Page 1

20911_ins_Duct_Strap_On_Passive

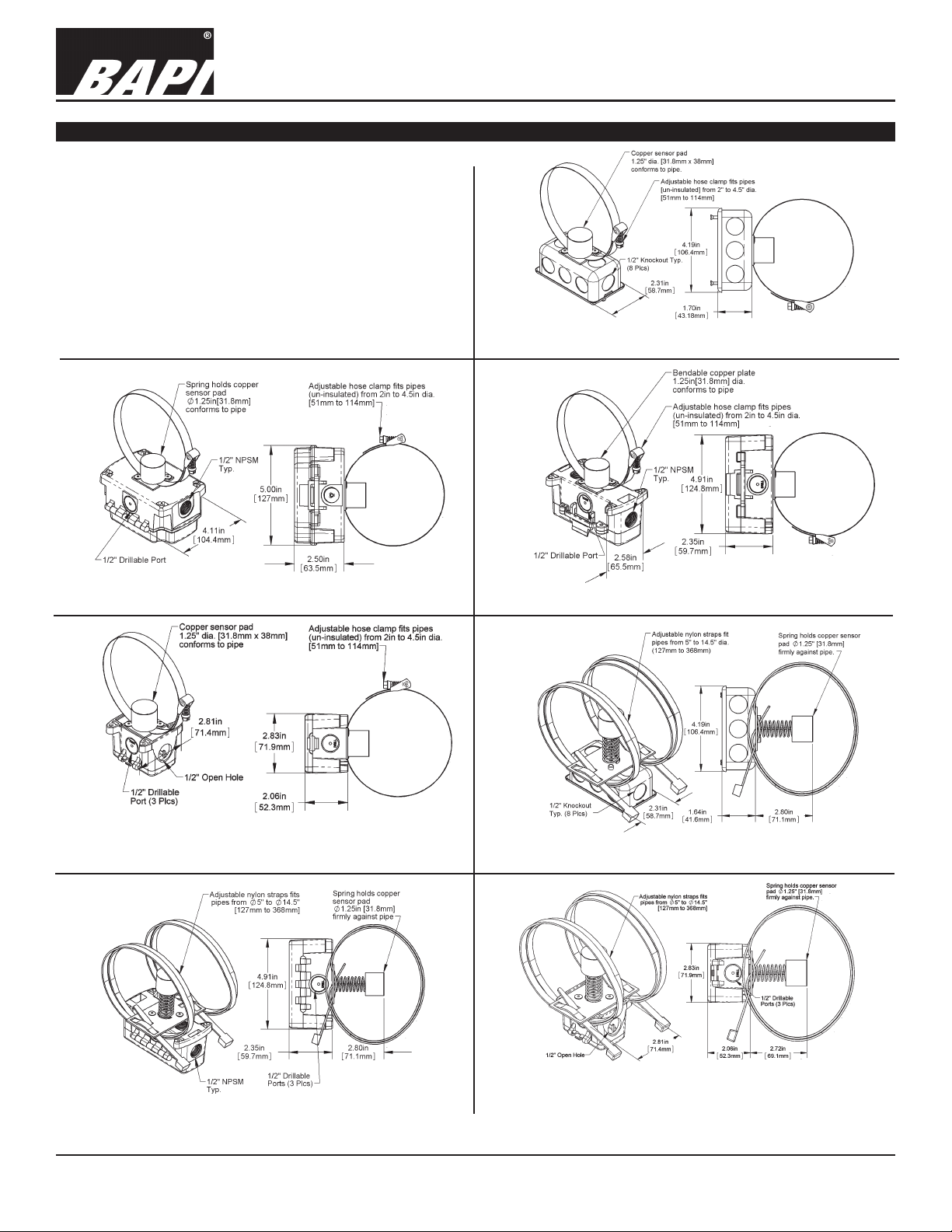

Overview and Identication

Strap Sensors are made for direct pipe mounting and

temperature measurement of water pipe applications.

The Clamp-On units are for mounting before any

insulation is on the pipe and the Spring-Loaded units are

for mounting to pipes with up to 2” of insulation using a

unique spring sensor extension.

Both units are available with multiple thermistor’s or RTD’s

as shown in the specications. Enclosure mounting styles

come in plastic or metal for both NEMA 1 and NEMA 4

applications and are all plenum rated.

