Page 1

Thermobuffer Sensors

BA/#- TB Temperature Sensor

Installation and Operation Instructions

19817_Ins_thermo_buffer

Overview

The BA/# -TB is for wall or hanging bracket mounting and temperature sensing in walk-in freezers or refrigerators. The buffers

are made in different lengths and are made to be lled with food grade glycol to slow down the temperature response to more

closely mimic the contents of the freezer or refrigerator. The BA/#-TB is available in multiple thermistor’s or RTD’s as shown in the

specications. The mounting enclosure styles come in NEMA 4 plastic or hanging bracket with the buffers available in stainless

steel or aluminum to t any application.

Identication

rev. 04/12/13

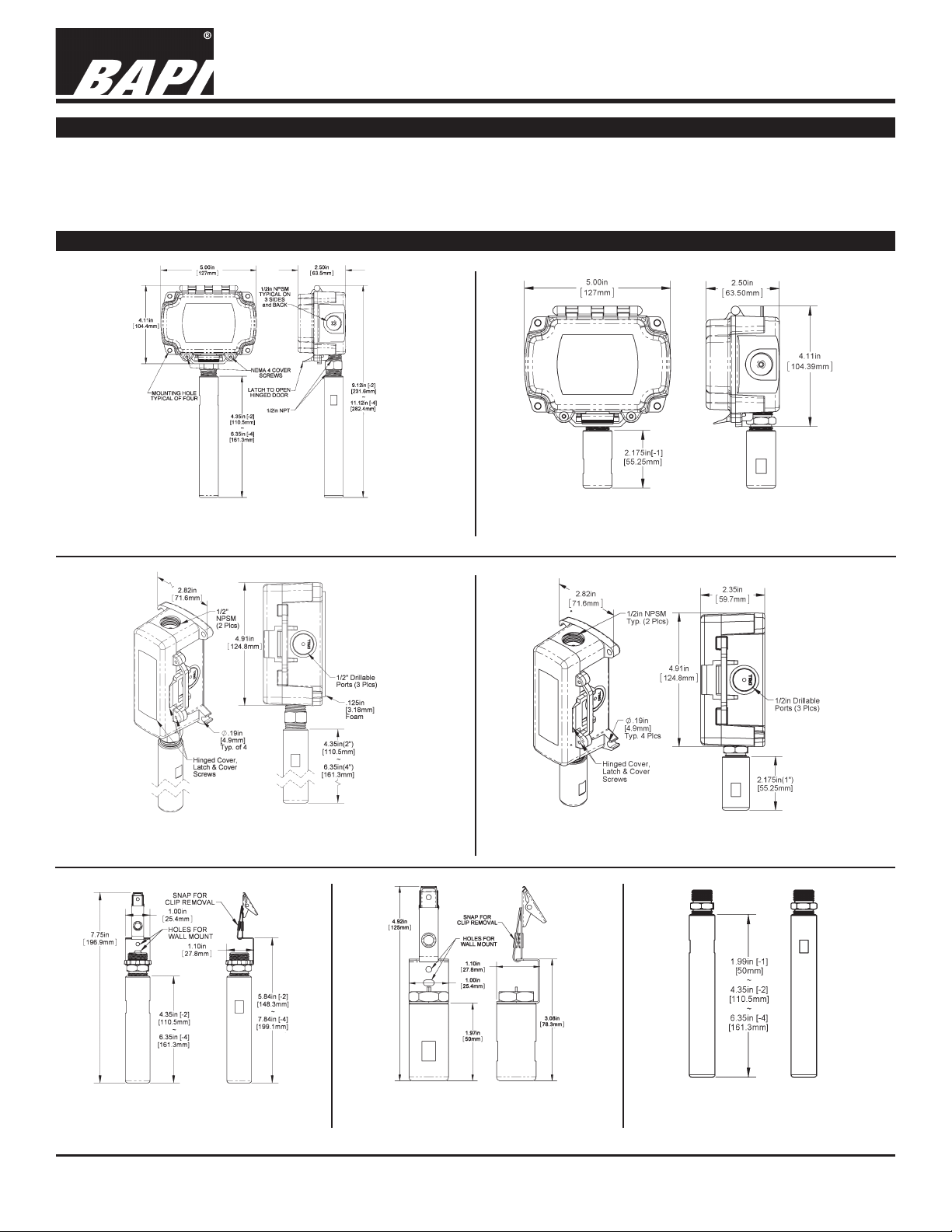

Fig 1: 2” & 4” Thermobuffer in a BAPI-Box

(BB) Enclosure

Fig 3: 2” & 4” Thermbuffer in a

BAPI-Box 2 (BB2) Enclosure

Fig 2: 1” Thermobuffer in a BAPI-Box (BB) Enclosure with

Plastic Threaded Fitting

Fig 4: 1” Thermobuffer in a BAPI-Box 2 (BB2)

Enclosure with Plastic Threaded Fitting

Fig 5: 2” & 4”

Thermobuffer

Hanging Bracket

Thermobuffer

Fig 7: No Box (NB) ThermobufferFig 6: 1” Hanging Bracket

Specications subject to change without notice.

