Page 1

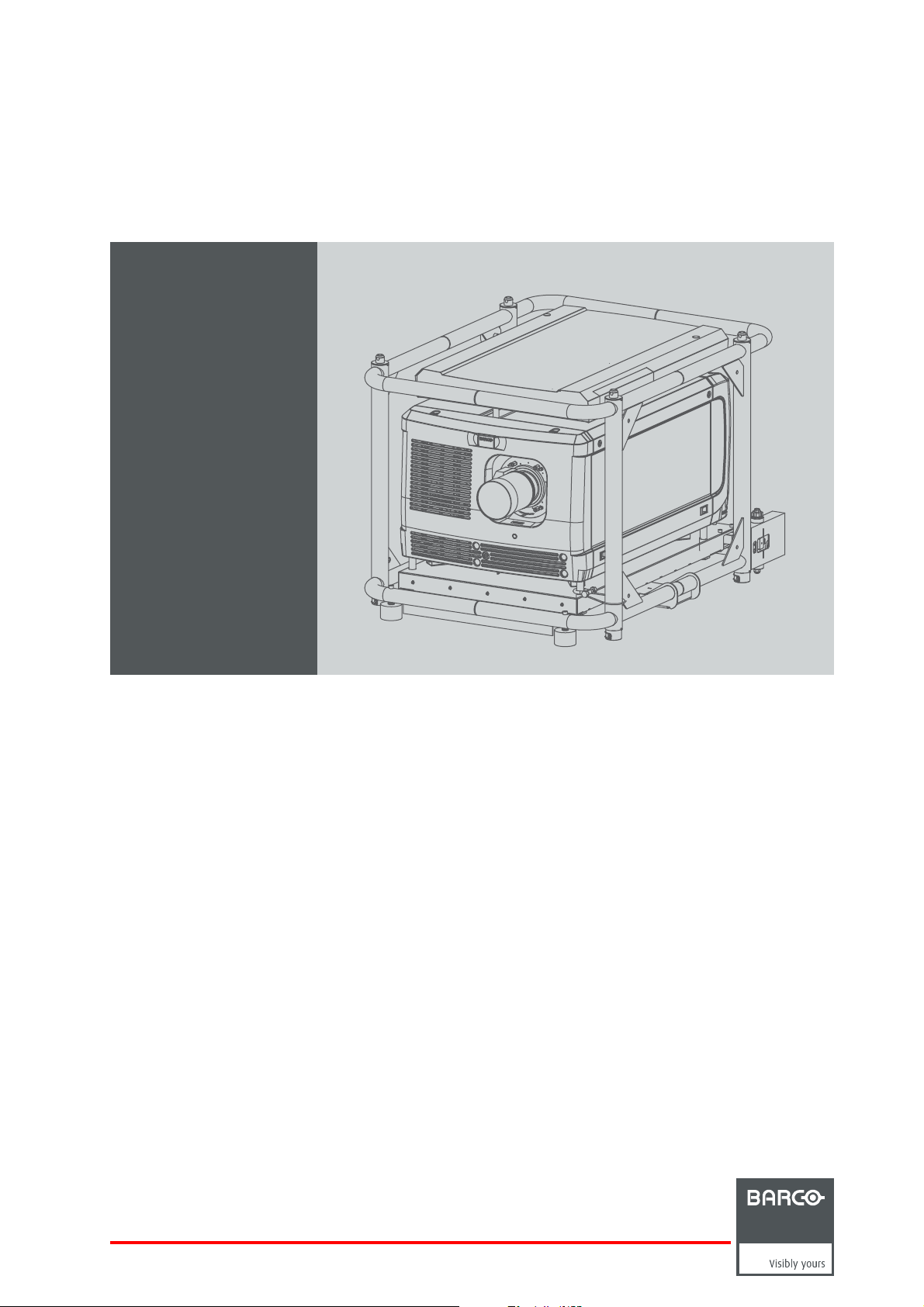

HDQ 4K35

User and Installation manual

R5905823/04

30/11/2015

Page 2

Barco NV

President Kennedypark 35, 8500 Kortrijk, Belgium

Phone: +32 56.36.82.11

Fax: +32 56.36.883.86

Support: www.barco.com/en/support

Visit us at the web: www.barco.com

Printed in Belgium

Page 3

Copyright ©

All rights reserved. No part of this document may be copied, reproduced or translated. It shall not otherwise be recorded, transmitted or

stored in a retrieval system without the prior written consent of Barco.

EN55022/CISPR22 Class A ITE (Information Technology Equipment)

Class A ITE is a category of all other ITE which satisfies the class A ITE limits but not the class B IT E limits. S uch equipm ent should not

be restricted in its sale but the following warning shall be included in the instructions for use:

Warning : This is a class A product. In a domestic environment this product may cause radio interference in which case the user may be

required to take adequate measures.

Federal Communications Commission (FCC Statement)

This equipment has been tested and found to comply with the limits for a class A digital device, pursuant to Part 15 of the FCC rules.

These limits are designed to provide reasonable protection against harmful interference when the equipment is operated in a commercial

environment. This equipment generates, uses, and can radiate radio f requency energy and , if not installed and used in a ccordance with

the instruction manual, may c ause harmful interference to radio communications. Oper ation of this equipment in a residential area may

cause harmful interference, in which case t he user will be responsible for correcting any interference at his own expense

Changes or modifications not expressly approved by the party responsible for c ompliance could void the user’s authority to operate the

equipment

Trademarks

Brand and product names mentioned in this manual may be trademarks, registered trademarks or copyrights of their respective holders.

All brand and product names mentioned in this manual serve as commen ts or examples and are not to be understood as advertising for

the products or their manufacturers.

Changes

Barco provides this manual ’as is’ without warranty of any kind, eit

ranties or merchantability and fitness for a particular purpose. Barco m ay make improvements and/or changes to the product(s) and/or the

program(s) described in this publication at any time without notice.

This publication could contain technical inaccuracies or typographical errors. Changes are periodically made to the information in this

publication; these changes are incorporated in new editions of this publication.

The latest edition of Barco manuals can be dow nloaded from the Barco web site w

h

ttps://www.barco.com/en/signin.

her expressed or implied, including but not limited to the implied war-

ww.barco.com or from the secured B arco web site

Guarantee and Compensation

Barco provides a guara ntee relating to perfect manufacturing as part of the legally stipulated terms of guarantee. On receipt, the purchaser

must immediately inspect a ll delivered goods for damage incurred during transport, as well as for material and manufacturing faults Barco

must be informed immediately in writing of any complaints.

The period of gu arantee begins on the date of transfer of risks, in the case of special systems and software on the date of commissioning,

at latest 30 days after the transfer of risks. I

at its own discretion w ithin an appropriate period. If this m easure proves to be impossible or uns ucce ssful, the purchaser can deman d a

reduction in the purchase pr ice or cancellation of the contract. All other claims, in particular th ose relating to compensation for direct or

indirect damage, and also damage attribut

of the system or independent service, will be deemed invalid provided the damage is not proven to be attributed to the absence of properties

guaranteed in writing or due to the intent or gross negligence or part of Barco.

If the purchaser or a third party carries out modifications or repairs o n goods delivered by Barco, or if the goods are handled incorrectly,

in particular if the systems are operated incorrectly or if, after the transfer of risks, the goods a re subject to influences not agreed upon in

the contract, all guarantee claims of the purchaser will be rendered invalid. Not included in the guarantee coverage are system failures

which are attributed to programs or s pecial electronic circuitry provided by the purchaser, e.g. interfaces. Normal wear as well as normal

maintenance are not subject to the guarantee provided by Barco either.

The environmental conditions as well as the servicing and maintenance regulations specified in this manual must be complied with by the

customer.

n the event of justified notice of complaint, Barco can repair the fault or provide a replacement

ed to the operation of software as well as to other services provided by Barco, being a component

Page 4

Page 5

Table of contents

TABLE OF CONTENTS

1. Safety................................................................................................................. 3

1.1 General considerations ............................................................................................................... 4

1.2 Important safety instructions ......................................................................................................... 5

2. General....... ................ ................ ................ ................ ................ ................ ........ 9

2.1 Installation requirements . . . ......................................................................................................... 10

2.2 Unpacking the projector ............................................................................................................. 11

2.3 Initial inspection......................................................................................................................14

2.4 Airinlets and outlets................................................................................................................. 15

2.5 Installation process overview........................................................................................................16

3. Physical installation ..............................................................................................17

3.1 Installation of the Lamp House ...................................................................................................... 18

3.2 Access to the power connection . . .................................................................................................. 19

3.3 Power input setup of the H DQ 4K35 ................................................................................................ 20

3.4 Connecting the projector with the power net ....................................................................................... 22

3.5 Connecting a UPS to the projector electronics . . ...................................................................................23

3.6 Landscape and portrait mode ....................................................................................................... 25

3.7 Stacking multiple projectors......................................................................................................... 27

3.8 Adjusting the multifunctional frame .................................................................................................30

3.9 Aligning the projected image on the screen ........................................................................................32

3.10 Aligning stacked projectors..........................................................................................................34

4. Lenses & Lens Holder ............... .................. ................ ................ ................ ...........37

4.1 Available lenses .....................................................................................................................38

4.2 Lens selection ....................................................................................................................... 40

4.3 Lens installation ..................................................................................................................... 41

4.4 Lens removal ........................................................................................................................ 43

4.5 Installing the lens fixation mechanism .............................................................................................. 44

4.6 Removing the lens fixation mechanism . .. . . ........................................................................................45

4.7 Lens shift, zoom & focus . .. .........................................................................................................46

4.8 Additional vertical shift of the Lens Holder. . ........................................................................................47

4.9 Scheimpflug adjustment............................................................................................................. 48

4.10 Fixation of the Lens Holder front plate ..............................................................................................52

5. Input and Communication .. ................ ................ ................ ................ .................. ...55

5.1 Introduction .......................................................................................................................... 56

5.2 Local keypad of the HDQ projector ................................................................................................57

5.3 Communication ports of the HDQ projector ........................................................................................58

5.4 Source input ports of the Barco HDQ 4K35 pr ojector . . . ...........................................................................60

5.5 ICMP status LEDs................................................................................................................... 63

5.6 ICMP reset...........................................................................................................................64

6. Starting up..........................................................................................................65

6.1 Switching ON the HDQ ..............................................................................................................67

6.2 Switching OFF the HDQ.............................................................................................................68

7. Maintenance....... ................ ................ ................ ................ ................ ................ .69

7.1 Cleaning the front dust fi lter......................................................................................................... 70

7.2 Cleaning the bottom dust filters .....................................................................................................71

7.3 Cleaning the lens . .. .................................................................................................................72

7.4 Cleaning the exterior of the projector ............................................................................................... 73

7.5 Checking cooling liquid level ........................................................................................................74

7.6 Topping up the cooling liquid reservoir..............................................................................................75

7.7 Removal of the Lamp House........................................................................................................77

7.8 Realignment of the lamp in its reflector.............................................................................................78

7.9 Authorization to clear security warning on the projector ...........................................................................79

8. Removal and installation of the projector covers .... ................ ................ ................ .......81

8.1 Removal of the lamp cover.......................................................................................................... 82

8.2 Installation of the lamp cover........................................................................................................ 83

8.3 Removal of the input cover. ......................................................................................................... 84

8.4 Installation of the input cover........................................................................................................85

8.5 Removal of the front cover .......................................................................................................... 86

8.6 Installation of the frontcover ........................................................................................................ 87

8.7 Removal of the back cover..........................................................................................................88

8.8 Installation of the back cover........................................................................................................ 89

8.9 Removal of the left cover............................................................................................................ 90

8.10 Installation of the left cover.......................................................................................................... 91

A. Dimensions and specifications ..................................................................................93

A.1 Dimensions of the Barco HDQ 4K35................................................................................................ 95

A.2 Specifications of the Barco HDQ 4K35 ............................................................................................. 96

R5905823 HDQ 4K35 30/11/2015

1

Page 6

Table of contents

A.3 Technical Regulations ...............................................................................................................98

B. Environmental information .. ................ .................. ................ ................ ................ ...99

B.1 Disposal information................................................................................................................100

B.2 RoHS compliance ..................................................................................................................101

B.3 Production address . ................................................................................................................102

B.4 Importers contact information ......................................................................................................103

Glossary ...... ................ ................ ................ .................. ................ ................ ....... 105

Index............. ................ ................ ................ ................ ................ .................. ..... 107

2 R5905823 HDQ 4K35 30/11/2015

Page 7

1. SAFETY

About this chapter

Read this chapter attentively. It co ntains important information to prevent personal injury while installing and us ing a Barco HDQ

4K35. Furthermore, it includes several cautions to prevent damage to the HDQ 4K35. Ensure that you understand and follow all

safety guidelines, safety instructions and war nings mentioned in this chapter before installing your HDQ 4K35. After this chapter,

additional “warnings” and “cautions” are given depending on the installation procedure. Read and follow these “warnings” and “cautions” as well.

1. Safety

R5905823 HDQ 4K35 30/11/2015

3

Page 8

1. Safety

1.1 General considerations

WARNING: E nsure you understand and follow a ll the safety guidelines, safety instructions, warnings and

cautions mentioned in this manual.

WARNING: Be aware of su spended loads.

WARNING: Wear a hard hat to reduce the risk of personal injury.

WARNING: Be careful while working with heavy loads.

WARNING: Mind your fingers while working with heavy loads.

CAUTION: High p ressure lamp may explode if improperly handled.

General safety instructions

• Before operating t his equipment please read this manual thoroughly and retain it for future reference.

• Installation and preliminary a djustments s hould be performed by qualified Barco personnel o r by authorized Barco service dealers.

• All warnings on the projector and in the documentation m anuals s hould be adhered to.

• All instructions for operating and use of this equipment must be followed precisely.

• All local installation codes should be adhered to.

