Instruction Manual

MACO® 4000, 5000 & 6000 Series

SPI Auxiliary Equipment Interface

Protocol

Table of Contents

1.0 Introduction.......................................................2

2.0 Setup Instructions ............................................2

2.1 Board Location.........................................2

2.2 Jumpers and Switches.............................2

2.3 Node Address ..........................................2

2.4 MACO Serial Communication Setup........2

2.4.1 Modfiles and Sample Screens .................2

2.4.2 COMM Setpoints......................................2

2.5 Wiring.......................................................3

2.6 Error Codes Screen .................................4

2.6.1 Baud Rate Setpoints ................................4

2.6.2 SPI Status Relays ....................................4

3.0 SPI Screens and RLD Programming...............5

3.1.0 List of SPI Devices Supported .................5

3.1.1 Mold Temp Controller Commands ........... 5

3.1.2 Chiller Commands ................................... 5

3.1.3 Dryer Commands.....................................5

3.1.4 Loader Commands .................................. 6

3.1.5 Melt Pump Commands ............................ 6

3.1.6 Additive Feeder Commands .................... 6

3.1.7 Self-tune Temp Controller Commands .... 6

3.1.8 General Purpose Temp Controller

Commands...............................................6

3.1.9 Robot Commands .................................... 6

3.2 Setup Screen ...........................................7

4.0 Status and STM/MTS Control Relays..............8

4.1 Status control relays ................................ 8

4.2 STM/MTS control relays .......................... 9

4.2.1 Building the STM/MTS Table.....................9

5.0 SPI Status Monitor / setup screens...............10

1640-IN-026-A-00

July 1995

Copyright © 1995 Barber-Colman Company

1640-IN-026-A-00 Page 1 of 10

1.0 INTRODUCTION

The Society of the Plastic Industry, Inc. has established a

standard communication protocol (SPI) that provides a platform for instrumentation manufactured by different companies to communicate together on the same RS-485 local area

network.

The SPI Auxiliary Equipment Interface module (71-946-X) will

®

allow the MACO

4000, 5000 and 6000 Series controllers to

communicate (via SPI protocol) with auxiliary equipment

typically found in plastic molding, extruding or blowmolding

facilities, including mold temperature controllers, hot runner

controllers, chillers, dryers, additive feeders and melt pumps.

A maximum of 32 separate devices can be connected to a

MACO on the same SPI auxiliary interface module. With this

interface the standard features of the MACO controllers would

be utilized, such as recipe storage (allowing fast setup times)

RLD interface capability without the need for extensive wiring

to the Sequence inputs/outputs Statistical Process Control

(SPC) of auxiliary equipment parameters.

The SPI Auxiliary Equipment Interface module is pre-configured to communicate with SPI compatible auxiliary equipment. The end user or OEM needs no programming skill, or

knowledge of the intricacies of the SPI protocol. You simply

need to know what SPI compatible devices being used and

the quantity you wish to communicate with. The user needs

a working knowledge of Barber-Colman OptiGrafix and RLD

programming software.

The SPI Auxiliary module will communicate with any device

listed in the current, released version 3.01a of the SPI Phase

I protocol (also listed in section 3.1 of this document). It will

communicate at a user selectable baud rate of 1200, 2400,

4800, 9600, and 19.2K. Every "required" command, as defined by the protocol, for the devices listed are supported in

this release of firmware.

2.0 SETUP INSTRUCTIONS

U10

A-13404-2

RS-485 COMMUNICATIONS

T1

8

7

6

5

4

3

2

1

ON OFF

S1

J2

IN OUT

J1

IN OUT

4

SHIELD

3

ISOCOM

2

DATA

1

DATA

Figure 2.2 SPI Auxiliary Interface module.

2.3 Node Address

The node address switch S1 on the SPI Auxiliary module is not

used.

