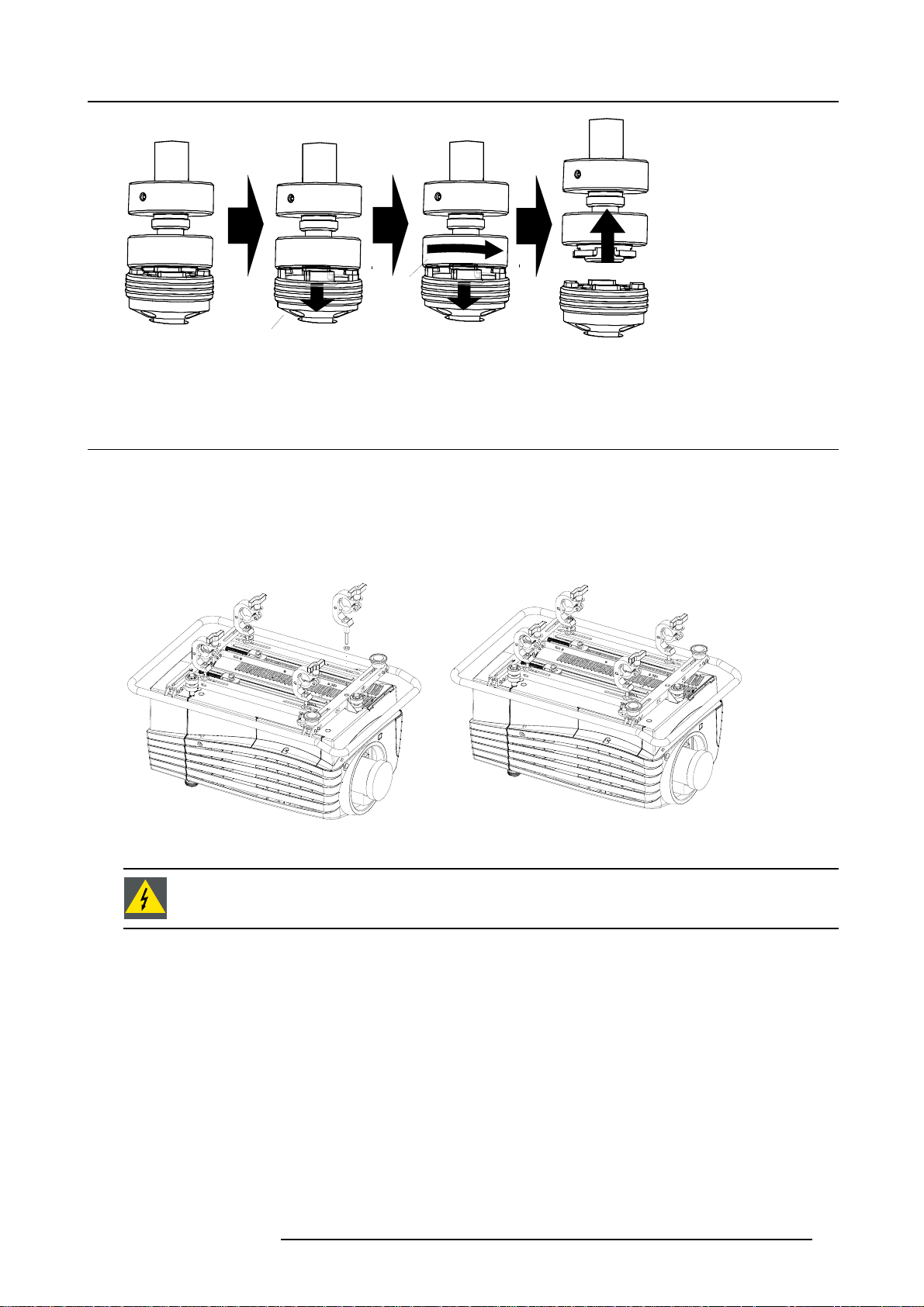

How to open a secured rigging point?

