TECHNICAL MANUAL

FOR

DYNA 8000, 8200 & 8400

ELECTRONIC GOVERNOR

DYNA 8000

DYNA 8400

DYNA 8200

DYNA 8000-400 & DYNA 8400-400

F-23721-5

CONTENTS

SECTION DESCRIPTION PAGE

1 GENERAL INFORMATION........................... 3

2 SPECIFICATIONS.........................................3

3 FUNCTIONAL DESCRIPTION .....................5

4 INSTALLATION.............................................6

5 CALIBRATION OF DYN1-1065X.................. 9

6 CALIBRATION OF DYN1-1068X................ 11

7 TROUBLESHOOTING................................13

8 INSTALLATION DIMENSIONS................... 15

2

1. GENERAL INFORMATION

1.1 INTRODUCTION

The DYNA 8000, DYNA 8200 and DYNA 8400 governor system

provides an engine governor for speed and power control of

piston and gas turbine engines or steam and water turbines.

The actuator is a simple, proportional, electric solenoid having

a sliding armature whose magnetic force is proportional to input

coil current. The armature glides on anti-friction bearings and is

balanced between the force of its return spring and the magnetic force, thus providing a hysteresis-free linear movement.

The linear motion is converted to an output shaft rotation by a

crank arm.

The hazardous duty DYNA 8000 and DYNA 8400 actuators

provide units that are UL listed for Class I, Division 2, Group D,

hazardous duty applications that are often encountered in the

petroleum or chemical industries. The hazardous duty actuators can be used to provide an engine governor for speed and

power control of piston and gas turbine engines.

1.2 TYPICAL APPLICATIONS

Typical applications are speed governing, remote throttle control, generator sets, power carts and pump set applications.

1.3 STANDARD FEATURES

• All electric

• All engine compatible

• Mounts in any position

• Engine mounted (actuator only)

• High reliability due to few moving parts

• Proportional actuator

• No hydraulic or oil lines

• No special maintenance

• Spring returns output shaft to minimum position on removal

of power or loss of magnetic pickup signal

• Precise repeatability

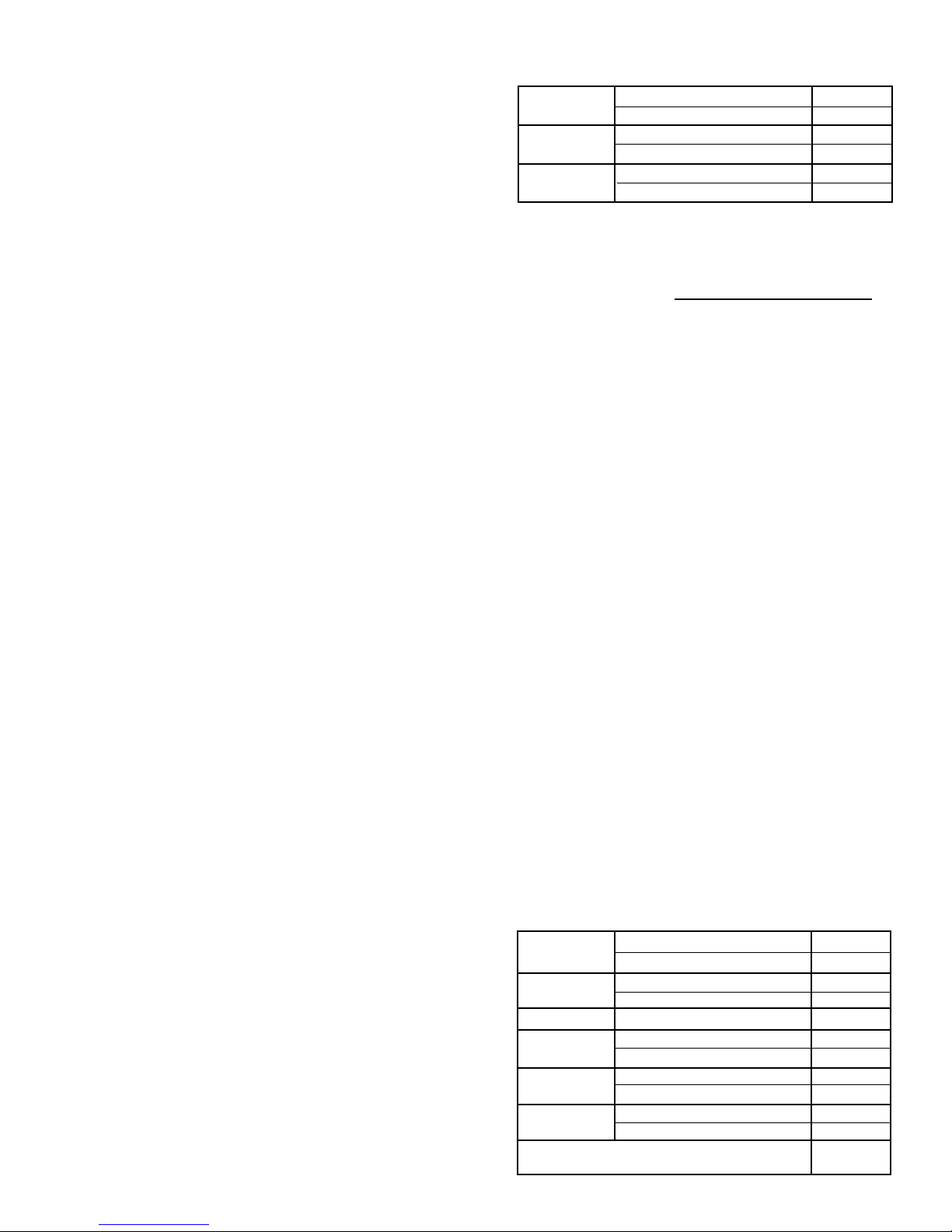

2.1.10 DYNA 8000 CONTROLLER

Output Current

@ 12 VDC

Output Current

@ 24 VDC

Weight

2.1.11 DYNA 8000 CONTROLLER

INPUT SIGNAL FREQUENCY

Input Signal

Frequency in Hertz

Select controller for the correct input signal frequency range

generated by the magnetic pickup at the maximum engine

operated (RPM) speed.

