Page 1

Water Leak Detector

BA/LDT Accessories

Termination and Troubleshooting

26268_ins_LDT

Overview & Identication

The Water Leak Detector is designed to sense the presence of water and alert a central monitoring system of the

potentially destructive situation. Upon water detection, an alarm relay changes state, and a local red LED illuminates.

The transmitter can be set for latching alarm or non-latching alarm with normally energized or de-energized operation.

An optional remote water sensor is available for small inaccessible locations such as AHU pans or under oor water

detection.

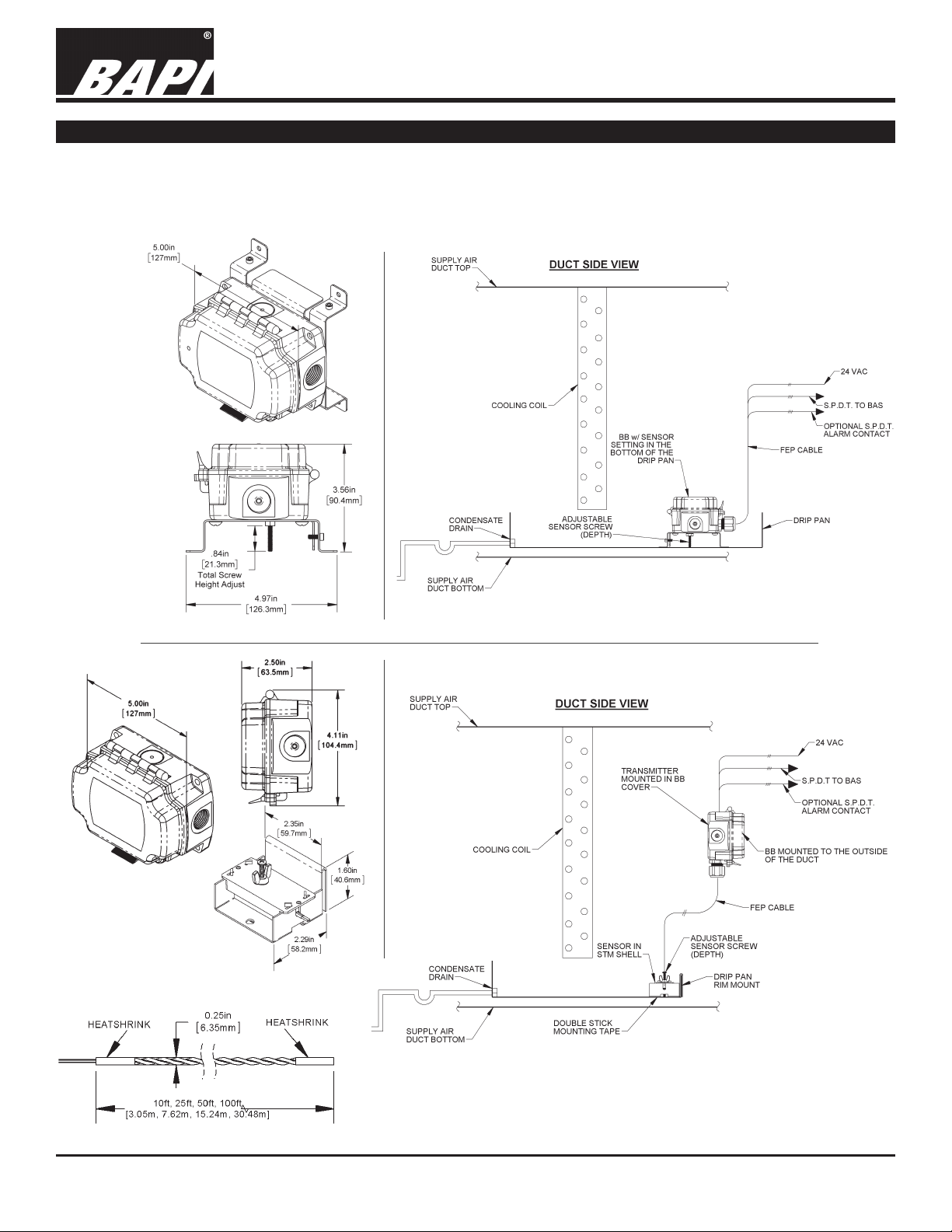

Fig. 1:

Water Leak

Detector

with Internal

Sensor Probe

rev. 11/16/18

Fig. 3:

Water Leak Detector

with Remote Spot

Sensor (right) and Water

Rope Sensor (below)

Fig. 2:

Water Leak Detector with Built In Sensor and a

5 Amp Relay in a System Diagram (Side View)

Fig. 4:

Water Leak Detector with Remote Spot Sensor or

optional Water Rope Sensor (not shown) and a 5 Amp

Relay in a System Diagram (Side View)

Specications subject to change without notice.

