Page 1

RµP Style Room Units (BA/RuP)

Installation and Operation Instructions

9556_ins_rupa_gen

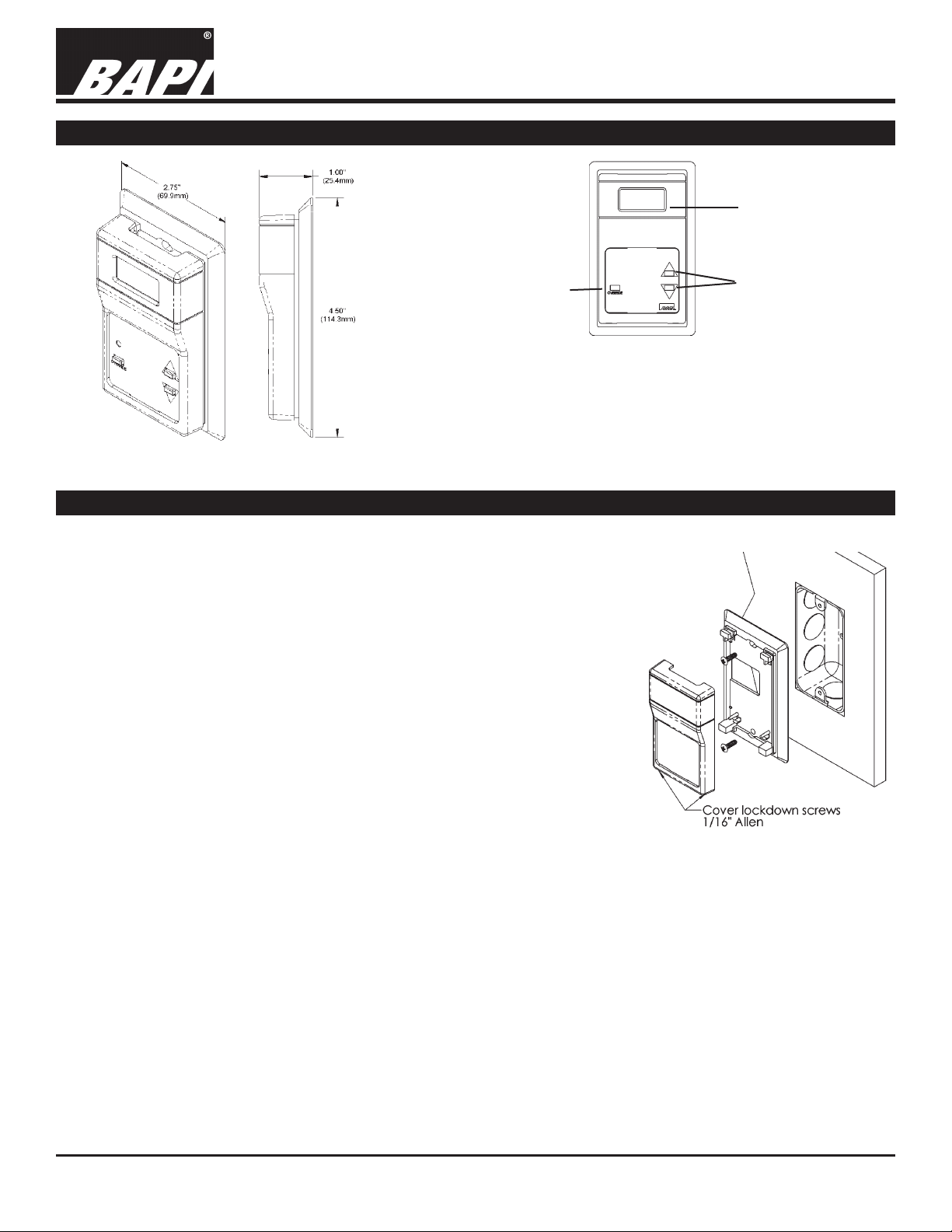

Product Identication

Front Panel

Description

Occupant

Override

Setpoint

When the setpoint buttons are pressed “UP” or “DOWN”, the

current setpoint will display. As the buttons are pressed again, the

display will change with each press.

Override

Fig 1: RuP Room Sensor

Mounting

Mounting hardware is provided for both junction box and drywall installation (junction box installation shown).

For Override, momentarily press the Override button.

Liquid Crystal

Display Readout

Setpoint Adjust

rev. 06/26/15

JUNCTION BOX

1. Pull wire through the wall and out of the junction box, leaving about 6 inches

free.

