Page 1

VOC Duct and Rough Service Sensor

Overview and Identication

Humans respirate Volatile Organic Compounds

(VOCs) as well as CO2. The BAPI sensor measures

these VOCs and indicates when a space is occupied

just as well as a CO

The advantage of the VOC sensor is that it

measures air contaminants from other sources

besides respiration, such as building materials,

cleaners, perfumes and furniture and carpet

off-gassing.

Using this sensor for Demand Controlled Ventilation

then is a way of achieving true indoor air quality,

rather than just CO

it requires no additional work on your part. That’s

because the sensor converts the VOC reading to a

equivalent level. This lets you use ASHRAE’s

CO

2

-based VRP schedule to ventilate.

CO

2

The Duct Sensor samples duct air using an aspiration

tube, while the Rough Service unit features a

ventilated BAPI-Box and is ideal for areas such as

outdoor air plenums, equipment rooms, green houses

and warehouses. The VOC level is indicated as

“Good, Fair or Poor” by three discrete green, yellow

and red LED’s on the front of the unit.

reaches 2,000 PPM, the red LED will begin to ash

because it has hit its maximum output.

sensor.

2

dilution. A further benet is that

2

If the output

Installation & Operating Instructions

rev. 06/05/1840699_ins_VOC_3LED_BB

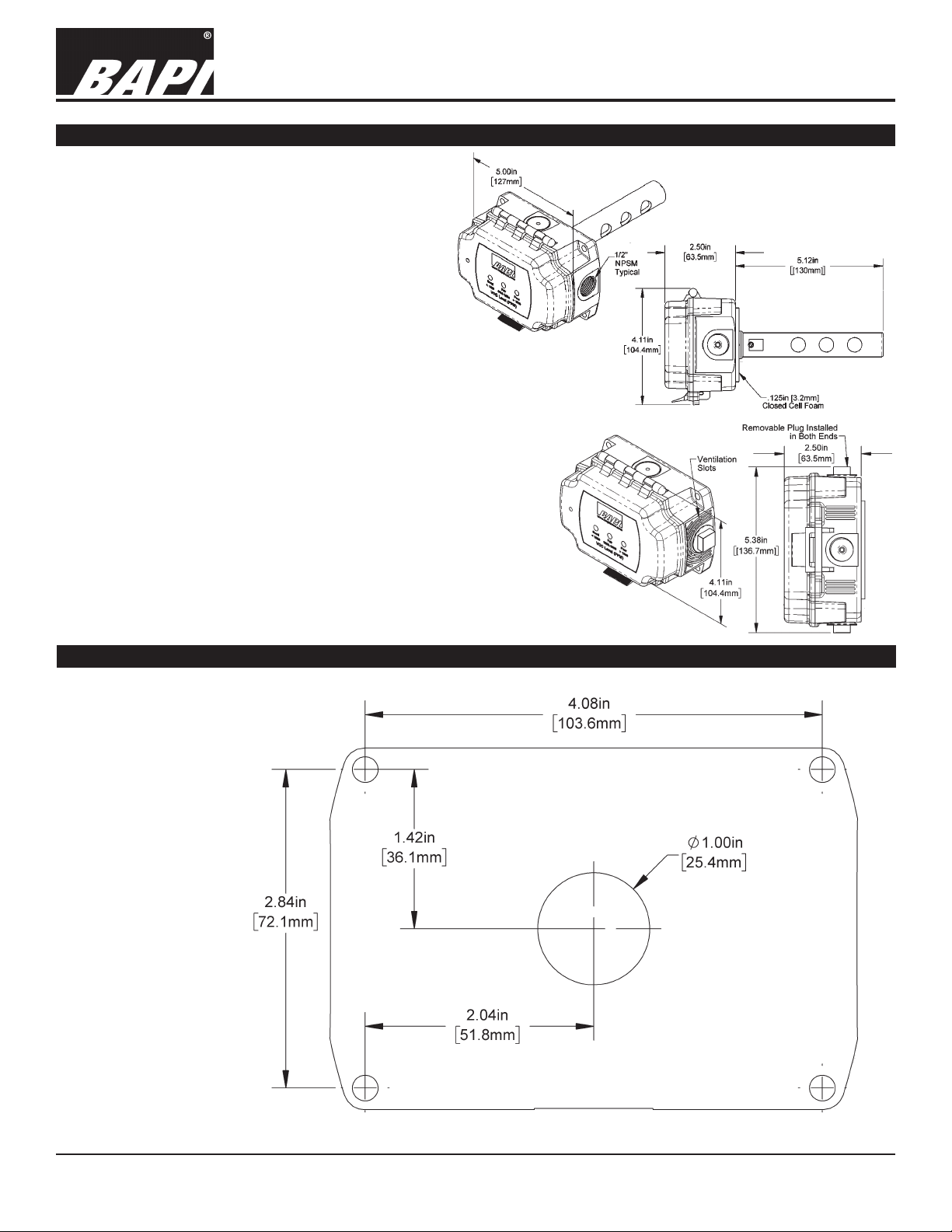

Fig. 1: Duct

VOC Sensor

Fig. 2: Rough

Service VOC

Sensor

Mounting Template

Fig. 3: Mounting

Template, Actual Size

Specications subject to change without notice.