1. Push the ring (A) of the first projector downwards and hold it in that position. (image 3-17)

2. Turn the locked part (B) of the second projector a quarter counter clockwise and move it upwards.

20

R5976654 SLM R12+ 09022004

Page 25

3. Installation Guidelines

B

A

Image 3-17

Opening the rigging sockets

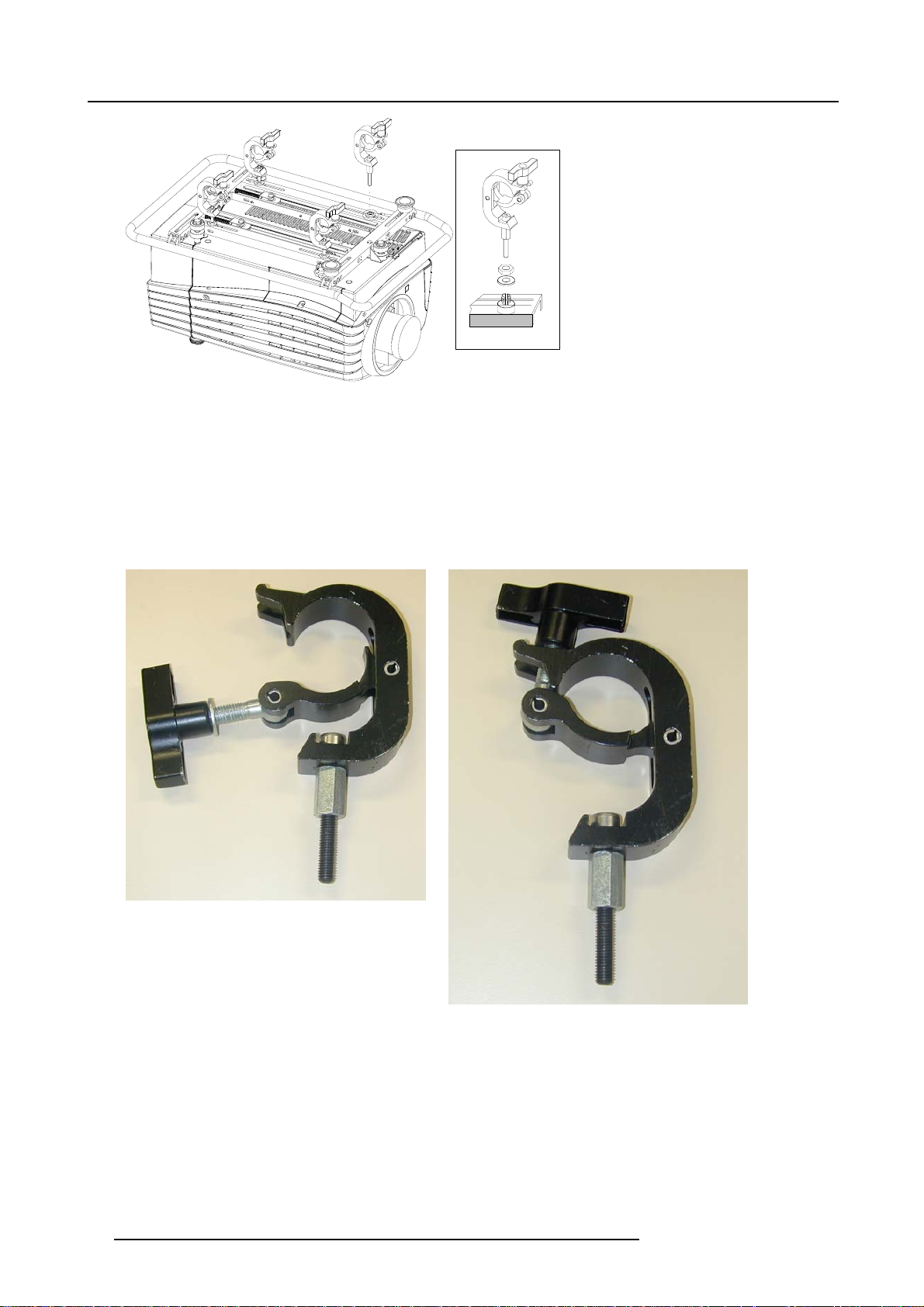

3.8 Rigging points and Accessories

Clamps

Slots are made in the carry handle frame for easy inserting the overlockers and for easy adjusting the clamps position so that this

position matches with the rigging points.

Consult a professional structural engineer prior to suspending the ceiling mount from a structure not intended for that use. Always

ensure the working load limit of the structure supporting the projector

.

Image 3-19

Image 3-18

Mounting the clamps

When mounting the projector to the ceiling or to a rigging system, always mount security chains.

Mounting the clamps

How to mount the clamps?

To fix the clamps to the U-profile, follow the next procedure :

1. Measure the distance, center tube as reference, between the two used support bars of a truss.

2. Slide the clamps holders (2 per profile) on its place in the U-profile according the measured distance and secure this position.

(image 3-20)

3. Turn the overlockers in the holes of the clamp holder.

The overlocker can turn around.

R5976654 SLM R12+ 09022004

21

Page 26

3. Installation Guidelines

Image 3-20

Mounting the clamp — detail

How to mount the Overlockers to the truss?

To mount the overlocker to the truss, handle as follow :

1. Open the fixation handle. (image 3-21)

2. Hook the clamp around the tube.

The trigger automatically shuts the clamp.

3. Close the fixation handle and secure it by turning the hand screw. (image 3-22)

Image 3-21

Opening the rigging clamp

Image 3-22

Closing the rigging clamp

22 R5976654 SLM R12+ 09022004

Page 27

4. Connections

4. CONNECTIONS

Overview

• Power connection

• Switching on

• Switching to standby

• Switching off

• Input Source Connections

• Communication Connections

4.1 Power connection

AC Power cord connection

Use the supplied power cord to connect your projector to the wall outlet. Plug the female power connector into the male connector

at the left of the projector. The power input is 230 VAC.

Fuses

The projector is protected with an automatic circuit breaker of 15A which is built in into the power switch.

4.2 Switching on

How to switch on.

1. Press the power switch to switch on the projector.

- When ’0’ is visible, the projector is switched off.

- When ’1’ is visible, the projector is switched on

The projector starts in standby mode. The projector indication lamp is red.

Starting image projection.

1. Press Stand by key once on the local keypad or on the remote control.

The projector mode indication lamp will be green (image 4-1)

Or,

Press a digit button to select an input source.

EXIT

ADJ

ENTER

FREEZTEXT

STBY

PAUSE

-

HELP

+

PHASE

?

-

+

0

SHARPNESS

9

-

+

7

TINT

8

-

+

6

5

COLOR

-

+

4

3

BRIGHTNESS

-

+

21

CONTRAST

32a

0

9

7

8

6

5

3

4

2

1

Image 4-1

Standby indication

STANDBY

TEXT

SHARPN

PHASE

ENTER

TINT

COLOR

A

EXIT

PAUSE

BRIGHTN

CONTRAST

R5976654 SLM R12+ 09022004 23

Page 28

4. Connections

Lamp run time indication while running

When the total run time of the lamp is 30 hours less then 500, the following warning message will be displayed for 1 minute. This

warning message will be repeated every 30 minutes. Press EXIT to remove the message before the minute is over.