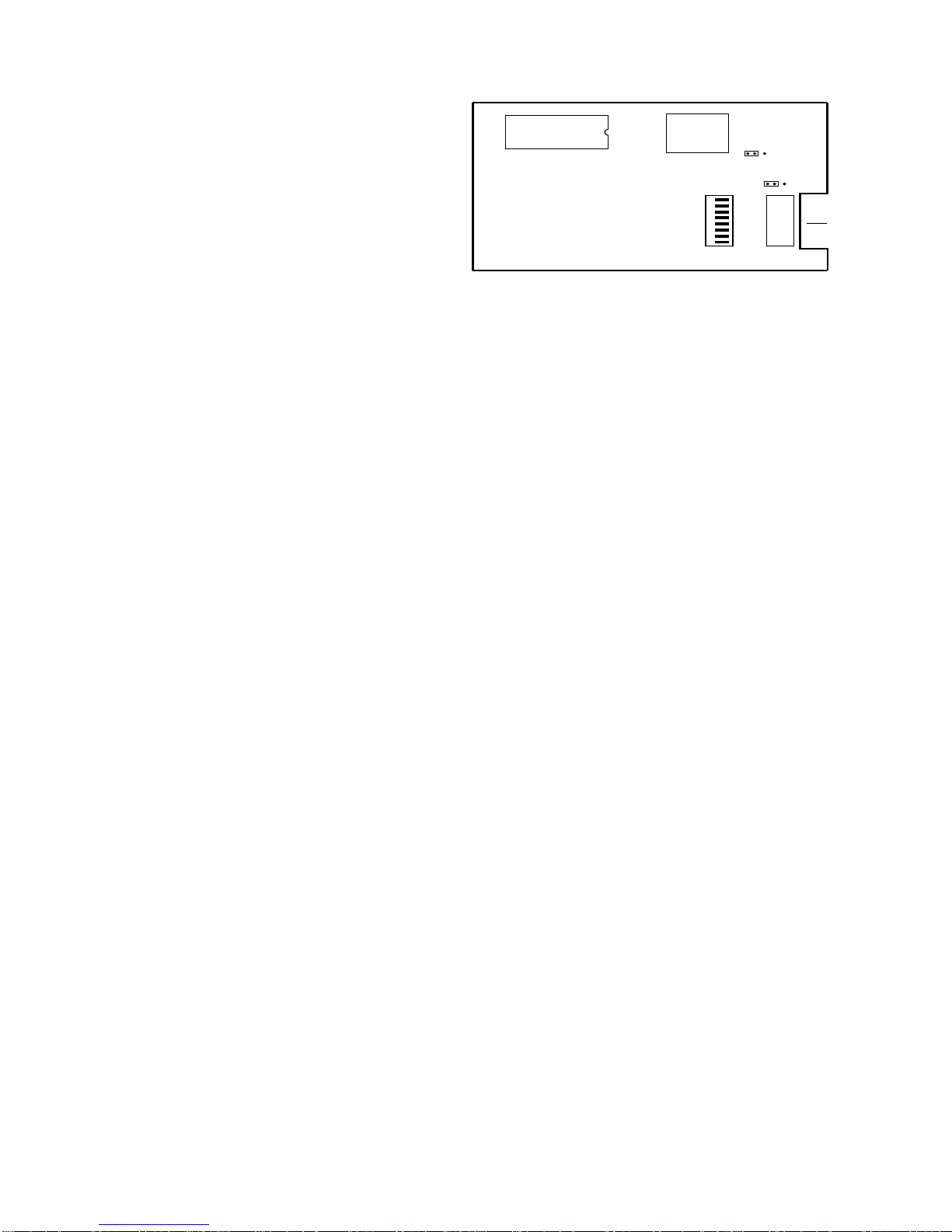

2.4 MACO SERIAL COMMUNICATION SETUP

The MACO serial communications setup screen (figure 2.4) is

used for setting baud rates and enabling communications.

This controller can have as many as three separate external

devices connected for use with serial communications.

Daughterboards purchased for the communications

motherboard determine what type of device can be connected. The COMM setpoints correspond to daughterboard

locations on the motherboard:

COMM 1 bottom slot.

COMM 2 middle slot.

COMM 3 upper slot.

2.4.1 Modfiles and Sample Screens

The diskette SA-00064-01X-0-00 is provided. It contains the

modfiles and sample SPI screens that will be required by the

MACO and OptiGrafix programming software. Preform the

following steps to install these files onto your user application.