1 of 6

Page 2

VOC Duct and Rough Service Sensor

Installation & Operating Instructions

rev. 06/05/1840699_ins_VOC_3LED_BB

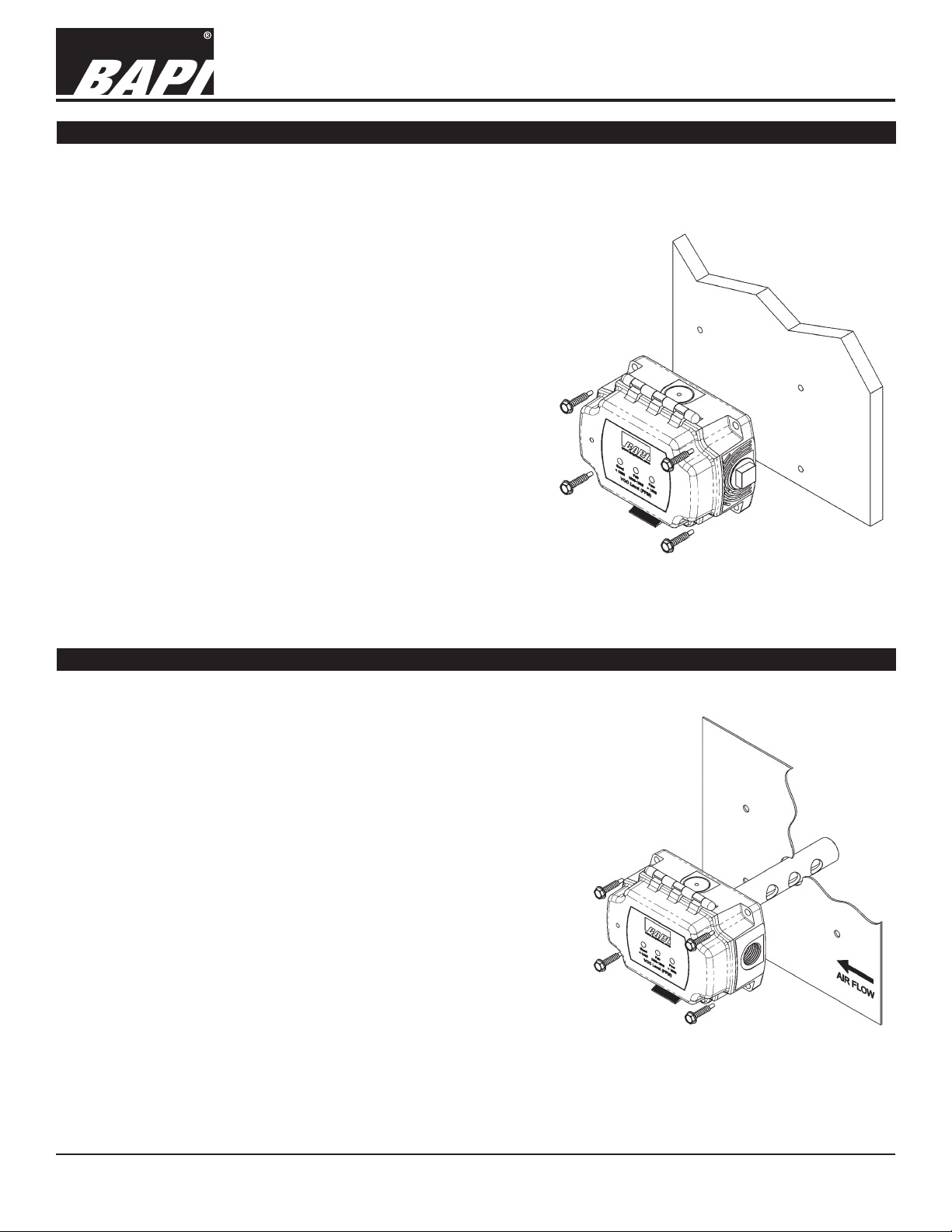

Rough Service Unit Mounting

Mount the Rough Service sensor on a solid, non-vibrating surface. Wall mounting in a room should be 3 to 5 feet

above oor level. The Rough Service VOC transmitter may be mounted in any orientation. If you are mounting

inside a duct or mixing box, mount with the latch facing into the moving air.

Refer to local codes for further sensor/transmitter installation

information. See BAPI’s “Coverage Area” Application Note for

further mounting recommendations. To get to this application

note, go to www.bapihvac.com, select “Resource Library” from

the banner. Click on “Application Notes” then scroll down the

page to the heading “Air Quality Related” and chose “Coverage

Area and Mounting Recommendations for BAPI Indoor Air

Quality Sensors”.

1. BAPI recommends #10 (provided) screws of a type and

length suitable for the mounting surface. Four mounting

screws keeps the box from twisting, twisting may prevent the

latch from operating properly. A pilot-hole makes mounting

easier. Use the enclosure mounting feet to mark the pilothole locations.

2. Snug up the screws so that the foam backing is depressed

but do not over-tighten or strip the screw threads.

3. Place the provided #6 screws into the holes on each site of

the lid latch to make the cover tamper resistant.

Fig. 4: Mounting the Rough Service

sensor to a wall

Duct Unit Mounting

1. BAPI recommends placing the sensor in the middle of the duct

wall, away from stratied air, to achieve the best reading. The unit

should also be a minimum of 3 duct diameters from an elbow,

damper or other duct restriction.

2. Drill a 1” hole for the aspiration probe.

3. Position the box so that airow is directly into the holes on

one side of the aspiration probe. There are no upstream or

downstream holes, the air direction is not important.

4. Mount the enclosure to the duct using BAPI recommended #10

screws (provided) through a minimum of two of the mounting feet

on opposite corners. A 1/8” pilot screw hole in the duct makes

mounting easier. Use the enclosure mounting feet to mark the

pilot-hole locations.

5. Snug up the screws until the foam backing is compressed about

50% to prevent air leakage but do not over-tighten.

6. Use the provided #6 screws to secure the cover for IP66 rating.

7. BAPI recommends sealing the conduit opening with berglass

insulation.

Fig. 5: Duct unit mounting

Specications subject to change without notice.