Remaining

Lamp run time

20h

Image 4-2

When the total run time of the lamp is 500 hours or more, the following warning message, with the exact run time is displayed on

the screen.

WARNING

Lamp run time is x hours

operating the lamp longer

than x hours may damage

the projector.

Please replace the lamp

<ENTER> to continue

Menu 4-1

Lamp run time is 500 hours. Operating the lamp longer than 1000 hours may damage the projector. Please re

When ENTER is pressed to go on, the warning will be repeated every 30 min.

The total lifetime of the lamp for a safe operation is 500 hours max. Do not use it longer. Always replace with a same type of lamp.

Call a BARCO authorized service technician for lamp replacement.

place the lamp.

Using a lamp for more than 500 hours is dangerous as the lamp could explode.

Lamp Light Output Indication

When starting up and the center lumens measurement is lower than 50 % of its ini

displayed. Press ENTER to continue. The message will not be repeated during operation.

WARNING

Lamp run time is X hours

The light output of the lamp

than 50% of its initial value.

It is advisable to replace the

Menu 4-2

is less

lamp

before damage occurs.

<ENTER> to confirm

When the ’Constant Light Output’ (CLO) options is installed, the light output message will appear on the screen when the light output

is reduced with 33% from its initial value.

This message will be repeated every hour.

tial value, the lamp light output warning will be

Lamp Z-axis indication

When starting up and the run time is 100 hours or 250 hours a Z-axis warning will be displayed. This warning will advise to adjust the

Z-axis of the lamp to obtain maximum light output. Press ENTER to continue. The message will not be repeated during operation.

WARNING

Lamp run time is X hours.

It is advisable to

adjust the Z-axis

of the lamp to

obtain maximum

light output

(see owner’s manual)

<ENTER> to confirm

Menu 4-3

24 R5976654 SLM R12+ 09022004

Page 29

4.3 Switching to standby

Howtoswitchtostandby?

1. Press Standby to switch the projector to standby.

4.4 Switching off

How to switch off the projector?