Notice on safety

This equipment is built in accordance with the requirements of the international safety standards IEC60950-1, EN60950-1,

UL60950-1 and CAN/CSA C22.2 No.60950-1, w hich are the safety standards of information technology equipment including

electrical business equipmen t. These s afety standards

materials and insulation, in order to protect the user or operator against risk of electric shock and energy hazard and having access

to live parts. Safety standards also impose limits to the internal and external temperature rises, radiation levels, mechanical stability

and strength, enclosure construction and protecti

safety of the equipm ent to the user even when the equipment’s normal operation fails.

impose important requirements on the use of s afety critical components,

on against the risk of fire. Simulated single fault con dition testing ensures the

Users definition

Throughout this manual, the term SE RVICE P ERS ONNEL refers to persons having appropriate technical training and experience

necessary to be knowledgeable of potential hazards to which they are exposed (including, but not limited to HIGH VOLTAGE ELECTRIC and ELECTRONIC CIRCUITRY and HIGH BR IGHTNESS PROJECTORS) in performing a task, and of measures to minimize

the potential risk to them selves or other persons. The term USER and OPERATOR refers to any person other than SERVICE PERSONNEL, AUTHORIZED to ope rate professional projection systems.

A Barco H DQ 4K35 is intended "FOR PROFESSIONAL USE ONLY" by AUTH O RIZE D PERSONNEL familiar with potential hazards

associated with high voltage, high intensity light beams, ultraviolet exposure and high temperatures generated by the lamp and

associated c ircuits. Only qualified SERVICE PERSONNEL, knowledgeable of such risks, are allowed to perform service functions

inside the product enclosure.

4

R5905823 HDQ 4K35 30/11/2015

Page 9

1.2 Important safety instructions

To prevent the risk of electrical shock

• This projector should be operated from an AC power source. Ensure that the mains voltage and capacity matches the projector

electrical ratings.

• Installation according to the local electrical code and regulations by qualified technical personnel only.

• This product is e quipped with a five-terminal barrier s trip for the connection of a 3W +N+P E or 3W+PE three phase power

system. If you are unable t o install the AC Requirements, contact your electrician. Do not defeat the purpose of the grounding.

• The cross-sectional area of the conductors in the power supply cord shall not be less than 4 mm

The cross-sectional area of the UPS inlet cord and external fan power cord shall be not less than 0.75 mm² or AWG 18.

• The electronics of the projector (UPS INLET) must be powered either from a suitable UPS unit or from the po wer outlet socket

(UPS OUTLET) provided on the projector. An adapted short power cord (2-pole 3-wire grounding) is added to the projector

accessories to loop through the power from UPS OUTLET to UPS INLET.

• The provided power output soc ket (UPS OUTLET) on the projector may only be used to provide power to the projector electronics. Never connect other devices to this power output socket.

• The building installation has to be provided with a circuit breaker of max. 40A to protect the comp lete unit.

• A readily accessible disconnect device must be incorporated externally to the equipmen t for rem oval o f the power to the projector mains terminals.

• Disconnect the power to the projector mains terminals and unplug the power cord at UPS INLET for removal of all power from

the projector.

• Warning: High leakage current. Earth connection essential before connecting supply.

• Do not allow anything to rest on the power cord. Do not locate this projector where persons will walk on the cord.

• Do not operate the projector with a damaged cord or if the projector has been dropped or damaged - until it has been examined

and approved for operation by a qualified service technician.

• Position the cord so that it will not be tripped over, pulled, or contact hot surfaces.

• If an extension cord is necessary, a cord with a current rating at least equal to that of the projector should be used. A cord rated

for less amperage than the projector may overheat.

• Never push objects of any kind into this pr ojector through cabinet slots as they m ay touch dangerous voltage points or short

circuit parts that could result in a risk of fire or electrical shock.

• Do not expose this projector to rain or moisture.

• Do not immerse or expose this projector in water or other liquids.

• Do not spill liquid of any kind on this projector.

• Should any liquid or solid object fall into the cabinet, unplug the set and have it chec ked by qualified service personnel before

resuming operations.

• Do not disassemble this projector, always take it to a trained service person w hen service or repair work is required.

• Do not use an accessory attachment which is not recommended by the manufacturer.

• Lightning - For added protection for this video product during a lightning

long periods of time, remove all powe r from the projector. This will prevent damage to the projector due to lightning and AC

power-line surges.

storm, or when it is left unattended and unused for

2

or AWG 10.

1. Safety

R5905823 HDQ 4K35 30/11/2015

5

Page 10

1. Safety

To prevent personal injury

• Isolate electrically before replacing the lamp or lamp house. Caution: Hot lamp (house).

• Caution: High pressure lam p may explode if improperly handled. Refer se rvicing to qualified service personnel.

• To pre vent injury a nd physical damage, always read this manual and all labels on the system before inserting the lamp casing,

powering the projector or adjusting the projector.

• It is forbidden to lift up the projector with manpower, use a hois ting tool instead. Do not underestimate the weight of the projector.

The projector weights ±210 kg (±462 lb.).

• To prevent injury, ensure that the lens, exhausting system and all cover plates are correctly installed. See installation instructions.

• Ensure safe fi xation of the projector lens. The lens fixation mechanism must be installed. See installation instructions.

• Warning: high intensity light beam. NEVER look into the lens ! High luminance c ould result in damage to the eye.

• Warning: extremely high brightness lam ps: T his projector uses extremely high brightness lamps. Never attempt to look

directly into the lens or at the lamp. If the projection distance is less than 6 meter, any person needs to be at least 4 meters

away from the projected image. Avoid close ran ge reflection of the projected image on any reflecting surface (such as glass,

metal, …) . When operating the projector, we strongly recommend wearing suitable sa fety glasses.

• Before attempting to remove any of the pr ojector’s covers, disconnect the power to the projector mains terminals and unplug

the power cord at UPS INLET for removal of all power from the projector.

• The projector m ay not be powered when the exhaust box on top of the projector is removed. Before attempting to remove the

exhaust box, disconnect the power to the projector m ains terminals and unplug the power cord at UPS INLET for removal of all

power from the projector.

• When r equired to remove all power from the projector, to access parts inside, always disconnect the power to the projector

mains terminals and unplug the power cord at UPS INLET.

• Do not place this equipmen t on an unstable cart, stand, or table. The product may fall, causing serious damage to it and

possible injury to the user.

• Never stack more than three (3) HDQ projectors in a standing configuration (table mount) and never stack more than two ( 2)

HDQ projectors in a hanging confi guration (ceiling mount).

• When u sing the projector in a hanging configuration (ceiling mount), always mount 2 safety cables on the projector frame. See

installation instructions for the correct use of these cables.

• Always check the safety cables for visible damage before operating the projector. If the safety cables are damaged, they must

be replaced with new ones.

• It is hazardous to operate without lens or shield. Lenses, shields or ultra violet screens shall be changed if they have become

visibly damaged to such an extent that their effectiveness is impaired. For example by cracks or deep s cratches.

• Warning: Protection from ultraviolet radiation: D o not look directly in the light beam. The lamp contained in this product is

an intense source of light and heat. One component of the light emitted from this lamp is ultraviolet light. Potential eye and s kin

hazards are present when the lamp is energized due to ultraviolet radiation. Avoid unnecessary exposure. P rotect y ourself and

your employees by ma king them aware of the hazards and how to protect themselves. Protecting the skin can be accomplished

by wearing tightly wov en garments and glov es. Protecting the eyes from UV can be accomplished by wearing safety glasses

that are designed to provide UV protection. In addition to the UV, the visible light from the lamp is intense and should also be

considered when choosing protective eye wear.

• Exposure to U V radiation: Some medications are known to m ake individuals extra sens itive to UV radiation. The American

Conference of Gov ernmental Industrial Hygienists (ACG

less than 0,1 micro-watts per square centimeters of effective UV radiation. An evaluation of the workplace is advised to assure

employees are not exposed to cumulative radiation levels exceeding these government guidelines.

• Cooling liquid circuit. The projector contains a cooling circuit filled with Blue antifreeze diluted (1/3 ethanediol – 2/3 Demi

water).

When the cooling circuit leaks, switch off the device and contact a service technician.

The liquid is not for household use. Keep out of reach of children. Harmful by oral intake. Avoid exposure to pregnant women.

Avoid contact with eyes , sk in and clothing. Avoid inhale of the noxious fumes.

IH) recommends o ccupational UV exposure for an-8 hour day to be

WARNING: E xposu re to hazardous m ovin g parts when the exhaust box is removed. Always disconnect the

power to the projector mains terminals and unplug the power cord at the UP S INLET for removal of all power

from the projector before removing the exhaust box.

WARNING: Exposure to high luminance and UV

nect the power to the projector mains terminals and unplug the power cord at the UPS INLET for removal of

all p ow er from the projector before removing the exhaust box.

radiation when the exhaust box is removed. Always discon-

WARNING: The complete exhaust box is very hot w h en the projector is on. To avoid burns, let the projector

cool down for at least 15 minutes before touching the exhaust box.

6 R5905823 HDQ 4K35 30/11/2015

Page 11

1. Safety

To prevent fire hazard

• Do not place flamma ble or combustible materials near the projector!

• Barco large screen projection products are designed and manufactured to meet the most stringent safety regulations. This

projector radiates heat on its external surfaces and from v entilation ducts during normal operation, which is both normal and

safe. E xpo sing flammable or combustible materials into close proximity of this projector c ould result in the spontaneous ignition

of that material, resulting in a fire. For this reason, it is absolutely necessary to leave an “exclusion zone” around all external

surfaces of the projector whereby no flammable or combustible materials are present. Th e ex clusion zone must be not less than

40 cm (16”) for all DLP projectors. The exclusion zone on the lens side must be at least 5 m. Do not c ove

r the projector or the

lens with any material while the projector is in operation. Keep flammable and combustible materials away from the projector at

all times. Mount the projector in a well ventilated area away from source s of ignition and out of direct sun light. Never expose

the projector to rain or moisture. In the event of fire, use sand, CO

electrical fire. Always have service per formed on this projector by authorized Barco service personnel. Alway s insist on genuine

or dry powder fire extingu

2

ishers. Never use wate r on an

Barco replacement parts. Never use non-Barco replacement parts as they may degrade the safety of this projector.

• Slots and openings in this equipm ent are provided for ventilation. To ensure reliable operation of the projector and to protect

it from overheating, these openings must not be blocked or covered. The openings should never be blocked by placing the

projector too close to walls, or other similar surface. This projector s hould never be placed near or over a radiator or heat

register. This p rojector should not be placed in a built-in installation or enclosure unless proper ventilation is provided.

• Projection rooms must be well ventilated or cooled in order to avoid build up of heat.

• Let the projector cool completely before storing. Remove cord from the projector when storing.

• Heat sensitive materials should not be placed in the path of the exhausted air or on the lam

p hous e.

• When the projector is used in portrait mode, the air outlet is positioned towards the floor. That’s why the floor covering can

become very hot and must be resistant to a temperature of 90 °C (194 °F).

To prevent projector damage

• This projector has been designed for use with a specific lamp (house) type. See installation instructions for its correct type.

•Theairfilters of the projector must be cleaned or replaced on a regular basis (a "clean" booth would be monthly-minimu m).

Neglecting this could result in disrupting the air flow inside th

projector shutting down during operation.

• The projector must a lways be installed in a manner which ens ures free flow of air into its air inlets and unimpeded evacuation

of the hot air from its cooling system.

• In order to ensure that correct airfl ow is maintained, and that the projector complies with Electromagnetic Compatibility (E MC)

and safety requirements, it should always be operated with all of it’s covers in place.

• Slots and openings in the cabinet are provided for ventilation. To ensure reliable operation of the product and to protect it from

overheating, these openings must not be blocked or covered. The openings should never be blocked by placing the product

on a bed, sofa, rug, or other similar surface. This product should never be placed near or over a radiator or heat register. The

device should not be placed in a built-in installation or enclosure unless proper ventilation is provided.

• Ensure that nothing can be spilled on, or dropped inside the projector. If this does happen, switch off and remove all power

from the projector. Do not operate the projector again until it has been checked by qualified s ervice personnel.

• Do not block the projector cooling fans or free air movement aroun d the projector. Lo ose papers or other objects may not be

nearer to the projector than 10 cm (4") on any side.

• Do not use this equipment near water.

• Proper operation of the cooling circuit c an only be guaranteed in the allowed projector positions. It is not allowed to use the

projector in another position. See installation instructions for correct installation.

• Special care for Laser Beams: Special care should be used when DLP projectors are us ed in the same room as high power

laser equipment. D irect or indirect hitting of a

laser beam on to the lens can severely damage the D igital Mirror Devices

which case there is a loss of warranty.

• Never place the projector in direct sun light. Sun light on the lens can severely damage the Digital Mirror Devices

case there is a loss of warranty.

• Save the original shipping carton and packing material. They will c ome in handy if you ever have to ship y our equipment. For

maximum protection, repack your set as it was originally packed at the factory.

• Disconnect the power to the projector mains terminals and unplug the power cord at UPS INLET before cleaning. Do not use

liquid cleaners or aerosol cleaners. Use a d amp cloth for cleaning. Nev er use strong solvents, such as thinner or benzine, or

abrasive cleaners, since these will damage the cabinet. Stubborn stains may be removed with a cloth lightly dampened with

mild detergent solution.

• To ensure the highes t optical performance and resolution, the projection lenses are specially treated with an anti-reflective

coating, therefore, avoid touching the lens. To remove dust on the lens, use a soft dry c loth. Do not use a damp cloth, detergent

solution, or thinner.

• Rated maximum ambient temperature, t

=35°C(95°F).

a

• The lamp house shall be replaced if it has become damaged or thermally deformed.

e projector, causing ov erheating. Overheating may lead to the

TM

TM

in which

in

R5905823 HDQ 4K35 30/11/2015

7

Page 12

1. Safety

On servicing

• Do not attempt to service this product yourself, as opening or rem oving covers may expose you to dangerous voltage potentials

and risk of electric shock.

• Refer all servicing to qualified service personnel.

• Attempts to alter the factory-set internal controls or to change other control settings not specially discussed in this manual can

lead to permanent damage to the projector and cancellation of the warranty.

• Remove all po wer from the projector and refer servicing to qualified service technicians under the following conditions:

- When the power cord or plug is da maged or frayed.

- If liquid has been spilled into the equipment.

- If the product has been exposed to rain or water.

