Page 1

Extreme Temperature RTD Sensors

BA/1x[1,2,3] Temperature Sensor

Installation & Operating Instructions

8612_ins_RTD_EXTRM

Overview

The Extreme Temperature Sensor is made for thermowell mounting, direct insertion or remote probe mounting. The probe is made

of Stainless Steel and made in different lengths for a custom t. The RTD’s are available in 100Ω or 1KΩ 385 curve as shown in the

specications. The enclosures come in plastic or metal for both NEMA 3R and NEMA 4 applications and are all plenum rated.

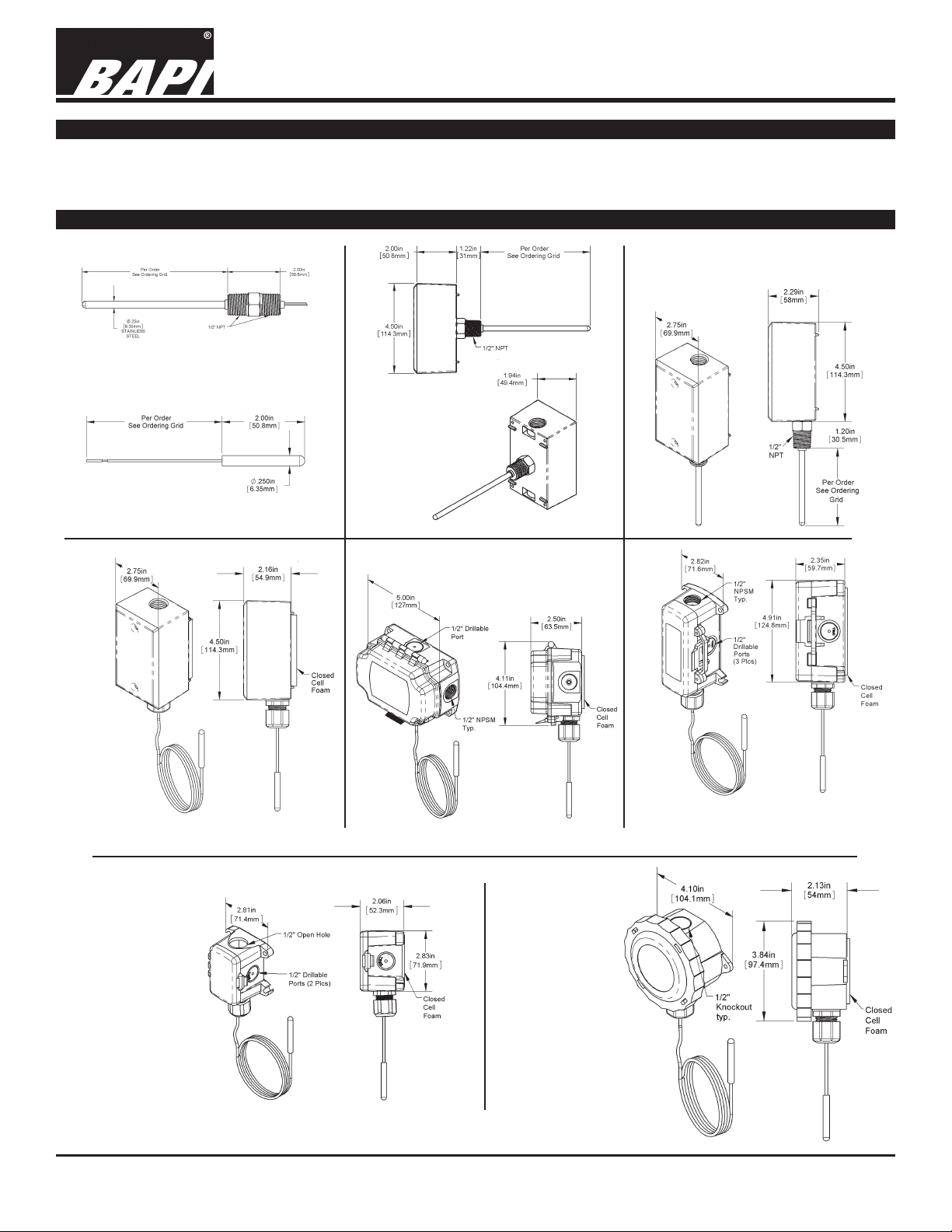

Identication

6

Fig. 4: Extreme Temp Immersion

with Weatherproof (WP) Enclosure,

Fig. 1: Extreme Temp Immersion Sensor

Fig. 3: Extreme

Temp Immersion

with Weatherproof

(WP) Enclosure,

Standard Mount

Outside Mount

rev. 07/07/16

Fig. 2: Extreme Temp Remote Probe

Fig. 5:

