Page 1

*

Zone Pressure Sensors (ZPS) - BACK MOUNT

Installation and Operation Instructions

18646_Ins_ZPS_BB_BM

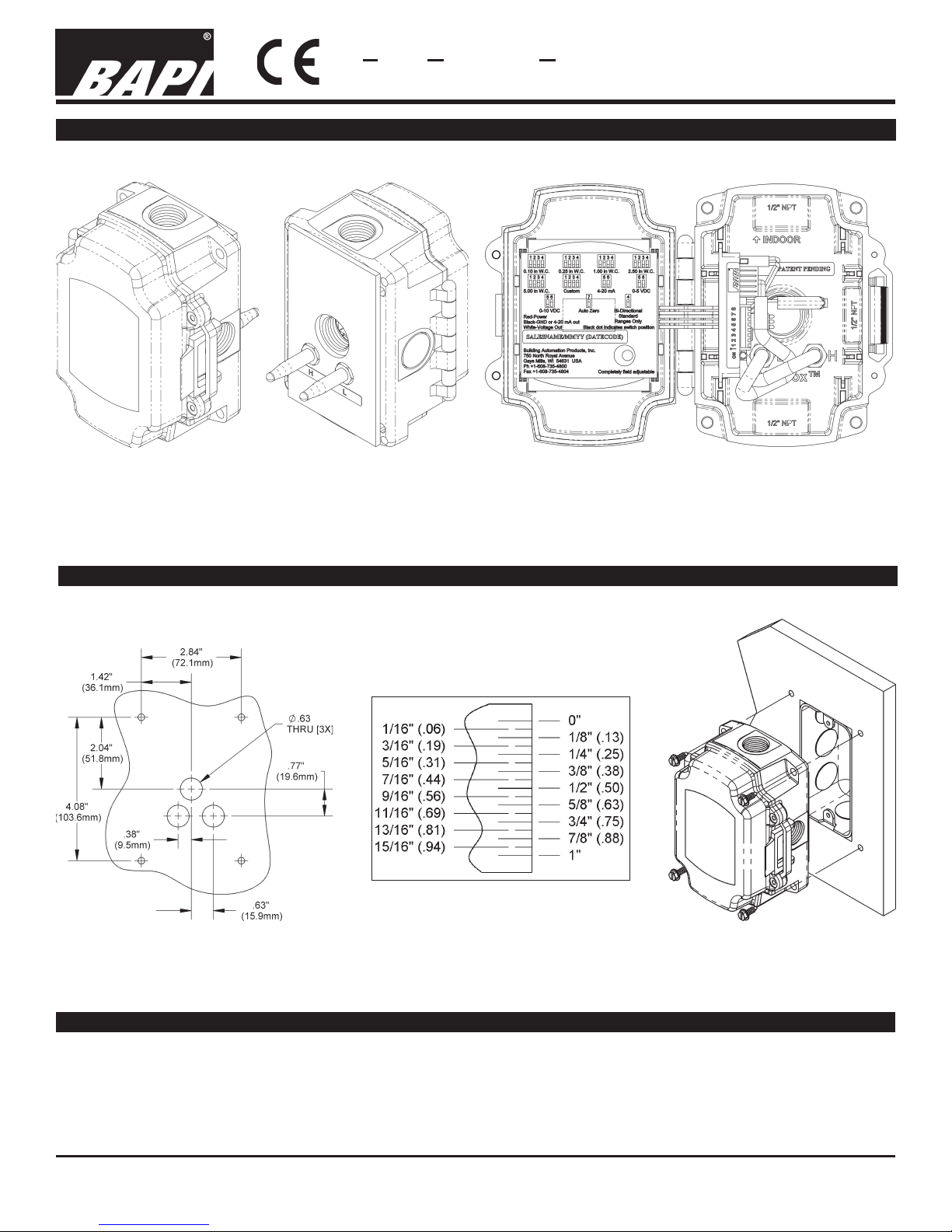

Product Identification

Fig. 1

Non-Display ZPS in a

BAPI-BoxBack Mount

Fig. 2

Rear Vew of ZPS in a

BAPI-Box Back Mount

4/6/07rev.

Fig. 3

Display ZPS in a BAPI-Box

Back Mount, Cover Open

Mounting

Mount the unit to its mounting surface with four #10 screws through the holes in the mounting feet. The preferred mounting orientation is with the pressure ports facing down.

Fig 4 Mounting Hole Pattern

Note: BAPI recommends using #10

screws that require 5/32" pilot holes.

