Page 1

Strap-On Sensors Transmitters

BA/Txx-(S, STP) Temperature Sensor

Installation & Operating Instructions

20922_ins_Strap on_Active

Overview

The BA/Txx#-(S, STP) Strap on Sensors are made for direct pipe mounting and temperature measurement of water pipe

applications. The BA/Txx#-S is for mounting before any insulation is on the pipe and the BA/Txx#-STP is for mounting to

pipes with up to 2” of insulation using a unique spring sensor extension. The 4 to 20mA transmitter can be ordered with

100Ω (385), 1KΩ (385) RTDs or 10KΩ type 2 thermistor sensor. A 0 to 5VDC or 0 to 10VDC transmitter is also available

with the 10KΩ type 2 thermistor sensor. Special high accuracy RTD matched transmitters (M) are available which match

the sensor to the transmitter for improved accuracy. Enclosure mounting styles come in plastic or metal for both NEMA 1

and NEMA 4 applications and are all plenum rated.

Identication

6

rev.04/18/13

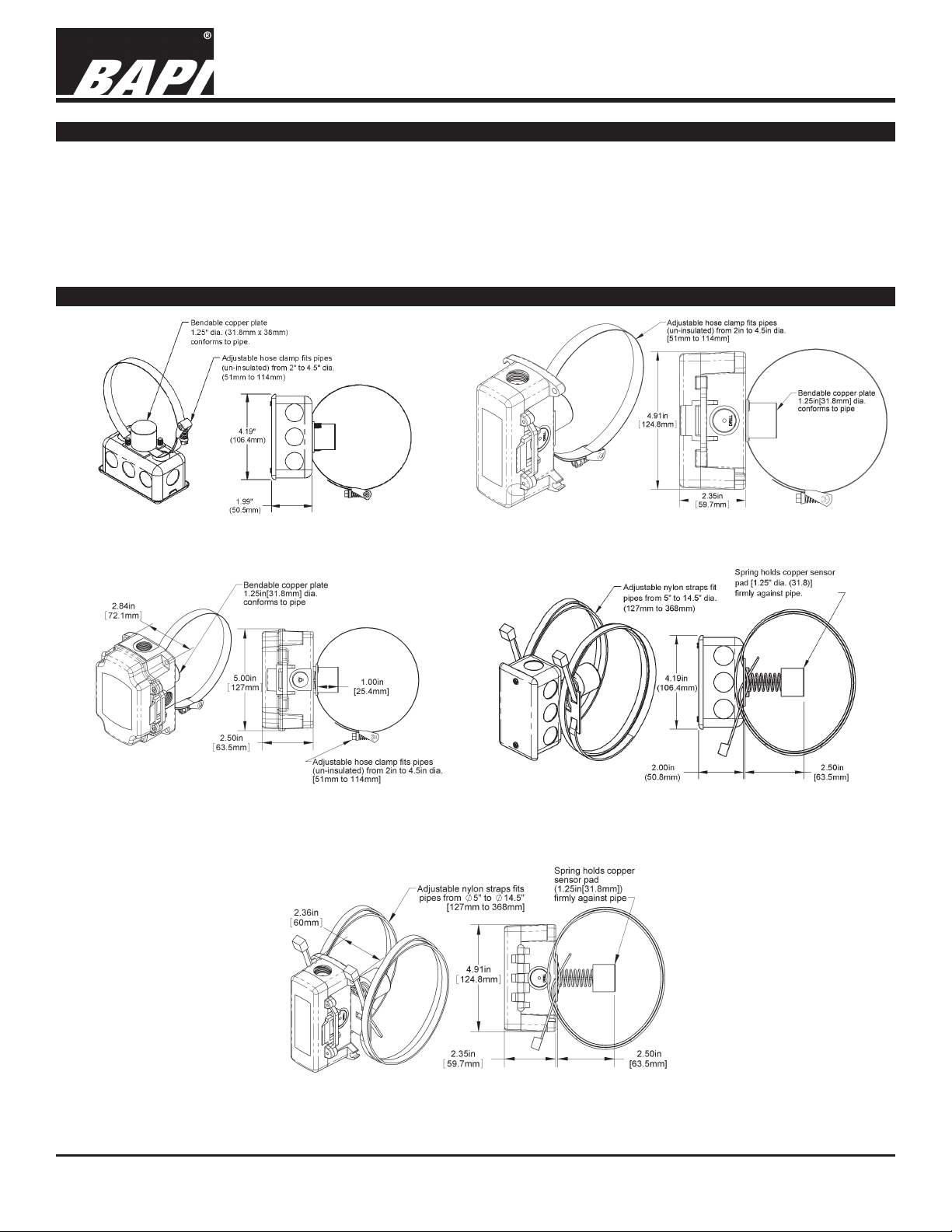

Fig. 1: Clamp-On Strap Unit with Junction Box (Standard)

Fig. 3: Clamp-On Strap Unit in BAPI-Box (BB) Enclosure

Fig. 2: Clamp-On Strap Unit in BAPI-Box 2 (BB2) Enclosure

Fig. 4: Spring Loaded Strap Unit in a Junction Box (Standard)

Fig. 5: Spring Loaded Strap Unit in a BAPI-Box 2 (BB2) Enclosure

Specications subject to change without notice.

1 of 4

Page 2

20922_ins_Strap on_Active

Strap Mount Application

Strap-On Sensors Transmitters

BA/Txx-(S, STP) Temperature Sensor

Installation & Operating Instructions

rev.04/18/13

Application: This sensor technique is for reading the uid temperature in

a pipe by reading the temperature of the pipe. Properly installed Strap-On

sensors with insulation around the local strap-on sight will offer a very accu-

2 inches of

insulation removed

to let the sensor

contact bare pipe

rate temperature of the water inside the pipe to within .5 °F or better of the

inside pipe water temperature.