2.1.12 AVAILABLE CONTROLLER MODELS

Controllers: Speed Input Signal Frequency

Nominal Quiescent Current 80 mA

Maximum Amperes @ Stall 13 amps

Nominal Quiescent Current 80 mA

Maximum Amperes @ Stall 13 amps

Kilograms 0.863

Pounds 1.9

Engine RPM x Number of Gear

=

Teeth on Flywheel

60 Seconds

• DYN1-10652-000-0-12/24 250 - 1200 Hz

• DYN1-10653-000-0-12/24 1200 - 2500 Hz

• DYN1-10654-000-0-12/24 2500 - 5000 Hz

• DYN1-10656-000-0-12/24 5000 - 9500 Hz

• DYN1-10682-000-0-12/24 250 - 1200 Hz

• DYN1-10683-000-0-12/24 1200 - 2500 Hz

• DYN1-10684-000-0-12/24 2500 - 5000 Hz

• DYN1-10686-000-0-12/24 5000 - 9500 Hz

2.2. DYNA 8000 & DYNA 8000 UL APPROVAL,

HAZARDOUS DUTY, CLASS 1, DIVISION 2, GROUP D

ACTUATOR SPECIFICATIONS

2.2.1 Operating Voltage: 12 VDC or 25 VDC ±20%

2. SPECIFICATIONS

2.1 CONTROLLER SPECIFICATIONS

2.1.1 Operating Voltage: 12 VDC or 24 VDC ±20%

2.1.2 Ambient Operating Temperature:

-40 to +180°F (-40 to +85°C).

2.1.3 Temperature Stability: Better than ±0.5% over a

temperature range of -40 to +167°F (-40 to +75°C).

2.1.4 Steady State Speed Band: ±0.25%

2.1.5 Adjustments: Speed, Gain, Integral, and Droop.

2.1.6 Circuit Boards: Boards are covered with a heavy

conformal coating for moisture and vibration protection.

2.1.7 Connection: Terminal strip.

2.1.8 Mechanical Vibration: Withstands the following vibra-

tion without failure of degraded performance: 0.06 inch double

amplitude at 5 to 18 Hz; 1 G at 18 to 30 Hz; 0.02 inch double

amplitude at 30 to 48 Hz; 2.5 G's at 48 to 70 Hz.

2.1.9 The same DYN1-1065X or DYN1-1068X Series can be

used on a DYNA 8000, DYNA 8200 or DYNA 8400 actuator.

The DYN1-1068X governor control box provides a wider range

of adjustment than the DYN1-1065X. The DYN1-1068X can be

used where maximum performance is desired or for some

engines which are possibly more difficult to control.

2.2.2 Ambient Operating Temperature:

-65 to +255°F (-55 to +125°C).

2.2.3 Sealed Unit: Oil, water and dust tight.

2.2.4 Connection: Terminal strip or "MS" Connector.

2.2.5 Mechanical Vibration: 5 to 500 Hz, Curve F, per

MIL-STD. 810D, Method 514-2.

2.2.6 DYNA 8000 ACTUATORS

Work

Torque

Output

Weight

Current @

12 VDC

Current @

24 VDC

Nominal Response Time for 63% of Stroke

(Seconds)

3

Joules 1.2

Foot-Pounds 0.9

Newton-Meters 1.4

Pound-Foot 1.0

Rotary 35°

Kilograms 5

Pounds 11.0

Maximum Amperes @ Stall 12.5

Nominal Steady State Amperes 3.5

Maximum Amperes @ Stall 9.5

Nominal Steady State Amperes 1.5

0.030

2.2.7 AVAILABLE DYNA 8000 ACTUATOR MODELS

WITH CLOCKWISE OUTPUT SHAFT ROTATION

(Standard Mounted Units)

• DYNC-11020-000-0-12 Standard Clockwise

DYNC-11020-000-0-24 Output Shaft Rotation

2.2.11 AVAILABLE DYNA 8000 HAZARDOUS DUTY

ACTUATOR MODELS WITH CLOCKWISE OUTPUT SHAFT

ROTATION (Standard Mounted Units)

• DYNC-11020-400-0-12 Standard Clockwise

DYNC-11020-400-0-24 Output Shaft Rotation

• DYNC-11021-000-0-12 Actuator Head Positioned 180°

DYNC-11021-000-0-24 from Standard DYNC-11020

• DYNC-11022-000-0-12 Actuator Head Positioned 90°

DYNC-11022-000-0-24 CCW from Standard DYNC-11020

• DYNC-11023-000-0-12 Actuator Head Positioned 90°

DYNC-11023-000-0-24 CW from Standard DYNC-11020

2.2.8 AVAILABLE DYNA 8000 ACTUATOR MODELS

WITH CLOCKWISE OUTPUT SHAFT ROTATION

(Side Mounted Units)

• DYNC-11020-300-0-12 Standard Clockwise

DYNC-11020-300-0-24 Output Shaft Rotation

• DYNC-11021-300-0-12 Actuator Head Positioned 180°

DYNC-11021-300-0-24 from Standard DYNC-11020

• DYNC-11022-300-0-12 Actuator Head Positioned 90°

DYNC-11022-300-0-24 CCW from Standard DYNC-11020

• DYNC-11023-300-0-12 Actuator Head Positioned 90°

DYNC-11023-300-0-24 CW from Standard DYNC-11020

2.2.9 AVAILABLE DYNA 8000 ACTUATOR MODELS

WITH COUNTERCLOCKWISE OUTPUT SHAFT

ROTATION (Standard Mounted Units)

• DYNC-11024-000-0-12 Standard Clockwise

DYNC-11024-000-0-24 Output Shaft Rotation

• DYNC-11025-000-0-12 Actuator Head Positioned 90°

DYNC-11025-000-0-24 CW from Standard DYNC-11024

• DYNC-11026-000-0-12 Actuator Head Positioned 180°

DYNC-11026-000-0-24 CCW from Standard DYNC-11024

• DYNC-11021-400-0-12 Actuator Head Positioned 180°

DYNC-11021-400-0-24 from Standard DYNC-11020

• DYNC-11022-400-0-12 Actuator Head Positioned 90°

DYNC-11022-400-0-24 CCW from Standard DYNC-11020

2.2.12 AVAILABLE DYNA 8000 HAZARDOUS DUTY

ACTUATOR MODELS WITH COUNTERCLOCKWISE

OUTPUT SHAFT ROTATION (Standard Mounted Units)

• DYNC-11024-400-0-12 Standard Clockwise

DYNC-11024-400-0-24 Output Shaft Rotation

• DYNC-11025-400-0-12 Actuator Head Positioned 90°

DYNC-11025-400-0-24 CW from Standard DYNC-11024

• DYNC-11026-400-0-12 Actuator Head Positioned 180°

DYNC-11026-400-0-24 CCW from Standard DYNC-11024

2.2.13 AVAILABLE DYNA 8000 HAZARDOUS DUTY

ACTUATOR MODELS WITH CLOCKWISE OUTPUT SHAFT

ROTATION (Side Mounted Units)