2 of 6

Page 3

VOC Duct and Rough Service Sensor

Installation & Operating Instructions

rev. 06/05/1840699_ins_VOC_3LED_BB

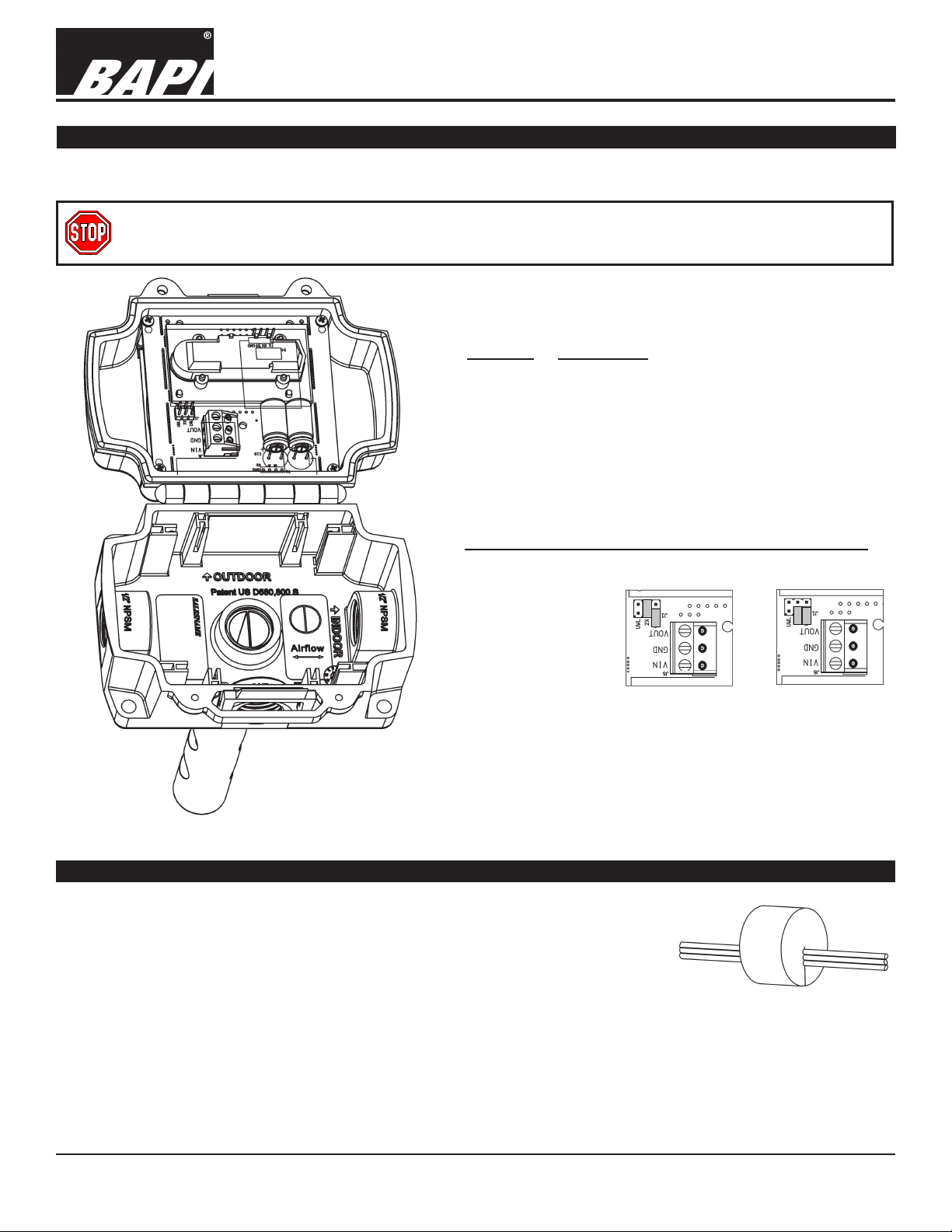

Termination

BAPI recommends using twisted pair of at least 22AWG and sealant lled connectors for all wire connections. Larger

gauge wire may be required for long runs. All wiring must comply with the National Electric Code (NEC) and local codes.

BAPI recommends wiring the product with power disconnected. Proper supply voltage, polarity and wiring

connections are important to a successful installation. Not observing these recommendations may damage

the product and void the warranty.