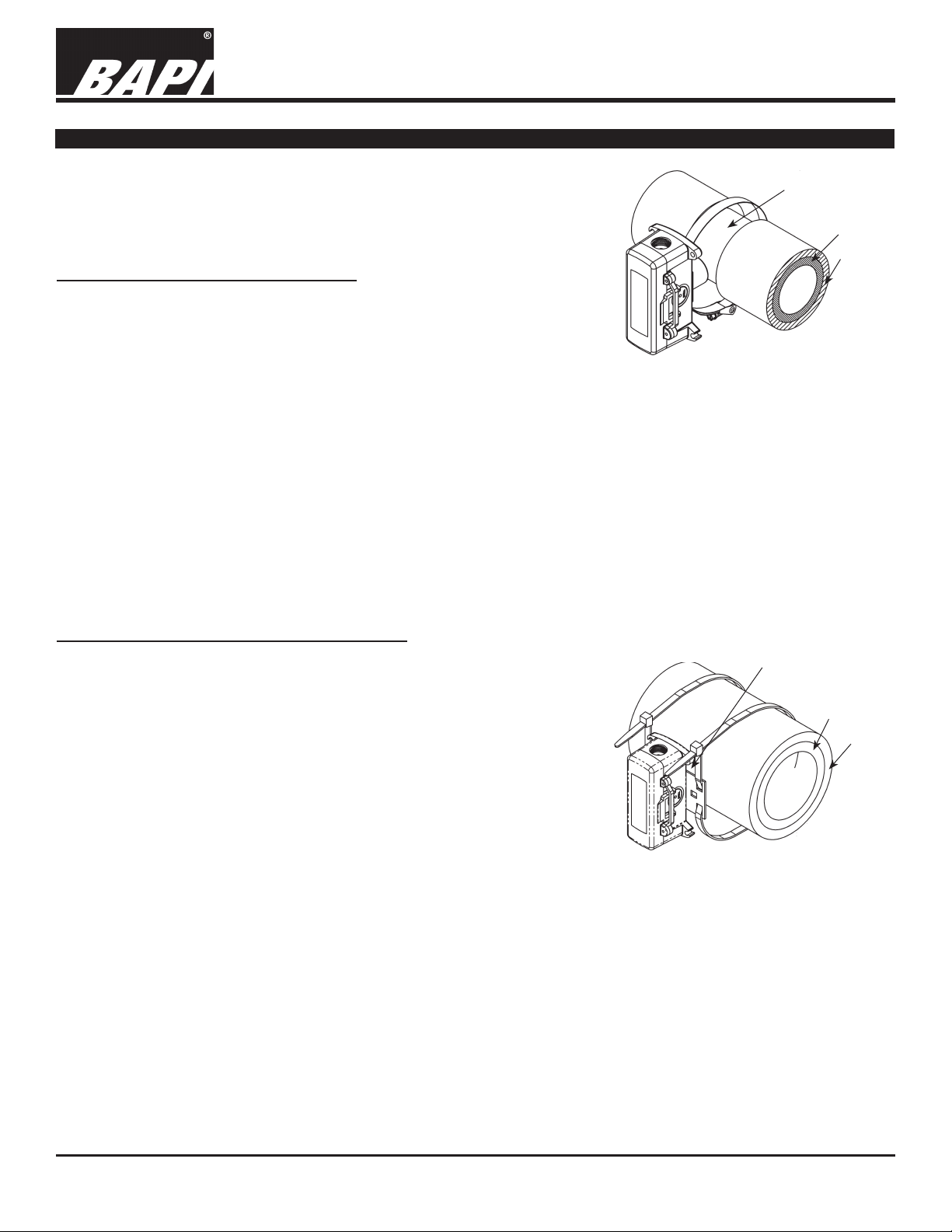

Clamp-On Strap Unit Installation: BA/#-S

1. Figure 6 show a typical direct pipe installation for pipes from 2” to

4.5”. Stripping away insulation is OK.

2. Larger pipes can be accommodated by adding another, customer

supplied, stainless steel hose clamp extending the possible pipe

diameter.

3. If there is insulation, clean away a section of the pipe insulation a

minimum of 2” all around the pipe. The copper sensor pad and SS

Fig. 6: Clamp-On Strap Unit Mounting

(BAPI-Box 2 Enclosure shown

but mounting is similar for all

BAPI-Boxes.)

strap must be in direct contact with the metal or plastic pipe. Note:

Nothing should be between the copper plate sensor and the bare pipe.

4. Tighten the strap-so that the sensor does not rotate around the pipe and so that the foam is compressed not more

than 50% allowing the copper sensor plate to form (bend) to the pipe curvature for maximum temperature conduction. BAPI recommends pre-forming the copper plate by bending it around the pipe with your ngers.

5. After the strap-on sensor is securely mounted, add insulation a minimum of 1” thick and a minimum of 4 pipe diameters on each side of the copper sensor pad. (EXPL. A 2” pipe should have 8” of insulation on each side of the

sensor). Only cover the sensor box to the top of the metal cover plate or to the BB door hinge so termination and

servicing can be completed.