1. Press first Standby.

2. Let cool down the projector until the fans stop blowing, at least 15 min.

3. Switch off the projector with the power switch.

4.5 Input Source Connections

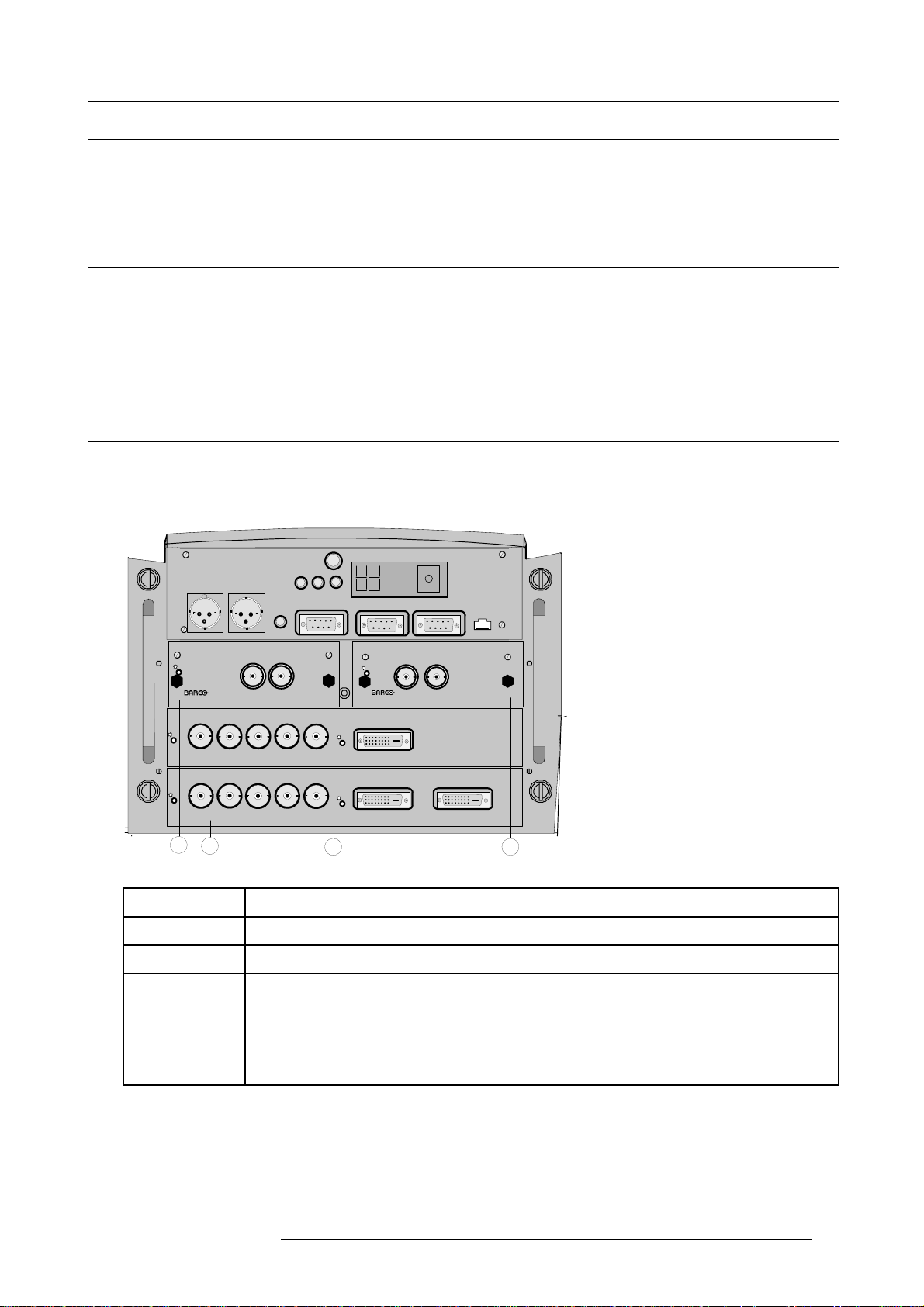

4.5.1 Input Facilities

Overview input facilities

4. Connections

IR-ReceiverDiagnostic Code

COMM PORT 10/(100)base-T

OUTIN

R9840450

HD SDI DIGITAL MODULE

DVI OUTPUT

4

On

On

3

Image 4-3

Input facilities

Input number

Green Operation

OUT IN

Red Stand-by

Hardwired

remote

CTRL 1

H/C V

H/C V

Two way

Hardwired

hardwired

remote

remote

CTRL 2

CTRL 3

On

SDI DIGITAL INPUT

GB

R

High Bandwidth 5 CABLE INPUT

GB

R

High Bandwidth 5 CABLE INPUT

1

Type of input

RS232/422 IN

IRSync OK

RS232/422 OUT

On

9840110

On

DVI INPUT

On

DVI INPUT

2

1 Fixed input, 5 cable input or DVI input and DVI output

2 Fixed input, 5 cable input or DVI input

3&4

Variable inputs

Two digital inputs available.

• SDI input (R9840110)

• HD SDI Digital input (R9840450)

Digital Video Decoder (R9841170)

4.5.2 Inputs via RCVDS05

Overview

When using a RCVDS05, the input configuration must be as follows:

R5976654 SLM R12+ 09022004

25

Page 30

4. Connections

slot 1

RGB/Component

slot 2 Video

slot 3 not used

slot 4 not used

When using a RCVDS05, it is recommended to use a 5-cable output module in the RCVDS. The outputs of this module has to be

connected to slot 1 of the projector. To switch the projector in the 5-cable mode see Fixed slot (slot 1 & 2), page 27.

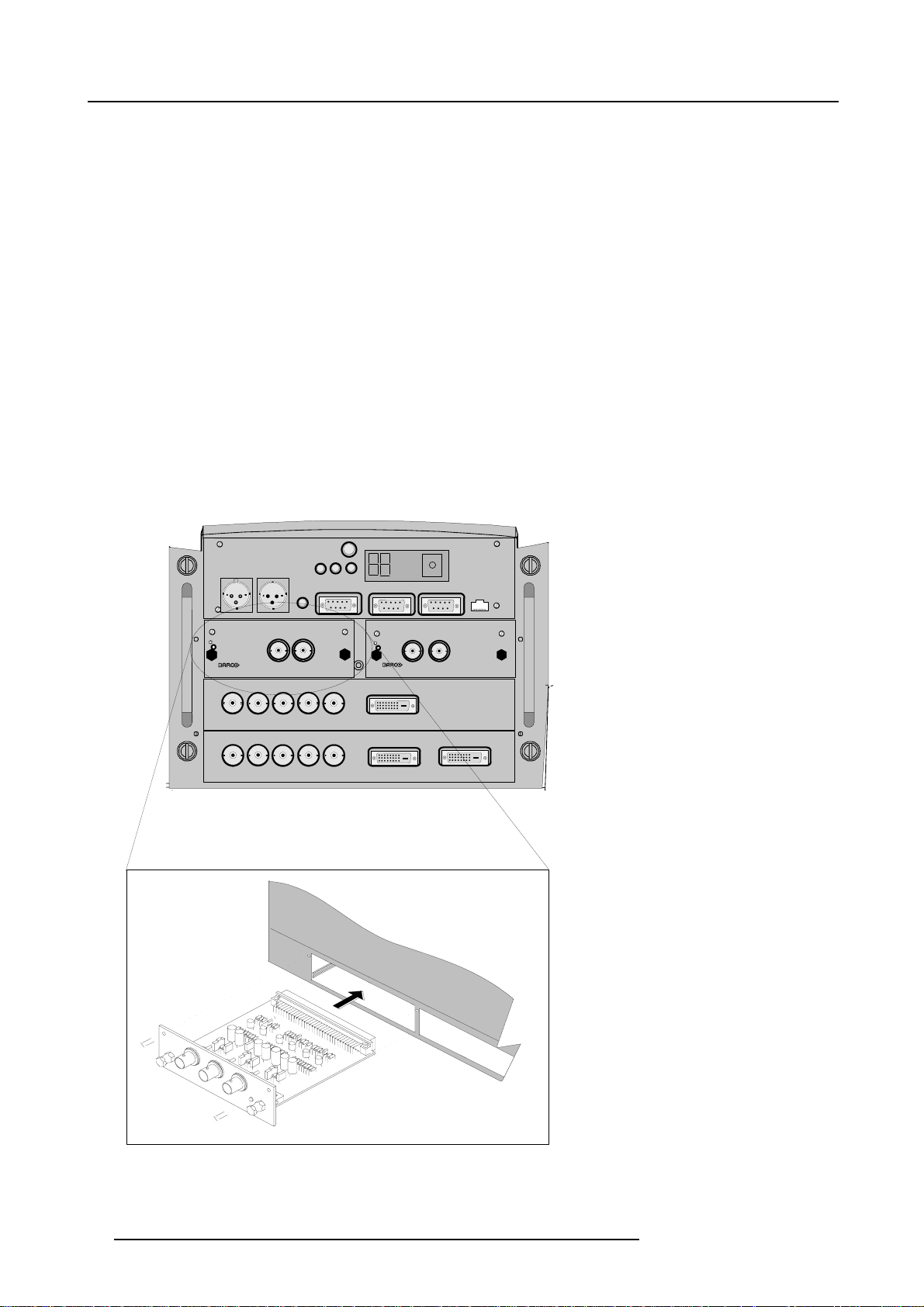

4.5.3 Input module insertion

How to insert an input module?