Terminal Description

VIN

..............Power, referenced to GND

12 to 24 VDC, 35 mA Peak

18 to 24 VAC, 4 VA Peak

GND

............To controller Ground [GND or Common]

..........Voltage Output, VOC Signal (0 to 2,000 ppm),

VOUT

referenced to GND

The VOC outputs

may be eld

congured for 0

to 5 VDC or 0 to

10 VDC outputs

at any time. Set

the jumpers on

J1 as shown in

Fig. 7: J1 set for 0

to 10 VDC output

Figures 7 and 8.

Fig. 6: Circuit board on open unit

Keeping the Enclosure Air Tight After Termination

For the sensor to work correctly, the wiring entrance must remain air tight. If the

VOC transmitter is mounted to a hollow wall and wired through its back, or wired

with conduit, it is possible that a draft of clean air may ll the enclosure through

the wiring opening. This draft may prevent the unit from measuring ambient

VOCs. BAPI recommends either a liquid-tight tting or plugging the conduit at the

enclosure.

• Liquid-Tight Fitting – BAPI’s Liquid-Tight Fitting (BA/LTF) allows wire cables of

0.1 to 0.3 inch outside diameter to enter the box. Tightening the collar onto the wire

cable keeps the wiring entrance air tight.

Fig. 8: J1 set for 0

to 5 VDC output

Fig. 9:

Wires Through Foam Plug

• Conduit – Included with the VOC transmitter is a foam plug to seal the ½ inch EMT. Place the wires into the plug as

shown in Fig. 9 and then insert the plug into the conduit sealing the conduit.

Specications subject to change without notice.

3 of 6

Page 4

VOC Duct and Rough Service Sensor

Installation & Operating Instructions

rev. 06/05/1840699_ins_VOC_3LED_BB

Sensor Start-Up

Do not set the control parameter to a VOC limit until the VOC sensor has been installed for a week. The rst few days

of install may provide different readings compared to several days later.

At each power up, the sensor enters the start-up period for 15 minutes. The VOC output will follow the timing shown in

Figure 10. During the start-up period, an optional verication/commissioning test, described below, may be performed.

This test is not mandatory. It is necessary only if building commissioning requires sensor verication or if verication of

VOC output is required for later troubleshooting.

Fig. 10: Sensor Start-up Timeline

Optional Sensor Performance Verication and Commissioning

BAPI’s VOC sensor contains an adaptive, self adjusting, Volatile Organic Compound (VOC) sensor element that

provides a CO

Demand Control Ventilation algorithm, ventilation using this sensor will achieve true indoor air quality and not just CO

dilution.

The fundamental performance criterion of the VOC sensor element is its dynamic sensing range. The VOC sensor

element requires a minimum dynamic range of 30% for proper operation. During BAPI’s verication/commissioning

test, the dynamic range is tested.

BAPI recommends installing the sensor and powering it for at least 48 hours before the rst verication test is

performed. BAPI further recommends ventilating the space such that the sensor reads 750 ppm or less CO

equivalent before any verication test is performed. Wait at least one hour before repeating the test.

equivalent control signal output. When incorporated into a control strategy based on ASHRAE’s

2

2

2

1. Start Automatic Verication/Commissioning Test

A. Remove sensor power for at least one minute and reapply. The VOC sensor will set the VOC output to zero

volts. (Power ON in Fig. 10)

B. Wait four minutes fteen seconds.

C. The VOC sensor will set the VOC output voltage to 5% of full scale (0.25 VDC for 0 to 5 VDC, 0.5 VDC or 0 to

10 VDC outputs).

D. The 5% output voltage conrms that the VOC sensor is in its verication/commissioning test. (Apply Test Gas

in Fig. 10.)

2. Apply Verication Stimulus

A. Apply the stimulus gas during the rst minute after the output voltage is set to 5% (See Stimulus Preparation

and Application section on next page).

B. Read and record the VOC output voltage approximately 2 to 4 minutes following the stimulus gas application to

determine the dynamic range measurement. (Dynamic Range Estimate period in Fig. 10)

C. Use the graph in Fig. 12 to determine dynamic range.

3. Termination of Verication Mode

A. For the last 7 minutes of the start-up period, the sensor adapts to its ambient environment. The VOC sensor

will maintain its output voltage at 450 ppm CO2 equivalent.