Strap-On Temperature Sensors - BA/#-(S,STP)

Installation & Operations

rev. 06/29/15

Fig 1: Clamp-On Strap with NEMA 1 J-Box (JB)

Fig 4: Clamp-On Strap with NEMA 1 BAPI-Box 4 (BB4)

(A Pierceable Knockout Plug is available from BAPI for the

open port in the BB4. Part #BA/PKP-100)

Fig 3: Clamp-On Strap with w/ NEMA 4 BAPI-Box 2 (BB2)Fig 2: Clamp-On Strap with w/ NEMA 4 BAPI-Box (BB)

Fig 5: Spring-Loaded Strap w/ NEMA 1 J-Box (JB)

Fig 6: Spring-Loaded Strap w/ NEMA 4 BAPI-Box 2 (BB2)

Specications subject to change without notice.

Fig 7: Spring-Loaded Strap w/ NEMA 1 BAPI-Box 4 (BB4)

(A Pierceable Knockout Plug is available from BAPI for the

open port in the BB4. Part #BA/PKP-100)

1 of 4

Page 2

20911_ins_Duct_Strap_On_Passive

Mounting

Strap-On Temperature Sensors - BA/#-(S,STP)

Installation & Operations

rev. 06/29/15

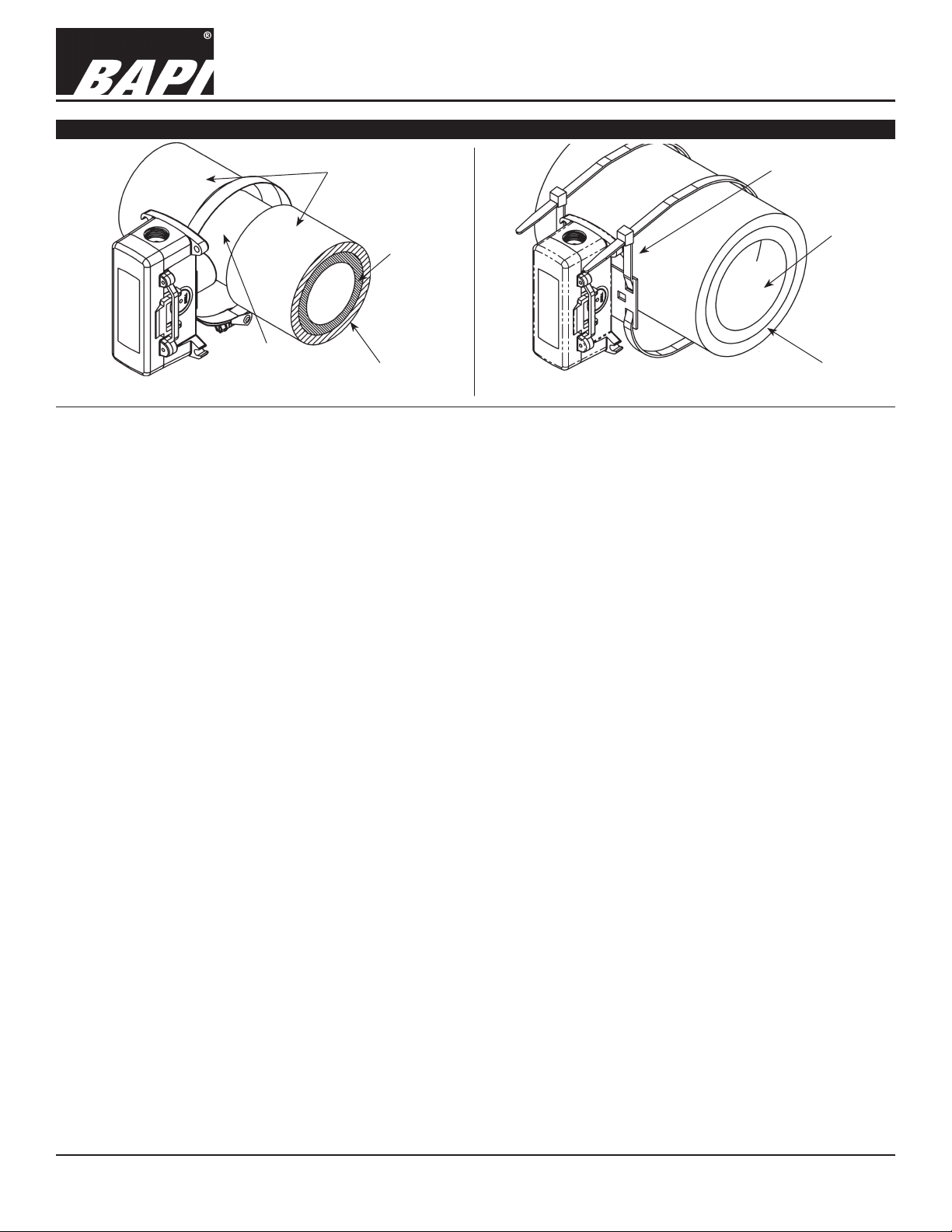

2 Inch Insulation

Cleaned off To

Bare Pipe

Fig 8: Typical Clamp-On (-S) Installation

The Pipe

Pipe

Insulation

Fig 9: Typical Spring-Loaded (-STP) Installation

1.5 Inch Hole In

The Insulation

Pipe

Insulation

Application: This sensor technique is for reading the uid temperature in a pipe by reading the temperature of the pipe.

Properly installed strap sensors with insulation around the local strap-on sight will offer a very accurate temperature of the

water inside the pipe to within .5 °F or better of the inside pipe water temperature.

Clamp-On Unit Installation: BA/#-S

1. Fig 8 shows a typical installation for pipes from 2” to 4.5”. Stripping away insulation is OK.

2. Larger pipes can be accommodated by adding another, customer supplied, stainless steel hose clamp extending the

possible pipe diameter.

3. If there is insulation, clean away a section of the pipe insulation a minimum of 2” all around the pipe. The copper sensor pad and SS strap must be in direct contact with the metal or plastic pipe. Note: Nothing should be between the

copper plate sensor and the bare pipe.

4. Tighten the strap-so that the sensor does not rotate around the pipe and so that the foam is compressed not more than

50% allowing the copper sensor plate to form (bend) to the pipe curvature for maximum temperature conduction. BAPI

recommends pre-forming the copper plate by bending it around the pipe with your ngers.

5. After the strap-on sensor is securely mounted, add insulation a minimum of 1” thick and a minimum of 4 pipe diameters

on each side of the copper sensor pad. (Example: A 2” pipe should have 8” of insulation on each side of the sensor).

Only cover the sensor box to the top of the metal cover plate or to the BB door hinge so termination and servicing can

be completed.