Toinsertamoduleinoneofthefreeslots,handleasfollow:

1. Power down the projector and disconnect the power cord from the wall outlet.

2. Remove the dummy plate covering the chosen input slot by turning out both screws.

3. Slide the input module in the free slot. Insure the module is seated correctly in the guide grooves.

4. Press on both handles of the input module until the module plug seats in the connector of the projector. (image 4-4)

RS232/422 OUT

ng screws.

IR-ReceiverDiagnostic Code

COMM PORT 10/(100)BASE-T

5. Secure the input module by tightening both retaini

6. Reconnect the power cord to the wall outlet and switch on the projector.

Green Operation

Hardwired

remote

CTRL 2

Hardwired

remote

CTRL 1

Red Stand-by

RS232/422 IN

IRSync OK

Two way

hardwired

remote

CTRL 3

On

R

High Bandwidth 5 CABLE INPUT

R

High Bandwidth 5 CABLE INPUT

OUT IN

SDI DIGITAL INPUT

GB

GB

H/C V

On

9840110

DVI INPUT

VH/C

DVI INPUT

OUTIN

R9840450

HD SDI DIGITAL MODULE

DVI OUTPUT

Image 4-4

26 R5976654 SLM R12+ 09022004

Page 31

4. Connections

How to select the new installed module?

The new installed module can be selected with the digit buttons on the RCU or the local keypad.

4.5.4 Fixed slot (slot 1 & 2)

Where to find?

Slot 1 & 2 has 5 BNC input terminals for 5 cable input and a DVI plug for DVI input. Slot 1 has also an DVI output for loop through

to a second projector. Within the installation mode it is possible to setup the input for 5 cable or DVI (PanelLink).

Which signals can be connected to slot 1 & 2?

Connector name/

Input signal

RGBHV

RGBS

RGsB

Composite Video

Super Video

Component Video — SS

Component Video — SOY

DVI signals can be connected to the DVI input connector.

Pin assignment for the DVI connector.

Pin 1

Pin 2

Pin 3

Pin 4

Pin 5

TMDS DATA2-

TMDS DATA2+

TMDS DATA2/4 Shield

TMDS DATA4-

TMDS DATA4+

R

R

R

R

-

-

R-Y Y B-Y

R-Y Ys B-Y

G

G

G

Gs

Video

Y

Pin 13

Pin14 +5Power

Pin 15

Pin 16 Hot Plug Detect

Pin 17

B H V

B H V

B

B

- - -

- -

TMDS DATA3+

Ground (for +5V)

TMDS DATA0-

S

- -

S

- -

-

C

-

Pin 6

Pin 7

Pin 8 No connect Pin 20

Pin 9

Pin 10

Pin 11

Pin 12

DDC Clock

DDC Data

TMDS DATA1-

TMDS DATA1+

TMDS DATA1/3 Shield

TMDS DATA3-

Pin 18

Pin 19

Pin 21

Pin 22

Pin 23

Pin 24

How to select input slot 1 or 2 ?

1. Key in 1 or 2 on the RCU or the local keypad.

How to change the input slot setting?

1. Press ADJUST or ENTER key to start up the Adjustment mode.

h the cursor key ↑ or ↓ to select Installation. (menu 4-4)

2. Pus

3. Press ENTER.

4. Press the cursor key ↑ or ↓ to select Input Slots. (menu 4-5)

TMDS DATA0+

TMDS DATA0/5 Shield

TMDS DATA5-

TMDS DATA5+

TMDS Clock Shield

TMDS Clock+

TMDS Clock-

R5976654 SLM R12+ 09022004

27

Page 32

4. Connections

5. Press ENTER.

The internal system will scan the inputs and displays the result in the Input Slots menu.

6. Push the cursor key ↑ or ↓ to select the first or second slot. (menu 4-6)

ADJUSTMENT MODE

Select a path from below :

RANDOM ACCESS

INSTALLATION

SERVICE

Select with ↑ or ↓

then <ENTER>

<EXIT> to return

Menu 4-4

Menu 4-5

INSTALLATION

INPUT SLOTS

800 PERIPHERAL

SOURCE SWITCHING

NO SIGNAL

CONTRAST ENHANCEMENT

CONVERGENCE

CONFIGURATION

LENS

QUICK ACCESS KEYS

OSD

INTERNAL PATTERNS

Select with ↑ or ↓

then <ENTER>

<EXIT> to return

INPUT SLOTS

Slot Module type [config]

1. RGB-SS [CV]

2. RGB-SOG

3. SDI

4. SDI

______________

1. DVI OUTPUT [DVI input]

Select with ↑ or ↓

then <ENTER>

<EXIT> to return

Menu 4-6

Possible indications on the input slot menu.

For the input side:

• RGS-SS [CV or HS&VS] = RGB analog signals, separate sync is composite sync or horizontal and vertical sync.

• RGB-SS [CV] = RGB analog signals, separate sync is composite video.

• RGB-SOG [SOG or 3LSOG] = RGB analog signals, sync on green is composite sync or composite tri-level sync.

• COMPONENT VIDEO - SS [SS or 3LSS] = separate sync is composite sync or composite tri-level sync.

