Page 1

Wireless Thermobuffer Temperature Transmitter 418 MHz

Installation & Operating Instructions

20414_ins_wireless_thermobuffer

Overview

The BAPI Wireless Thermobuffer Temperature Transmitter measures the temperature of a refrigerator or freezer and

transmits the data through 418MHz RF to a receiver. The transmitter is mounted in a BAPI-Box style enclosure and

has a usable range of 100 feet. The added mass of the Thermo Buffer, lled with a water-glycol solution, alcohol or

mineral oil, approximates the temperature at the center of a small box on the freezer’

s shelf.

The transmit rate is approximately once every 20 seconds with an estimated battery life of 5 to 8 years using two

high-capacity 3.6V lithium batteries. Each transmitter has a unique address with built in error detection. Each

variable sent by the transmitter is picked up by the receiver and converted by a BAPI Analog Output Module to a

voltage, current or resistance signal which is sent to the controller.

A point manager may be used to collect the

temperature data for large systems.

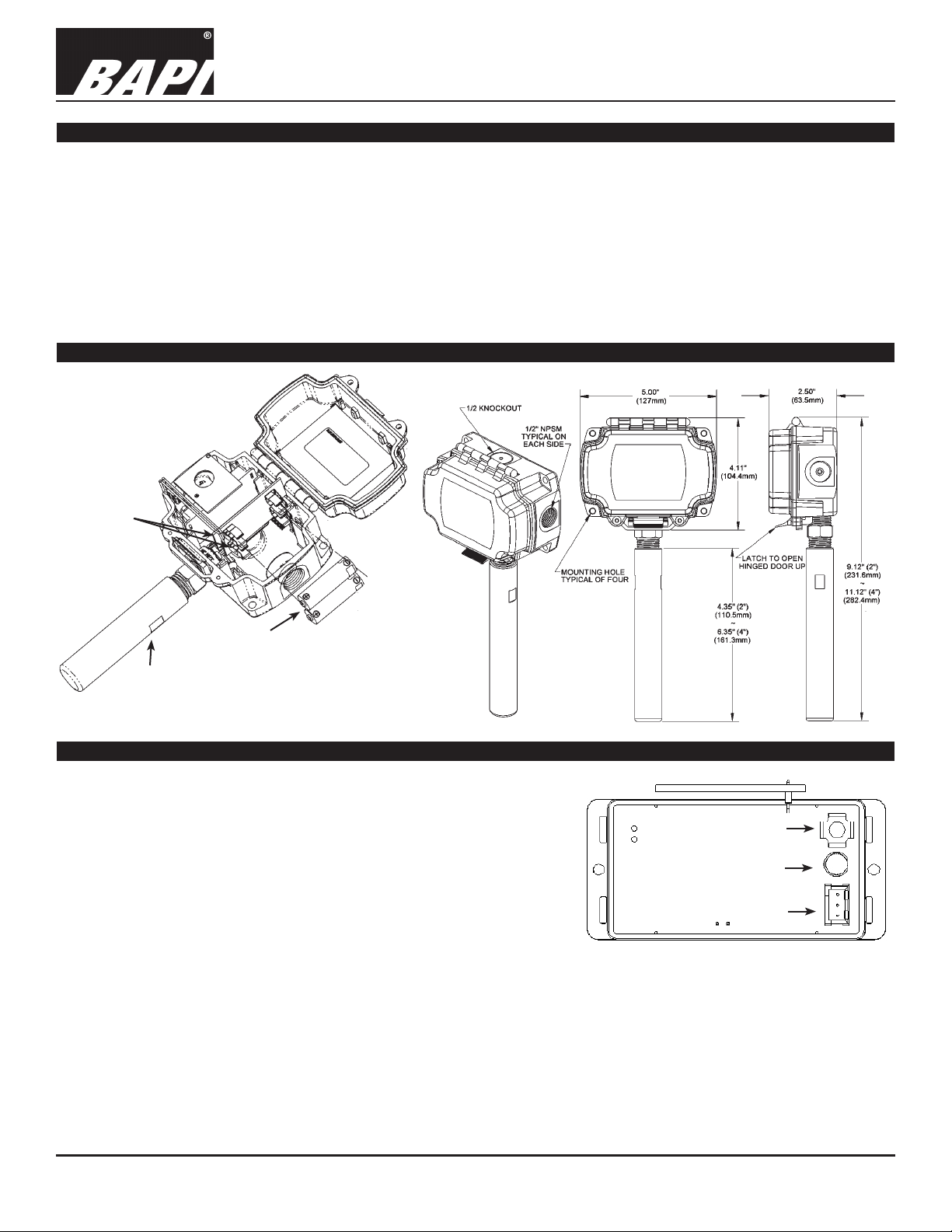

Product Identication

Two

Battery

Tabs

rev. 04/21/15

Battery Polarity Is Important!