Tools & Material List

Fig. 5 Mounting over a 2x4 Junction Box

Screwdriver #10 Screws Sealant Filled Connectors

Drill with 5/32” bit Wire

Building Automation Products, Inc., 750 North Royal Avenue, Gays Mills, WI 54631 USA

Tel:+1-608-735-4800 • Fax+1-608-735-4804 • E-mail:sales@bapihvac.com • Web:www.bapihvac.com

Specifications subject to change without notice.

1 of 3

Page 2

Zone Pressure Sensors (ZPS) - BACK MOUNT

Installation and Operation Instructions

18646_Ins_ZPS_BB_BM

Output Termination

4/6/07rev.

Desired Output Wire connections

4 to 20 mA Red (V+); Black (Return{4 to 20 mA Signal}); White (Not used)

0 to 5 V or 0 to 10 V Red (V+); Black (Ground); White (Output Voltage)

4 to 20 mA is “two wire” operation, the ZPS’s red wire connects to a positive direct current voltage of 7 to 45 VDC,

the ZPS’s black wire becomes the return of the 4 to 20 mA signal and the ZPS’s white wire, while unused, must be

insulated from accidental contact with ground or any other potential. For 4 to 20 mA signaling only direct current can

be used to power the ZPS.

0 to 5 V or 0 to 10 V is “three wire” operation, the ZPS’s red wire connects to either 7 to 45 VDC or 7 to 32 VAC (0-5

VDC output) or 13 to 45 VDC or 13 to 32 VAC (0-10 VDC output), the ZPS’s black wire is connected to ground and

the ZPS’s white wire is connected to an analog input of the controller. BAPI insulates the white wire in the factory

before shipping to you, please remove the connector and strip the insulation from the white wire as desired.

To ensure that all wires are properly terminated, twist the stripped ends of each circuit together before inserting into

the splice terminals. Gently tug on the wire after terminating to make sure of a good connection. If the wire comes

out of the termination repeat the splice procedure.