• COMPONENT VIDEO - SOY [SOY or 3LSOY] = component video with composite sync on Y or composite tri-level s

•VIDEO

•S-VIDEO

•DVI

When changing from an analog signal on the 5 cable module to the PanelLink input the indication led on the front panel of the module

will switch from the 5 cable input to the DVI (PanelLink) input also.

For the output on fixed slot 1:

• DVI input : DVI in signal is looped through to the DVI out connector as it is.

• Active image : active image signal, what ever the input is, is available in DVI on the DVI output signal (processing is incorporated

in the signal). Set the minimum delay in Inst allation > Advanced processing to OFF.

• DVI resync : DVI in signal is resyncronized with a stable clock and put on the DVI out connector

ync on Y.

When using an RCVDS 05 with a 5 cable output module, connect these 5 cables to this fixed 5

-input slot (slot

1) of the projector. All sources of the RCVDS can now be accepted by the projector.

4.5.5 Serial Digital Input (slot 3 & 4)

What can be connected to this input?

This input is full compatibility with digital Betacam, or other digital video sources. This avoids the need for analog video processing

anywhere in the video production chain and guarantees the ultimate image quality.

An active loop-through of the SDI input signal is provided for monitoring or for double and or triple stacking applications.

How to connect ?

1. Connect the output of your SDI source to the input BNC of the SDI input. (image 4-5)

Note: The input is always 75 Ω terminated.

2. If loop through is needed, use the OUT to connect to the next device.

28

R5976654 SLM R12+ 09022004

Page 33

4. Connections

Image 4-5

Two way

Hardwired

hardwired

remote

remote

CTRL 2

CTRL 3

On

R

On

Hardwired

remote

CTRL 1

OUT IN

SDI DIGITAL INPUT

GB

H/C V

High Bandwidth 5 CABLE INPUT

R

GB

H/C V

High Bandwidth 5 CABLE INPUT

Digital

Video

DIGITAL VIDEO SOURCE

Green Operation

Red Stand-by

RS232/422 IN

IR-ReceiverDiagnostic Code

IRSync OK

RS232/422 OUT

On

9840110

On

COMM PORT TRIGGER OUT

OUTIN

R9840450

HD SDI DIGITAL MODULE

DVI INPUT

OnOn

DVI INPUT

DVI OUTPUT

How to select the digital input?

1. Key in the corresponding slot number on the RCU or the local keypad.

When a RCVDS05 is connected to the projector, the SDI input is available by keying in 83 or 84 on the RCU.

4.5.6 HD SDI Digital input (slot 3 & 4)

What can be connected to this input?

This input is full compatibility with HD digita

production chain and guarantees the ultimate image quality.

An active loop-through of the HD SDI input signal is provided for monitoring or for double and or triple stacking applications.

l sources. This avoids the need for analog video processing anywhere in the video

How to connect ?

1. Connect the output of your HD SDI source to the input BNC of the HD SDI input. (image 4-6)

Note: The input is always 75 Ω terminated.

2. If loop through is needed, use the OUT to connect to the next device.

R5976654 SLM R12+ 09022004

29

Page 34

4. Connections

Image 4-6

Two way

Hardwired

hardwired

remote

remote

CTRL 2

CTRL 3

On

R

On

Hardwired

remote

CTRL 1

OUT IN

SDI DIGITAL INPUT

GB

H/C V

High Bandwidth 5 CABLE INPUT

R

GB

H/C V

High Bandwidth 5 CABLE INPUT

Green Operation

Red Stand-by

IRSync OK

9840110

RS232/422 OUT

On

On

RS232/422 IN

DVI INPUT

OnOn

DVI INPUT

Digital

Video

DIGITAL VIDEO SOURCE

IR-ReceiverDiagnostic Code

TRIGGER OUT

COMM PORT

OUTIN

HD SDI DIGITAL MODULE

DVI OUTPUT

R9840450

How to select the digital input?

1. Key in the corresponding slot number on the RCU or the local keypad.

When a RCVDS05 is connected to the projector, the SDI input is available by keying in 83 or 84 on the RCU.

4.5.7 Digital Video Decoder Input

What can be connected to this input?

The following source types can be connected:

•S-Video

• Component Video

• Composite Video

Which signal can be connected to the Digital Video Decoder module?

Connector name/

Input signal

Component Video

Composite Video

S-Video

Pb

Y/Vid

B-Y Ys R-Y

-

Video

- - -

Pr

- -

S-Video

-

S-Video

How to connect?

1. Connect

30

the output of your source to the corresponding inputs on the Digital Video Decoder module. (image 4-7)

R5976654 SLM R12+ 09022004

Page 35

4. Connections

IR-ReceiverDiagnostic Code

COMM PORT

HD SDI DIGITAL MODULE

Ethernet

OUTIN

DVI OUTPUT

R9840450

Two way

Hardwired

hardwired

remote

remote

CTRL 2

CTRL 3

On

R

On

P

R

DIGITAL VIDEO DECODER

Hardwired

remote

CTRL 1

Y/Vid

GB

High Bandwidth 5 CABLE INPUT

GB

R

High Bandwidth 5 CABLE INPUT

1

2

Green Operation

Red Stand-by

S-Video

PB

H/C V

H/C V

RS232/422 IN

3

IRSync OK

RS232/422 OUT

On

On

DVI INPUT

OnOn

DVI INPUT

Image 4-7

1 Component video input

2 Composite Video input

3 S-Video input

How to select the digital video decoder input?

1. Key in the corresponding slot number on the RCU or the local keypad.

How to change the input slot setting?

1. Press ADJUST or ENTER key to start up the Adjustment mode.

2. Push the cursor key ↑ or ↓ to select Installation. (menu 4-7)

3. Press ENTER.

4. Press the cursor key ↑ or ↓ to select Input Slots. (menu 4-8)

5. Press ENTER.

The internal system will scan the inputs and displays the result in the Input Slots menu.