1 of 6

Page 2

BA/LDT Accessories

26268_ins_LDT

Mounting

Place the transmitter in a location where a water leak is

likely to cause damage such as a cooling coil pan, a hot

water tank pan, under a sink, under an elevated oor,

or in a drop ceiling under pipes. The transmitter can be

independently mounted in a visible location by using a

remote water sensor and waterproof cable as shown

in Fig. 4. Terminate the transmitter as shown in the

termination section.

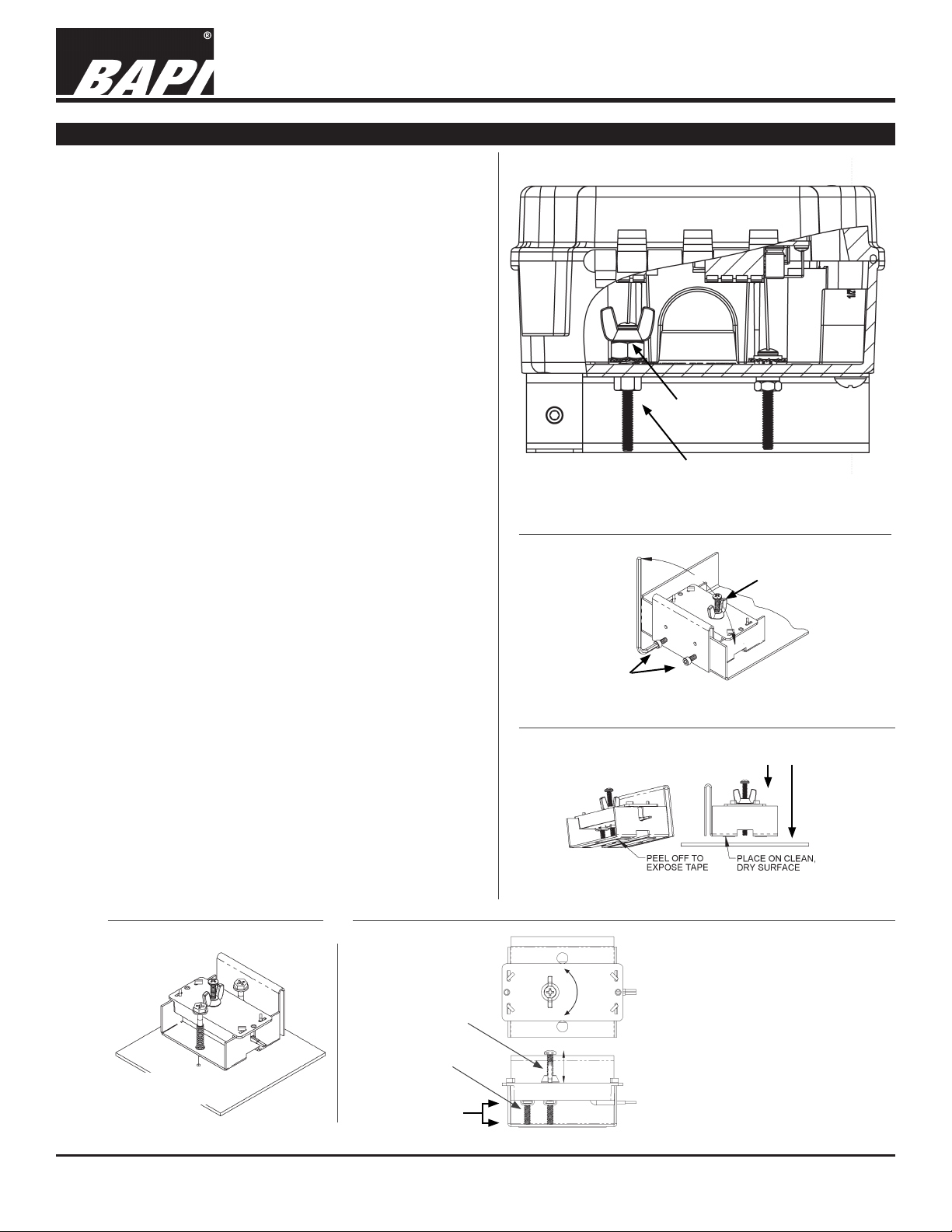

1. Set the transmitter where water is most likely to be a

problem or in the collection pan under the water coil or

heater (Fig. 5).

• Alternatively a water sensor or remote water sensor

can be attached to the pan edge with two set screws

(Fig. 6). Do not over tighten or puncture the pan.

• Alternatively a remote water sensor can be attached

to the pan or oor with mounting tape (Fig. 7). Clean

surface thoroughly before setting the sensor in place

and push sensor down rmly. Mount the detector

enclosure in a visible location within cable length of the

remote water sensor.

• Alternatively a remote water sensor can be attached

to the oor with screws (Fig. 8). Mount the detector

enclosure in a more visible location within cable length

of the remote water sensor.

• Alternatively the rope water sensor can be laid on the

oor or under pipes as shown in Figs. 10, 11, 12 & 13.

Cable clamps can be used to secure the sensor to the

oor.

2. Adjust the depth screw on the sensor probe in the middle

of the open enclosure to the alarm depth (Fig. 5). If using

a remote water sensor, adjust the depth screw as shown

in Fig. 9. The rope sensor detects water 1/8” off the oor

and has no adjustment.

3. Run the cable to the transmitter location leaving enough

slack to terminate and allow for some repositioning as