2.1 Board Location

The SPI Auxiliary module may be placed in slot 1, 2, or 3 of the

communications motherboard (A-13408-1). The communications motherboard must be installed in primary chassis 1 in a

slot which has a control data bus connector; this is the middle

connector on the back-plane of the MACO controllers. You

may only have one (1) RS-485 SPI Module per system.

The SPI Auxiliary Equipment module can be used with data

handler version V20.75 or newer.

2.2 Jumpers and Switches

There are two hardware jumpers that have to be manual set

before installing the SPI Auxiliary module (daughterboard)

onto the communications motherboard A-13408-1XX.

Jumpers J1 and J2 are to be in the "IN" position, see Figure

2.2. These jumpers connect the bus termination resistors to

the Data(+) and Data(-) terminals.

1640-IN-026-A-00 Page 2 of 10

A. Copy the two modfiles; to copy the modfiles place

the diskette into floppy drive and copy to your existing modfile directory.

Example: Copy A:\modfiles\*.* C:\modfiles.

B. Using the OptiGrafix screen editor copy the SPI

sample screens from the diskette (A:\ADB0001 name

of application to copy from) to your user application

on the hard drive using the Application ...

Utilities...Copy from ... Screens Feature.

2.4.2 COMM Setpoints

Examine the Module Information Screen to determine which

communications boards are present and then enter a setpoint

for each daughterboard, see Figure 2.4. COMM 1, 2 or 3 may

be an RS-485 device (a setpoint of 0 to enable SPI communications) and COMM 1, 2 or 3 may be an RS-232 device (a

setpoint of 0, 1 or 2). Note that only one of EACH DEVICE is

allowed (i.e., can’t have two RS-232 printers or two RS-232

PCs, etc.). Al other information on this screen (Figure 2.4) is

for RS-232 communications.

Figure 2.4 SERIAL COMMUNICATIONS SETUP SCREEN

1

ISOCOM

3

DATA (+)

1

DATA (-)