1 of 4

Page 2

19817_Ins_thermo_buffer

Assembly & Installation

Thermobuffer Sensors

BA/#- TB Temperature Sensor

Installation and Operation Instructions

rev. 04/12/13

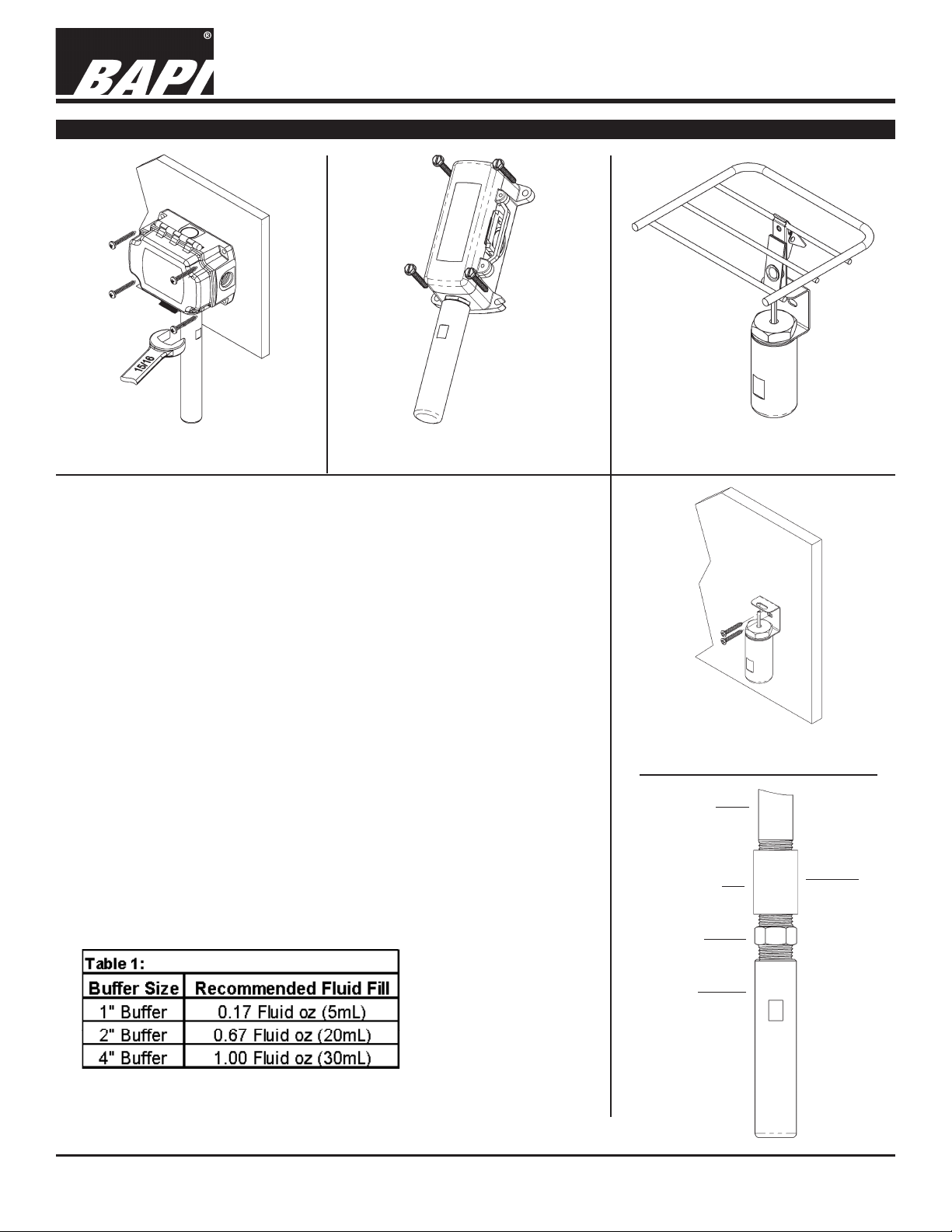

Fig 8: 2” & 4” Thermobuffer in a BAPI-Box

(BB) Enclosure Installation

Fig 9: 2” & 4” Thermobuffer in a BAPI-Box 2

(BB2) Enclosure Installation

1. Fill the buffer with the appropriate amount of customer provided glycol

to the amount as dictated by table 1.

2. Wrap the probe threads with Teon tape with at least 4 wraps so a water

tight seal is established.

3. Insert the probe into the buffer and screw in for a secure water tight t.

4. Towel off excess uid which may leak out during assembly and check

for leaking. If the assembly leaks, a 15/16ths wrench may be used to

snug up the probe to the buffer. More tape may also be needed. The

use of food safe silicon may also be used.

5. Select a location on a wall or hanging from a wire rack near the contents

you wish to monitor.

6. Mount the Thermo Buffer with the buffer facing down (Probe on top).

Any other orientation is not recommended due to leaking concerns.

7. We recommend BAPI Box surface mounting be positioned over the

refrigerator wire way hole using the rear BAPI Box knock out. Pull the

wiring into the unit and terminate using sealant lled connectors. Best

practice is to caulk the wiring hole after the wiring is installed. Secure

with mounting screws and ensure that the foam backing compresses

to about 50% of its thickness to make a gasket type seal against the

surface.

Fig 10: 1” Hanging Bracket Rack

Fig 11: 1” Hanging Bracket Wall Installation

1/2” NPT Pipe

(Customer Provided)

1/2” NPT Nipple

(Customer Provided)

BAPI Sensor

Installation

(Customer Provided Screws)