2. Pull the wire through the hole in the base plate.

3. Secure the plate to the box using the #6-32 x 1/2” mounting screws provided.

4. Terminate the unit according to the Termination Guidelines section.

5. Attach Cover by latching it to the top of the base, rotating the cover down and

snapping it into place.

6. Secure the cover by backing out the lock-down screws using a 1/16” allen

wrench until they are ush with the bottom of the cover.

DRYWALL MOUNTING

1. Place the base plate against the wall where you want to mount the sensor.

2. Use a pencil to mark the two mounting holes and the area where the wires will

come through the wall.

3. Drill two 3/16” holes in the center of each marked mounting hole. Insert a drywall anchor into each hole.

4. Drill one 1/2” hole in the middle of the marked wiring area.

5. Pull the wire through the wall and out of 1/2” hole, leaving about 6” free.

6. Pull the wire through the hole in the base plate.

7. Secure the base to the drywall anchors using the #6 x 1 inch mounting screws provided.

8. Terminate the unit according to the Termination Guidelines section.

9. Attach cover by latching it to the top of the base, rotating the cover down and snapping it into place. Secure the

cover by backing out the lock-down screws using a 1/16” Allen wrench until they are ush with the bottom of the

cover.

Fig 2: Junction box mounting

NOTE: In a wall-mount application, the wall temperature and the temperature of the air within the wall cavity can cause

erroneous readings. The mixing of room air and air from within the wall cavity can lead to condensation, erroneous

readings and premature failure of the sensor. To prevent these conditions, seal the conduit leading to the junction box

and use BAPI’s adhesive backed, foam insulating pad centered over the hole (order part number BA/FOAMBACK).

Specications subject to change without notice.

1

Page 2

RµP Style Room Units (BA/RuP)