• DYNC-11020-401-0-12 Standard Clockwise

DYNC-11020-401-0-24 Output Shaft Rotation

• DYNC-11021-401-0-12 Actuator Head Positioned 180°

DYNC-11021-401-0-24 from Standard DYNC-11020

• DYNC-11022-401-0-12 Actuator Head Positioned 90°

DYNC-11022-401-0-24 CCW from Standard DYNC-11020

2.2.14 AVAILABLE DYNA 8000 HAZARDOUS DUTY

ACTUATOR MODELS WITH COUNTERCLOCKWISE

OUTPUT SHAFT ROTATION (Side Mounted Units)

• DYNC-11024-401-0-12 Standard Clockwise

DYNC-11024-401-0-24 Output Shaft Rotation

• DYNC-11028-000-0-12 Actuator Head Positioned 90°

DYNC-11028-000-0-24 CCW from Standard DYNC-11024

2.2.10 AVAILABLE DYNA 8000 ACTUATOR MODELS

WITH COUNTERCLOCKWISE OUTPUT SHAFT

ROTATION (Side Mounted Units)

• DYNC-11024-300-0-12 Standard Clockwise

DYNC-11024-300-0-24 Output Shaft Rotation

• DYNC-11025-300-0-12 Actuator Head Positioned 90°

DYNC-11025-300-0-24 CW from Standard DYNC-11024

• DYNC-11026-300-0-12 Actuator Head Positioned 180°

DYNC-11026-300-0-24 CCW from Standard DYNC-11024

• DYNC-11028-300-0-12 Actuator Head Positioned 90°

• DYNC-11028-300-0-24 CCW from Standard DYNC-11024

• DYNC-11025-401-0-12 Actuator Head Positioned 90°

DYNC-11025-401-0-24 CW from Standard DYNC-11024

• DYNC-11026-401-0-12 Actuator Head Positioned 180°

DYNC-11026-401-0-24 CCW from Standard DYNC-11024

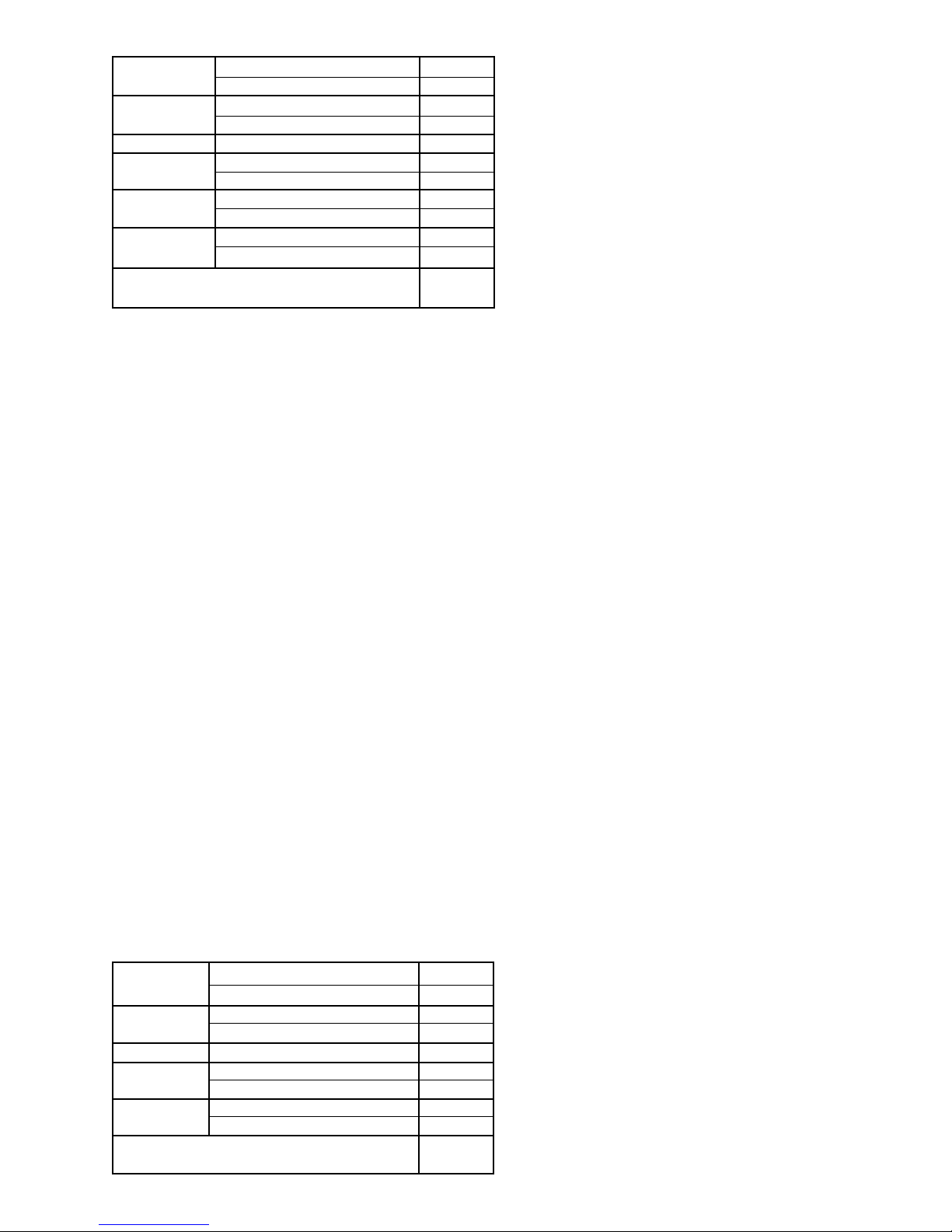

2.3 DYNA 8200 ACTUATORS

2.3.1 Operating Voltage: 12 or 24 VDC ±20%.

2.3.2 Ambient Operating Temperature:

-65 to +255F (-55 to +125°C).

2.3.3 Sealed Unit: Oil, water and dust tight.

2.3.4 Connection: Terminal strip or "MS Connector.

2.3.5 Mechanical Vibration: 5 to 500 Hz, Curve F, per MIL-

STD. 810D, Method 514-2.