2

SHIELD

4

MACO SPI Port

1

3

3

4

8

5

9

DEVICE

NODE 1

Beldon 8772 Cable

Figure 2.5 Wire multiple Device's

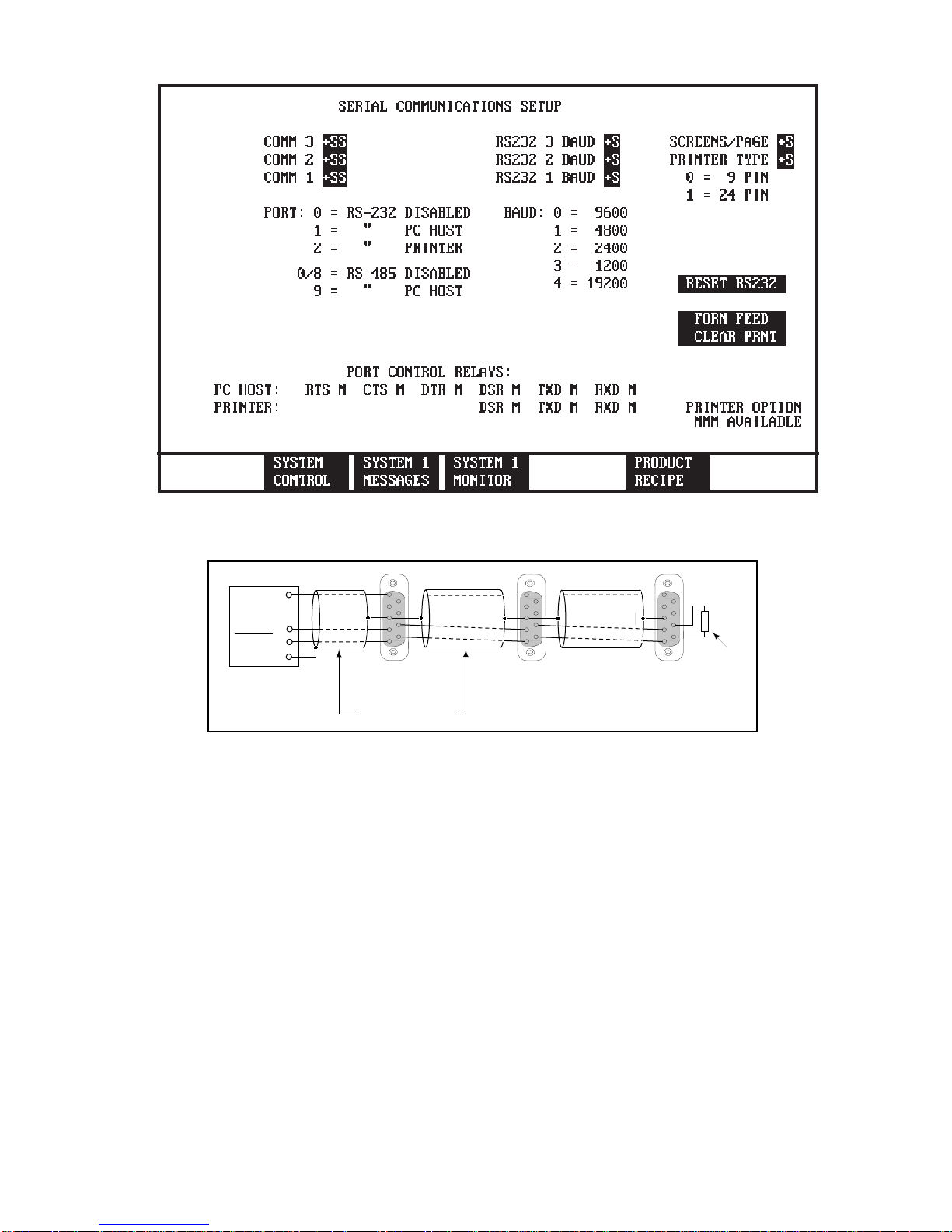

2.5 Wiring

The SPI Auxiliary Interface module uses a four pin connector

to communicate with the devices. Connector E23-1134-004

is provided with screw terminals for field wiring. Figure 2.5

illustrate the device wiring, note the SPI module terminals are

not in order, see Figure 2.2.

The RS-485 cabling shall run on the low voltage side of the

MACO controllers cable tray located at the bottom of each

chassis.

The Device that is located farthest from the MACO require a

bus terminator resistor, see Figure 2.5.

1

1

3

3

4

8

5

9

DEVICE

NODE 2

9 Pin Female Connectors (Rear View)

1

3

4

5

DEVICE

NODE X

8

9

Termination

Resistor

100 Ohms

1640-IN-026-A-00 Page 3 of 10

Figure 2.6 Error Code Screen

2.6 Error Codes Screen

This screen will list sixteen (16) lines of errors. An error line will

contain the device number, CMD1 byte, CMD 2 byte, and an

error code. The command 1 and 2 bytes distinguish what

parameter failed, and the error code tells why it failed. An error

code of 16 represents that a time-out occurred, the device did

not respond to the command within the allotted one second.

Any other error code is a SPI generated error from the device

and must be interpreted based on the following definition:

BIT 7 MSbit - Invalid data

BIT 6 - Reserved by SPI

BIT 5 - Set to 1

BIT 4 - Reserved by SPI

BIT 3 - Command not supported

BIT 2 - Command not executed

BIT 1 - Invalid preamble

BIT 0 LSbit - Communication error

An error code value of 44 = 2C hex would indicate that the

device does not support this command and the command was

not executed. After 16 lines of errors have been accumulated,

or at any other time the clear error codes reverse video area

can be energized to allow for more errors to be displayed.

2.6.1 Baud Rate Setpoints

Baud rate is set by entering a baud rate setpoint on the error

code screen figure 2.6. The baud rate must match that of the

host. Enter a baud rate setpoint for each device;

0 = 9600 3 = 1200

1 = 4800 4 = 19200

2 = 2400

If the baud rate setpoint is not programmed on a screen it

defaults to 9600 baud.