Installation and Operation Instructions

9556_ins_rupa_gen

rev. 06/26/15

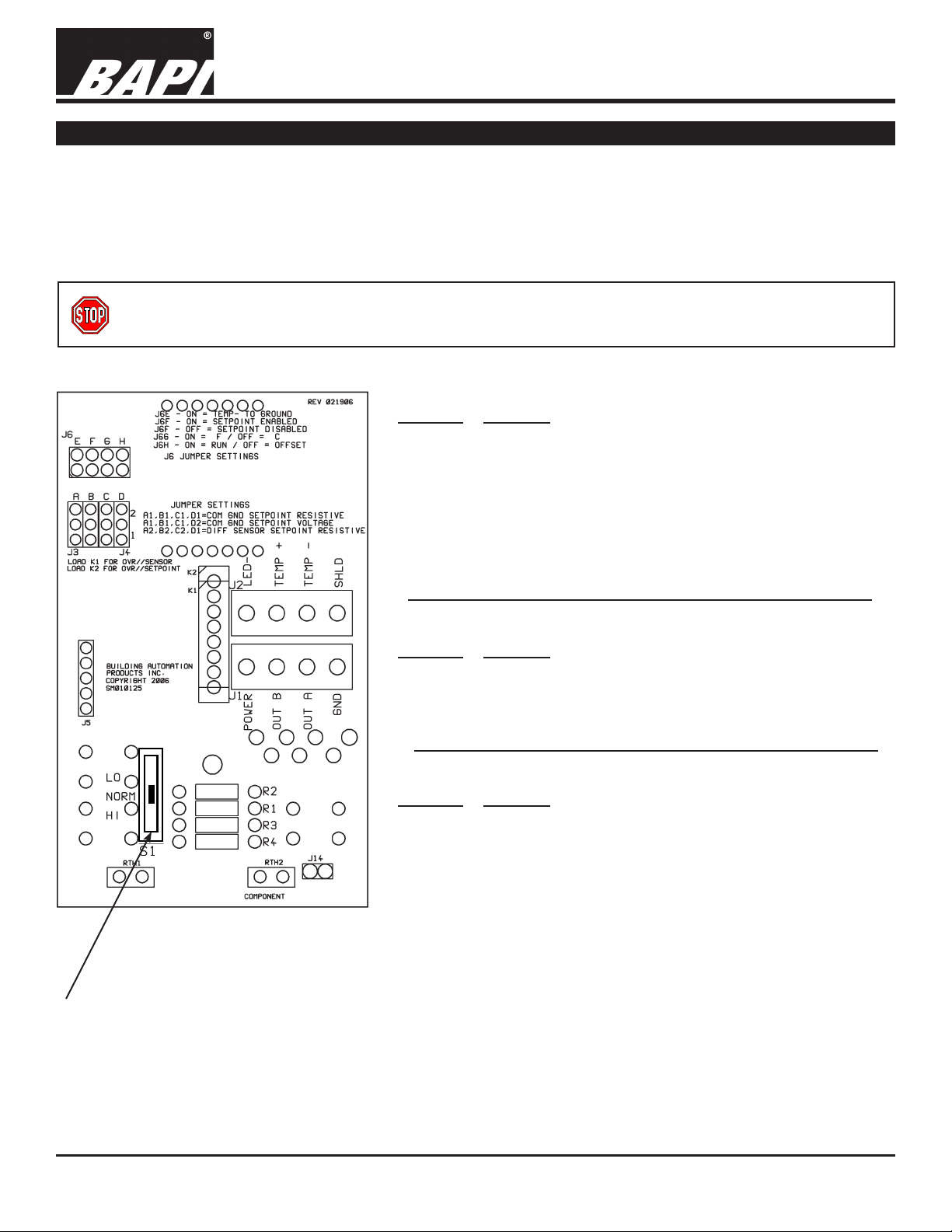

Termination

BAPI recommends using twisted pair of at least 22AWG and sealant lled connectors for all wire connections. Larger

gauge wire may be required for long runs. All wiring must comply with the National Electric Code (NEC) and local codes.

Do NOT run this device’s wiring in the same conduit as AC power wiring of NEC class 1, NEC class 2, NEC class 3 or

with wiring used to supply highly inductive loads such as motors, contactors and relays. BAPI’s tests show that uctuating and inaccurate signal levels are possible when AC power wiring is present in the same conduit as the signal lines. If

you are experiencing any of these difculties, please contact your BAPI representative

BAPI recommends wiring the product with power disconnected. Proper supply voltage, polarity, and

wiring connections are important to a successful installation. Not observing these recommendations may

damage the product and will void the warranty.

ALL RUP UNITS

Terminal Function

POWER 5 VDC (only if 5 VDC option is selected when ordered)

7 to 35 VDC (15 to 24 VDC recommended)

12 to 30 VAC (requires a separate pair of shielded wires)

GND To Controller GND, GROUND or Common terminal

LED –

SHLD External sensor cable shield (Not used in this

Lights Occupancy LED when shorted to ground. To

Controller Digital Output

configuration)

Fig 3: RµP Circuit Board

Shown with optional

T&B Switch (S1)

COMMON GROUND UNITS ONLY

Terminal Function

OUT A Setpoint (Resistive or Voltage Output). To Controller

Analog Input

OUT B

Temperature Sensor Output (Resistive Output). To

Controller Analog Input

DIFFERENTIAL GROUND UNITS ONLY

Terminal Function

TEMP + Temperature Sensor Output. To Controller Analog Input

TEMP – Temperature Sensor Output. To Controller Analog Input

OUT A Setpoint (Resistive Output). To Controller Analog Input

OUT B Setpoint (Resistive Output). To Controller Analog Input

NOTES

For Common Ground (CG) units, the GND (Common) terminal is

common beween the POWER, OUT A, and OUT B.

For Differential Ground (DF) units, OUT A and OUT B are the Setpoint Outputs, and TEMP + and TEMP – are the Thermistor or RTD

sensor outputs.

Specications subject to change without notice.

2

Page 3

RµP Style Room Units (BA/RuP)

C11 Wiring

C35 Wiring

Offset Temperature - Use

UP/DOWN arrows to set

Installation and Operation Instructions

9556_ins_rupa_gen

Factory Set J3, J4 & J6 Jumper Block Settings (for reference only)

Jumper Block J3 and J4 Settings -

Fig 4:

Common Ground with

Common Ground with

Resistive Setpoint

Note: Incorrect J3, J4 Jumper Settings can damage the sensor.

Optional Communications Jack in Base

Ground Black

Tip White

Ring Red

Note: Male

Jack shown

for clarity

Fig 5:

0 to 5VDC Setpoint

Wire Color

Fig 6:

Differential Ground with

Resistive Setpoint

Fig. 8: Front View

of Base with C35

Comm Jack

Jumper Block J6 Settings

Jumper Block J6 Settings (For Reference Only)