4

Work

Torque

Output

Weight

Current@

12 VDC

Current @

24 VDC

Nominal Response Time for 63% of Stroke

(Seconds)

Joules 2.85

Foot-Pounds 2.10

Newton-Meters 4.07

Pound-Foot 3.00

Rotary 45°

Kilograms 8.4

Pounds 18.5

Maximum Amperes @ Stall 14.75

Nominal Steady State Amperes 4.5

Maximum Amperes @ Stall 14.0

Nominal Steady State Amperes 3.5

.138

2.3.6 AVAILABLE DYNA 8200 ACTUATOR MODELS

WITH CLOCKWISE OUTPUT SHAFT ROTATION

• DYNC-12000-000-0-12 Standard Clockwise

DYNC-12000-000-0-24 Output Shaft Rotation

• DYNC-12001-000-0-12 Actuator Head Positioned 180°

DYNC-12001-000-0-24 from Standard DYNC-12000

• DYNC-12002-000-0-12 Actuator Head Positioned 90°

DYNC-12002-000-0-24 CCW from Standard DYNC-12000

• DYNC-12003-000-0-12 Actuator Head Positioned 90°

DYNC-12003-000-0-24 CW from Standard DYNC-12000

2.4 DYNA 8400 & DYNA 8400 UL APPROVAL,

HAZARDOUS DUTY, CLASS 1, DIVISION 2, GROUP D

ACTUATOR SPECIFICATIONS

2.4.1 Operating Voltage: 24 VDC ±20%.

2.4.2 Ambient Operating Temperature:

-65 to +255F (-55 to +125°C).

2.4.3 Sealed Unit: Oil, water and dust tight.

2.4.4 Connection: Terminal strip or "MS Connector.

2.4.5 Mechanical Vibration: 5 to 500 Hz, Curve F, per MIL-

STD. 810D, Method 514-2.

2.4.6 DYNA 8400 ACTUATORS

Work

Torque

Output

Weight

Current @

24 VDC

Nominal Response Time for 63% of Stroke

(Seconds)

Joules 5.8

Foot-Pounds 4.3

Newton-Meters 7.3

Pound-Foot 5.4

Rotary 45°

Kilograms 12.2

Pounds 27

Maximum Amperes @ Stall 13

Nominal Steady State Amperes 2.0

0.104

2.4.7 AVAILABLE DYNA 8400 ACTUATOR MODELS

WITH TERMINAL STRIP CONNECTION

• DYNC-14800-000-0-24 Through Output Shaft Making

Available CW and CCW Output

2.4.8 AVAILABLE DYNA 8400 ACTUATOR MODELS

WITH 2-PIN MS SCREW ON CONNECTOR

• DYNC-14801-000-0-24 Through Output Shaft Making

Available CW and CCW Output

2.4.9 AVAILABLE DYNA 8400 HAZARDOUS DUTY

ACTUATOR WITH TERMINAL STRIP CONNECTION

INSIDE CAST IRON JUNCTION BOX

• DYNC-14800-400-0-24 Through Output Shaft Making

Available CW and CCW Output

3. FUNCTIONAL DESCRIPTION

3.1 ACTUATOR

The actuator consists of an electro-magnet with an iron

armature rolling on the center shaft bearings. The actuator is

provided with a return spring which balances the magnetic

force of the armature. When DC current flows in the coil, the

magnetic force tends to move the armature in the stator and

this linear motion is transformed into rotary motion through a

crank arm that forms part of the output shaft.

3.2 CONTROLLER

The electronic controller is the information processing unit of

the governor assembly. It contains electronic components

which process the input signal from the magnetic pickup and

control the engine to the desired speed/RPM set into the

controller. Electronic adjustments are available on the controller for field adjusting the unit as necessary.

3.3 DC POWER SOURCE

The governor system receives its power from a battery or an

AC to DC power supply supplying 12 or 24 VDC ±20% to

match the governor voltage. The average operating current

consumption is 2.5 to 3.5 amperes and the highest consumption is 14.75 amperes during engine start-up or during a large

load change. The power source must be rated above maximum stall current.

3.4 COMPONENT LOCATION

The actuator of the governor assembly is mounted on the

engine next to the fuel system. The magnetic pickup is

normally mounted in the flywheel housing in such a way that

it can count the teeth on the starter ring gear. The controller is

off-mounted or installed in the engine control panel or cabinet.