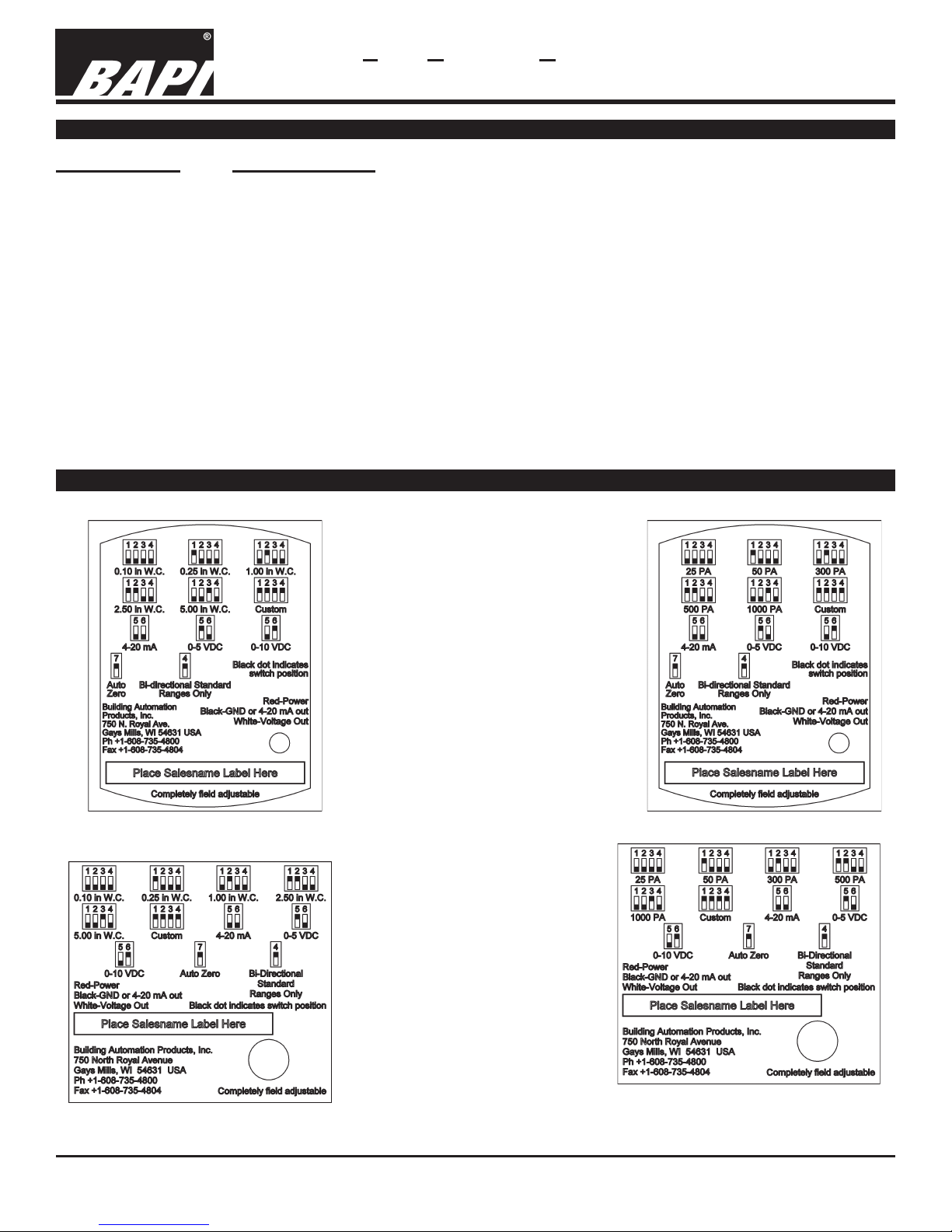

Dip Switch Settings - Inches, Pascals, Display and No Display

Figure 6:

DIP Switch Settings,

ZPS with No Display,

Inches W.C.

Figure 8:

DIP Switch Settings,

ZPS with Display,

Inches W.C.

DIP Switch Settings,

Figure 7:

DIP Switch Settings,

ZPS with No Display ,

Pascals

Figure 9:

ZPS with Display ,

Pascals

Building Automation Products, Inc., 750 North Royal Avenue, Gays Mills, WI 54631 USA

Tel:+1-608-735-4800 • Fax+1-608-735-4804 • E-mail:sales@bapihvac.com • Web:www.bapihvac.com

Specifications subject to change without notice.

2 of 3

Page 3

Zone Pressure Sensors (ZPS) - BACK MOUNT

Installation and Operation Instructions

18646_Ins_ZPS_BB_BM

Pressure Range Select

4/6/07rev.

To adjust the pressure range, set dip switches 1-4 to the desired pressure range using the the label found inside the

cover of the ZPS unit (or shown on this pg 2). Moving the Bi-Directional dip switch (#4) to the up position doubles

the pressure range. For example, the 0 to .25” W.C. range becomes -.25” to .25” W.C. if the Bi-Directional dip

switch is in the up position.

Note: If any of the switches are placed in an undefined combination the LED will fast blink and the output will be forced

to 4mA or zero volts.

Output Range Select

To adjust the output range, set dip switches 5 & 6 to the desired output range using the the label found inside the

cover of the ZPS unit (or shown on pg 2).

Note: If any of the switches are placed in an undefined combination the LED will fast blink and the output will be forced

to 4mA or zero volts.

Auto-Zero Select

To auto zero the BAPI ZPS, remove the tubing

from the pressure ports (to remove the normal

pressure source). Make sure that the pressure ports are sheltered from any drafts,

including the technician’s breath. Ideally the

two ports should be connected together with a

short piece of tubing. Turning on switch 7

starts the auto-zero process. Switches 1 through 6 may be in any allowed

configuration. The LED will blink at a fast rate and the output will be

forced to zero (4mA or 0V) while the auto-zero is being performed. When

Before

auto-zero

Fig. 10 Auto-Zero

During

auto-zero

After

auto-

zero

the LED blinks at a slow rate, turn off switch 7 and reconnect the pressure

source.

Switch 8

Switch 8 is reserved for Factory use, leave in the off position.

Diagnostics

PROBLEMS:

LED does not light

LED is blinking fast

(1/2 second on, 1/2 second off)

Output stuck (high or low)

Output not tracking pressure properly

LED Operation

POSSIBLE SOLUTIONS:

- Check power connections for proper power

- The unit may be performing an auto-zero. Wait 10 seconds and check again.

- The dip switches are in an unsupported configuration, check the dip switch

settings, both pressure and output, and change them to ranges desired

- Remove pressure from ports and perform auto-zero procedure

- Check dip switches for proper pressure range selection

- Check dip switches for proper output range selection

LED off No Power

LED Blinking 1/2 sec on, 1/2 sec off Auto-zero or dip switch in undefined configuration

LED on Normal operation

LED Blinking 1/2 sec on, 4 sec off Auto-zero complete

Building Automation Products, Inc., 750 North Royal Avenue, Gays Mills, WI 54631 USA

Tel:+1-608-735-4800 • Fax+1-608-735-4804 • E-mail:sales@bapihvac.com • Web:www.bapihvac.com

Specifications subject to change without notice.

3 of 3

Loading...

Loading...