6. Terminate per the following Wiring and Termination Section.

Pipe

Insulation

String-Loaded Strap Unit Installation: BA/#-STP

1. Figure 7 shows a typical direct pipe installation for insulated pipes

from 5” to 14”. Insulation thickness accommodated is 0.5” to 2.5”.

2. Larger pipes can be accommodated by adding another, customer

1.5 inch hole in the

Insulation to let the

spring-loaded sensor

contact bare pipe

supplied, tie rap strap extending the possible pipe diameter.

3. Make a 1.5 inch diameter hole in the insulation where the sensor

is to be placed and clean the pipe from debris. Extend the spring

so the copper sensor pad is in direct contact with the metal or

plastic pipe. Note: No debris should be between the copper plate

sensor and the bare pipe. The spring can retract to a minimum

insulation thickness of ~.5” compressed to ~2.5” extended.

4. Position the box and sensor over the hole.

5. Tighten the strap so that the sensor spring is compressed no

more than 50% allowing the copper sensor plate to form (bend)

to the pipe curvature for maximum temperature conduction. BAPI

Fig. 7: Spring Loaded Strap Unit Mounting

(BAPI-Box 2 Enclosure shown but

mounting is similar for all BAPI-Boxes.)

recommends pre-forming the copper plate by bending it around

the pipe with your ngers. Extend the spring further by turning it

clockwise if the copper sensor plate contact is questionable. The copper sensor plate must be in direct contact

with the pipe.