5

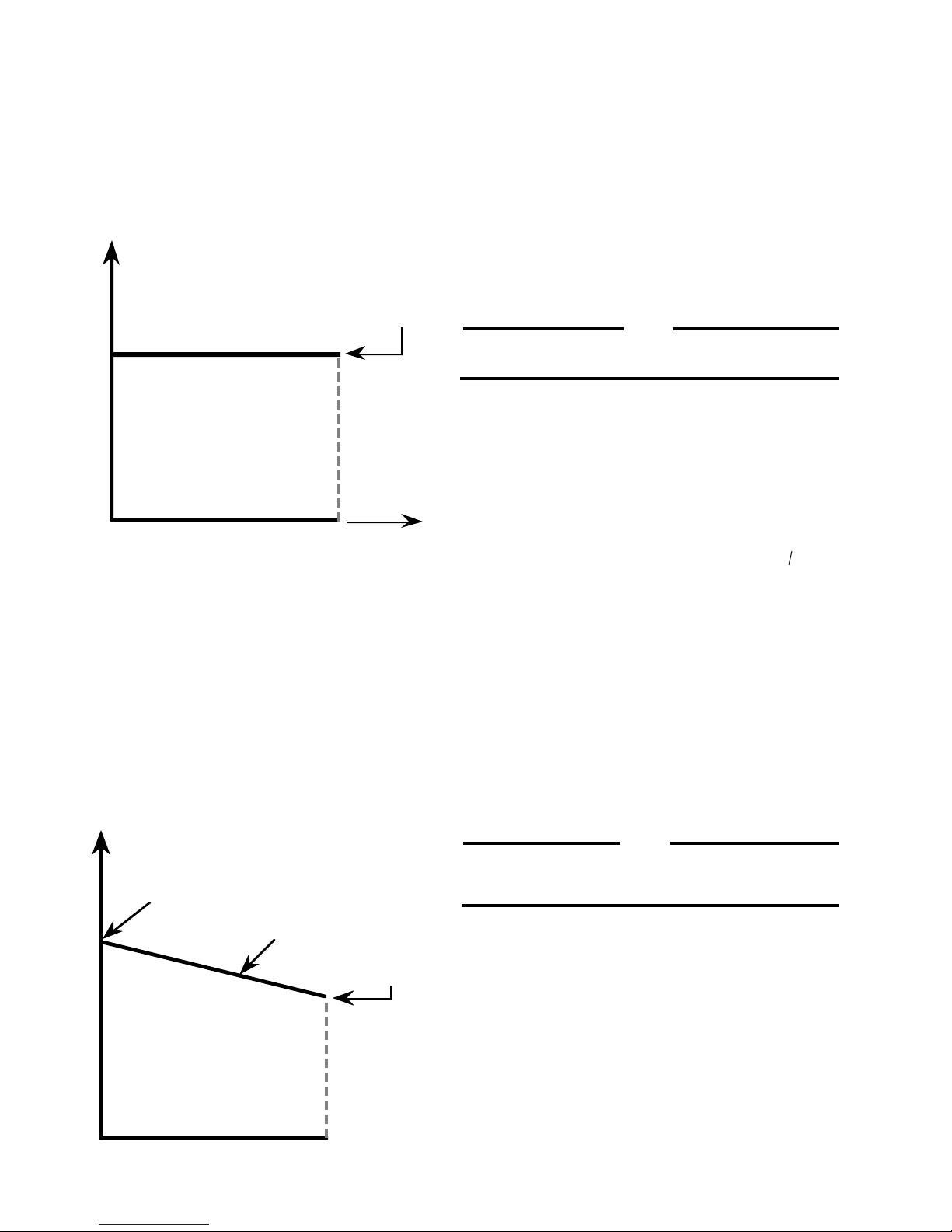

3.5 ISOCHRONOUS OPERATION

3.7 REMOTE SPEED ADJUSTMENT

Isochronous operation is obtained by setting droop potentiometer fully counterclockwise. The DYNA governor is all electric,

and it is normally operated in the isochronous mode; i.e.,

engine RPM is constant (±0.25%) under steady state load

conditions, up to the engine's maximum capability, regardless

of load on the engine.

Desired

Engine RPM

Engine

RPM

Isochronous

Operation Mode

Engine Load

100%

An optional remote speed selector (DYNS-10000) is available

for adjusting engine RPM from up to 90 meters (300 ft.) from the

engine. See the Electrical Wiring Schematic. The potentiometer can be connected for a narrow (fine) or wide speed range

control.

4. INSTALLATION

4.1 PROCEDURE

4.1.1 Mount the actuator on a suitable rigid steel bracket or

plate.

NOTE

Mounting information and kits are usually available for

a particular engine. Contact Sales Representative.

4.1.2 Set up the linkage and rod end bearings (see 4.2).

4.1.3 Install the speed sensor with SAE threads (magnetic

pickup)*.

*Magnetic pickups with metric threads are available.

Thread — M16 x 1.5 — 6 g. Tap Drill Size — 14.5 0 mm.

3.6 DROOP OPERATION

Droop operation is obtained by setting the droop potentiometer. Clockwise increases the droop. The amount of droop for

a given setting depends on the magnetic pickup frequency

and no load to full load actuator shaft rotation. A droop

potentiometer setting of 10 o'clock will give about 4% droop,

no load to full load when the pickup frequency is 4260 Hz and

actuator shaft rotation is approximately 30 degrees from no

load to full load. Lower pickup frequency or smaller shaft

rotation results in less droop for the system.

No Load

Engine RPM

Adjustable

Full Load

Engine RPM

Engine

RPM

4.1.3.1 Remove the inspection cover over the ring gear teeth.

The teeth should be free of burrs, excessive grease or dirt.

4.1.3.2 The magnetic pickup should not be installed in inspection covers. Inspect the ring gear housing and pick a location

where a 37/64" hole can be drilled such that the ring gear teeth

will pass in front of the pickup pole face. After the 37/64" hole

is drilled, use a 5/8-18 starting tap to cut threads for the

magnetic pickup, then run a bottom tap through the hole.

NOTE

The tapped hole should be drilled as nearly perpendicular

as possible over the center of the ring gear teeth.

4.1.3.3 Manually rotate the ring gear until a tooth face is directly

in the center of the tapped hole. Gently turn the magnetic pickup

clockwise into the hole until it bottoms on the tooth, and back off

1/4 turn. Tighten the jam nut firmly, maintaining the 1/4 turn

position.

0%

% of Engine Load

100%

6

Magnetic Pickup

has 5/8-18 Threads

2 Pin Connector

No.MS3106A 10-SL-4S

Gap

.37 ± .127 mm

[.015 ± .005]

Jam Nut

Ring Gear

Speed Sensor

Engine

Housing

INSTALLATION OF MAGNETIC PICKUP

4.1.4 Mount the controller in the control panel.

4.1.5 Connect the wiring as shown in section 4.3 or according to your particular wiring diagram.

4.2 TYPICAL LINKAGE ARRANGEMENTS FOR THE ACTUATOR AND FUEL SYSTEM

4.2.1 ROTARY ACTUATOR TO ROTARY FUEL PUMP

Rod End

Bearing

Max

Fuel

2

Lever

Assembly

Min

Fuel

Max

Fuel

Rod End

Bearing

1

Lever

Assembly

Rod

Fuel

Min

Actuator

Pump

Fuel

4.2.2 ROTARY ACTUATOR TO LINEAR FUEL PUMP

Max

Fuel

2

Rod End

Bearing

Min

Fuel

Choose hole in actuator lever which causes actuator to rotate through its maximum rotation to provide

1

minimum to maximum fuel.

Lever

Assembly

Actuator

1

Rod

Min

Fuel

Rod End

Bearing

Fuel

Pump

Max

Fuel

Non-Linear linkage to actuator is proper for best operation. Provides low GAIN at light loads and high

2

GAIN at heavy loads.

7

4.3 TYPICAL WIRING DIAGRAM & CONTROLLER INSTALLATION DIMENSIONS

DIMENSIONS -- DYNA 8000 CONTROLLER -- DYN1 1065X and DYN1 1068X

Dimensions are in mm except as otherwise noted.

Dimensions in [ ] are in inches.

I

Chassis ground

screw

Wiring Diagram for Controllers

Failsafe

TP1

TP2

5

1

2

+

-

Battery

4

3

Actuator

6

+8V

Chassis

Gnd

Screw

+4V

7

ILS

8

9

External

Speed

Adjust

10

Chassis

Gnd

Screw

Magnetic Pick-up

Cable A -- DYNK-44-XX (specify length) (90° connector)

Cable B -- E26-22 (specify length)

Cable C -- DYNZ-70-4 (specify length) (terminal strip)

Cable C -- DYNK-210 (specify length) (MS connector)

* Shielded cable -- Should be purchased from Barber-Colman or

customer should purchase a cable with a wrapped mylar supported

aluminum foil shield with a drain wire.