- If the p roduct does not operate normally wh en the operating instructions are followed. Adjust only those controls that are

covered by the operating instructions since improper adjustment of the other controls may result in damage and will often

require extensive work by a qualified technician to restore the product to normal operation.

- If the product has been dropped or the cabinet has been damaged.

- If the product exhibits a distinct change in performance, indicating a need for service.

• Replacement pa rts: When replacement parts are required, be sure the s ervice technician has used original B arco replacement

parts or authorized replacement parts whic h have the same characteristics as the Barco original part. Unauthorized substitutions m ay result in degraded performance and reliability, fire, electric shock or other h azards. Unauthorized substitutions may

void warranty.

• Safety check: Upon completion of any service or repairs to this projector, ask the service technician to perform safety checks

to determine that the product is in proper operating condition.

• Possible explosion hazard: A lways keep in mind the caution below:

CAUTION: Xeno n co mp act arc lamps are highly pressurized. When ignited, the normal operating temperature

of the bulb increases the pressure to a level at which the bulb may explode if not handled in strict accordance

to the manufacturer’s instructions. The bulb is stable at room temperature, but may still explode if dropped or

otherwise mishandled. Whenever the lamp house, containing a xenon lamp, has to be dismantled or whenever

the protective container or cloth has to be removed from the xenon lamp, authorized protective clothing M U ST

be wo r n!

Authorized protective clothing for xenon lamp handling

WARNING: Always we ar face protection (full face shield) wh en handling xenon lamps.

WARNING: Always wear protective clothing (welder’s jacket) when handling xenon lamps.

WARNING: Always wear clean leather gloves with wrist protectors when handling xenon lamps.

To prevent battery explosion

• Danger of explosion if battery is incorrectly installed.

• Replace only with the same or equivalent type recommended by the manufacturer.

• For disposal of used batteries, always consult federal, state, local and provincial hazardous waste disposal r ules and regulations

to ensure proper disposal.

8

R5905823 HDQ 4K35 30/11/2015

Page 13

2. GENERAL

About this chapter

Read this chapter before ins talling your Barco HDQ 4K35. It contains important information concerning installation requirements for

the HDQ 4K 35, such as minimum and maximum allowed ambient temperature, humidity conditions, required safety area around the

installed projector, required power net, etc.

Furthermore, careful consideration of things such as image size, ambient light level, projector placement and type of screen to use

are critical to the optimum use of the projection system.

Barco provides a guarantee relating to perfect manufacturing as part of the legally stipulated terms of guarantee. Observing the s pecifi cation mentioned in this chapter is critical for projector performance. Neglecting

this can result in loss of warranty.

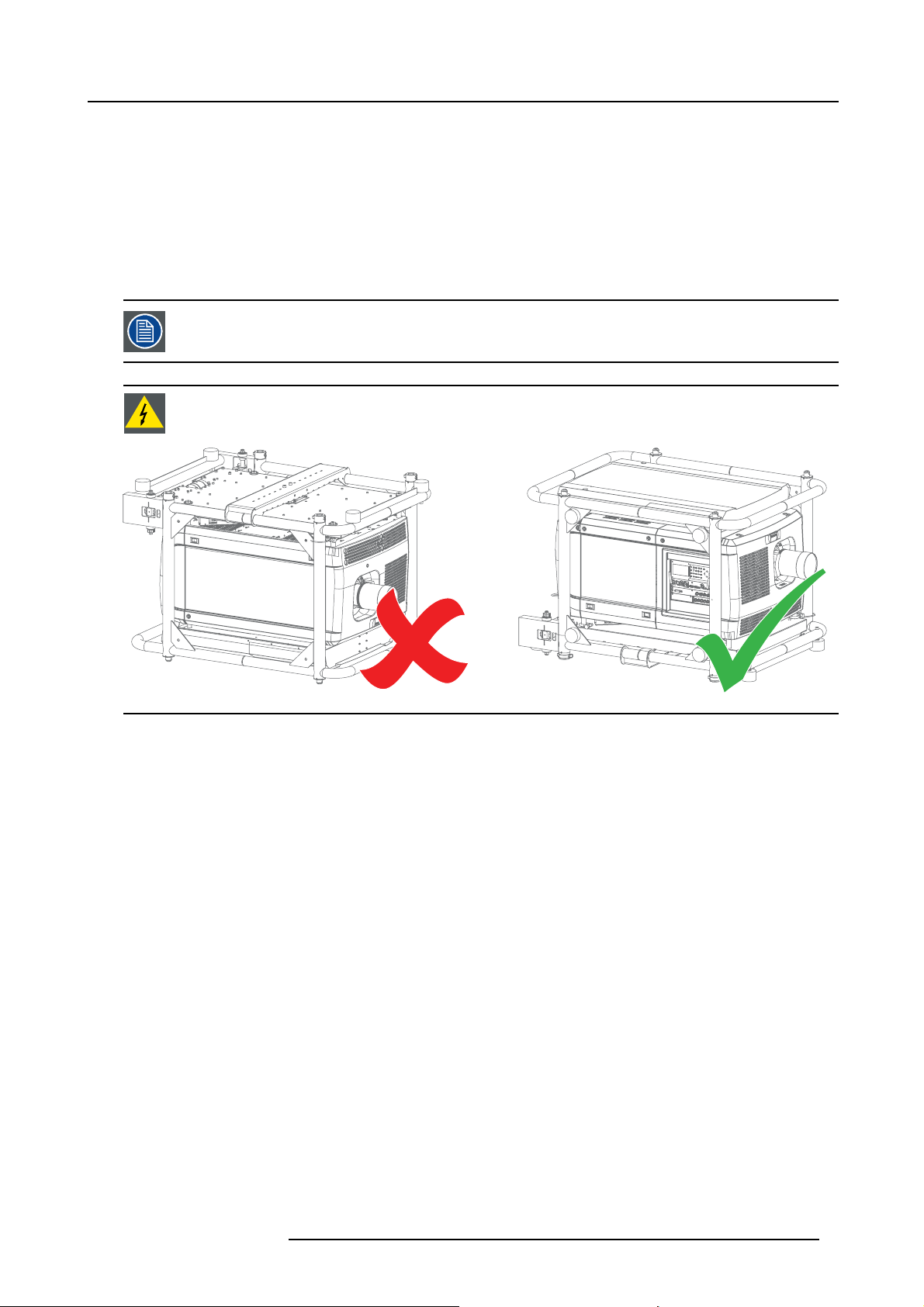

WARNING: Never transport the HDQ projector in an u pside down p osition. Failure to do so can cause damage

to t he frame. This can cause the frame to break and the projector to fall dow n .

2. General

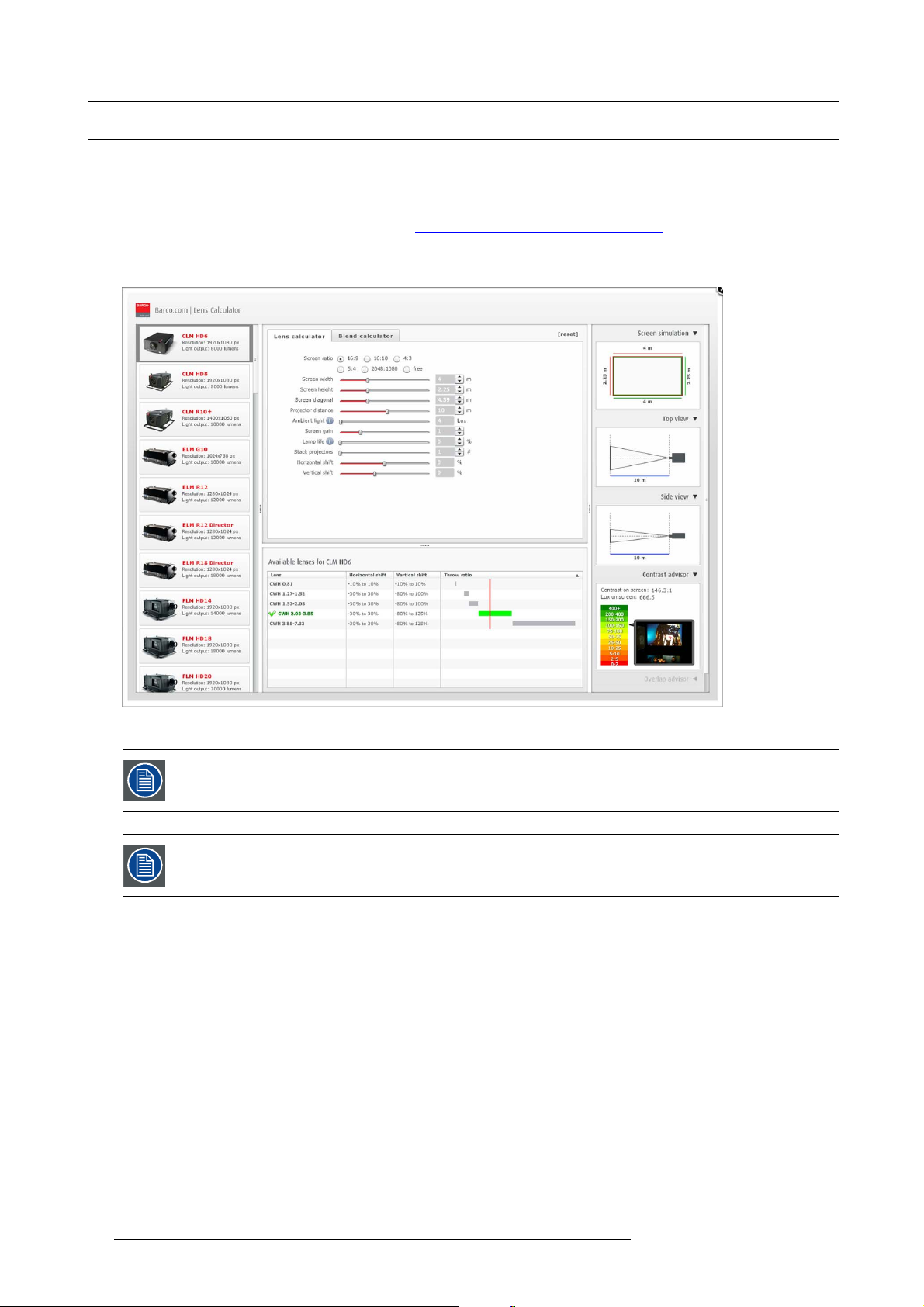

Image 2-1

Overview

• Installation requirements

• Unpacking the projector

• Initial inspection

• Air inlets and outlets

• Installation process overview

R5905823 HDQ 4K35 30/11/2015

9

Page 14

2. General

2.1 Installation requirements

Environment conditions

Table below summ arizes the physical environment in which the HDQ may be safely ope rated or stored.

Environment Operating Non-Operating

Ambient Temperature 10 °C (50 °F) to 35 °C (95 °F) -15°C (5°F) to 60°C (140°F)

Humidity 5% to 85% R H Non-condensed 5% to 95% RH Non -Condensed

Altitude -60 (-197Ft) to 3000m (9843Ft) -60 (-197Ft) to 10000m (32810Ft)

Let the projector acclimatise after unpacking. Neglecting this may result in a startup failure of the

cessor Unit.

Light Pro-

Cooling requirements

The projector is fan cooled and must be installed with sufficient space around the projector he ad, minimum 20 cm (8”) to ensure

sufficient air flow. It should be us ed in an area where the ambient temperature, as measured at the projector air inlet , does not

exceed +35°C (+95°F).

For an ov erview of all air inlets and outlets of the projector, see "Air inlets and outlets", page 15.

Clean air environment

A projector mus t always be m ounted in a mann er which ensures the free flow of clean air into the projectors ventilation inlets. For

installations in environments where the projector is subject to airborne contaminants such as that produced by smoke machines or

similar (these deposit a thin layer of greasy residue upon the projectors internal optics and imaging electronic surfaces, degrading

performance), then it is highly advisable and desirable to have this contamination removed prior to it reaching the projectors clean

air supply. Devices or structures to extract or shield c ontaminated air well away from the projector are a prerequisite, if this is not a

feasible solution then measures to relocate the projector to a clean air environment should be considered.

Only ever use the manufacturer’s recommended cleaning kit which has been specifically designed for cleaning optical p arts, never

use industrial strength cleaners on the projector ’s optics as these will degrade optical coatings and damage sensitive optoelectronics

components. Failure to take suitable pr ecautions to protect the projector from the effects of persistent and prolonged air contaminants will culminate in extensive and irreversible ingrained optical damage. At this stage cleaning of the internal optical units will

be noneffective and impracticable. Damage of this nature is under no circumstances covered under the manufacturer’s warranty

and may deem the warranty null and void. In such a case the client shall be held solely responsible for all costs incurred during any

repair. It is the clients r espons ibility to ensure at all times that the projector is protected from the harmful effects of hostile airborne

particles in the environment of the projector. The manufacturer reserves the right to refuse repair if a projector has be en subject to

knowingly neglect, abandon or improper use.

Main Power requirements

The HD Q 4K35 operates from a nom inal 230/4

switched internally between a star connection to a delta connection or vice versa. See "P ower input setup of the HDQ 4K35", page

20.

For a 3W+N+PE system, 400V is measured between the lines, 230V is measured between the lines and the neutral.

For a 3W+PE system, 208V is measured between the lines.

The powe r cord required to connect the projector with the power net is not delivered with the projector. It is the responsibility of the

customer to provide the correct type of power cord.

The cross-sectional area of the conductors in the power supply cord shall not be less than 4 mm

The power cord must be rated for minimum 300V in case of a 3W+PE (208V) power system, and minimum 500V in case of a

3W+N+PE (230/400V) power system.

To protect operating personnel, the National Electrical Manufacturers Association (NEMA) recommends that the instrument panel

and cabinet be grounded. In no event shall this projector be operated without an adequate cabinet ground connection.

The AC supply must be installed by a qualified electrician in conformance to local codes. Hardware, wire sizes and conduit types

must comply with local codes.

A readily accessible disconnect device shall be incorporated externally to the equipment for removal of the power to the equipment

mains terminals.

The building installation must be provided with a circuit break er of max. 40A to protect the complete unit.

00V 3W +N+PE 16A 50-60Hz or 208V 3W+PE 27A 50-60Hz. The projector must be

2

or AWG 10.

