Page 1

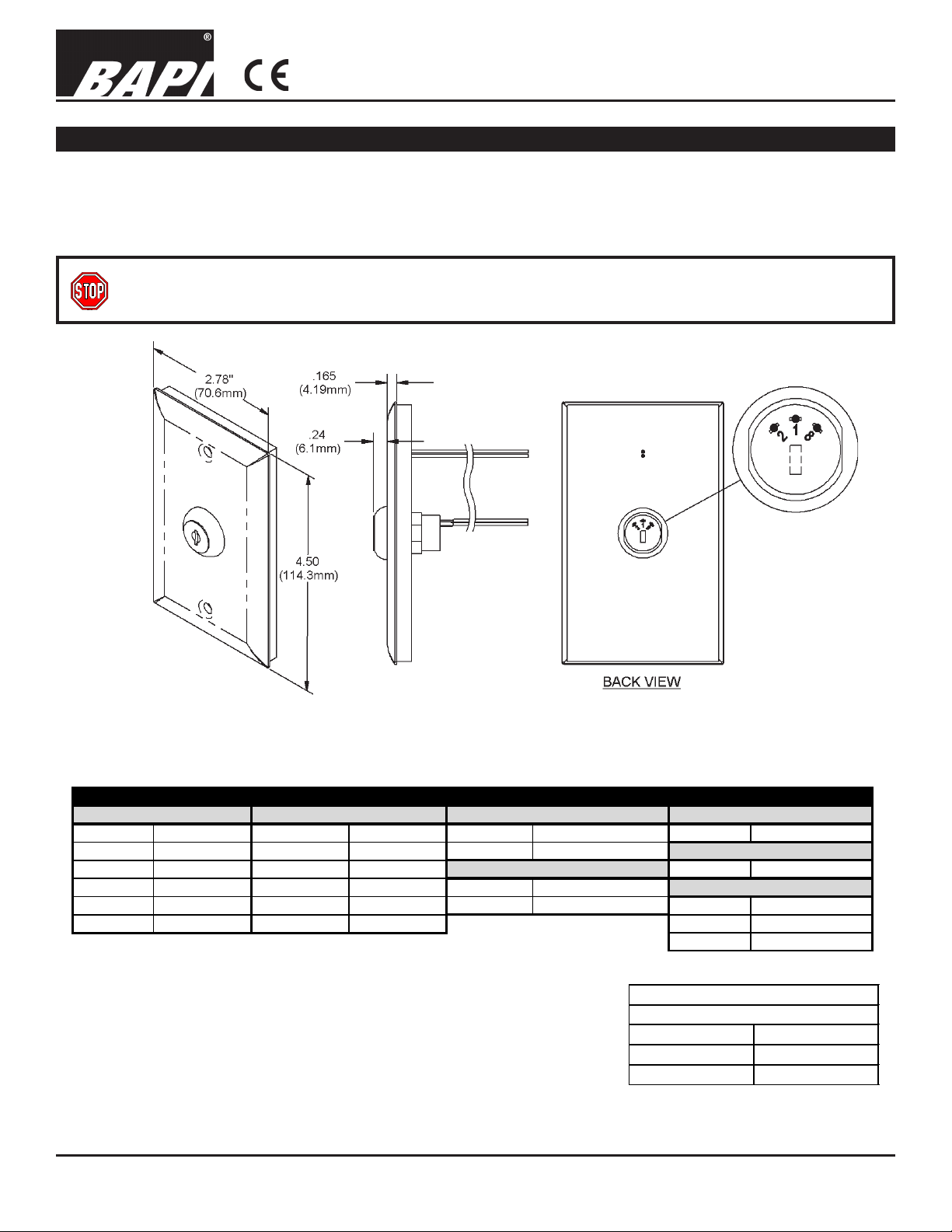

Wall Plate with Keyswitch Override (BA/-SP/AP-K)