** Remote speed potentiometer and 499K ohm resistor is B-C P/N

(DYNS-10000).

11

Blk

Wht

† The 5K remote speed potentiometer can be wired two different ways:

1. As shown by the solid line from the wiper of the 5K potentiometer

and then connected to terminal #9 (no resistor required). Adjustable range is approximately ±5% at 1800 RPM.

2. As shown by the dashed line from the wiper of the 5K potentiometer through resistor R and then connected to terminal #8.

Reducing the value of R increases the remote adjustable speed

range.

8

5. CALIBRATION OF DYNA 8000 SERIES CONTROLLER — DYN1-1065X

Input Signal

Frequency

Part Number

DYN1-10652-000-0-12/24

DYN1-10652-001-0-12/24*

DYN1-10653-000-0-12/24

DYN1-10653-001-0-12/24*

*

5.1 CONNECTION INFORMATION

5.1.1 When using an ILS unit, the remote speed potentiom-

eter may be left connected to the controller as shown.

5.1.2 When an ILS unit is used, connect 3-wire shielded cable

to terminals 6, 7 and 8. Connect drain shield wire to terminal 10

at the controller only. Other end of drain shield wire is to be cut

off and taped.

5.2 CALIBRATION AND ADJUSTMENTS

5.2.1 See diagram on page 8 for a reference guide before

making any adjustments of the potentiometers, DROOP, I,

GAIN and SPEED.

5.2.2 Power OFF - engine not operating.

Maximum

250 to 1200 Hz

]

1200 to 2500 Hz

]

See Step 5.3 for proper procedures for setting switches S1

and S2, if you have a controller that has the two switches

located on top of the controller.

Input Signal

Frequency

Part Number

DYN1-10654-000-0-12/24

DYN1-10654-001-0-12/24*

DYN1-10656-000-0-12/24

DYN1-10656-001-0-12/24*

Maximum

2500 to 5000 Hz

]

5000 to 9000 Hz

]

NOTE

5.2.5 Start the engine.

5.2.5.1 Adjust the controller speed potentiometer until the

engine is operating at the desired engine RPM. Clockwise

increases engine RPM.

5.2.5.2 If the governor system is unstable, slightly reduce the

GAIN setting.

NOTE

Except for the speed adjustment, the potentiometers

have internal stops at the 0 and 100% positions.

5.2.6 With the engine unloaded, finalize the settings, I and

GAIN adjustments as follows:

5.2.3 Initial potentiometer settings:

5.2.3.1 Set the I adjustment three divisions from zero and

the GAIN at the second division from zero.

5.2.3.2 For isochronous operation, set DROOP counterclockwise to minimum position as shown in paragraphs 3.5

and 3.6.

5.2.3.3 For DROOP operation, set DROOP potentiometer

clockwise to obtain desired amount of DROOP from no-load to

full load. Turning potentiometer clockwise increases DROOP.

NOTE

If the full 35° rotation of the actuator shaft is used and

the linkage adjusted to use only the active fuel range,

the maximum obtainable DROOP would be approximately 12% at full load.

5.3.3.4 See step 5.3 for setting switches S1 and S2.

5.2.4 If a remote speed potentiometer is used for narrow

range, set it to mid-range. If the remote speed potentiometer is

connected to terminals 6, 7 and 9, a resistor "R" in the wiper is

not needed. This will provide approximately a ±5% adjustable

speed range.

5.2.6.1 Turn the GAIN adjustment clockwise slowly until the

actuator lever oscillates. (One may need to disturb actuator

lever to cause oscillation.) Reduce the GAIN adjustment slowly

counterclockwise until the lever is stable. Upset the lever by

hand. If the lever oscillates 3 to 5 diminishing oscillations and

stops, the setting is correct.

If system performance to load changes is satisfactory, omit step

5.2.6.2.

5.2.6.2 Reduce the GAIN setting counterclockwise one division. Next, turn the I adjustment fully clockwise while observing

the actuator lever. If the lever does not become unstable, upset

it by hand. When the lever slowly oscillates, turn the adjustment

counterclockwise slowly until the lever is stable. Upset the lever

again; it should oscillate 3 to 5 times and then become stable

for optimum response.

NOTE

Use the settings of step 5.2.6.1 or step 5.2.6.2,

whichever provides the best performance.

5.2.6.3 Unit is now calibrated.

9

5.3 ALL CONTROLLERS WITH REVISION J AND ABOVE

HAVE SWITCHES S1 AND S2

5.5 PROPER PROCEDURES FOR SETTING SWITCHES S1

AND S2

These units have two new features now added to the DYN1

1065X series controllers. They are:

5.3.1 Two response ranges, for matching either the diesel or

gas engine dynamics.

• Set S1 to the OFF position for diesel engine applications.

• Set S1 to the ON position for gas/gasoline engine

applications.

5.3.2 Two actuator selections, so the same controller can be

used on the DYNA 8000, DYNA 8200 or DYNA 8400 actuator.*

• Set S2 to the OFF position when using a DYNA 8000

actuator.

• Set S2 to the ON position when using a DYNA 8200 or DYNA

8400 actuator.

5.4. GENERAL INFORMATION ON S1 AND S2

• Switch S1 selects one of two integrating rate ranges. The

diesel version integrates at twice the rate of the gas version

• Switch S2 selects the point at which actuator coil current

level causes the integrator limit to be actuated. This level

is nominally 6.3 amperes for the DYNA 8000 and 7.3 amperes for the DYNA 8200 and 8400 actuator.

Question: How do I know if the switches in the dual-in-line

packages are correctly set as far as being in the OFF position

or the ON position?

Top View

O

N

O

F

F

ON OFF

Side View

"On"

OFFON

Side View

"Off"

S1 S2

Answer: The drawings above should clarify any confusion

about switch settings. The easiest way to set the switches is to

apply pressure with a small pointed object until the switch clicks

into position.

CAUTION

As a safety measure, the engine should be equipped with

an independent overspeed shutdown device in the event

of failure which may render the governor inoperative.

* DYNA 8000 -- DYNC 11020 Series

DYNA 8200 -- DYNC 12000 Series

DYNA 8400 -- DYNC 14800 Series

These actuators do not have a potentiometer feedback

transducer.