6. Push the cursor key ↑ or ↓ to select the third or fourth sl

7. Press ENTER to toggle.

Possible indications on the input slot menu.

- VIDEO[VDEO]

- VIDEO[S-VIDEO]

- VIDEO[YUV]

ot. (menu 4-9)

ADJUSTMENT MODE

Select a path from below :

RANDOM ACCESS

INSTALLATION

SERVICE

Select with ↑ or ↓

then <ENTER>

<EXIT> to return

Menu 4-7

Menu 4-8

INSTALLATION

INPUT SLOTS

800 PERIPHERAL

SOURCE SWITCHING

NO SIGNAL

CONTRAST ENHANCEMENT

CONVERGENCE

CONFIGURATION

LENS

QUICK ACCESS KEYS

OSD

INTERNAL PATTERNS

Select with ↑ or ↓

then <ENTER>

<EXIT> to return

INPUT SLOTS

Slot Module type [config]

1. RGB-SS [CV]

2. RGB-SOG

3. SDI

4. SDI

______________

1. DVI OUTPUT [DVI input]

Select with ↑ or ↓

then <ENTER>

<EXIT> to return

Menu 4-9

R5976654 SLM R12+ 09022004 31

Page 36

4. Connections

4.6 Communication Connections

Overview

• RS232 (RS422) Connection

• Communication with peripherals

• Network connection

4.6.1 RS232 (RS422) Connection

Application

1. Remote control :

- easy adjustment of projector via an IBM PC (or compatible) or MAC connection.

- allow storage of multiple projector configurations and set ups.

- wide range of control possibilities.

- address range from 0 to 255.

2. data communications : sending data to the projector or copying the data from the projector to a hard memory device (hard disc,

floppy, etc.).

Set up of the Baud Rate for communication with a computer.

see Baud rate Setting, page 97.

4.6.2 Communication with peripherals

What is possible with an RCVDS05 connected.

• Up to 20 inputs with the RCVDS 05 and 90 inputs when RCVDS’s are linked via the expansion module.

• Serial communication with the projector.

• Remote control buttons on the RCVDS to control the projector (source selection and analog settings).

• Theselectedsourcenumberwillbedisplayedona2digitdisplayandtheselectedinput modul

on the rear.

For more information about the use of the RCVDS05, consult the owner’s manual of the RCVDS05.

ewillbeindicatedwithaLED

What is possible with an VS05 connected.

The VS05 can switch up to 5 Composite Video sources, 3 Super Video sources and 1 RGB analog or component video source to

the projector. In addition, the audio signal proper to the source, can be switch

For more information about the use of the VS05, consult the VS05 owner’s manual.

ed to an audio amplifier. Order number : R9827890

Connecting an IR Remote Receiver to the projector.

This infrared receiver unit makes it possible to control the projector from another room. There is a communication line cable between

the IR receiver and the projector or the RCVDS. The control information from the RCU can now be sent to the IR Remote Receiver.

The IR Remote Receiver displays the selected source on a 7-segment display.

Connecting a Rugged Remote to the projector.

The Rugged Remote Control allows following functions:

• Remote mode : sends actions to and reads information from the projector.

• Lamp read mode : reads information stored in the lamp information module.

The following types of Rugged Remote Control are available:

• wireless (order number R9840171)

• wired to CTRL3 (order number R9840170)

For more information about the use of this remote control, consult the user manual R5976251.

4.6.3 Network connection

Only 10 Base-T connection

32 R5976654 SLM R12+ 09022004

Page 37

4. Connections

What can be done?

When the optional network connection is installed, the projector can be connected to a LAN (local area network) (Ethernet). Once

installed and connected to the LAN, users are capable of accessing the projector from any location, inside or outside their company

network from a standard web browser. The projector acts as web server and generates a web site with all functions of the projector

listed. Via an internet explorer 4.0 or higher, or a Netscape communicator, the user can insert the correct IP-address of the projector

and access the webpages. Once the web site is accessed, it is possible to check and manipulate all the projector settings. Remote

diagnostics, control and monitoring of the projector can then become a daily and very simple operation. The network connectivity

permits to detect potential errors and consequently improve the time to servicing.

Image 4-8

Two way

Hardwired

hardwired

remote

remote

CTRL 2

CTRL 3

On

R

On

Hardwired

remote

CTRL 1

OUT IN

SDI DIGITAL INPUT

GB

H/C V

High Bandwidth 5 CABLE INPUT

R

GB

H/C V

High Bandwidth 5 CABLE INPUT

Ethernet

connection

Green Operation

Red Stand-by

RS232/422 IN

IR-ReceiverDiagnostic Code

IRSync OK

RS232/422 OUT

On

9840110

On

COMM PORT TRIGGER OUT

OUTIN

R9840450

HD SDI DIGITAL MODULE

DVI INPUT

OnOn

DVI INPUT

DVI OUTPUT

Always use an Ethernet cable with ferrite core to connect the projector to the LAN.