1.8KΩ Orange/Red 10K-3Ω Yellow/Red 100Ω Red/Red 1KΩ Green/Green

2.2KΩ Brown/White 10K-3(11K)Ω Yellow/Blue 1KΩ Orange/Orange

3KΩ Yellow/Black 20KΩ White/White 2KΩ Brown/Blue

3.25KΩ Brown/Green 47KΩ Yellow/Orange 100Ω Red/Red/Black

3.3KΩ Yellow/Brown 50KΩ White/Blue 1KΩ Orange/Orange/Black LM334 Red/Black

10K-2Ω Yellow/Yellow 100KΩ Yellow/White AD592 Red/Black

AD592-10K Red/Black/White

Nickel RTD

Silicon RTD

Semiconductors

Thermistors

Table 1: Temperature Sensor Lead Wire Colors

Thermistors

Platinum RTDs - 2 Wire

Platinum RTDs - 3 Wire

Common Pin 1

Normally Open

Pin 2

Normally Closed

Pin 8

Table 2

Key Sw itch Contacts

*

Installation & Operating Instructions

8589_ins_sp_ap_k rev. 08/01/18

Termination

BAPI recommends using twisted pair of at least 22AWG and sealant lled connectors for all wire connections. Larger gauge

wire may be required for long runs. All wiring must comply with the National Electric Code (NEC) and local codes.

Do NOT run this device’s wiring in the same conduit as AC power wiring. BAPI’s tests show that uctuating and inaccurate

signal levels are possible when AC power wiring is present in the same conduit as the signal lines.

BAPI recommends wiring the product with power disconnected. Proper supply voltage, polarity, and

wiring connections are important to a successful installation. Not observing these recommendations may

damage the product and will void the warranty.

Fig. 1: Wall Plate

with Keyswitch

Temperature Sensor Termination:

Terminate the sensor wires to your controller wires using BAPI sealant lled connectors. The wallplate’s foamback

insulates the temperature sensor from the wall temperature and/or conduit drafts.

Keyswitch Termination:

The keyswitch has normally open and normally closed contacts. The switch

closes with a 45° clockwise turn. The key will spring return to the open position.

The switch is terminated with three white wires. The switch contacts are

indicated on the back of the switch. The keyswitch is for NEC Class 2 circuits

only, 4 amps maximum.

*All Thermistors 20KΩ and smaller are CE compliant.

Specications subject to change without notice.

1 of 2

Page 2

Wall Plate with Keyswitch Override (BA/-SP/AP-K)