2.6.2 SPI Status Relays

The SPI status relays are located on the middle right of the

Error Code screen and indicate the status of any ongoing

communications. SPI status is indicated by “TXD” or an

“RXD” will indicate direction (transmit or receive) and an

asterisk will indicate if data is actually being transmitted or

received (these are not “real time” indicators - they are meant

only to show that communication is taking place).

1640-IN-026-A-00 Page 4 of 10

3.0 SPI SCREENS AND RLD PROGRAMMING

The SPI screens will depend on the type(s) of SPI devices that

will be connected to the SPI Auxiliary Equipment Interface. An

example would be one user wants to connect a mold temperature controller as device one (1) and a different user might

want a melt pump as device one (1). The mold temperature

controller has four setpoints and two values that are read back

to the screen, whereas a melt pump has seven setpoints and

three values updated to the MACO. The standard screens

have device one setup as a mold temperature controller, to

support a melt pump three additional setpoints and two

additional values would have to be added to the screen. Also

the text used to describe the process status control relays

would differ between the two devices.

There is no RLD programming required to transfer setpoints

and values from a SPI device to the MACO. RLD programming is only necessary when you want to incorporate the

status returned from the device, such as alarm monitoring or

for example turn the auxiliary device ON/OFF.

3.1.0 List of SPI Devices Supported

1 - Mold Temperature Controller

2 - Chiller

3 - Dryer

4 - Loader

5 - Melt Pump

6 - Additive Feeder

7 - Self-Tuning Temperature Controller

8 - General Purpose Temperature Controller

11 - Robot

The Device number in the following descriptions depends on

the device address assignment the user on the SPI setup

screen. The modfile column is the descriptor from the modfile

definitions provided for screen building, see tabbed sections

of this manual. The version (ASCII string is the software

version descriptor that a device manufacture defines.

The machine mode control relay command can be used to

toggle the auxiliary equipment on/off with the use of a user

defined STM relay (see Control Relay Listing on defining

STM/MTS control relays). This command is not supported by

all the auxiliary equipment manufactures. If a response is not

received for this command five times, the command will not be

asked for again until a system reset occurs.

Sequence to Module (STM) is used to transmit the status of

control relays in the sequence modules to other non-sequence modules in a MACO system.

Module to Sequence (MTS) is used to transmit the status of

non-sequence module control relays to all sequence modules.

3.1.1 Mold Temp Controller Commands

Setpoints Modfile Values Modfile Control Relay Modfile

Process temperature (SP 1 Dev #) Temp to process (Value 1 Dev#) Process Status (Dev# CR1-CR16)

High temperature deviation (SP 2 Dev #) Version (ASCII string) Machine Mode (STM) (Dev# CR17-CR32)

Low temperature deviation (SP 3 Dev #)

Echo (ASCII string) (Echo Dev #)

3.1.2 Chiller Commands

Setpoints Modfile Values Modfile Control Relay Modfile

Process temperature (SP 1 Dev #) Temp to process (Value 1 Dev#) Process Status (Dev# CR1-CR16)

High temperature deviation (SP 2 Dev #) Version (ASCII string) Machine Mode (STM) (Dev# CR17-CR32)

Low temperature deviation (SP 3 Dev #)

Echo (ASCII string) (Echo Dev #)

3.1.3 Dryer Commands

Setpoints Modfile Values Modfile Control Relay Modfile

Process temperature (SP 1 Dev #) Temp to process (Value 1 Dev#) Process Status (Dev# CR1-CR16)

High temperature deviation (SP 2 Dev #) Version (ASCII string) Machine Mode (STM) (Dev# CR17-CR32)

Low temperature deviation (SP 3 Dev #)

Echo (ASCII string) (Echo Dev #)

1640-IN-026-A-00 Page 5 of 10

3.1.4 Loader Commands

Setpoints Modfile Values Modfile Control Relay Modfile

Load Time A (SP 1 Dev#) Version (ASCII string) Process Status (Dev# CR1-CR16)

Load Time B (SP 2 Dev#) Material Mode (STM) (Dev# CR17-CR32)

Echo (ASCII string) (Echo Dev#)