6. Terminate per the following Wiring and Termination Section.

Spring Loaded Unit Installation: BA/#-STP

1. Fig 9 shows a typical installation for insulated pipes from 5” to 14”. Insulation thickness accommodated is 0.5” to 2.5”.

2. Larger pipes can be accommodated by adding another, customer supplied, tie rap strap extending the possible pipe

diameter.

3. Make a 1.5 inch diameter hole in the insulation where the sensor is to be placed and clean the pipe from debris. Extend the spring so the copper sensor pad is in direct contact with the metal or plastic pipe. Note: No debris should be

between the copper plate sensor and the bare pipe. The spring can retract to a minimum insulation thickness of ~.5”

compressed to ~2.5” extended.

4. Position the box and sensor over the hole.

5. Tighten the strap so that the sensor spring is compressed no more than 50% allowing the copper sensor plate to form

(bend) to the pipe curvature for maximum temperature conduction. BAPI recommends pre-forming the copper plate by

bending it around the pipe with your ngers. Extend the spring further by turning it clockwise if the copper sensor plate

contact is questionable. The copper sensor plate must be in direct contact with the pipe.

6. After the strap on sensor is securely mounted, add insulation back in (backll) around the spring extension, using the

removed insulation, so that no heat or cold from the pipe can escape.

7. If more insulation is desired, only cover the sensor box to the top of the metal cover plate or to the BB door hinge so

termination and servicing can be completed.

8. Terminate per the following Wiring and Termination Section.

Specications subject to change without notice.

2 of 4

Page 3

Strap-On Temperature Sensors - BA/#-(S,STP)

Installation & Operations

20911_ins_Duct_Strap_On_Passive

Wiring & Termination

BAPI recommends using twisted pair of at least 22AWG and sealant lled connectors for all wire connections. Larger gauge wire may

be required for long runs. All wiring must comply with the National Electric Code (NEC) and local codes. Do NOT run this device’s wiring

in the same conduit as high or low voltage AC power wiring.

BAPI’s tests show that inaccurate signal levels are possible when AC power wiring is present in the same conduit as the sensor wires.

To Controller

Analog Input (AI)

Thermistor

(No Polarity)

or RTD

Sensor

To Controller

Analog Input (AI)

(No Polarity)

Fig. 10: 2 Wire Lead Wire Termination for Thermistor or RTD Fig. 11: 3 Wire Lead Wire Termination for RTD

rev. 06/29/15

Fig. 12: Terminal Strip (-TS) Option for 2 Wire Sensors Termination

Specications subject to change without notice.