•

•

•

Termination

•

Wire

Within

Pipe

Specications subject to change without notice.

BAPI Buffer

Fig 12: No

Box (NB)

Thermobuffer

Installation

•

2 of 4

Page 3

Thermobuffer Sensors

BA/#- TB Temperature Sensor

Installation and Operation Instructions

19817_Ins_thermo_buffer

Wiring & Termination

BAPI recommends using twisted pair of at least 22AWG and sealant lled connectors for all wire connections. Larger gauge wire may

be required for long runs. All wiring must comply with the National Electric Code (NEC) and local codes. Do NOT run this device’s wiring

in the same conduit as high or low voltage AC power wiring.

BAPI’s tests show that inaccurate signal levels are possible when AC power wiring is present in the same conduit as the sensor wires.

rev. 04/12/13

To Controller

Analog Input (AI)

(No Polarity)

Sensor

To Controller

Analog Input (AI)

(No Polarity)

Fig. 13: 2 Wire Lead Wire Termination for Thermistor or RTD

To 3 Wire Transmitter

Sensor

To 3 Wire Transmitter

Fig. 14: 3 Wire Lead Wire Termination for RTD

Fig. 15: Terminal Strip (-TS) Option for 2 Wire Sensors

Termination

Fig. 17: Test & Balance (-TB) Option for 2 Wire Sensors

Termination

Specications subject to change without notice.

Fig. 16: Terminal Strip (-TS) Option for 3 Wire

Sensors Termination

Fig. 18: Test & Balance (-TB) Option for 3 Wire

Sensors Termination

3 of 4

Page 4

19817_Ins_thermo_buffer

Diagnostics

Problems:

Controller reports higher or lower

than actual temperature

Possible Solutions:

- Conrm the input is set up correctly in the front end software

- Check wiring for proper termination & continuity. (shorted or open)

- Disconnect wires and measure sensor resistance and verify the “Sensor” output

is correct.