Extreme

Temp Remote

Sensor with

Weatherproof

(WP)

Enclosure

Fig. 6: Extreme Temp Remote

Sensor with BAPI-Box (BB)

Enclosure

Fig. 7: Extreme Temp Remote Sensor

with BAPI-Box 2 (BB2) Enclosure

Fig. 8: Extreme

Temp Remote Sensor

with BAPI-Box 4

(BB4) Enclosure

(A Pierceable

Knockout Plug

is available from

BAPI for the open

port in the BB4.

Part #BA/PKP-100)

Fig. 9: Extreme

Temp Remote Sensor

with Weather Tight

(EU) Enclosure

Specications subject to change without notice.

1 of 4

Page 2

Extreme Temperature RTD Sensors

BA/1x[1,2,3] Temperature Sensor

Installation & Operating Instructions

8612_ins_RTD_EXTRM

Mounting

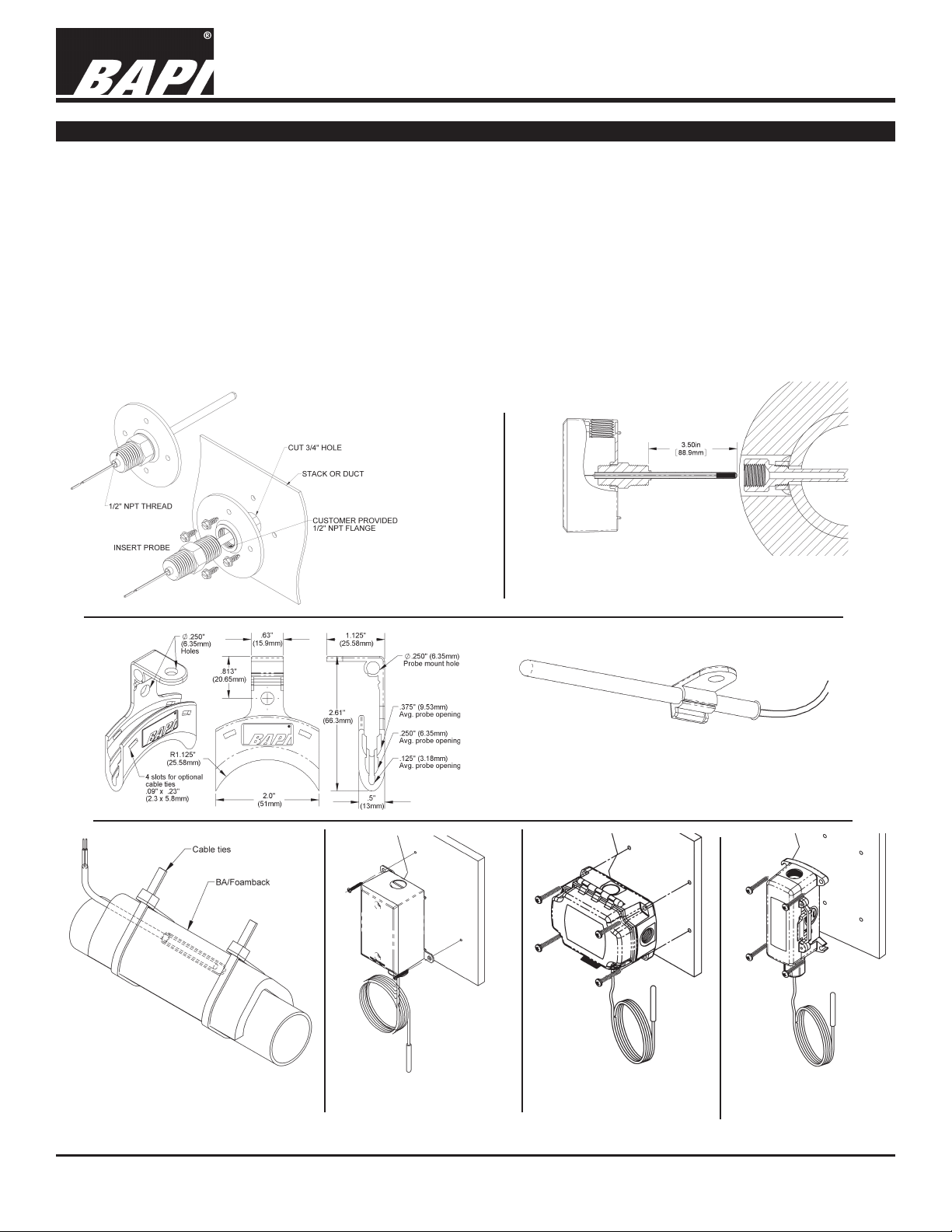

Application: Figure 9 shows a typical four-inch thermowell and four-inch immersion probe installed into an eight inch pipe. In a

properly insulated pipe with liquid or steam, the temperature is essentially the same across the entire cross section of the pipe. Usually

thermowells are sized to extend to the center of the pipe; however, shorter thermowells will give proper temperature readings if properly

insulated. The shorter thermowells are used in pipes with high ow velocities. See Application notes “Thermowells Explained” on our

website at www.bapihvac.com

Thermowell Installer: Typically a Pipe Fitter drills a ¾-inch hole into the pipe where the thermowell is needed. A customer provided

tting, called a Threadolet or Weldolet, is welded to the pipe over the hole. The Threadolet has a ½” NPT thread in the center. Thread

sealant such as Teon tape or pipe dope is applied to the ½” NPT threads of the thermowell. The thermowell is then inserted into the

Threadolet and tightened. Estimates on insertion depths can be seen in our Application note “Thermowells Explained” on our website

at www.bapihvac.com

Sensor Installation: Insert the immersion sensor into the well with the stainless steel screw tting into the opening on the well. Hand