R5976654 SLM R12+ 09022004 33

Page 38

4. Connections

34 R5976654 SLM R12+ 09022004

Page 39

5. Getting Started

5. GETTING STARTED

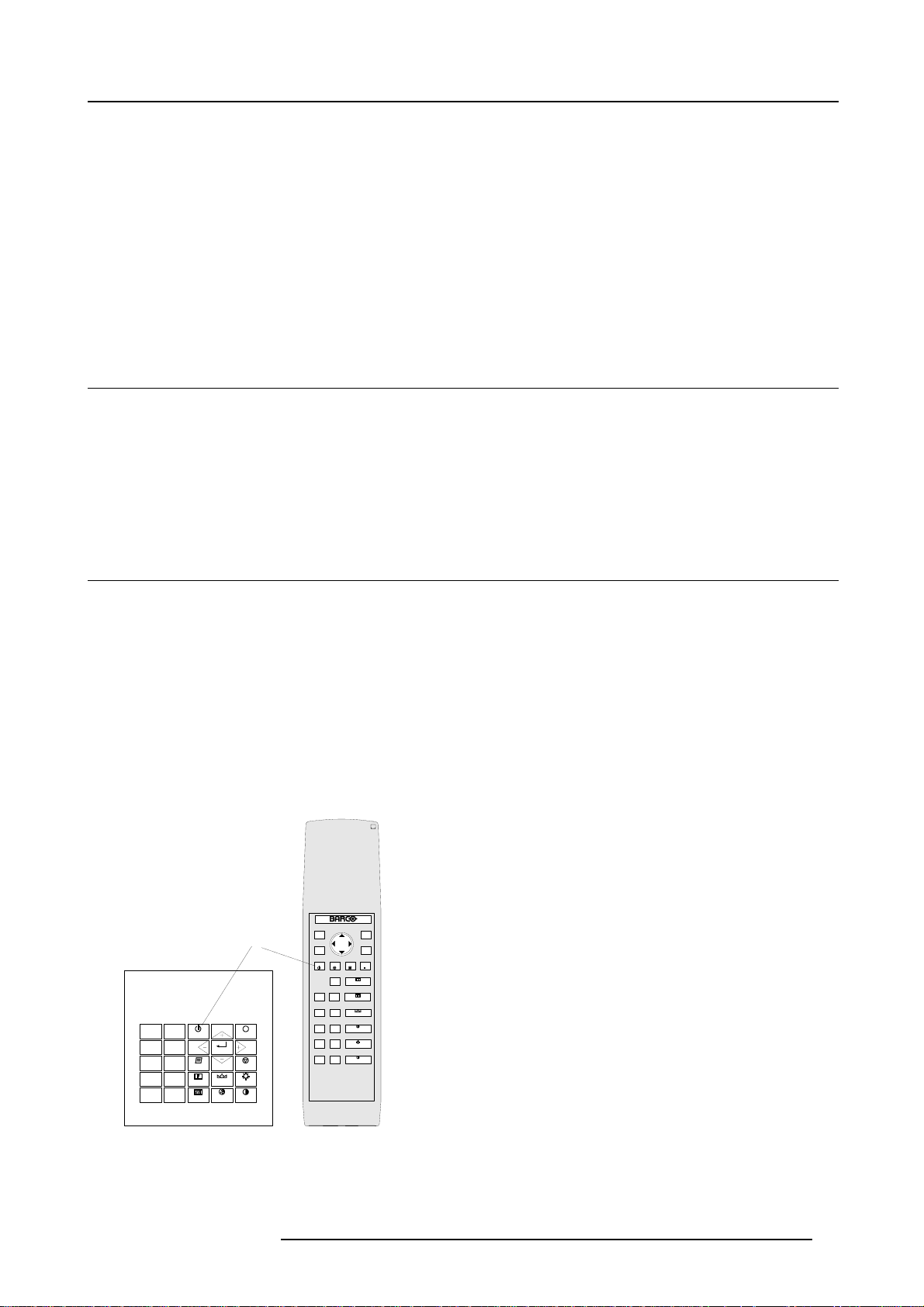

5.1 RCU & Local keypad

How controlling the projector ?

The projector can be controlled by the local keypad or by the remote control unit.

Location of the local keypad ?

The local keypad is located on the input side of the projector.

Remote control functions.

This remote control includes a battery powered infrared (IR) transmitter that allows the user to control the projector remotely. This

remote control is used for source selection, control, adaptation and set up. It includes automatic storing of picture controls (Brightness, Sharpness...) and settings.

Other functions of the remote control are :

• switching between stand by and operational mode.

• switching to "pause" (blanked picture, full power for immediate restarting)

• direct access to all connected sources.

5.2 Terminology overview

Overview

The following table gives an overview of the different functionalities o

4

14

0

9

7

5

3

1

STANDBY

8

6

TEXT

4

SHARPN

2

PHASE

ENTER

TINT

COLOR

EXIT

PAUSE

BRIGHTN

CONTRAST

13

12

5

10

8

9

f the keys.

15

1

TEXT

-

PHASE

-

SHARPNESS

-

TINT

-

COLOR

-

BRIGHTNESS

-

CONTRAST

EXIT

ENTER

FREEZ

2

ADJ

3

STBY

4

5

6

7

PAUSE

HELP

?

0

9

7

8

6

5

4

3

21

14

13

12

11

10

+

9

+

+

+

+

+

8

Image 5-1

Local keypad & RCU

7

32a

R5976654 SLM R12+ 09022004 35

Page 40

5. Getting Started

1 Barco key selection key, to get direct access to the lens adjustment menus.

2 ADJ

3 Address key

4

STDY

5

PAU SE to stop projection for a short time, press ’PAUSE’. The image disappears but full power

6 Help

7

Digit buttons direct input selection

8 Picture controls use these buttons to obtain the desired picture analog level.

9

PHASE used to remove the instability of the image.

10 TEXT

11 FREEZ

12 ENTER

13 EXIT to leave the adjustment mode or to scroll upwards when in the adjustment mode.

ADJUST key, to enter or exit the adjustment mode.

(recessed key), to enter the address of the projector (between 0 and 9). Press the

recessed address key with a pencil, followed by pressing one digit button between