3.1.5 Melt Pump Commands

Setpoints Modfile Values Modfile Control Relay Modfile

RPM (SP 1 Dev#) Inlet Pressure (Value 1 Dev#) Process Status (Dev# CR1-CR16)

High RPM deviation (SP 2 Dev#) Outlet Pressure (Value 2 Dev#) Machine Mode (STM) (Dev# CR17-CR32)

Low RPM deviation (SP 3 Dev#) RPM (Value 3 Dev#)

Inlet Pressure (SP 4 Dev#) Version (ASCII string)

High Pressure deviation (SP 5 Dev#)

Low Pressure deviation (SP 6 Dev#)

Echo (ASCII string) (Echo Dev#)

3.1.6 Additive Feeder Commands

Setpoints Modfile Values Modfile Control Relay Modfile

Additive setpoint (SP 1 Dev#) Material Usage (Value 1 Dev#) Process Status (Dev# CR1-CR16)

Reference setpoint (SP 2 Dev#) Version (ASCII string) Machine Mode (STM) (Dev# CR17-CR32)

Calibration setpoint (SP 3 Dev#)

Echo (ASCII string) (Echo Dev#)

3.1.7 Self-tune Temp Controller Commands

Setpoints Modfile Values Modfile Control Relay Modfile

Process temperature (SP 1 Dev#) Process Value (Value 1 Dev#) Alarm Active (Dev# CR1-CR16)

Cycle Time 1 (SP 2 Dev#) Version (ASCII string)

Echo (ASCII string) (Echo Dev#)

3.1.8 General Purpose Temp Controller Commands

Setpoints Modfile Values Modfile Control Relay Modfile

Process temperature (SP 1 Dev#) Process Value (Value 1 Dev#) Alarm Active (Dev# CR1-CR16)

Cycle Time 1 (SP 2 Dev#) Version (ASCII string)

Proportional Band 1 (SP 3 Dev#)

Reset 1 (SP 4 Dev#)

Rate 1 (SP 5 Dev#)

Echo (ASCII string) (Echo Dev#)

3.1.9 Robot Commands

Setpoints Modfile Values Modfile Control Relay Modfile

Echo (ASCII string) (Echo Dev#) Version (ASCII string) Process Status (Dev# CR1-CR16)

Sequence Selection (Dev# CR17-CR32)

1640-IN-026-A-00 Page 6 of 10

Figure 3.2 Setup Screen

3.2 Setup Screen

This screen allows the user to choose what SPI Auxiliary

Equipment device(s) will be communicating to the MACO.

The first setpoint entry in the device address assignments

section should correspond to your SPI equipment which you

have configured as device address 20 hex. Device 2 would

have device address 21 hex. If device address 20H is a dryer,

you should enter a setpoint of three (3) for this setpoint. You

continue entering setpoints for all of the SPI equipment you

wish to communicate with.

If your SPI device is a Self-Tuning or General Purpose

temperature controller types seven (7) or eight (8), you must

enter in a zone number for each zone of the controller you

wish to communicate with. A controller zone occupies one

device slot, for example if a Self-Tuning temperature controller with 32 zones of control, you would enter in a seven (7) for

all 32 device address assignment setpoints, and a setpoint of

1 through 32 for each of the 32 device zone number setpoints.

If the 10th device on your SPI network is a self-tuning or

general purpose controller with three zones of control. Enter

a one (1) for the device zone number setpoint 10, for zone

setpoint 11 enter a two (2), and for zone setpoint 12 enter a

3. A seven (7) or eight (8) must be entered in the device

address assignment setpoint 11 & 12.

Note: The device zone number for type 7 & 8 setpoints could

be removed by the user with OptiGrafix if SPI device types 7

& 8 are not used.

1640-IN-026-A-00 Page 7 of 10

4.0 STATUS AND STM/MTS CONTROL RELAYS

Status control relays are used to display messages on the

operator station, STM relays (CR# 3769 - 3832) and MTS

relays (CR# 3833 - 3896) are used in RLD.