tighten the immersion sensor snugly without too much torque. Make sure that the tip of the immersion sensor is inserted as close

to the well bottom as possible. The well is close tting to the sensor and will offer an accurate reading without the need for thermal

compound.

rev. 07/07/16

Fig. 13: Extreme Temp Remote Sensor

in a strap-on application

Fig. 10: Extreme Temp

Probe with ange mount

Fig. 14:

Extreme

Temp Remote

Sensor with

Weatherproof

(WP)

Enclosure

Fig. 11: Extreme Temp Immersion with

Weatherproof Enclosure

Fig. 12: Remote Sensor mounting using the scored break off

of the Flexible Probe Bracket (FPB) which is shown at left.

Fig. 15: Extreme Temp

Remote Sensor with

BAPI-Box (BB)

Fig. 16: Remote Sensor

with BAPI-Box 2 (BB2)

Specications subject to change without notice.

2 of 4

Page 3

Extreme Temperature RTD Sensors

BA/1x[1,2,3] Temperature Sensor

Installation & Operating Instructions

8612_ins_RTD_EXTRM

Mounting continued....

Fig. 18: Extreme

Fig. 17: Extreme Temp

Remote Sensor with

BAPI-Box 4 (BB4)

Enclosure

Temp Remote

Sensor with

Weather Tight (EU)

Enclosure

Fig. 19: Immersion Thermowell

Wiring & Termination

BAPI recommends using twisted pair of at least 22AWG and sealant lled connectors for all wire connections. Larger

gauge wire may be required for long runs. All wiring must comply with the National Electric Code (NEC) and local codes.

Do NOT run this device’s wiring in the same conduit as high or low voltage AC power wiring.

BAPI’s tests show that inaccurate signal levels are possible when AC power wiring is present in the same conduit as the

sensor wires.

rev. 07/07/16

To Controller

Analog Input (AI)

(No Polarity)

Thermistor

or RTD

Sensor

Fig. 20: 2 Wire Lead Wire Termination for Thermistor or RTD

To Controller

Analog Input (AI)

(No Polarity)

Fig. 21: 3 Wire Lead Wire Termination for RTD

Fig. 22: Terminal Strip (-TS) Option for 2 Wire Sensors

Termination

Specications subject to change without notice.