needed. Use a strain relief on the entering cable so the

wires do not tug on the terminals directly.

4. Terminate and congure in accordance with the

termination section.

Water Leak Detector

Termination and Troubleshooting

rev. 11/16/18

Mounting

Nut

Sensor Probe

Screw

Fig. 5: Leak Detector with Sensor in a BAPI-Box

Detection depth

adjust screw

Pan edge

mounting

screws

Fig. 6: Water Sensor Pan Rim Mounting

Firmly push down

on clean surface

Fig. 7: Remote Water Sensor Tape Mount

Fig. 8: Remote

Water Sensor

Floor Mount

Installer-provided

mounting screws

Fig. 9: Remote

Water Sensor

Up

Depth Adjusting

Detection depth

adjust screw

Reference probe

Detection depth

adjust from 1/16”

to 1/2” depth

Specications subject to change without notice.

Down

1. Loosen wing nut.

2. Set the required depth of the

sensor probe screw using a #2

Phillips screwdriver.

3. Hold the sensor probe screw

stationary with the screwdriver.

4. Turn the wing nut down the probe

screw until it engages the plastic.

5. Tighten the wing nut 1/4 turn into

the plastic.

2 of 6

Page 3

26268_ins_LDT

Mounting continued...

Fig. 10:

Hot Water Tank

Pan Mounting

Water Leak Detector

BA/LDT Accessories

Termination and Troubleshooting

rev. 11/16/18

Fig. 12:

Vertical

Pipe Sensor

Mounting

Fig. 11: Sub-Floor Sensor Mounting

The following combinations of sensors can be used:

1. Two rope sensors with a combined length of no more

than 100’.

2. Two spot sensors with a combined length of no more

than 75’.

3. One spot sensor with a maximum length of 25’ and

one rope sensor of no more than 50’.

Note: Shielded or twisted pair wire cannot be used

to extend the sensor wires. This applies to both the

remote spot sensor as well as the rope sensor.

Fig. 13: Horizontal Pipe Sensor Mounting

Specications subject to change without notice.