4.1 Status control relays

Any control relay retrieved from the SPI equipment can be

used to display messages on the operator station, this is

known as a status control relay. Each of the 32 devices that

can be connected to the SPI interface can have 32 status

Process Status Modfile Definition Machine Mode Modfile Definition

bit 0 - processing Dev. 1 CR1 bit 0 - machine, ON/OFF Dev. 1 CR17

bit 1 - system alarm Dev. 1 CR2 bit 1 - alarm acknowledge Dev. 1 CR18

bit 2 - process alarm Dev. 1 CR3 bit 2 - reserved Dev. 1 CR19

bit 3 - machine alarm Dev. 1 CR4 bit 3 - reserved Dev. 1 CR20

bit 4 - reserved Dev. 1 CR5 bit 4 - reserved Dev. 1 CR21

bit 5 - reserved Dev. 1 CR6 bit 5 - reserved Dev. 1 CR22

bit 6 - reserved Dev. 1 CR7 bit 6 - reserved Dev. 1 CR23

bit 7 - reserved Dev. 1 CR8 bit 7 - reserved Dev. 1 CR24

bit 8 - reserved Dev. 1 CR9 bit 8 - reserved Dev. 1 CR25

bit 9 - reserved Dev. 1 CR10 bit 9 - reserved Dev. 1 CR26

bit 10 - augur jam alarm Dev. 1 CR11 bit 10 - reserved Dev. 1 CR27

bit 11 - low material alarm Dev. 1 CR12 bit 11 - reserved Dev. 1 CR28

bit 12 - reserved Dev. 1 CR13 bit 12 - reserved Dev. 1 CR29

bit 13 - reserved Dev. 1 CR14 bit 13 - reserved Dev. 1 CR30

bit 14 - open Dev. 1 CR15 bit 14 - reserved Dev. 1 CR31

bit 15 - open Dev. 1 CR16 bit 15 - reserved Dev. 1 CR32

control relays, for a total count of 1,024. Status control relays

cannot be used in the RLD and are listed in the Control Relay

section of this manual.

The first sixteen (16) status control relays are always linked to

the first supported control relay command (see 3.1.1 - 3.1.9)

and the next sixteen are linked to the second control relay

command.

For an example look at an additive feeder assigned as device

one (1) on the setup screen. The process status and machine

mode definition is a follows:

Table 1 Process Status and Machine Node with a additive feeder as Dev. 1

For an example look at a chiller assigned as device four (4) on the setup screen. The process status and machine mode

definition is a follows:

Process Status Modfile Definition Machine Mode Modfile Definition

bit 0 - processing Dev. 4 CR1 bit 0 - machine, ON/OFF Dev. 1 CR17

bit 1 - system alarm Dev. 4 CR2 bit 1 - alarm acknowledge Dev. 4 CR18

bit 2 - process alarm Dev. 4 CR3 bit 2 - reserved Dev. 4 CR19

bit 3 - machine alarm Dev. 4 CR4 bit 3 - reserved Dev. 4 CR20

bit 4 - high temp. alarm Dev. 4 CR5 bit 4 - reserved Dev. 4 CR21

bit 5 - low temp. alarm Dev. 4 CR6 bit 5 - reserved Dev. 4 CR22

bit 6 - high pressure alarm Dev. 4 CR7 bit 6 - reserved Dev. 4 CR23

bit 7 - low pressure alarm Dev. 4 CR8 bit 7 - reserved Dev. 4 CR24

bit 8 - reserved Dev. 4 CR9 bit 8 - reserved Dev. 4 CR25

bit 9 - low flow alarm Dev. 4 CR10 bit 9 - reserved Dev. 4 CR26

bit 10 - reserved Dev. 4 CR11 bit 10 - reserved Dev. 4 CR27

bit 11 - reserved Dev. 4 CR12 bit 11 - reserved Dev. 4 CR28

bit 12 - reserved Dev. 4 CR13 bit 12 - reserved Dev. 4 CR29

bit 13 - reserved Dev. 4 CR14 bit 13 - reserved Dev. 4 CR30

bit 14 - open Dev. 4 CR15 bit 14 - reserved Dev. 4 CR31

bit 15 - open Dev. 4 CR16 bit 15 - reserved Dev. 4 CR32

Table 2 Process Status and Machine Node with a chiller as Dev. 4

If you were interested in placing the status of the system alarm

(table 1) from the process status on the operator station, you

would use Dev. 1 CR #2 from the SPI modfile. If you wanted

to know the status of the machine on/off bit (table 1), you

would use Dev. 1 CR #17.