NOTE

For some diesel engines, better operation may be

obtained by placing SW1 in "ON" position. If

difficulty is experienced in "OFF" position, try SW1

ON and recalibrate.

10

6. CALIBRATION PROCEDURE FOR 8000 GOVERNOR CONTROLLER —

DYN1-10682, 10683, 10684, 10686

Input Signal

Frequency

Part Number

DYN1-10682-000-0-12/24

DYN1-10682-001-0-12/24*

DYN1-10683-000-0-12/24

DYN1-10683-001-0-12/24*

*

6.1 CALIBRATION PROCEDURE

6.1.1 Observe that potentiometer settings are adjustable from

zero to 100%. Each small division is 10%. The speed potentiometer is 10K, 20 turn.

6.1.2 Set the small dip switch, S1, for the correct engine. (See

paragraph 6.4) Set switch S2 in the "OFF" position for actuator

DYNA 8000 or in the "ON" position for DYNA 8200 and 8400.

6.1.3 If a remote speed potentiometer is used for narrow

range, set to mid range.

6.2 INITIAL POTENTIOMETER SETTINGS

GAIN 20%

I 20%

D 30%

DROOP Zero

6.2.1 For isochronous operation, set DROOP counterclock-

wise to minimum position as shown in paragraphs 3.5 and 3.6.

6.2.2 For DROOP operation, set DROOP potentiometer clock-

wise to obtain desired amount of DROOP from no-load to full

load. Turning potentiometer clockwise increases DROOP.

Maximum

250 to 1200 Hz

]

1200 to 2500 Hz

]

See Step 6.4 for proper procedures for setting switches S1

and S2, if you have a controller that has the two switches

located on top of the controller.

Input Signal

Frequency

Part Number

DYN1-10684-000-0-12/24

DYN1-10684-001-0-12/24*

DYN1-10686-000-0-12/24

DYN1-10686-001-0-12/24*

Maximum

2500 to 5000 Hz

]

5000 to 9000 Hz

]

NOTE

6.3.5 After calibration, it may be necessary to readjust the

speed.

6.3.6 Following the above calibration, conduct the following

test. With the engine operating at rated speed, turn the electric

governor off. When engine speed slows to approximately half

of rated speed, turn the electric governor back on. Observe the

overshoot. If there is a small hunt at steady state, slightly turn

the "I" potentiometer counterclockwise until stable. In some

cases, 2 to 3 Hz overshoot may be acceptable.

WARNING

For gas engines, make certain that method used

does not put gas in exhaust which might result in

an explosion.

If possible, operate the unit through various load ranges up to

100% to ensure stability.

6.4 CONTROLLERS HAVE SWITCHES S1 AND S2

These units have two new features now added to the DYN1

1068X series controllers. They are:

6.4.1 Two response ranges for matching either the diesel or

gas engine dynamics.

6.3 START ENGINE (NO LOAD)

6.3.1 Adjust the controller speed potentiometer for desired

engine speed.

6.3.2 Adjust the GAIN potentiometer clockwise until the en-

gine begins to hunt. (If the engine remains stable at 100%

GAIN, physically disrupt the actuator linkage by hand.) With

the engine hunting, turn the GAIN potentiometer counterclockwise until stable.

6.3.3 Repeat step 6.3.2 for the "D" setting.

6.3.4 Repeat step 6.3.2 for the "I" setting.

• Set S1 to the OFF position for diesel engine applications.

• Set S1 to the ON position for gas/gasoline engine

applications.

6.4.2 Two actuator selections, so the same controller can be

used on the DYNA 8000, DYNA 8200 or DYNA 8400 actuator.*

• Set S2 to the OFF position when using a DYNA 8000

actuator.

• Set S2 to the ON position when using a DYNA 8200 or DYNA

8400 actuator.

11

6.5 GENERAL INFORMATION ON S1 AND S2

• Switch S1 selects one of two integrating rate ranges. The

diesel version integrates at twice the rate of the gas version.

• Switch S2 selects the point at which actuator coil current

level causes the integrator limit to be actuated. This level is

nominally 6.3 amperes for the DYNA 8000 and 7.3 amperes

for the DYNA 8200 and 8400 actuator.

6.6 PROPER PROCEDURES FOR SETTING SWITCHES S1

AND S2

Question: How do I know if the switches in the dual-in-line

packages are correctly set as far as being in the OFF position

or the ON position?

Top View

O

N

O

F

F

S1 S2

ON OFF

Side View

"On"

OFFON

Side View

"Off"

Answer: The drawings above should clarify any confusion

about switch settings. The easiest way to set the switches is to

apply pressure with a small pointed object until the switch

clicks into position.

* DYNA 8000 -- DYNC 11020 Series

DYNA 8200 -- DYNC 12000 Series

DYNA 8400 -- DYNC 14800 Series

These actuators do not have a potentiometer feedback

transducer.

NOTE

A warm engine is normally more stable than a cold one. If the

governor is adjusted on a warm engine, turn the adjustment

potentiometers counterclockwise 5% (1/2 div.) to ensure a

stable engine when started cold.

CAUTION

As a safety measure, the engine should be equipped with an

independent overspeed shutdown device in the event of failure

which may render the governor inoperative.

12

7. DYNA 8000 SERIES TROUBLESHOOTING CHART

7.1 PROBLEM: GOVERNOR IS COMPLETELY DEAD AND ACTUATOR LEVER STAYS AT MINIMUM POSITION

WHEN POWER IS APPLIED TO GOVERNOR.

Means of Detection

7.1.1 Check battery voltage at terminals 1 and 2 on

controller. Terminal 1 is positive.

7.1.2 Check for proper linkage setup.

7.1.3 Magnetic pickup signal absent or too low.

Measure AC voltage across terminals 10 and 11

while cranking the engine. Voltage should be

min. 2.5 VAC. Note: The voltmeter should have

an impedance of 5000 ohms/volts or higher.

7.1.4 Measure the resistance of the magnetic pickup

coil. This should be above 150 ohms.

7.1.5 Measure the resistance of each pin to the metal

case of the magnetic pickup. No continuity

should be evident.

7.1.6 DC SUPPLY OFF. Place an insulated jumper

between terminals 2 and 3 (TP1 & TP2). With DC

ON, the actuator should go to full stroke. DC

voltage at terminals 4 and 5 should be within 3

volts of the supply.

7.1.7 Measure actuator coil resistance:

Corrective Action

Check battery connections and contacts for turning power

ON to the controller.

Correct and free linkage.

Check pole tip gap over gear tooth. Should be

.037 mm ±0.127 mm (0.015" ±0.005").