Specications

Sensor: Passive

Thermistor NTC, 2 wire

RTD PTC, 2 or 3 wire

Thermistor: Thermal resistor (NTC)

Temp. Output Resistance

Accuracy (std) ±0.36ºF, (±0.2ºC)

Accuracy (Hi) ±0.18ºF, (±0.1ºC), [XP] option

Stability < 0.036ºF/Year, (<0.02ºC/Year)

Heat dissipation 2.7 mW/ºC

Temp. Drift <0.02ºC per year

Probe range -40º to 221ºF (-40º to 105ºC)

RTD: Resistance Temperature Device,

Platinum (Pt) 100Ω and 1KΩ @0ºC, 385 curve,

Platinum (Pt) 1KΩ @0ºC, 375 curve

Pt Accuracy (Std) 0.12% @Ref, or ±0.55ºF, (±0.3ºC)

Pt Accuracy (High) 0.06% Ref, or ±0.277ºF (±0.15ºC),

[A] Option

Pt Stability ±0.25ºF, (±0.14ºC)

Pt Self Heating 0.4 ºC/mW @0ºC

Pt Probe range -40º to 221ºF, (-40 to 105ºC)

Nickel (Ni) 1000Ω @70ºF, JCI curve

Ni Probe range -40º to 221ºF (-40 to 105ºC)

Sensitivity: Approximate

Thermistor Non-linier - Go to bapihvac.com

“Sensor Specs”

RTD (Pt) 3.85Ω/ºC for 1KΩ RTD, @0ºC

0.385Ω/ºC for 100Ω RTD, @0ºC

Nickel (Ni) 2.95Ω/ºF for the JCI RTD, @70ºF

Lead Wire: 22awg stranded

Insulation: Etched Teon, Plenum rated

Probe: 304 Stainless Steel (SS), 0.25” OD

Probe Process Connection:

-TB 304 SS Double threaded ½” NPT

Probe Length: Probe tip to thread start

1” 0.75”

2” 3.5”

4” 5.5”

Thermobuffer Sensors

BA/#- TB Temperature Sensor

Installation and Operation Instructions

rev. 04/12/13

Buffer Chamber Dimensions:

1” Buffer 2.75”H x 1”Dia

2” Buffer 5.1”H x 1”Dia

4” Buffer 7.1”H x 1”Dia

Mounting:

Plastic Box 4 extension tabs (ears), 7/16” hole,

Hanging Bracket SS bracket with 1/8” holes or 3/8” spring clip

Enclosure Types:

No Box -NB, intended for direct ½” NPT pipe mount

BAPI-Box: -BB, w/ four ½” NPSM & one ½” drill-out

BAPI-Box 2: -BB2, w/ three ½” NPSM & three ½” drill-outs

Hanging Bracket -HB, Intended to hang from shelving

Enclosure Ratings:

No Box -NB, No rating

BAPI-Boxes -BB & -BB2, NEMA 4, IP66

Hanging Bracket -HB, No rating

Enclosure Materials:

BAPI-Boxes

Hanging Bracket -HB, 304 Satinless Steel bracket and clip

Buffer Chamber Construction:

M-304 Machined 304 Stainless Steel, 0.7” core

MAL Machined Aluminum, 0.7” core

Liquid Fill: Food Grade Glycol (Customer provided)

1” Buffer 5 mL

2” Buffer 20 mL

4” Buffer 30 mL

Color:

BAPI-Boxes Warm White (beige)

SS Buffer Polished Stainless Steel

Aluminum Buffer Wire Brushed Aluminum

Ambient (Enclosure):

BAPI-Boxes -40ºF to 185ºF, (-40º to 85ºC)

No Box, w/ sensor -40ºF to 212ºF, (-40º to 100ºC)

Hanging Bracket -40ºF to 122ºF, (-40º to 50ºC)

Agency: RoHS, CE (Thermistors 10KΩ and smaller),

Pt= DIN43760, IEC Pub 751-1983,

JIS C1604-1989

-BB & -BB2, Polycarbonate, UL94V-0, UV rated

0 to 100% RH, Non-condensing

Specications subject to change without notice.

4 of 4

Loading...

Loading...