3 of 6

Page 4

26268_ins_LDT

Wiring and Termination

Water Leak Detector

BA/LDT Accessories

Termination and Troubleshooting

rev. 11/16/18

Terminal Description

A ..........Water Sensor (No polarity to water

sensor cable)

B ..........Water Sensor (No polarity to water

sensor cable)

NC2* .......Alarm Contact 2, Normally Closed to

C2 when De-energized

C2 .........Alarm Contact 2, Common

NO2 ........Alarm Contact 2, Normally Open to

C2 when De-energized

NC1* .......Alarm Contact 1, Normally Closed to

C1 when De-energized

C1 .........Alarm Contact 1, Common

Fig. 14: Leak Detector Circuit Board

Sensitivity Adjustment for 10’ and 100’ Remote Rope Sensors

The unit’s leak detection sensitivity is set at the

factory. However, for the 10’ and 100’ remote rope

sensors, the sensitivity may need to be adjusted

in the eld.

If you are using a 10’ remote rope and it won’t

respond, rotate the sensitivity adjustment

potentiometer 5 turns counterclockwise.

If you are using a 100’ remote rope and it is too

sensitive, then rotate the sensitivity adjustment

potentiometer 5 turns clockwise.

NO1 ........Alarm Contact 1, Normally Open to

C1 when De-energized

GND/NEU Power supply ground/neutral

V+/HOT ...Power supply input 24VAC +/- 10%

*Not used for low current relay version, SPST,

Form A

Sensitivity Adjustment Potentiometer

Fig. 15: Leak

Detector Circuit

Board

Specications subject to change without notice.

4 of 6

Page 5

Water Leak Detector

BA/LDT Accessories

Termination and Troubleshooting

26268_ins_LDT

Set Up and Commissioning

Indication/Controls Description

Red LED

.........................LED illuminates when water is detected

Green LED .....................LED illuminates when normal power is applied

Reset Button

Latching Relay

Non-Latching Relay

Supervised Relay***

Unsupervised Relay

..................Resets latching alarm contact (only if water is no longer present)

................Left side of J1 set to top two pins listed as “L”

........Left side of J1 set to bottom two pins listed as “N” (Default)

.......Right side of J1 set to top two pins listed as “S” (Default)

.......Right side of J1 set to bottom two pins listed as “U”

*** Supervised means the relay is energized when not in alarm and the relay de-energizes on a power failure or alarm.

1. After the unit is installed and wired, turn on the power. (24VAC +/- 10%)

2. Check that the green LED is “on”. If it is not “on”, check the power source.

3. Dampen a cloth or sponge and touch both the sensor probe tip and the sensor base. An alarm should occur

within 5 seconds.

4. The red LED should illuminate and the relay(s) should de-energize, or energize if set up as unsupervised. (To

check relay status, measure the resistance at the relay contacts or monitor the status from the BAS screen.)

5. Remove the dampened rag or sponge to clear the alarm. If the unit is set up for a non-latching relay (J1 jumper

across the “N” pins), the red LED and relay(s) will energize, or de-energize if set up as a unsupervised relay. If

the unit is set up for a latching relay (J1 jumper across the “L” pins), the operator must push the reset switch on

the detector board or interrupt power to clear the alarm.

6. Check the depth screw (see Mounting Section) to be sure it’s at the appropriate water depth for alarm.

rev. 11/16/18

Operation Sequence

When power is applied, the green LED will illuminate and and the unit will start to detect for water at the sensor

probe. When there is no detection of water (normal condition), the relays are not in an alarm state and the red LED

remains off. For units set up in the “unsupervised” relay mode, the relays are de-energized. For units set up in the

“supervised” relay mode (default), the relays will be energized. (Note: When there is a loss of power, a supervised

relay will drop out indicating a water detection alarm.)

Within 5 seconds of water detection, the relays go into an alarm state and the red LED illuminates. For units set

up in the “unsupervised” relay mode, the relays are energized. For units set up in the “supervised” relay mode

(default), the relays are de-energized.

If the unit is in non-latching or auto-reset (default) operation, then the alarm state will automatically reset when the

water has dried up. If the unit is in latching or manual-reset operation, then the unit will stay in an alarm state until

the reset button is pressed or power is cycled. If there is still water detected during a reset button push, the unit will

not reset. If there is still water detected after a power interrupt, the unit will initiate another alarm within 5 seconds.

Diagnostics

Possible Problem Possible Solution

Green LED Not On 1. Check for proper power to the unit (see power specs on back page).