Installation & Operating Instructions

8589_ins_sp_ap_k rev. 08/01/18

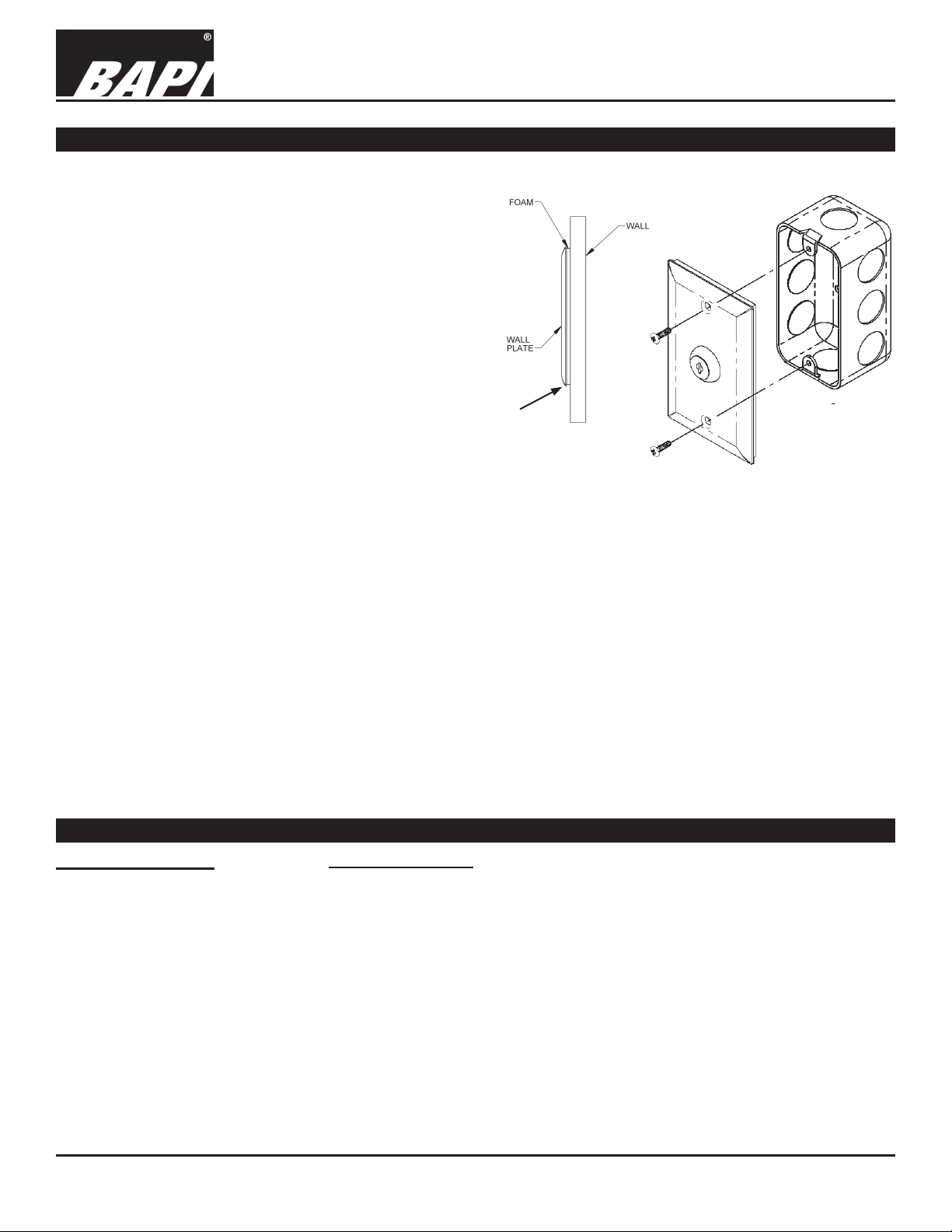

Mounting

Ensure the plate does not touch the wall when it is mounted as this will lead to slower response

rates when the environment changes.

Mounting hardware is provided for both junction

box and drywall installation.

Junction Box

1. Pull the wire through the wall and out of the

junction box, leaving about 6” free.

2. Terminate the unit according to the guidelines

in Termination on page 1.

3. Secure the plate to the box using the

#6-32 x 1/2” mounting screws provided or with

security screws which are sold separately.

(Call BAPI or visit the Accessories section of

our website for security screw ordering.)

4. Tighten screws until the foam gasket on the

back plate is compressed about 50%. Ensure

the plate doesn’t touch the wall (Fig 2).

Note: Louvered wall plates require a mounting

adapter bracket for J-Box mounting. The bracket

is not shown in the diagram above but is included with any louvered wall plates ordered from BAPI.

Verify visible

air gap

between plate

and wall.

Fig 2:

Side View of

Mounted Plate

Fig 3:

J-Box Mounting

Drywall Mounting

1. Place the plate against the wall where you want to mount the sensor and mark out the two mounting holes.

2. Drill two 3/16” holes in the center of each marked mounting hole. Insert a drywall anchor into each hole.

3. Cut hole between the mounting holes that clears the apparatus mounted on plate. Pull the wire through the wall hole

cut in step 2, leaving about 6” free.

4. Terminate the unit according to the guidelines in Termination on page 1.

5. Secure the plate to the drywall anchors using the #6 x 1” mounting screws provided. Tighten screws until the foam

gasket on the back plate is compressed about 50%. Ensure the plate doesn’t touch the wall.

Note: In any wall-mount application, the wall temperature and the temperature of the air within the wall cavity can cause

erroneous readings. The mixing of room air and air from within the wall cavity can lead to condensation, erroneous

readings and premature failure of the sensor. To prevent these conditions, seal the conduit leading to the junction box or

ll the box with insulation.

Diagnostics

Possible Problems:

Controller reports

inaccurate temperature

Possible Solutions:

- Conrm that the input is set up correctly in the controller software.

- Check wiring for proper termination and verify that the wires are not electrically

shorted or open

- Disconnect the controller wires from the sensor. Measure the temperature

sensor’s resistance with an ohm-meter. Verify the sensor’s output is correct

(see note below). If the measured resistance is different from the temperature

table by more than 5%, call BAPI technical support. To view the appropriate

temperature table on the BAPI website, go to http://www.bapihvac.com. Click

on “Resource Library” and “Sensor Specs”, then on the table needed.

Keyswitch is not working

correctly

- Disconnect the controller wires from the keyswitch. Without turning the

key, verify the resistance from pin 1 to pin 8 is 1Ω or less. While turning the

keyswitch, verify the resistance from pin 1 to pin 2 is 1Ω or less.

Specications subject to change without notice.

2 of 2

Loading...

Loading...