Antenna

Fig 1: Wireless Thermobuffer Temperature Sensors

Analog Output Module Training

Note: It is best to perform this procedure before mounting the transmitters.

1. Pick the transmitter and analog output module that you want to train to

one another. Connect the output module to the receiver.

Training Button

2. Apply power to the receiver and output module.

3. The power LED on the Receiver should light and remain lit. The

Transmitter LED

powered analog output module’s LED should ash and go out. (The

ash is very quick.)

Battery Connector

4. Open the cover of the transmitter and remove battery tabs or install the

batteries, observe polarity (Figure 1). The transmitter LED, next to the

Fig 2: Transmitter Module

Transmitter Training Button in Figure 4, should ash approximately once

every 20 seconds. (The ash is very quick.)

5. Press and hold the plastic service button on the top of the Output Module, at the same time press for one second and

release the training button on the transmitter module. When the LED on the analog output module lights, release

its button (The LED will go out when you release the button). The output module will now report the environmental

conditions from the transmitter trained to it. The output module’s LED will quickly ash whenever it receives an update

from the transmitter.

6. Close the cover and mount the transmitter at the desired location. If needed, remove the batteries to do so. The units

will remain trained to one another through power failures and battery replacement.

Specications subject to change without notice.

1 of 2

Page 2

Wireless Thermobuffer Temperature Transmitter 418 MHz

Installation & Operating Instructions

20414_ins_wireless_thermobuffer

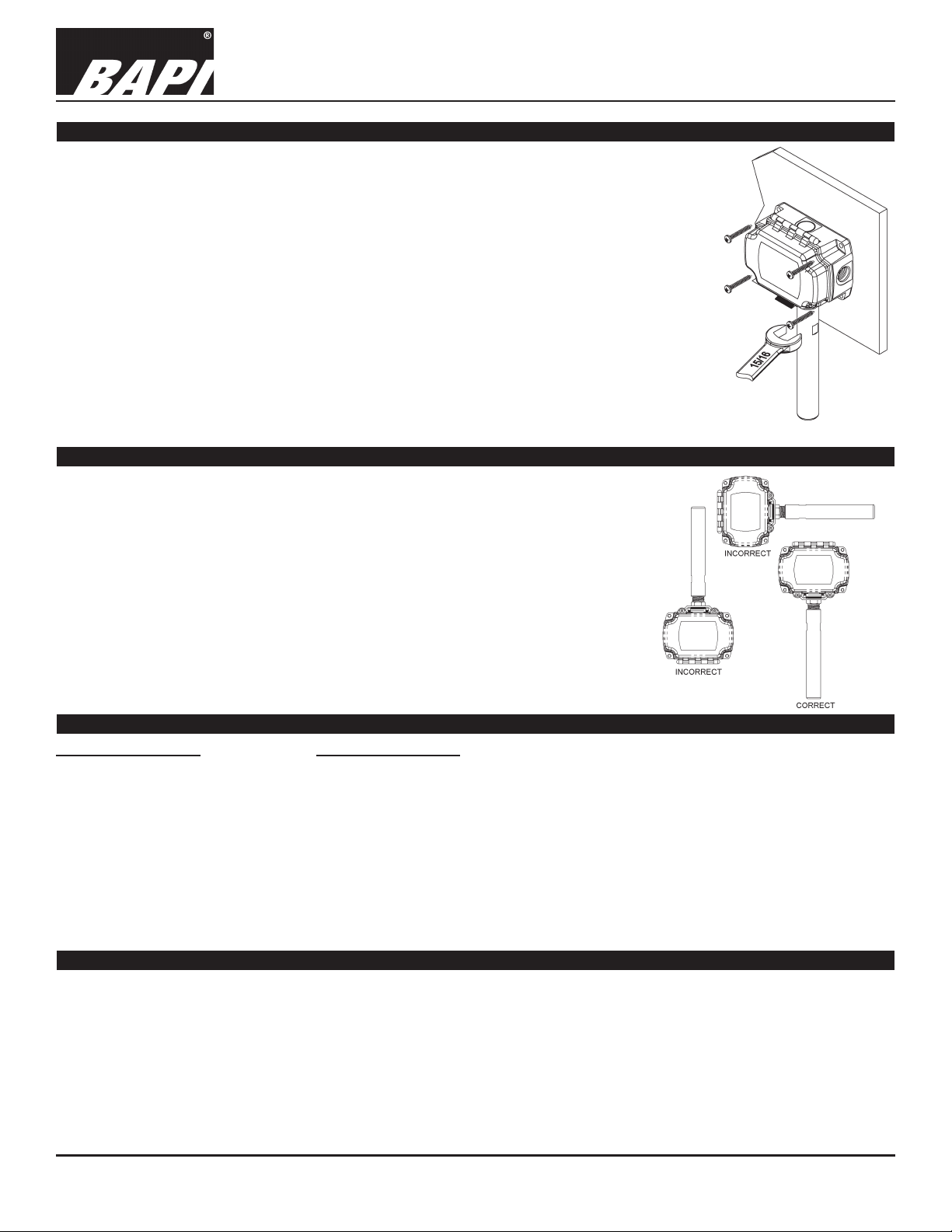

Assembly

First train the modules as described on the previous page.

There are two sizes of Thermobuffers, a 2-inch and 4-inch. The recommended amounts of

Glycol, alcohol or mineral oil are as follows:

The two inch buffer requires 30 CC

The four inch buffer requires 40 CC.

Use a glycol deemed food safe such as Cool Flow FG. Be sure that the glycol solution is

mixed for a temperature below the lowest expected freezer temperature.