10 R5905823 HDQ 4K35 30/11/2015

Page 15

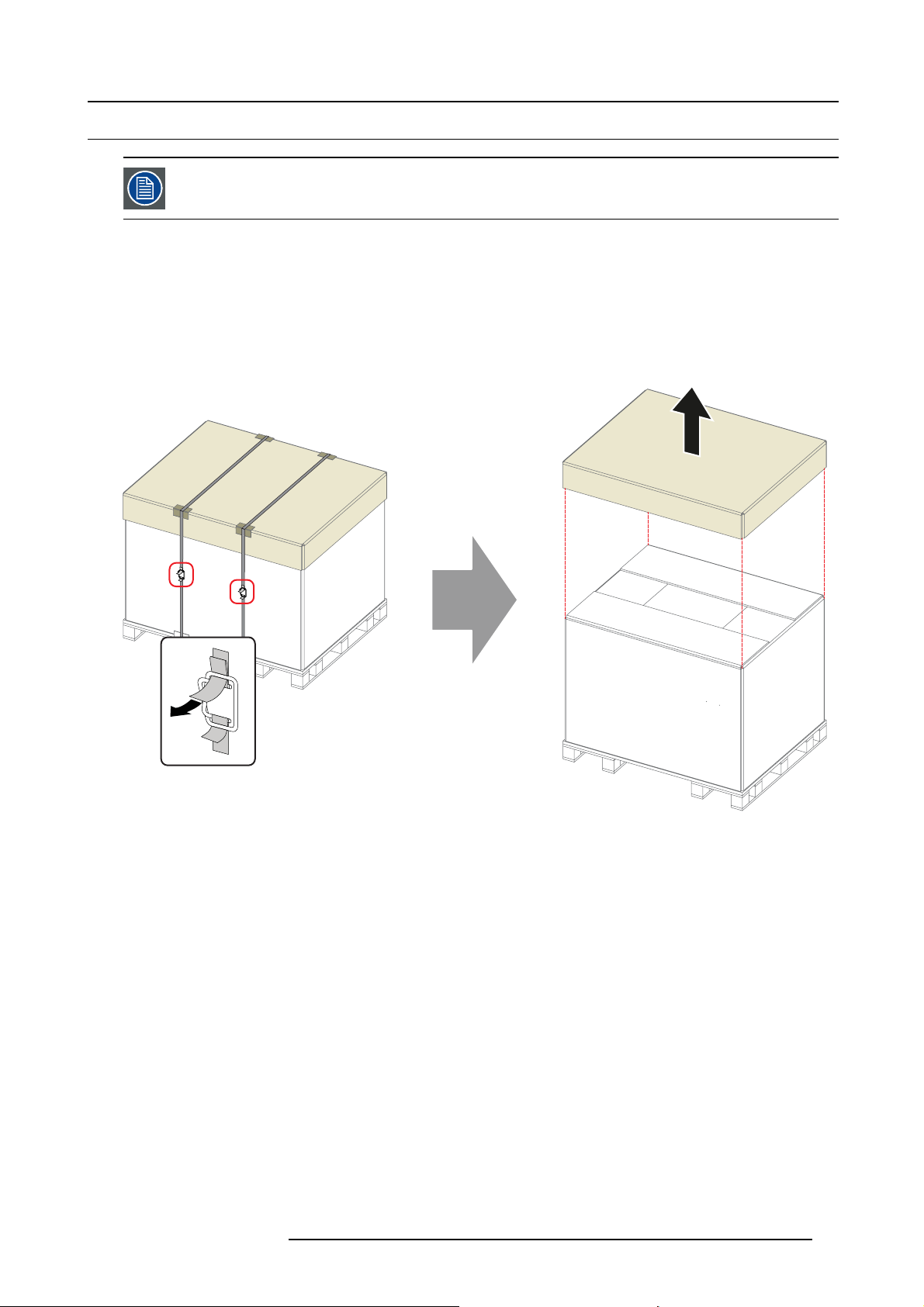

2.2 Unpacking the projector

Let t he projector acclimatize after unpacking. Neglecting this may result in a startup failure of the Light Processor Unit.

Introduction

Upon delivery, the projector is packed in a cardboard box placed on a pallet and secured with banding and fastening clips. To provide

protection during transportation, the projector is surrounded with foam. Once the projector has arrived at its destination, it needs to

be re moved from the cardboard box and the pallet in a safe manner and without damaging the projector.

How to unpack the projector?

1. L oosen the banding by pulling the free end of the banding loop in the c lip.

Remove the box cover.

2. General

Image 2-2

2. Unfold the top side of the outer cardboard box.

Take out the small box located between inner and outer cardboard box (this box contains the accessories such as manuals,

remote control, etc.).

Remove the outer cardboard box by sliding it up above the projector.

R5905823 HDQ 4K35 30/11/2015

11

Page 16

2. General

Image 2-3

3. Remove the inner cardboard box by sliding it up above t he projector.

Loosen the banding by pulling the free end o f the banding lo

op in the clip.

Remove the upper piece o f cardboard from the projector.

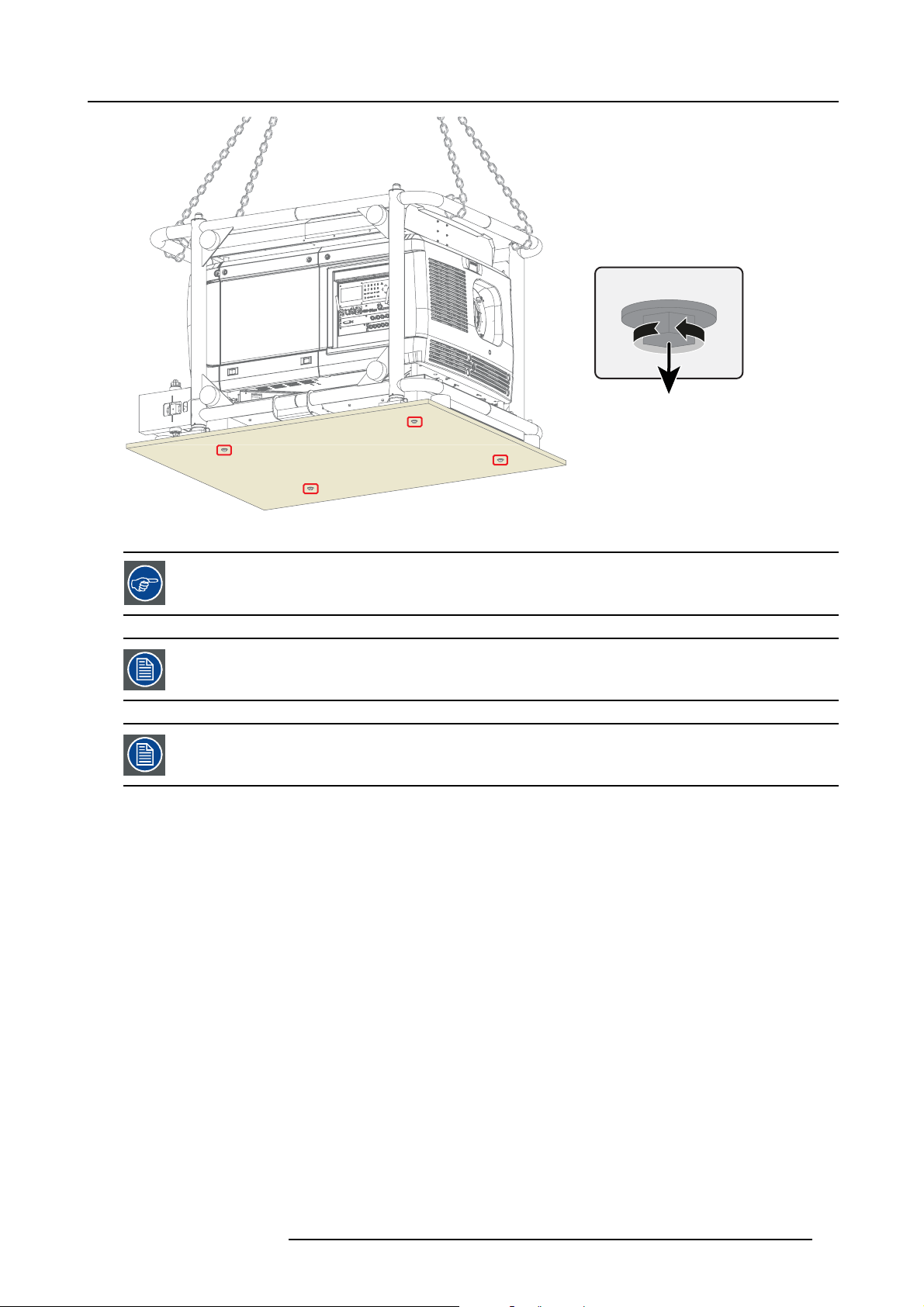

Image 2-4

4. L ift up the projector (with the supporting wooden board) from the pallet. A hoisting tool is recommended.

Make sure the 4 screws on the underside of the wooden board are accessible.

Release the projector from the supporting wooden board by removing the 4 screws.

Warning: It is forbidden to lift up the projector with manpower, use a hoisting tool instead. Do n ot underestimate the weight of

the projector. The projector weights ± 210 kg (±462 lb.).

12

R5905823 HDQ 4K35 30/11/2015

Page 17

Image 2-5

2. General

4x

Save the original shipping carton and p acking material, they will be necessary if you ever have to ship your

projector. For maximum protection, repack you r projector as it was o riginally packed at the factory.

A rubber foam inside a plastic bag is placed into the lens opening of the projector. It’s recommended to reuse

this foam and plastic back each time yo u transport the projector. This to prevent intrusion of dust and foreign

particles.

The lens is delivered in a separate box.

R5905823 HDQ 4K35 30/11/2015 13

Page 18

2. General

2.3 Initial inspection

General

Before shipment, the projector was inspected and found to be free of mechanical and electrical defects. As soon as the projector is

unpacked, inspect for any damage that m ay have occurred in transit. Save all packing material until the inspection is completed. If

damage is found, file claim with carrier immediately. The Barco Sales and Service office should be notified as soon as possible.

The packaging of the HDQ 4K35 projector is provided with a shock-watch label. If this shock-watch label

was triggered (red colored at arrival) during transport, that indicates that the package w as possi

handled by the transport company. In this case, the instructions m entioned on the label, should be followed,

which are: adding a note on the “bill of lading” and informing the transport company and the Barco sales and

service office as s oon as possible.

bly roughly

Box content

After unpa cking the projector it is recommended to check if all following items where include

• Safety manual

• Quick start guide

• Warranty card

• CD-ROM with electronic version of the manuals

d:

Mechanical check

This chec k should confirm that there are no broken knobs or connectors, that the cabinet and panel surfaces are free of dents and

scratches, and that the operating panel is not scratched or cracked. The Barco Sales and Service office should be notified as soon

as possible if this is not the case.

14

R5905823 HDQ 4K35 30/11/2015

Page 19

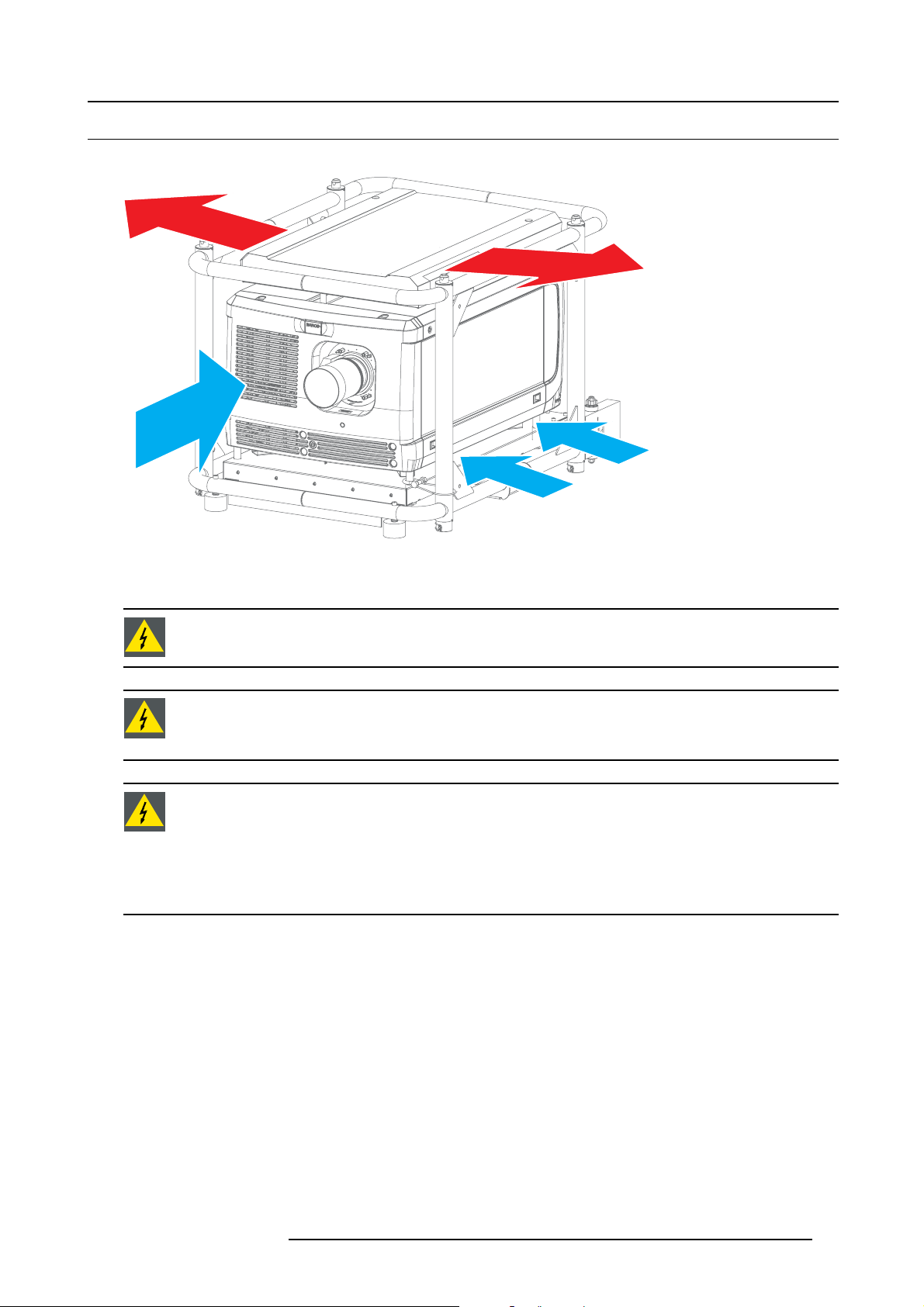

2.4 Air inlets and outlets

Air inlets and outlets

2. General

Image 2-6

The HDQ 4K35 projector has 3 air inlets (1 at the front and 2

projector).