B. At 15 minutes the VOC sensor will terminate the start-up period and begin normal operation.

C. The VOC output will now report the VOCs present as CO2 equivalents.

4. Result Analysis and Recommendations

The VOC algorithm requires a dynamic range of greater than 30% for proper operation. Sensors reporting a

dynamic range of 30% or less should be considered for replacement. (See Fig. 12)

Specications subject to change without notice.

4 of 6

Page 5

VOC Duct and Rough Service Sensor

Installation & Operating Instructions

Stimulus Preparation and Application for Dynamic Range Testing

Place 50ml of Isopropyl Alcohol (70% minimum) into a 200ml bottle (2oz in an

8oz bottle) with stopper and allow to reach room temperature (65° to 80°F, 18° to

27°C), a minimum of 15 minutes.

1. Using a medical grade syringe, remove the stopper from the alcohol bottle,

place the tip of the syringe at least half-way into the bottle and withdraw a 60

ml sample of the ALCOHOL VAPOR. (NO LIQUID)

2. Replace the stopper on the alcohol bottle.

3. Place the end of the syringe under, or into the bottom ventilation slot of the

VOC monitor’s housing.

4. Empty the syringe into the sensor using one continuous motion. Compare

the sensor output to the Dynamic Range chart below to verify acceptable

operation. Sensors reporting a dynamic range of 30% or less should be

considered for replacement.

rev. 06/05/1840699_ins_VOC_3LED_BB

Fig. 11: Alcohol Bottle

and Syringe included in

the VOC Verication Kit

(BA/VOC-KIT)

Fig. 12: Acceptable Dynamic Range Output Graph

Specications subject to change without notice.

5 of 6

Page 6

Diagnostics

VOC Duct and Rough Service Sensor

Installation & Operating Instructions

rev. 06/05/1840699_ins_VOC_3LED_BB

Possible Problems:

General Troubleshooting

Incorrect VOC Reading

Possible Solutions:

- Determine that the input is set up correctly in the controller and BAS

software.

- Check wiring at the sensor and controller for proper connections. If

there is corrosion on any terminations, clean off the corrosion, re-strip

the interconnecting wire and reapply the connection. In extreme cases,

replace the controller, interconnecting wire and/or sensor.

- Label the VOC sensor wire terminals at the sensor and controller ends.

Disconnect the wires and measure the resistance from wire-to-wire

with a multimeter. The meter should read greater than 10 Meg-ohms,

open or OL depending on the meter. Short the wires at one end and

measure the resistance from wire-to-wire at the other end. The meter

should read less than 10 ohms (22 gauge or larger, 250 feet or less). If

either test fails, replace the wire.

- Check the power supply and controller voltage supply.

- Disconnect sensor and check power wires for proper voltage (see

power specs).

- Wait 15 minutes after a power interruption.

- Check all software parameters.

- Determine if the sensor is exposed to an external environment different

from the room (conduit draft).

Specications

Power:

12 to 24 VDC, 35 mA Peak

18 to 24 VAC, 4 VA Peak

VOC Sensor:

Micro-machined Metal Oxide

Mounting:

Duct or Surface Mount - screws provided

VOC Detection Range:

0 to 2,000ppm CO

Equivalent, Analog Output

2

Response Time:

Less Than 60 Seconds (after start-up)

Start-up Time:

15 minutes

Operating Environment:

32 to 122°F (0 to 50°C)

5 to 95%RH non-condensing

Analog Outputs:

0 to 5, or 0 to 10VDC >4KΩ impedance

LED VOC CO2 Equivalent Indicator:

Good, Green < 1,000 ppm

Fair, Yellow = 1,000 to 1,500 ppm

Poor, Red > 1,500 ppm

Material:

ABS Plastic, Material Rated UL94V-0

Certications:

RoHS

Warranty Period:

Five years from manufacture date

Specications subject to change without notice.

6 of 6

Loading...

Loading...