Fig. 23: Terminal Strip (-TS) Option for 3 Wire

Sensors Termination

3 of 4

Page 4

8612_ins_RTD_EXTRM

Diagnostics

Extreme Temperature RTD Sensors

BA/1x[1,2,3] Temperature Sensor

Installation & Operating Instructions

rev. 07/07/16

Problems:

Controller reports higher or

lower than actual temperature

Possible Solutions:

- Conrm the input is set up correctly in the front end software

- Check wiring for proper termination & continuity. (shorted or open)

- Disconnect wires and measure sensor resistance and verify the “Sensor” output

is correct.

Specications

S

ensor Passive resistance

RTD PTC, 2 or 3 wire

RTD Resistance Temperature Device

Platinum (Pt) 1KΩ @0ºC, 385 curve,

Pt Accuracy (std) 0.12% @Ref, or ±0.55ºF, (±0.3ºC)

Pt Stability ±0.25ºF, (±0.14ºC)

Pt Self Heating 0.4 ºC/mW @0ºC

RTD Probe range

1KΩ [1] -328 to 32ºF, (-200 to 0ºC)

1KΩ [2] 77 to 500ºF, (25 to 260ºC)

1KΩ [3] 77 to 1,112ºF, (25 to 600ºC)

Sensitivity Approximate @ 32ºF (0ºC)

RTD (Pt) 3.85Ω/ºC for 1KΩ RTD

0.385Ω/ºC for 100Ω RTD

Lead wire 22awg stranded

Wire Insulation Plenum rated

1KΩ[1] PTFE, -328 to 32ºF, (-200 to 0ºC)

1KΩ[2] PTFE, 77 to 500ºF, (25 to 260ºC)

1KΩ[3] Fiberglass, 77 to 1,112ºF, (25 to 600ºC)

Probe Rigid, 304 Stainless Steel, 0.25” OD

Probe Length

Probe 2”, 4”, 8” or custom per order

Remote Sensor 2” w/ customer cable length

Mounting

Probe ½” NPT Double Threaded

Remote Sensor Probe with or without enclosure

Enclosure Types

Note: The double threaded immersion probe is only

available with the Weatherproof (-WP) box due to the very

high or very low temperature RTD capabilities.

Weatherproof -WP, w/ two ½” FNPT entries, (Bell box)

BAPI-Box

BAPI-Box 2

BAPI-Box 4:

-BB, w/ our ½” NPSM & one ½”

drill-out

-BB2, w/ three ½” NPSM & three ½” drill-outs

-BB4, w/ four ½” drill-outs & one ½” open port

Weather Tight -EU, w/ two ½” knockouts

Enclosure Ratings

Weatherproof -WP, NEMA 3R, IP14

BAPI-Box -BB, NEMA 4X, IP66

BAPI-Box 2 -BB2, NEMA 4X, IP66

BAPI-Box 4 -

BB4, IP10

(IP44 with Knockout Plug in the open port)

Weather Tight -EU, NEMA 4X, IP66

Enclosure Materials

Weatherproof -WP, Cast Aluminum, UV rated

BAPI-Box -BB, Polycarbonate, UL94V-0, UV rated

BAPI-Box 2

-BB2, Polycarbonate, UL94V-0, UV rated

BAPI-Box 4 -BB4, Polycarbonate & Nylon, UL94V-0

Weather Tight -EU, ABS Plastic, UL94V-0

Ambient (Encl.) 0 to 100% RH, Non-condensing

All 3 BAPI-Boxes -40ºF to 185ºF, (-40º to 85ºC)

Weather Tight -40ºF to 185ºF, (-40º to 85ºC)

Weatherproof -100ºF to 1,000ºF, (-73º to 538ºC)

Agency RoHS, CE

PT= DIN43760, IEC Pub 751-1983,

JIS C1604-1989

Specications subject to change without notice.

4 of 4

Loading...

Loading...