Wrap the threads on the sensor with Teon tape. Use food safe silicone if desired to make

a good liquid tight seal. Do not use pipe dope as it is not food safe.

After lling the thermobuffer with the appropriate amount of glycol, thread the buffer onto

the probe by rst threading it onto the ½” NPT threads until it is snug. It should not leak.

Use a 15/16” (24mm) wrench to tighten.

Do not use a channel locks or pliers as it may leave marks in the material that may allow for

bacteria growth.

Mounting

Mount the unit to its mounting surface with four #10 screws through the holes in

the mounting feet. #10 sheet metal screws require 5/32” (4mm) pilot holes. For

concrete or cinder block, drill four 5/32” (4mm) holes, 1-3/4 inch (45mm) deep.

Make sure that all screws are started in their holes before tightening. Tighten

evenly. Only squeeze the foam gasket to about 1/2 of its original thickness.

rev. 04/21/15

Fig 3:

Assembly

BAPI recommends BA/Screw-Pan-1.5x10-SS-100 and BA/Anchor-10-100

for drywall and BA/ScrewHexConcrete1.5x10SS100 for concrete

Diagnostics

Possible Problems: Possible Solutions:

Temperature reading is incorrect Check wire from output modules to controller for proper connections and polarities.

Check to see if the controller’s software is congured properly.

Check power to the receiver and output module.

Check transmitter to see if its LED ashes about once every 20 seconds. If not

replace the batteries. If the transmitter LED ashes but the output module does not

ash, retrain the transmitter and output module to each other.

Temperature reading is coming

out the wrong output module Retrain the transmitter and output module to each other..

Mounting

Supply Power: Two 3.6V Lithium batteries. (5 to 8 year battery

life at 20 second transmit rate)

Inputs: Replaceable Temperature/Relative Humidity Sensor

Accuracy: ±0.3 °C

Transmitted Range: -40° to 85°C

FCC Approval: FCC ID# T4F06811RH

Antenna: Built inside the enclosure

Environmental Operation Range:

Temp: -22°F to 158°F (-30°C to 70°C)

Humidity: 0% to 100% RH, Non-condensing

Material: ABS Plastic

Material Rating: UL94 V-0

Radio Frequency: 418 MHz

Transmitter Interval: ~20 seconds

Specications subject to change without notice.

2 of 2

Loading...

Loading...