If there is an open or shorted coil, replace the magnetic

pickup.

If there is continuity to case, replace the magnetic pickup.

If the actuator still does not move to full stroke, continue

with steps below.

If actuator coil is open or shorted to case, replace actuator.

DYNA 8000

12 VDC unit. Coil resistance 0.75 ±0.2 ohms.

24 VDC unit. Coil resistance 2.3 ±0.4 ohms.

DYNA 8200

12 VDC unit. Coil resistance .710 ±0.2 ohms.

24 VDC unit. Coil resistance 1.600 ±0.4 ohms.

DYNA 8400

24 VDC unit. Coil resistance 1.630 ±0.4 ohms.

7.1.8 Measuring the resistance of each coil lead to

the actuator case should indicate an open circuit

on a low scale of the ohm meter.

7.1.9 With the DC to the governor ON and the engine

OFF, measure the DC voltage from terminal 6 (+)

to terminal 2 (-). This should be approx. 8 VDC.

7.1.10 Between terminal 7 (+) to terminal 2 (-), the

voltage should be approx. 4 VDC.

If governor still does not operate, continue with steps below.

If continuity is detected, replace the actuator.

If 8 VDC is not present, replace the controller.

If 4 VDC is not present, replace the controller.

13

7.2 PROBLEM: ACTUATOR GOES TO FULL STROKE WHEN DC POWER IS TURNED ON

(ENGINE IS NOT OPERATING).

Means of Detection Corrective Action

7.2.1 Check magnetic pickup leads for proper

Verify and correct wiring as necessary.

shielded wire or open shield.

7.2.2 Be sure there is no jumper between terminals

Verify and correct wiring as necessary.

2 and 3.

7.2.3 Failsafe circuit in the controller may be

Replace controller.

damaged or defective.

7.2.4 With DC power OFF remove leads at actuator.

If continuity is detected, replace the controller.

Check continuity of each terminal to case.

There should be no continuity between any

terminal and case of the controller.

7.2.5 If remote speed potentiometer has been

connected to terminals 6, 7 and 9 of the

Turn DC power ON to the governor if the actuator is now

normal. Proceed to step 7.3.1.

controller, DISCONNECT THESE LEADS.

7.3 PROBLEM: IMPROPER OPERATION FROM REMOTE SPEED POTENTIOMETER

Means of Detection

7.3.1 Investigate wiring to remote speed

Check wiring.

Corrective Action

potentiometer for open or shorted circuits.

7.3.2 If the leads at terminals 6 and 7 to the remote

Correct wiring.

speed potentiometer are reversed, speed

control by the remote speed potentiometer

will be reversed.

7.3.3 Lead wire to remote speed setting potentiometer

should be 3-wire shielded cable.

7.3.4 If terminal 7 lead to the remote speed

potentiometer is open, engine speed will go high.

7.3.5 If lead 9 (wiper lead to remote potentiometer) is

open, there will be no control by the remote

speed potentiometer.

7.3.6 If lead 6 to the clockwise terminal of the remote

speed potentiometer is open, speed will remain

at the value set in the controller.

7.4 PROBLEM: ERRATIC GOVERNOR OPERATION

Means of Detection

7.4.1 Measure DC voltage at 1 and 2 on controller

terminal strip. Normal battery voltage should

be indicated.

7.4.2 Low battery voltage 20% below rated can

cause erratic operation.

7.4.3 RFI noise due to incorrect shielding.

Verify that the drain shield wire is isolated from ground

at the potentiometer.

Correct the wiring.

Verify and correct wiring.

Corrective Action

If nominal voltage is present, wiring is correct.

Check battery and charging system.

Correct wiring.

7.4.4 RFI noise fed through power supply leads.

Connect power leads directly to the battery.

14

7.5 PROBLEM: SLOW, SMALL AMPLITUDE HUNTING OF SPEED OR FREQUENCY

Means of Detection

7.5.1 Sticking or very loose linkage.

7.6 PROBLEM: FAST OSCILLATION OF GOVERNOR LINKAGE

Means of Detection

7.6.1 Verify calibration settings of the controller.

7.7 PROBLEM: ENGINE WILL NOT START -- ACTUATOR GOES TO FULL FUEL DURING CRANKING

Means of Detection Corrective Action

7.7.1 Make sure fuel is available.

7.7.2 Air may be trapped in fuel line.

7.7.3 Try to operate engine manually.

Correct Linkage.

Readjust settings as necessary.

Check fuel to engine. Check for correct wiring to the

automatic shutdown circuits.

Check fuel lines for leaks.

Corrective Action

Corrective Action

8. ACTUATOR INSTALLATION DIMENSIONS

DYNC-11020-000

STANDARD

ACTUATOR —

CLOCKWISE

ROTATION

DYNC-11020-300

SIDE MOUNTED

ACTUATOR —

CLOCKWISE

ROTATION

15

DYNC-11024-000

ACTUATOR —

COUNTERCLOCKWISE

ROTATION

DYNC-11024-300

SIDE MOUNTED

ACTUATOR —

COUNTERCLOCKWISE

ROTATION

DYNC-12000-000

16

DYNC-14800-000

TERMINAL STRIP CONNECTION

DYNC-14801-000

2-PIN MS CONNECTOR CONNECTION

DYNC-11020-401

UL APPROVAL, HAZARDOUS DUTY, CLASS 1, DIVISION 2, GROUP D

CLOCKWISE UNIT

17

DYNC-11024-400

UL APPROVAL, HAZARDOUS DUTY, CLASS 1, DIVISION 2, GROUP D

COUNTERCLOCKWISE UNIT

DYNC-14800-400

UL APPROVAL, HAZARDOUS DUTY, CLASS 1, DIVISION 2, GROUP D

Barber-Colman DYNA Products

1354 Clifford Avenue (Zip 61111) Telephone (815) 637-3000

P.O. Box 2940 Facsimile (815) 877-0150

Loves Park, IL 61132-2940 www.dynaproducts.com

United States of America

In Europe contact: Barber-Colman GmbH

Am Neuen Rheinhafen 4, D-67346 Speyer, Germany

Telephone (49) 6232 29903, Facsimile (49) 6232 299155

In Japan contact: Ranco Japan Ltd.

Shiozaki Bldg. 7-1, 2-chome, Hirakawa-Cho, Chiyoda-Ku

Tokyo 102, Japan

Telephone (81) 3 3261 4293, Facsimile (81) 3 3264 4691

An Invensys company

F-23721-5

Loading...

Loading...