6. After the strap on sensor is securely mounted, add insulation back in (backll) around the spring extension, using

the removed insulation, so that no heat or cold from the pipe can escape.

7. If more insulation is desired, only cover the sensor box to the top of the metal cover plate or to the BB door hinge

so termination and servicing can be completed.

8. Terminate per the following Wiring and Termination Section.

Pipe

Insulation

Specications subject to change without notice.

2 of 4

Page 3

Strap-On Sensors Transmitters

BA/Txx-(S, STP) Temperature Sensor

Installation & Operating Instructions

20922_ins_Strap on_Active

Wiring & Termination

BAPI recommends using twisted pair of at least 22AWG and sealant lled connectors for all wire connections. Larger gauge wire

may be required for long runs. All wiring must comply with the National Electric Code (NEC) and local codes. Do NOT run this

device’s wiring in the same conduit as high or low voltage AC power wiring. BAPI’s tests show that inaccurate signal levels are

possible when AC power wiring is present in the same conduit as the sensor wires.

rev.04/18/13

Fig. 8: Typical RTD 4 to 20 mA Transmitter with Flying Leads

Fig. 10: Typical Thermistor 4 to 20mA Transmitter

Fig. 9: Typical RTD 4 to 20mA Transmitter with Terminals

Fig. 11: Typical Thermistor Voltage Transmitter

Diagnostics

Possible Problems: Possible Solutions:

•

Unit will not operate. - Measure the power supply voltage by placing a voltmeter across the transmitter’s (+) and

- Check if the RTD wires are physically open or shorted together and are terminated to the

- Measure the physical temperature at the temperature sensor’s location using an accurate

• The reading is incorrect in the controller.

- For a 4-20mA current transmitter measure the transmitter current by placing an ammeter

Voltage Temperature Equation

T = TLow + (V x TSpan)

VSpan

T = Temperature at sensor

TLow = Low temperature of span

THigh = High temperature of span

TSpan = THigh - TLow

VLow = Low transmitter voltage

usually=(0, 1 or 2v)

VHigh = High transmitter voltage

usually=(5 or 10v)

VSpan = VHigh - VLow

V = Signal reading in volts

(-) terminal. Make sure that it matches the drawings above and power requirements in the

specications.

transmitter.

temperature standard. Disconnect the temperature sensor wires and measure the

temperature sensor’s resistance with an ohmmeter. Compare the temperature sensor’s

resistance to the appropriate temperature sensor table on the BAPI web site.

- Determine if the input is set up correctly in the controllers and BAS software.

in series with the controller input. The current should read according to the “4-20mA

Temperature Equation” shown below.

- For a voltage transmitter, measure the signal with a volt meter (Orange or Orange/Black to

Black). The signal should read according to the “Voltage Temperature Equation” shown below.

4-20mA Temperature Equation

T = TLow + (A -4) x (TSpan)

16

T = Temperature at sensor

TLow = Low temperature of span

THigh = High temperature of span

TSpan = THigh - TLow

A = Signal reading in mA

Specications subject to change without notice.

3 of 4

Page 4

20922_ins_Strap on_Active

Specications

Strap-On Sensors Transmitters

BA/Txx-(S, STP) Temperature Sensor

Installation & Operating Instructions

rev.04/18/13

RTD Transmitter

Power Required: 7 to 40VDC

Transmitter Output: 4 to 20mA, 850Ω@24VDC

Output Wiring: 2 wire loop

Output Limits: <1mA (short), <22.35mA (open)

Span:

Zero:

Min. 30ºF (17ºC), Max 1000ºF, (555ºC)

Min. -148°F (-100°C), Max 900ºF (482ºC)

Zero & Span Adjust: 10% of span

Accuracy: ±0.065% of span

Linearity: ±0.125% of span

Power Output Shift: ±0.009% of span

RTD Sensor: 2 wire Platinum (Pt), 385 curve

Transmitter Ambient -4 to 158ºF(-20 to 70ºC)

0 to 95% RH, Non-condensing

Thermistor Transmitter

Supply Voltage:

10 to 35 VDC (0 to 5 VDC or 4 to 20 mA Outputs)

15 to 35 VDC (0 to 10 VDC Output)

12 to 24 VAC (0 to 5 VDC Outputs)

15 to 24 VAC (0 to 10 VDC Output)

Transmitter Output: 4 to 20mA, 700Ω@24VDC

0 to 5 & 0 to 10VDC, 10KΩ min

Output Wiring: 2 & 3 wire (See wiring detail on pg. 3)

Transmitter Limits: -40 to 185ºF, (-40 to 85ºC)

Accuracy: ±1.015ºC, from (0 to 65ºC)

Linearity: ±0.065ºC, from (0 to 65ºC)

Resolution: Span/1024

Thermistor Sensor: 10K-2 Thermistor, 10KΩ @77ºF

Transmitter Ambient: 32 to 158ºF, (0º to 70ºC)

0 to 95% RH, Noncondensing

Thermistor:

10K-2,Thermal Resistor (Bare Sensor)

Accuracy (Std): ±0.36ºF, (±0.2ºC)

Accuracy (High): ±0.18ºF, (±0.1ºC), [XP] option

Stability: < 0.036ºF/Year, (<0.02ºC/Year)

Heat Dissipation: 2.7 mW/ºC

Probe Range: -40º to 221ºF (-40º to 105ºC)

Wire Colors:

Standard: Yellow/Yellow (no polarity)

High Acc. [XP]: Yellow/Yellow (no polarity)

RTD:

Resistance Temp Device (Bare Sensor)

Platinum (Pt): 100Ω and 1KΩ @0ºC, 385 curve,

Pt Accuracy (Std): 0.12% @Ref, or ±0.55ºF, (±0.3ºC)

Pt Accuracy (High): 0.06% @Ref, or ±0.277ºF,

(±0.15ºC), [A]option

Pt Stability: ±0.25ºF, (±0.14ºC)

Pt Self Heating: 0.4 ºC/mW @0ºC

Pt Probe Range: -40º to 221ºF, (-40 to 105ºC)

Wire Colors:

General color code (other colors possible)

1KΩ, Class B Orange/Orange (no polarity)

1KΩ, Class A Orange/White (no polarity)

100Ω, Class B Red/Red (no polarity)

100Ω, Class A Red/Red-w/black stripe (no polarity)

Sensitivity: Approximate @ 32ºF (0ºC)

Thermistor: Non-linier (See www.bapihvac.com,

click “Sensor Specs”)

RTD (Pt): 3.85Ω/ºC for 1KΩ RTD

0.385Ω/ºC for 100Ω RTD

Lead Wire: 22awg stranded

Insulation: Etched Teon, Plenum rated

Probe: Copper Sensor Plate, 24awg, 1.25” dia.

Mounting:

-S, ½” Stainless steel worm gear hose clamp

-STP, 48” Nylon tie strap, ½” wide

Enclosure Types: (Part number designator in bold)

2”x4” J-Box: Standard w/ eight ½” knock-outs

BAPI-Box: -BB, w/ four ½” NPSM & one ½” drill-out

BAPI-Box 2:

-BB2, w/ three ½” NPSM & three ½” drill-outs

Enclosure Ratings: (Part number designator in bold)

2x4 J-Box: Standard, NEMA 1

BAPI-Box: -BB, NEMA 4, IP66, UV Rated

BAPI-Box 2: -BB2, NEMA 4, IP66, UV Rated

Enclosure Material: (Part number designator in bold)

2x4 J-Box: Galvanized steel, UL94H-B

BAPI-Box: -BB, Polycarbonate, UL94V-0, UV rated

BAPI-Box 2:

-BB2, Polycarbonate, UL94V-0, UV rated

Ambient (Enclosure): 0 to 100% RH, Non-condensing

BB, BB2: -40ºF to 185ºF, (-40º to 85ºC)

J-Box, WP: -40ºF to 212ºF, (-40º to 100ºC)

Agency: RoHS

PT= DIN43760, IEC Pub 751-1983,

JIS C1604-1989

Specications subject to change without notice.

4 of 4

Loading...

Loading...