WARNING: When the projector is used in portrait mode, the air outlet is positioned towards the floor. That’s

why the floor covering can become ve ry hot and must be resistant to a temperature of 90 °C (194 °F).

WARNING: The air fi lters of the projector must be cleaned or replaced on a regular basis (a "clean" booth

would be monthly-minimum). Neglecting this could result in disrupting the air flow inside the projector, causing overheating. Overheating may lead to the projector shutting down during operation. See "Cleaning the

front dust filter", page 70 and "Cleaning the bottom dust filters", page 71.

WARNING: The projector is fan co oled and mu st be installed with sufficient space around the air inlets, mini-

mum 20 cm (8”) to ensure sufficient air fl

than 10 cm (4") on any side.

The pro jector must always be installed in a manner which ensures unimpeded evacuation of the hot air from

its cooling system.

The projector should be used in an area where the amb ien t tem perature, as measured at the projector air inlet,

does not exceed +35°C (+95°F).

ow. Loose papers or other objects may not be nearer to the projector

at the bottom) and 2 air outlets (on the exhaust box on top of the

R5905823 HDQ 4K35 30/11/2015 15

Page 20

2. General

2.5 Installation process overview

Let t he projector acclimatize after unpacking. Neglecting this may result in a startup failure of the Light Processor Unit.

Setup from A to Z

After you have unpacked and checked the projector you can start with the installation process of your Barco HDQ 4K35. T his chapter

gives y ou an overview of all the different stages in the installation process which you have to follow to set your HDQ 4K35 up and

running. Each stage is briefly described and r efers to more detailed step by step procedures in this manual. U se this overview as a

checklist to ensure that you have followed all stages in the setup process of your HDQ 4K35.

What has to be done?

1. C heck if all installation requirements are fulfilled such as the environment conditions of the installation area, electrical facili-

ties, etc. For m ore info see chapter "Installation requirements", page 10.

2. In stallation of the Lamp House. The Lamp House is delivered separately from your projector. Unpack the Lamp House and

install it in your projector. See chapter "Installation of the Lamp House", page 18.

3. In stallation of the Lens. Select and install an appropriate lens for your specific situation. Don’t forget to install the additional

lens fixation mechanism. S ee chapter "Installing the lens fixation mechanism", page 44.

4. Connect the pr ojector with the power net. Choose the correct power input configuration according to your local power net

and connect the projector. See chapters "Access to the power connection", page 19, and "Connecting the projector with the

power net", page 22. If necessary connect the projector electronics with a U PS. See c hapter "Connecting a UPS to the p rojector

electronics", page 23.

5. P o wer input set up and Electrical connection with the power net.Se

20 and "Connecting the projector with the power net", p age 22.

6. In stallation of the Comm un icator Touch Panel. See c hapter X XXX XX .

7. P hysical installation of the projector. Position your HDQ 4K35 in landscape or po rtrait mod e, see chapter "Landscape and

portrait m ode", page 25. If necessary, choose to stack multiple projectors, either in a standing (table mount) or hanging (ceiling

mount) configuration, see chapter "Stacking multiple projectors", page 27.

8. Switch ON the projector. See "Switching ON the HDQ", page 67.

9. C onnect your source to the appropriate input. Se e "Source input ports of the Barco HDQ 4K35 projector", page 60.

10.Select the input to w hich the source is connected. Use Communicator to make the selection.

11. Alignment of the projected image on the screen. The projector can now be switched on to project its first image (test pattern)

on the screen. Then the image can be aligned with the screen size of the application. Follow the nex t steps to ach ieve that:

a) Place the ON/OFF switch of the projector in the ”I” position. As a result the pr ojector starts to initialize. The status lights of

the projector lights up GREEN onc e the projector is initialized.

b) Press the STANDBY button on the local keypad to activate the lamp.

c) Press the DOWSER button on the local keypad to open th e dowser of the projector. T he dowser is open if the color of the

DOWSER button is GREEN.

d) Press the TEST PATTERN button on the local keypad to project one of the internal test patterns of the projector on the screen.

e) Use the lens ZOOM, SHIFT and FOCUS buttons on the local keypad the match the projected image with the screen. Tilt the

projector in ca se y ou can not SHIF T the image completely upon the screen.

12.Resetting the lamp p aram eters. The lamp parameters MUST be updated after each installation of an x enon lamp inside the

lamp house or when replac ing the complete lam p house.

time of the xenon lamp. Consult the Comm unicator software manual section Installation → Lamp.

13.Realignment of the xenon lamp in its reflector. For optimal performance of the xenon lamp it is required to realign the lamp

after installation in the lamp hous e. See "Realignment of the lamp in its refl ector", page 78 for more information.

14.Adjusting the light path

Nevertheless, some applications require a readjustment of the lens holder, convergence or both. See procedure "Sc heimpfl ug

adjustment", page 48.

15.(if applicable) A lign the projected images of the stacked projectors. See chapters "Adjusting the multifunctional frame", page

30 and "Aligning stacked pro jectors", page 34.

16.Projection of a source signal. Apply a single or dual channel DisplayPort (DP) source to the input ports of the projector and

start up the projector. See chapter "Source input ports o f the Barco HDQ 4K35 projector", page 60. Use the Communicator Touch

Panel to configure the applied source. S

. Normally the lens holder and the convergence of the projector is perfectly adjusted at the factory.

ee the user guide of the Communic ator Touch Panel for more detailed information.

Neglecting this update will result in poor performance and short life

e c hapter "Power input setup of the HDQ 4K35", page

16

R5905823 HDQ 4K35 30/11/2015

Page 21

3. PHYSICAL INSTALLATION

Overview

• Installation of the Lam p House

• Access to the power connection

• Power input setup of the HDQ 4K35

• Connecting the projector with the power net

• Connecting a UPS to the projector electronics

• Landscape and portrait mode

• Stacking multiple projectors

• Adjusting the multifunctional frame

• Aligning the projected image on the screen

• Aligning stacked projectors

3. Physical installation

R5905823 HDQ 4K35 30/11/2015

17

Page 22

3. Physical installation

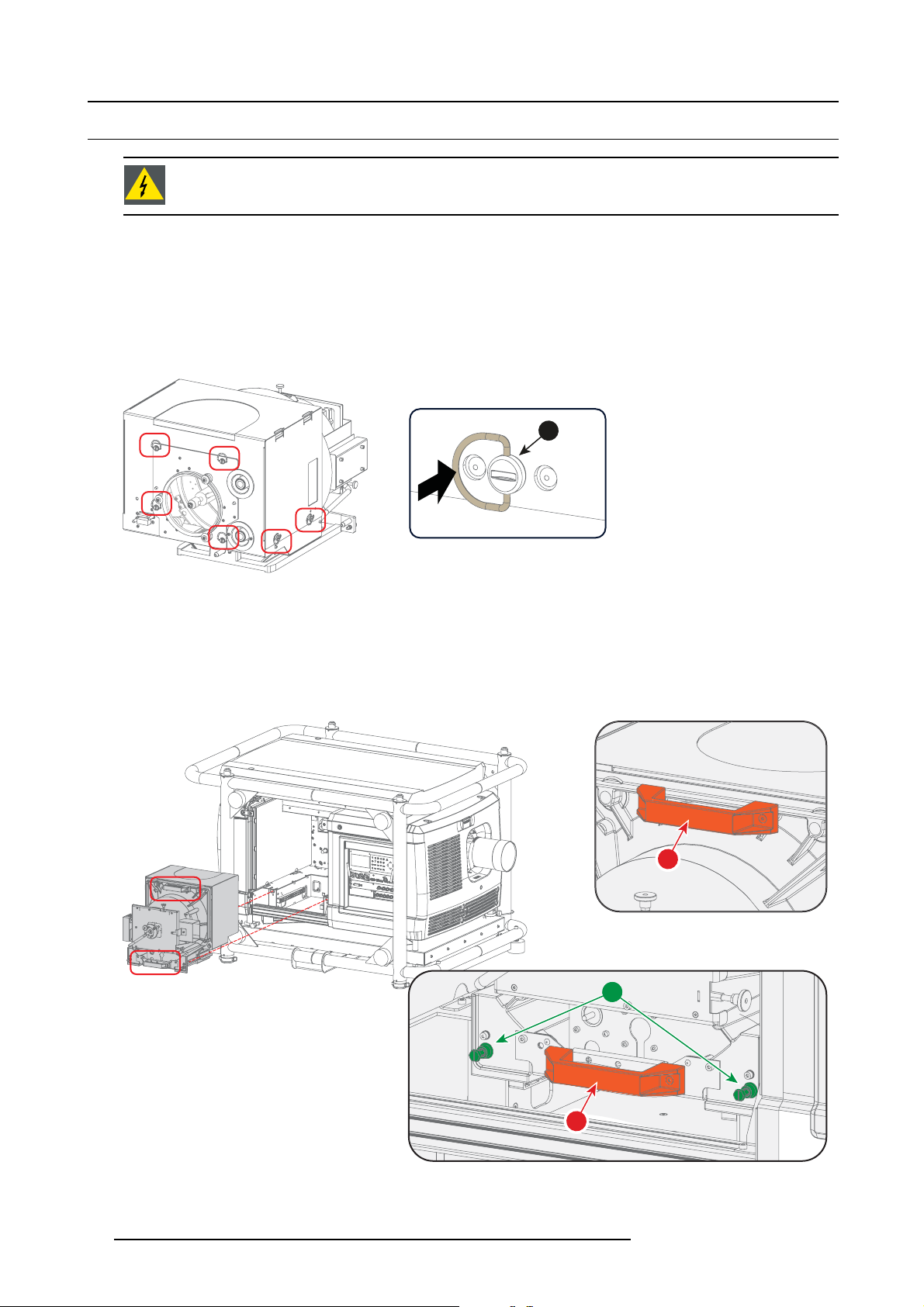

3.1 Installation of the Lamp House

WARNING: Bef ore installing the Lamp House, d isconnect the power to the pro jector mains terminals and

unplug the power cord at the U PS INLET for removal of all power from the projector.

Necessary tools

10 mm nut driver or flat screwdriver

How to install the Lamp House in the projector?

1. Remove the lamp cover.

2. P osition the turning wires of the six quarter turn screw s (1) so that they are fl ush w ith the cover. If this is not the case, interfer-

ence may occur while inserting the Lamp House.

1

Image 3-1

Positioning the quarter turn screws

3. G rip the Lamp House by both handles (2 and 3) and place the front of the Lamp House on the base plate inside the lamp com-

partment of the projector, lining up the foot of the Lam p H ouse w i

Warning: Be aware of the weight of the Lamp House. Take the necessary precautions to avoid personal injury.

4. P ush the Lamp House fully into the slots.

5. S ecure the Lamp House by fastening the two retaining screws (1) at the base of the Lamp House. Use a 10 mm nut driver or a

flat scre w d river.

th the s lots on the base.

3

1

Image 3-2

Installation of the Lamp House

6. Install the lamp cover.

18

2

R5905823 HDQ 4K35 30/11/2015

Page 23

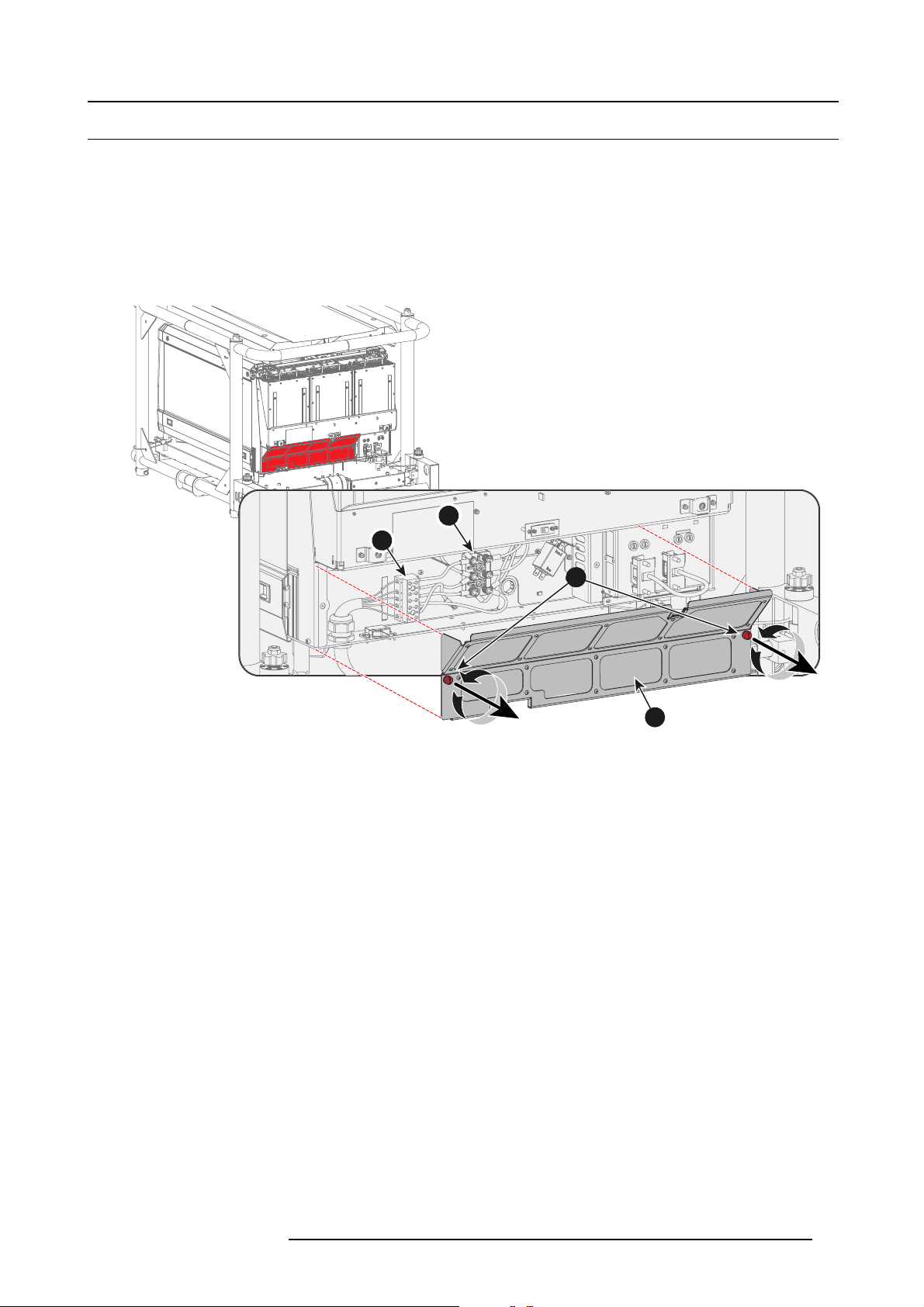

3.2 Access to the power connection

Necessary tools

Flat screwdriver - 6 mm

How to get access to the power connection of the projector?