1640-IN-026-A-00 Page 8 of 10

4.2 STM/MTS control relays

Figure 4.2 STM & MTS Control Relays Screen

There are 56 user-definable STM control relays (CR# 3777 -

3832) and 56 user definable MTS relays (CR# 3841 - 3896)

to be used in RLD. Any of the control relay commands read

back from the SPI equipment can be setup as a MTS, but only

those with a STM next to them (see 3.1.1 and 3.1.9) can be

setup as STM relays. MTS relays are typically setup in RLD

to monitor alarms or faults in the auxiliary equipment and react

accordingly in the RLD. STM relays are typically used in RLD

to turn on/off the auxiliary equipment and acknowledge alarms.

4.2.1 Building the STM/MTS Table

Table Figure 4.2, is used for defining which relays from the SPI

equipment are assigned as usable in RLD. The user can

define 56 MTS relays, with up to 32 MTS relays for a single

device. Refer to the bit definitions listed in table 1 for the

process status and machine mode commands for an additive

feeder as device one (1). If you wanted to assign the process

alarm of device number one as your first MTS relay, you would

enter a setpoint of 102. The one (1) represents the device

address number, and the 02 (bit number) is assigned to the

process alarm. If you wanted the process alarm from the

sixteenth (16) device, the setpoint entered would be 1602.

The first MTS setpoint entered links CR #3841 with the device

and bit definition encoded in the setpoint definition. Therefore, you can assign CR #3841 in your RLD to react accordingly based on your first MTS setpoint. The second setpoint

entered affects CR #3842. The user defines the CR meaning

based on the setpoints entered on this screen. For devices

with two control relay commands, the setpoints would range

from 100-131 for device address number one, and 3200-3231

for device address number thirty-two (32).

The user can also define up to 56 STM relays. Only those

control relay commands with a (STM) next to the command

can be setup. The setpoints range from 116-131 for device

address number one, and 3216-3231 for device address

number thirty-two (32). The setup of the STM relays is the

same as the MTS relays, except the setpoints entered affect

CR #3777 - CR #3832. In order to assign STM CR #3777 to

turn on/off your chiller at device address one, you would enter

a setpoint of 116 for STM setpoint number one.

CR #3841

PROCESS ALARM

(SPI DEV. 1 BIT 2 SP=102)

CR #1657

OPERATOR CR

OUT 1

CR #3777

CHILLER

ON/OFF

After you have defined all of your MTS and STM setpoints you

must activate the BUILD STM/MTS TABLE reverse video

area or energize CR #3769. Once the table is built CR #3833

will be energized. This is indicated by an asterisk next to the

build STM/MTS table. You must rebuild the table anytime you

change any MTS or STM setpoint.

MTS Control Relays STM Control Relays

3833 - STM/MTS table is built 3769 - Build STM/MTS table

3834 - Reserved 3770 - Reserved

3835 - Reserved 3771 - Reserved

3836 - Reserved 3772 - Reserved

3837 - Reserved 3773 - Reserved

3838 - Reserved 3774 - Reserved

3839 - Reserved 3775 - Reserved

3840 - Reserved 3776 - Reserved

3841 - 3896 = User define MTS 3777 - 3832 =User define STM

1640-IN-026-A-00 Page 9 of 10

5.0 SPI STATUS MONITOR / SETUP SCREENS

Seven screens are provided to monitor the status or setup of

each SPI device. Each screen displays five devices and their

variables.

Figure 5.0 SPI Status Monitor Screens

Barber-Colman Company

INDUSTRIAL INSTRUMENTS DIVISION

1354 Clifford Avenue

Loves Park, IL U.S.A. 61132-2940

1-815-637-3000

1640-IN-026-A-00 Page 10 of 10

Loading...

Loading...