Red LED Not Working 1. Check for proper power to the unit (see power specs on back page).

Or Relay Not Energizing. 2. Check if water is touching the sensor probe and reference probe.

3. Adjust sensor probe depth.

4. For rope sensor units, check the sensitivity adjustment as described on page 4.

Unit Will Not Reset 1. Check for the presence of water or debris touching the two sensor probes.

2. Be sure the sensor wires are not shorted.

3. If the L pins on J1 are shorted, push the reset button or cycle power.

4. For rope sensor units, check the sensitivity adjustment as described on page 4.

Specications subject to change without notice.

5 of 6

Page 6

Water Leak Detector

BA/LDT Accessories

Termination and Troubleshooting

26268_ins_LDT

Maintenance

Check the water sensor probe once a year to be sure there is no dirt or debris collected around the probes. Dirt or

debris around the probes may cause nuisance alarms in moist situations. Change the service intervals depending

on environmental conditions. In very clean conditions the probe may never need maintenance. Rope sensor may be

wiped down with isopropyl alcohol, warm soapy water on a cotton cloth or placed in a dishwasher.

Cautions/Warnings

This unit is not intended to be a safety device. In no event shall BAPI or its ofcers, directors, employees or agents be

liable to any company or individual for any indirect, incidental, special, exemplary, punitive or consequential damages

including, without limitation, economic or commercial losses, arising out of or resulting from the misuse of this water

detector as a safety device.

Specications

rev. 11/16/18

Power: 24VAC +/- 10%

5 Amp Relays: 4 Watt/ 4 VA max

0.5 Amp Relays: 2 Watt/ 2 VA max

(not intended to switch a load)

Wiring: Flex Connector or Liquid Tight Fitting

Relays Up to 6 wires

Transmitter 2 wires for Power

Mounting: Lays in the pan or attached with a pan edge

hook with screws

Sensor:

Standard Single SS probe from bottom of BB with

adjustable depth screw from .063” to .84”

Optional Remote water sensor with depth screw with

adjustable depth from 1/16” to 1/2”

Optional Remote long line water sensor (Rope)

Detects water over the full length at

depths >0.125”. Note: 100 ft maximum

including non-sensing extension cable.

Detector Transmitter:

Alarm Contacts

LDT2: Two SPST, 0.5A relay outputs, 10W max

LDT3: One SPDT, 5A relay output

LDT4: Two SPDT, 5A relay outputs

SPST or SPDT, 30 VAC/DC max

Selectable as normally Energized or

De-energized

Indication 1 Green Power LED, 1 Red Alarm LED

Reset Action If latching, local push button or power

Sensor Reaction

Termination: Terminal strip, 4-10 terminals, 12-24AWG

Agency: RoHS, UL94V-0, UV-rated in Enclosure

LDT1: One SPST, 0.5A relay output, 10W max

interrupt

Responds to presence of water within 5

seconds

Set Up:

BB Sensor Adjustable depth from .063” to

.84” (≈1/16th” default)

Remote Sensor Adjustment depth from 1/16” to

1/2” (≈1/16th” default)

Latching Latching Version - Stays

Jumper

Non-Latching Version (default) -

Supervision Supervised Version (default) Jumper De-energized when in alarm.

Unsupervised Version -

Enclosure Ratings:

Remote Sensor Submersible, w/FEP plenum-

Rope Sensor Plenum rated

Transmitter BAPI-Box, NEMA 4

Ambient:

Remote Sensor -40 to 185ºF (-40 to 85ºC),

0 to 100%RH, Condensing

Transmitter (BB) -40 to 185ºF (-40 to 85ºC),

0 to 95%RH, Non-condensing

Rope Sensor 32 to 167ºF (0 to 75ºC),

0 to 95%RH, Non-condensing

Enclosure Materials:

Remote Sensor Aluminum bracket w/ABS plastic

Transmitter (BB) Polycarbonate

Note: This unit is not intended to be a

energized after water has dried up

Alarm follows wet or dry surface

Note: Relay will drop out on

loss of power indicating a water

detection alarm.

Energized when in alarm.

rated, waterproof cable

shell

safety device.

Specications subject to change without notice.

6 of 6

Loading...

Loading...