1. R emov e the back cover of the projector. See "Removal of the back cover", page 88.

2. R elease the 2 captive screws (1).

3. R emov e the power connection cover (2).

4

3

3. Physical installation

Image 3-3

Power connection access

The terminal barrier strip (3) and Y-Δ configuration block (4) is accessible.

1

2

R5905823 HDQ 4K35 30/11/2015

19

Page 24

3. Physical installation

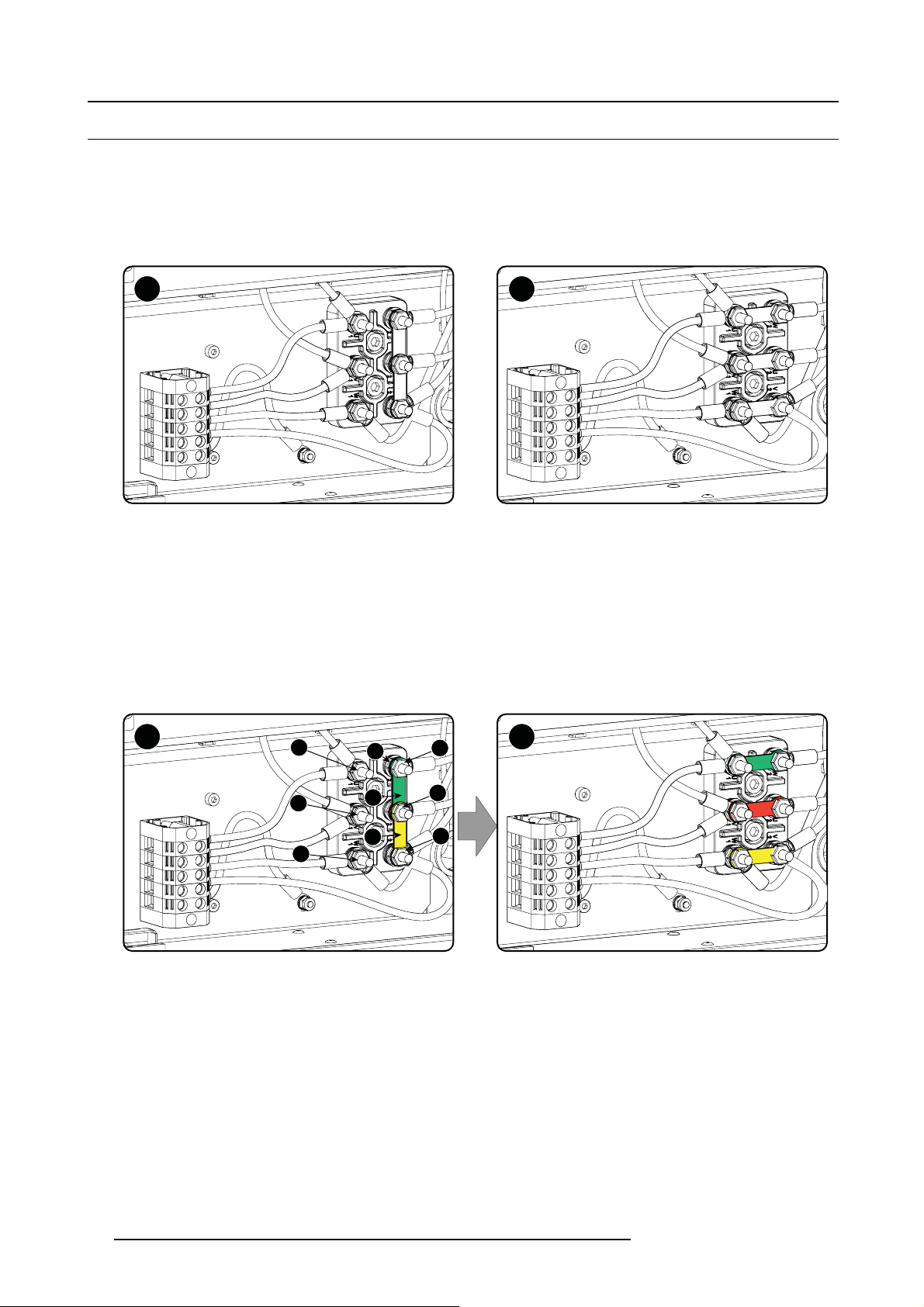

3.3 Power input setup of the HDQ 4K35

About the power input

The projector power input can be configured for a power supply of 230/400V 3W+N+PE (Υ-connection) or for 208V 3W+PE (Δ-connection). Before operating the projector, place the links in the correct position depending on the local power supply.

For a 3W+N+PE system, 400V is measured between the lines, 230V is measured between the lines and the neutral.

For a 3W+PE system, 208V is measured between the lines.

A B

Image 3-4

Υ-Δ connection

A Υ connection

B Δ connection

Necessary tools

• Flat screw driver

• Wrench10mm

• Torque wrench 10 mm

HowtoswitchfromaΥ-connection to Δ-connection

1. L oosen the 6 top nuts on the Υ/Δ configuration block. (1 to 6)

Y Δ

Image 3-5

Υ to Δ connection

2. Take off the mounted lins (A, B and C). Two links above each other or mounted between the upper and middle pin (A, B) and one

link between the middle pin and lower pin (C).

3. M ount the links horizontally on the pins.

4. Turn a nut on each pin and secure wit

1

2

3

A

B

C

h a torque wrench set to 7.5 Nm.

4

5

6

HowtoswitchfromaΔ-connection

1. L oosen the top nuts on the Υ/Δ configuration block (1 to 6).

20

to Υ-connection

R5905823 HDQ 4K35 30/11/2015

Page 25

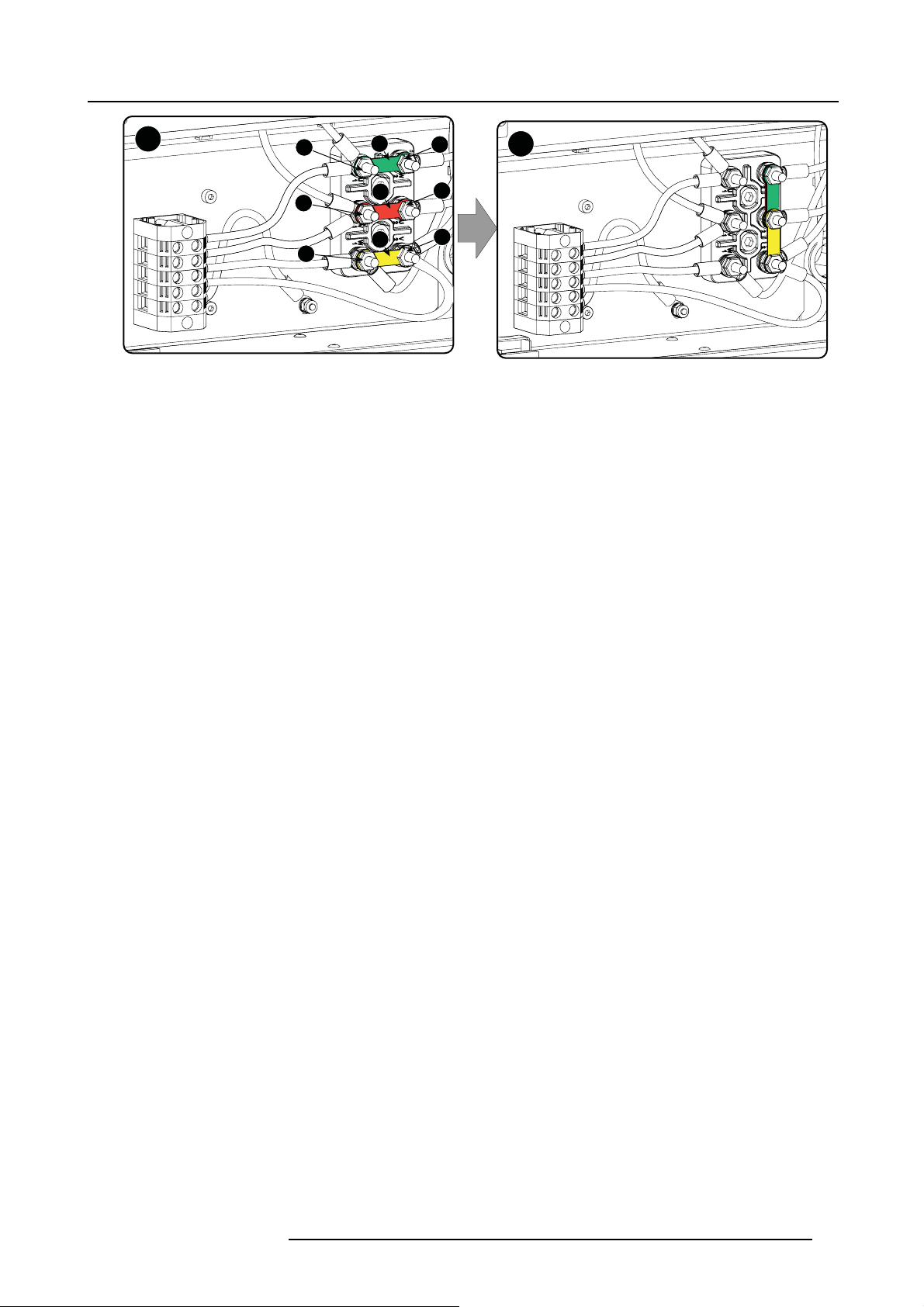

3. Physical installation

Δ

Image 3-6

Δ to Υ connection

2. Take off the mounted links (A, B and C).

3. Connect the right pins together. Place 2 links between the upper pin and the m iddle pin (A, B)and 1 link between the m iddle pin

and the lower pin (C).

1

2

3

A

B

C

4

5

6

Y

R5905823 HDQ 4K35 30/11/2015

21

Page 26

3. Physical installation

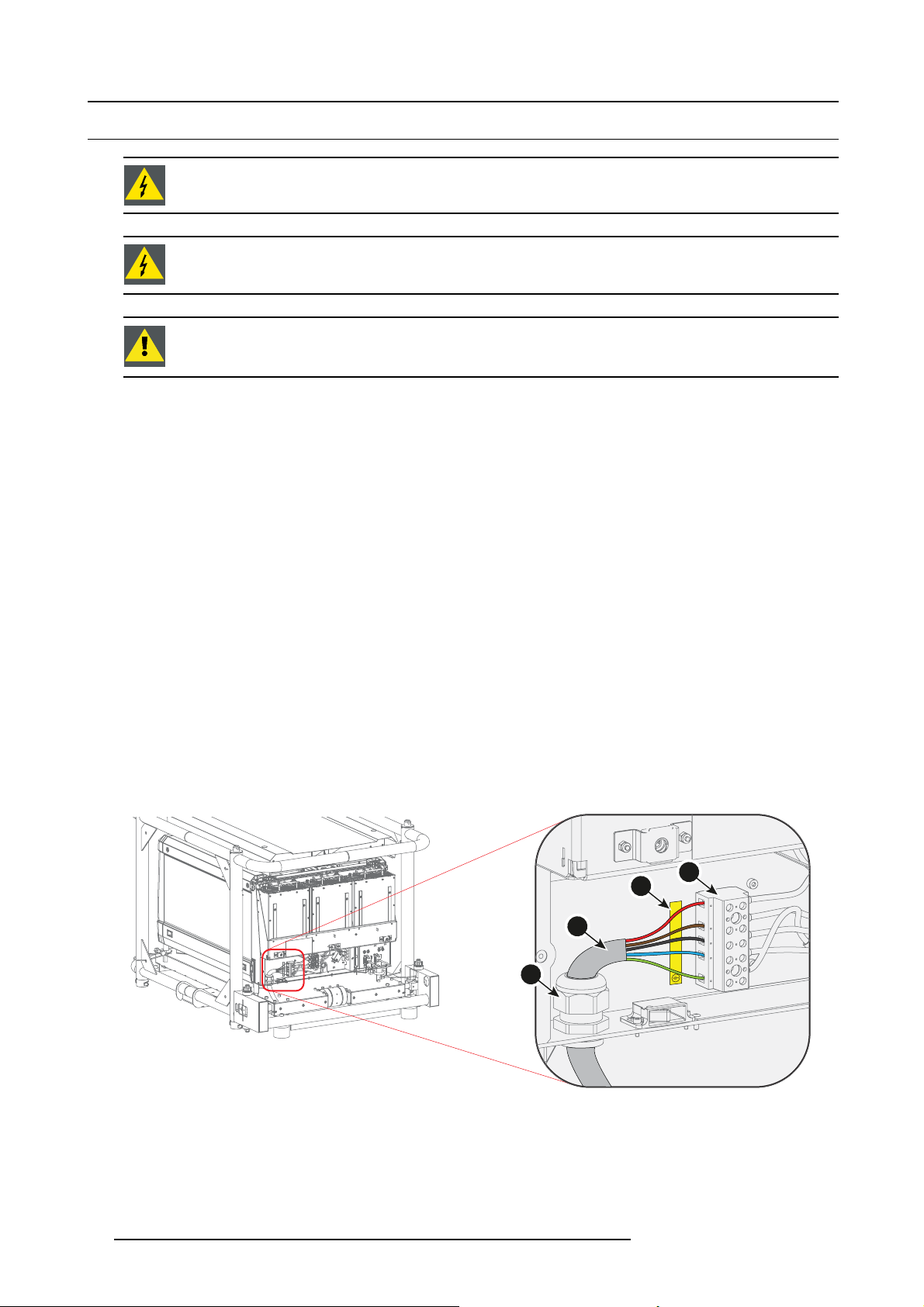

3.4 Connecting the projector with the power n et

WARNING: T he total electrical installation should be protected by an appropriate rated and readily accessi-

ble disconnect switch, circuit breakers and ground fault current interrupters. The installation shall be done

according to the local electrical installation codes.