Fig. 13: Terminal Strip (-TS) Option for 3 Wire Sensors Termination

Fig. 15: Test & Balance (-TB) Option for 3 Wire Sensors TerminationFig. 14: Test & Balance (-TB) Option for 2 Wire Sensors Termination

3 of 4

Page 4

20911_ins_Duct_Strap_On_Passive

Diagnostics

Possible Problem:

Controller reports higher or

lower than actual temperature

Specications

Strap-On Temperature Sensors - BA/#-(S,STP)

Installation & Operations

rev. 06/29/15

Possible Solutions:

- Conrm the input is set up correctly in the front end software

- Check wiring for proper termination & continuity. (shorted or open)

- Disconnect wires and measure sensor resistance and verify the

“Sensor” output is correct.

Sensor Passive

Thermistor NTC, 2 wire

RTD PTC, 2 or 3 wire

Thermistor Thermal resistor

Temp. Output Resistance

Accuracy (Std) ±0.36ºF, (±0.2ºC)

Accuracy (High) ±0.18ºF, (±0.1ºC), [XP] option

Stability < 0.036ºF/Year, (<0.02ºC/Year)

Heat dissipation 2.7 mW/ºC

Temp. Drift <0.02ºC per year

Probe range -40º to 221ºF (-40º to 105ºC)

RTD Resistance Temperature Device

Platinum (Pt) 100Ω or 1KΩ @0ºC, 385 curve,

Platinum (Pt) 1KΩ @0ºC, 375 curve

Pt Accuracy (Std) 0.12% @Ref, or ±0.55ºF, (±0.3ºC)

Pt Accuracy (High) 0.06% @Ref, or ±0.277ºF

(±0.15ºC), [A]option

Pt Stability ±0.25ºF, (±0.14ºC)

Pt Self Heating 0.4 ºC/mW @0ºC

Pt Probe range -40º to 221ºF, (-40 to 105ºC)

Nickel (Ni) 1000Ω @70ºF, JCI curve

Ni Probe range -40º to 221ºF (-40 to 105ºC)

Sensitivity Approximate @ 32ºF (0ºC)

Thermistor Non-linier

See bapihvac.com “Sensor Specs”

1KΩ RTD (Pt) 3.85Ω/ºC

100Ω RTD (Pt) 0.385Ω/ºC

Nickel (Ni) 2.95Ω/ºF for the JCI RTD

Lead wire 22awg stranded

Wire Insulation

Etched Teon, Plenum rated

Probe Copper sensor plate, 24 AWG,

1.25” diameter

Mounting

Clamp-On -S, ½” Stainless steel worm gear hose

clamp

Strap-On -STP, 48” Nylon tie strap, 1/2” wide

Enclosure Types: (Part number designator in bold)

J-Box: -JB, w/ eight ½” knock-outs

BAPI-Box: -BB, w/ four ½” NPSM & one ½” drill-out

BAPI-Box 2:

BAPI-Box 4:

-BB2, w/ three ½” NPSM & three ½” drill-outs

-BB4, w/ three ½” drill-outs & one ½” open port

Enclosure Ratings: (Part number designator in bold)

J-Box: -JB, NEMA 1

BAPI-Box: -BB, NEMA 4, IP66, UV Rated

BAPI-Box 2: -BB2, NEMA 4, IP66, UV Rated

BAPI-Box 4: -BB4, IP10 (with spring installed)

(IP44 without spring and with Knockout

Plug installed in the open port)

Enclosure Material: (Part number designator in bold)

J-Box: -JB, Galvanized steel, UL94H-B

BAPI-Box: -BB, Polycarbonate, UL94V-0, UV rated

BAPI-Box 2: -BB2, Polycarbonate, UL94V-0, UV rated

BAPI-Box 4: -BB4, Polycarbonate & Nylon, UL94V-0

Ambient (Enclosure): 0 to 100% RH, Non-condensing

J-Box: -JB, -40ºF to 212ºF, (-40º to 100ºC)

BAPI-Box: -BB, -40ºF to 185ºF, (-40 to 85ºC)

BAPI-Box 2: -BB2, -40ºF to 185ºF, (-40 to 85ºC)

BAPI-Box 4: -BB4, -40ºF to 185ºF, (-40 to 85ºC)

Agency: RoHS, *CE

PT= DIN43760, IEC Pub 751-1983,

JIS C1604-1989

*Passive Thermistors 20KΩ and smaller are

CE Compliant

Specications subject to change without notice.

4 of 4

Loading...

Loading...