WARNING: Make sure that the vo ltage range of projector mat ches with the voltage of the local power net.

CAUTION: The cross-sectional area of the conductors in the Power Supply Cord shall not be less than 4 mm

or AWG 10.

Necessary tools

• Flat torque screwdriver - 4 mm

• Adjustable wrench

Necessary parts

• (for 3W+N+PE, 230/400V) Certified power cable, minimum 4 mm² or AWG 10, 500V rated, cable diameter between 11 mm and

21 mm, or

• (for 3W+PE, 208V) Certified power cable, minimum 4 mm² or AWG 10, 300V rated, cable diameter between 11 mm and 21 mm

• Circuit breaker - maximum 40A

How to c onnect the projector with the power net?

1. R emov e the back cover of the projector. See "Removal of the back cover", page 88.

2. R emov e the power connection cover. See "Access to the power connection", page 19.

3. L oosen the cable gland fixation ring (1).

Note: The cable gland is specified for cables with a diameter between 11 mm and 21 mm .

4. P ush the stripped power supply cable (2) through the cable gland. When using a flexible power cord, make s ure each con ductor

end is provided with an end sleeve.

5. S ecure the cable in the cable gland by tightening the fixation ring with an adjustable w rench.

6. Connect each wire of the power cable with the term inal ba rrier strip (3), according to the legend on the decal (4). Tighten the

screws to a torque of 1.4 Nm.

Warning: Always connect ground conductor (PE) first.

Note: Always connect the neutral conductor (N) when available.

2

Image 3-7

Power connection

7. Install the power connection cov er.

8. Install the back cover of the projector. See "Removal of the back cover", page 88.

22

4

3

2

L2 NL3

L1

1

R5905823 HDQ 4K35 30/11/2015

Page 27

3. Physical installation

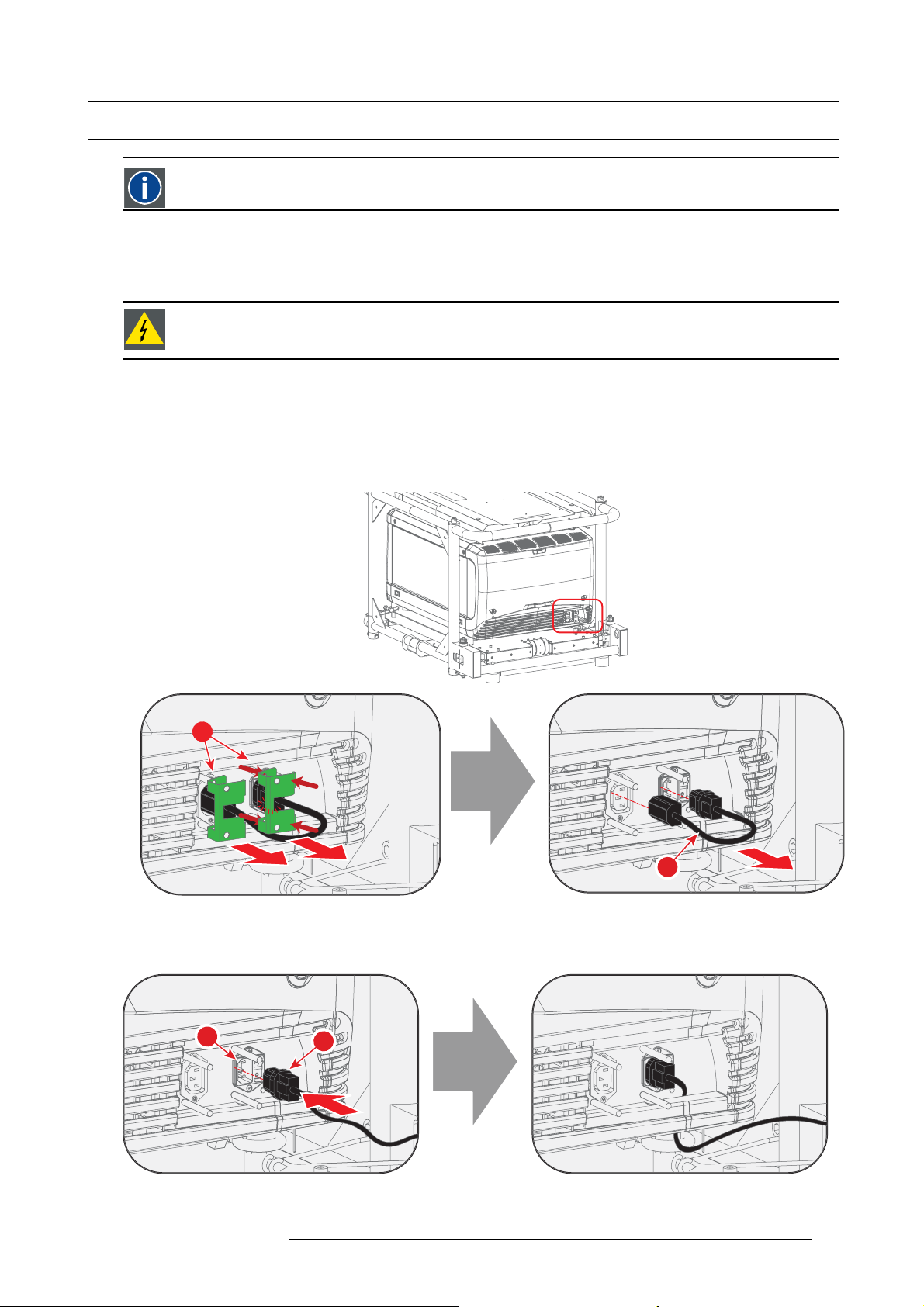

3.5 Connecting a UPS to the projector electronics

UPS

Uninterruptible Power Supply

Introduction

This proce dure explains how the projector electronics can be connected with a UPS. By default, the projector is configured for use

without a UPS. A short power link cable (with plug type C13/C14) loops the power through to the projector elec

WARNING: Only use UPS units which are suitable for the HDQ 4K35.

How to connect a UPS to the projector electronics?

1. Install the UPS according to the instructions of the manufacturer and the local regulations.

2. Remove the short power link cable if present:

a) Remove both fixation springs (1) by squeezing them together and pulling them away from the power plugs.

b) Unplug both power plugs from the short power link cable (2).

tronics.

1

1

Image 3-8

3. Connect the power output cord from the UPS unit (1) to the UPS inlet socket of the projector (right socket) (2).

Tip: Position the cable behind the back cover instead of directly connecting the power p lug. This will make it possible to

remove the back cover without unplugging the UPS inlet cable.

2

Image 3-9

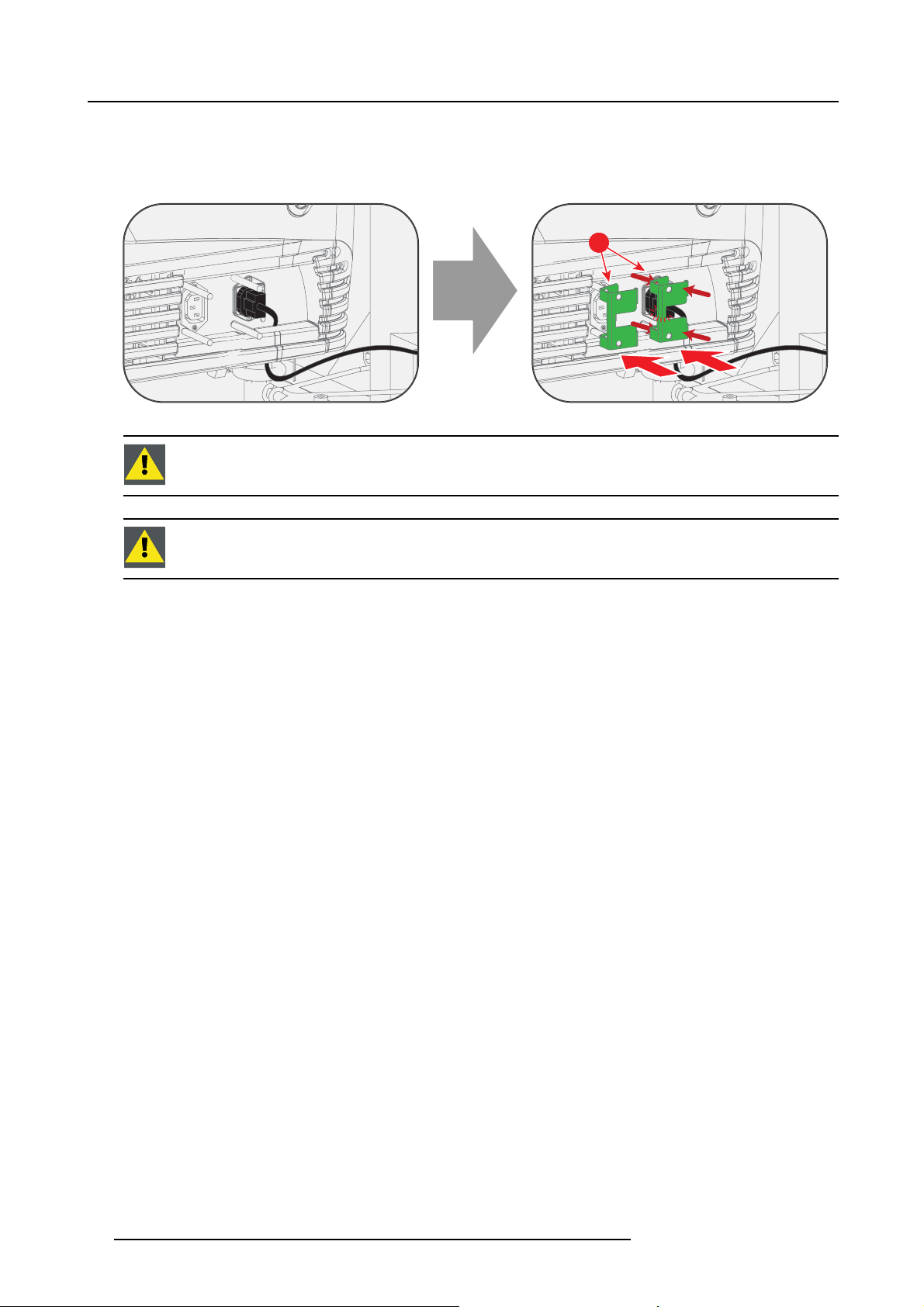

4. S e cure the UPS inlet soc ket with a fixation spring:

1

1

2

R5905823 HDQ 4K35 30/11/2015

23

Page 28

3. Physical installation

a) Squeeze the fixation spring together (1).

b) While squeezing, slide the fixation spring on the pins and push it against the power plug.

c) Release the fixation spring.

Tip: Install the second fixation spring on the power outlet socket to prevent losing it.

Image 3-10

CAUTION: The electrical connection with the UPS INLET socket of the projector must be done with a certified

AC power supply cord (minimum 0,75 mm² or 18 AWG and minimum 300V)

CAUTION: Do not use the power OUTLET socket of the projector to provide power to other equipment!

1

1

24 R5905823 HDQ 4K35 30/11/2015

Page 29

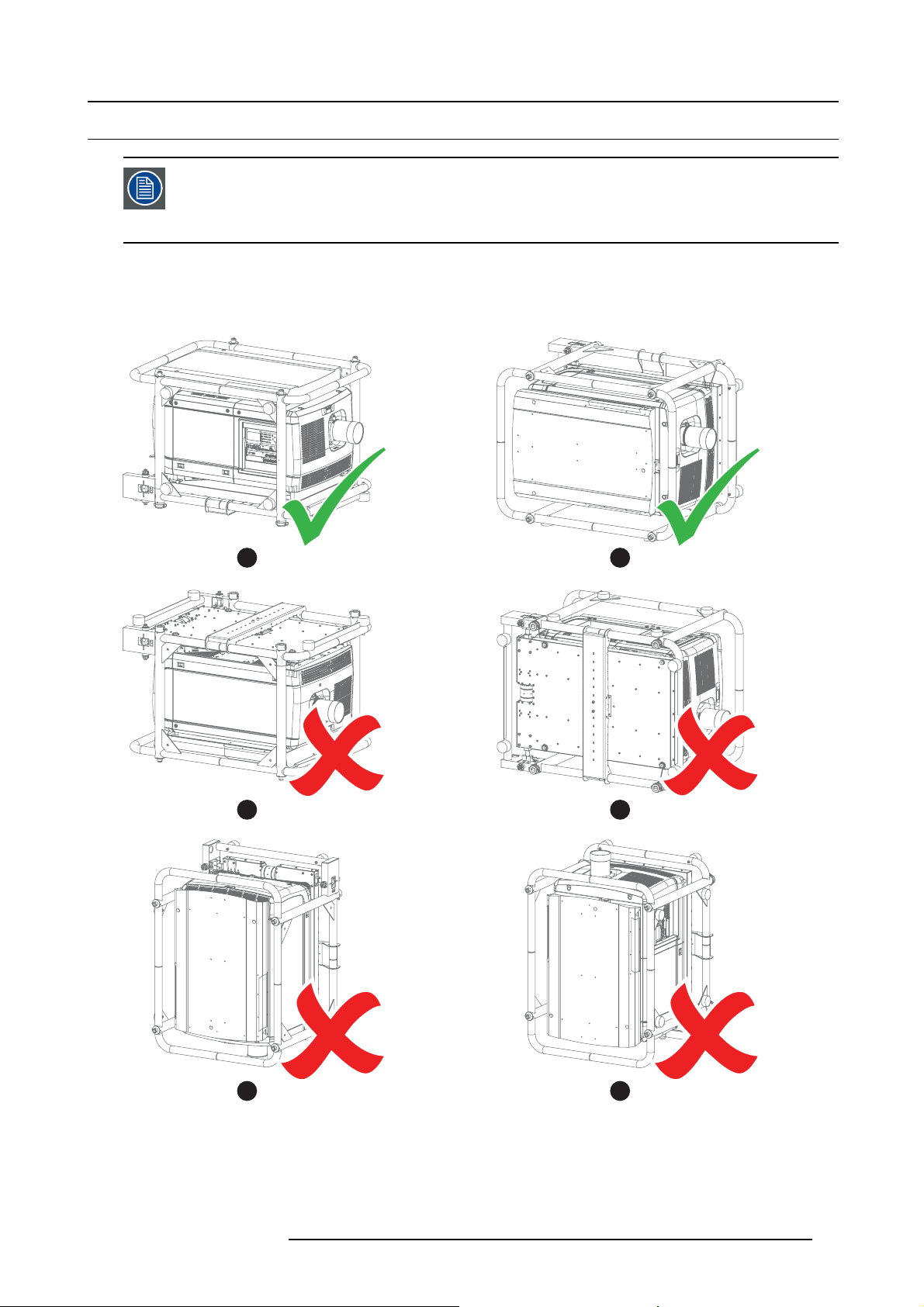

3.6 Landscape and portrait mode

In the allowed positions, an additional inclination or rotation of ±15° is tolerated.

The inclination and rotation of the projector in the frame is included in these ±15°.

Example: the p rojector is positioned in lan dscape mode and is rotated in the frame for 3°. An additional frame

rotation of 12° of is allowed.

Landscape and portrait mode

The projector can be used in landscape or portrait mode.

The illustrations below shows which positions are allowed and which are not.

3. Physical installation

A B

C D

E F

Image 3-11

A Landscape mode (allowed)

B Por trait mode (allowe d)

C Upside down (disallowed)

D Turned over portrait mode (disallowed)

E Upwards (disallowed)

F Downwards (disallowed)

R5905823 HDQ 4K35 30/11/2015 25

Page 30

3. Physical installation

CAUTION: Do not use the projector in a d isallowed position. Failure to do so can cause irreversible damage

to the projector.

WARNING: It is not allowed to stack multiple projectors in portrait mode.

CAUTION: When the pro jector is used in portrait m ode, always ensure the cooling liquid level is sufficient.

To check the cooling liquid level, see "Checking cooling liquid level", page 74.

26 R5905823 HDQ 4K35 30/11/2015

Page 31

3. Physical installation

3.7 Stacking mult iple projectors

Introduction

The Barco HDQ 4K35 is mounted by default in a multifunctional frame. This frame can be used to stack multiple projectors onto

each other. The stacked projectors can be used in a standing (table mount) or hanging configuration (ceiling mount).

WARNING: Never stack more than three (3) projectors in a standing configuration (table mount) and never

stack more than two (2) pro jectors in a hanging co nfiguration (ceiling mount). Failure to do so can cause

serious injury or death.

WARNING: It is not allowed to stack multiple projectors in portrait mode.

WARNING: It is forbidden to lift up the projector with manpower, use a hoisting tool instead. Do not under-

estimate the w eight of the projector. The projector weights ±210 kg (±462 lb.).

WARNING: When the projector is suspended from a truss, m inimum four (4) clamps must be used to secure

the projector. The clamp s must be fixed to the projector frame. Use a truss which is capable of handling five

(5) times the complete load of the system.

WARNING: W hen the projector is suspended from a truss, always mount 2 safety cables around the projector

frame and the truss.

When a dual stacking configuration is suspended from a truss, always m oun t 2 extra safety cables around

both projector frames. See the procedure below for the correct use of these cables.

Allowed configurations

The illustrations below show which configurations are allowed. All other stacking configurations are not allowed.

Image 3-12

Allowed con figurations - table mount

R5905823 HDQ 4K35 30/11/2015 27

Page 32

3. Physical installation

Image 3-13

Allowed con figurations - ceiling mount

How to stack multiple projectors?

1. P osition the first projector on a solid and level surface.

2. Remove the 4 pipe lynch pins (1) from the frame of the second projector.

3. L ift up the second projector and position it on the fi rst projector (2). Make sure the pins of the lo wer frame fit in the holes of the

upper frame.

Warning: It is forbidden to lift up the projector with manpower, use a hoisting tool instead. Do n ot underestimate the weight of

4. S lide in the 4 pipe lynch pins (3) and secure them by swinging the lever (4).

1

the projector. The projector weights ± 210 kg (±462 lb.).

1

1 1

2

3

Image 3-14

Stacking projectors

5. M ount 2 (two) safety cables to secure both projector frames to each other:

28

4

R5905823 HDQ 4K35 30/11/2015

Page 33

3. Physical installation

2x

a) Push the safety hook through the loop of the safety cable and wrap the bottom frame.

b) Mount the other end of the safety cable around the upper frame and clasp the safety hook around the cable as illustrated.

Make sure that the falling distance is max imum 20 cm (8”). If necessary, before clasping the safety hook around the cable,

turn the cable a few time around the fram e.

c) Repeat this procedure for the other safety cable on the other side of the frame.

2x

Image 3-15

R5905823 HDQ 4K35 30/11/2015 29

Page 34

3. Physical installation

3.8 Adjusting the multifunctional frame

Introduction

The Barco HDQ 4K35 is mounted by default in a multifunctional frame. This frame can be used to adjust the projector po sition. The

frame can be adjusted in 3 different ways:

• inclinating

• rotating

•skewing

The image below ex plains these 3 terms.

Image 3-16

A Inclinating

B Rotating

CSkewing

A

B

C

Necessary tools

• 2.5 mm Allen wrench

• 17 mm wrench

How to inclinate and rotate the projector in the frame?

1. Release the locking screw(s) (1) on the adjustment mechanism(s) on the back of the fram e. Use a 2.5 mm Allen wrench.

2. Turn the left and right adjustment screw (2) anti clockwise to lower the back of the projector

Or,

clockwise to rise the back of the projector.

Note: A 17 mm wrench can be used to turn the adjustment sc rews.

3. Turn the left and right adjustment screw (2) in the opp osite direction to rotate the projector.

4. Tighten the locking screw(s) (1). Use a 2.5 mm Allen wrench.

30

R5905823 HDQ 4K35 30/11/2015

Page 35

3. Physical installation

1

2

2

1

Image 3-17

Inclinating and ro tating the projector

How to skew the projector i n the frame?

1. Release the locking screw(s) (1) on the adjustment mechanism on the bac k of the frame. Use a 2.5 mm Allen wrench.

Tip: Only the most reachable locking screw(s) on the adjustment rod may have been secured previously.

2. Turn the adjustme nt rod (2) clockwise to skew the projector clockwise

Or,

anti clockwise to skew the projector anti clockwise.

3. Tighten the locking screw(s) (1). Use a 2.5 mm Allen wrench.

Tip: Only secure the most reachable locking screw(s).

2

1

Image 3-18

Skewing the projector

R5905823 HDQ 4K35 30/11/2015 31

Page 36

3. Physical installation

3.9 Aligning the projected image on the screen

About aligning

Use the Communicator software to align the projector. For more detailed information, consult the Communicator software user guide.

Alignment steps

1. P roject an internal hatch pattern w ith the projector. In the navigation pane, click on Control → Test Patterns.

Use one of the short cuts to display a test pattern.

2. A djust the rotation of the projector.

Adjust until the outline of the hatch pattern is most symm etric with the projection screen.

Rotation

Image 3-19

3. A djust the inclination of the projector.

Adjust until the outline of the hatch pattern is most symm etric with the projection screen.

Inclination

Image 3-20

4. A djust the skew of the projector.

Adjust until the outline of the hatch pattern is most symm etric with the projection screen.

Skew

Image 3-21

5. S hift the hatch pattern horizontally and vertically until the outline of the hatch pattern is most symmetrically placed with respect

to projection screen.

Use Communicator software to shift. In the navigation pane, click on Configuration → Lens.TheLens settings menu opens.

Use the Lens shift buttons to shift the image.

Or, use the shift buttons on the local keypad.

32

R5905823 HDQ 4K35 30/11/2015

Page 37

3. Physical installation

Shift

Image 3-22

6. Z oom the hatch pattern in or out until the outline of the hatch pattern matches exactly the outline of the projection screen.

Use Communicator software to zoom . In the navigation pane, click on Configuration → Lens.TheLens settings menu opens.

Use the Lens zoom buttons to zoom the image.

Or, use the zoom buttons on the local keypad.

Zoom

Image 3-23

7. Repeat from step 2 until the hatch pattern of the stacked projec tor is perfectly aligned with the projection screen.

8. F ocu s the projector to the screen until the hatch pa ttern is perfectly sharp.

Use Communicator software to focus. In the navigation pane, click on Configuration → Lens.TheLens settings menu opens.

Use the Lens focus buttons to focus the image.

R5905823 HDQ 4K35 30/11/2015

33

Page 38

3. Physical installation

3.10 Aligning stacked projectors

Prior to starting the procedure below, make yourself familiar with the adjustment mechanism of the multifunctional frame. See " Adjusting th e multifunction a l frame", pag e 30.

Reference projector

In c ase of a s tanding configur ation (table mount), this is the lowest projector.

In c ase of a hanging configur ation (ceiling mount), this is the uppermost projector.

Necessary tools

• 2.5 mm Allen wrench

• 17 mm wrench

How to align stacked projectors

1. A lign the reference projector on the screen. See "Aligning the projected im age on the screen", page 32.

2. P roject an internal hatch pattern with the reference projector. In the na vigation pane, click on Control → Te s t Pa t t e r n s and

select a hatch pa ttern .

Note: The pattern must be s harp and must have a perfect rectangle outline.

If this is not the case, readjust the reference projector before aligning the other stacked projector(s) with the reference

hatch pattern.

3. P roject the same internal hatch pattern with the stacked projector. I n the navigation pane, click on Control → Test Patterns and

select a hatch pa ttern .

4. A djust the rotation of the stacked projector with respect to the reference projector.

Adjust until the outline of the hatch pattern is most symmetric with the reference ha

tch pattern.

Rotation

Image 3-24

5. A djust the inclination of the stacked projector with respect to the reference projector.

Adjust until the outline of the hatch pattern is most symmetric with the reference hatch pattern.

Inclination

Image 3-25

6. Adjust the skew of the stacked projector with respect to the reference projector.

Adjust until the outline of the hatch pattern is most symmetric with the reference hatch pattern.

34

R5905823 HDQ 4K35 30/11/2015

Page 39

3. Physical installation

Skew

Image 3-26

7. S hift the hatch pattern horizontally and vertically until the outline of the hatch pattern is most symmetrically placed with respect

to the reference hatch pattern.

Use Communicator software to shift. In the navigation pane, click on Configuration → Lens.TheLens settings menu opens.

Use the Lens shift buttons to shift the image.

Or, use the shift buttons on the local keypad.

Shift

Image 3-27

8. Z oom the hatch pattern in or out until the outline of the hatch pattern matches exactly the outline of the reference hatch pattern.

Use Communicator software to zoom . In the navigation pane, click on Configuration → Lens.TheLens s ettings m enu opens.

Use the Lens zoom buttons to zoom the image.

Or, use the zoom buttons on the local keypad.

Zoom

Image 3-28

R5905823 HDQ 4K35 30/11/2015 35

Page 40

3. Physical installation

9. Repeat from step 2 until the h atch pattern of the stacked projector is perfectly aligned with the hatch pattern of the reference

projector.

10.Focus the projector to the screen until the hatch pattern is perfectly sharp.

Use Communicator software to focus. In the navigation pane, click on Configuration → Lens.TheLens settings menu opens.

Use the Lens focus buttons to focus the image.

In case of a triple stacked standing projector configuration (table mount) adjust and align the reference projector fi rst, than the middle projector and finally the uppermost projector.

36 R5905823 HDQ 4K35 30/11/2015

Page 41

4. Lenses & Lens Holder

4. LENSES & LENS HOLDER

About this chapter

This chapter gives an overview of available lenses for the Barco HDQ 4K35 and explains how you can select the best suited lens for

your specific situation using the lens formulas. Also, it is explained how to install and remove a lens from the projector lens holder.

Furthermore, it is described how you can perform the Scheimpflug adjustment.

CAUTION: Never transport the projector with a lens mounted in the Lens Holder. A lways remove the le

before transporting the projector. Neglecting this can d amag e the Lens Holder and Prism.

Overview

• Available lenses

• Lens selection

• Lens installation

• Lens removal

• Installing the lens fixation mechanism

• Removing the lens fixation mechanism

• Lens shift, zoom & focus

• Additional vertical shift of the Lens Holder

• Scheimpflug adjustmen t

• Fixation of the Lens Holder front plate

ns

R5905823 HDQ 4K35 30/11/2015

37

Page 42

4. Lenses & Lens Holder

4.1 Available lenses

Which lenses are available for my projector?

The table below is subject to changes. Consult Barco’s w eb site and click on myBarco for the most recent

information about available lenses.

Product Number Zoom range Image

R9852950 1,0 ( fixed) image 4-1

R9852090 1,45 – 1,8 image 4-2

R9852092 1,8–2,4 image4-3

R9852094 2,2–3 image4-4

R9852100 2,8–5,5 image4-5

R9852920 5,5–8,5 image4-6

R9856294 1,35 – 1,86 image 4-7

R9856297 1,46 – 2,10 image 4-8

R9856300 1,65 – 2,60 image 4-9

Image 4-1

R9852950

Image 4-4

R9852094

Image 4-2

R9852090

Image 4-5

R9852100

Image 4-3

R9852092

Image 4-6

R9852920