Jumper Pin Jumper Function

J6E

J6F

J6G

J6H

Front

View

ON "TEMP -" to Ground

OFF Differential Ground

ON Setpoint Enabled

OFF Setpoint Disabled

ON Fahrenheit

OFF Celsius

ON Normal Operation

OFF

Back

View

rev. 06/26/15

Fig. 7: C35 Comm Jack

C11 or C22 Wiring

Comm Jack Pin Wire Color

1 Not Connected

2 Black

3 Red

4 Yellow

5 White

6 Not Connected

C11 or C22

Comm Jack

Optional Test & Balance Switch - S1

LO: Sets the sensor value to

LOW temperature

NORM: Temperature Sensor

operates Normally

HI: Sets the sensor value to

HIGH temperature

Fig. 10

Fig. 9: Front

View of Base

with C11 or

C22 Comm

Front

View

Back

View

Jack

Sensor Type

1000W RTD 1.02KW (41.2°F) 1.15KW (101.5°F)

3000W Thermistor 7.87KW (39.5°F) 1.5KW (106.8°F)

10K-2W Thermistor 30.1KW (34.9°F) 4.75KW (109.2°F)

10K-3W Thermistor 26.7KW (35.9°F) 5.11KW (108.4°F)

10K-3(11K)W Thermistor 7.32KW (43.7°F) 3.65KW (105.2°F)

Low Resistance

(Temp)

High Resistance

(Temp)

Specications subject to change without notice.

3

Page 4

RµP Style Room Units (BA/RuP)

Installation and Operation Instructions

9556_ins_rupa_gen

rev. 06/26/15

Temperature, Setpoint and Occupancy Override LED Diagnostics

If the RuP doesn’t work upon installation, no LCD and no Output from terminals OUTA and/or OUTB. Check that the correct power is being supplied to the RuP by measuring the DC voltage between terminals POWER and GND. Also check

to see that the RuP is wired with the proper polarity, terminal GND as common and terminal POWER as V+. V+ should

be within the range of 7 to 35VDC, 12 to 30 VAC or optional 5 Volt and supply a minimum of 10mA for each RuP. If the

RuP’s LCD is working but there’s still no output from terminal OUTA or OUTB. Power down the Rup and remove the output wire(s) from the suspect terminal pin(s). Apply power and use a meter to measure the ohms (or voltage) output of the

terminal pin in question, as described in the three sections below.

TEMPERATURE OUTPUT

Determine that the temperature sensor’s wires are connected to the correct controller input terminals and are not loose.

Check the wires at the sensor and controller for proper connections. Measure the physical temperature at the temperature

sensor’s location using an accurate temperature standard. Disconnect the temperature sensor wire (SEN1) and measure

the temperature sensor’s resistance across the sensor output pins with an ohmmeter. Put the ohmmeters black lead on

Ground (GND) for common ground units or put the black lead on SEN2 for differential ground units and the red lead on

SEN1. Compare the temperature sensor’s resistance to the appropriate temperature sensor table on the BAPI web site.

If the measured resistance is different from the temperature table by more than 5% call BAPI technical support. Find

BAPI’s web site at www.bapihvac.com; click on the button labeled SENSORS on the left of the screen and then click on

the type of sensor you have. Don’t forget to reconnect the wires. Make sure that the test and balance switch is in the correct position. Make sure that the temperature sensor element leads are not touching one another.

SETPOINT OUTPUT

The setpoint output may be measured on CG (common ground) units between terminals OUTA

output is measured on DF (differential input) units between terminal OUTA and OUTB. To test the setpoint output, rst remove any wires from the setpoint output terminals, apply power to the RuP and measure the setpoint output. Compare the

measured reading to the setpoint information printed on the RuP’s label. The temperature setpoint value will be displayed

on the RuP’s LCD.

and GND. The setpoint

LED INDICATOR

The LED is internally connected to the RuP’s 5 Volt supply and can be turned on by connecting the terminal LED- to the

RuP’s GND terminal. Most often this is done through a dry contact at the controller. To test the LED, rst remove any wires

from the LED- terminal, apply power to the RuP and then use a short piece of wire to short between the LED- and GND

terminals. Observe the LED operation from the front of the RuP. Power down the RuP and reconnect the output(s) to the

controller. If the output(s) still are non-functional, remove power and check the controller’s input conguration.

Communications Jack Diagnostics

PROBLEMS:

No connection to controller can be made

Information received through wires is garbled

POSSIBLE SOLUTIONS:

- Conrm connection from patch cable to remote computer

- Check wiring for proper termination

- Check wiring for proper termination

- Verify that no wires are shorted together

Specications

Power: 5 VDC (only if 5 VDC option is selected when ordered)

7 to 35 VDC (15 to 24 VDC recommended)

12 to 30 VAC (requires a separate pair of shielded wires)

Power Consumption: 10 mA max. DC, .2 VA maximum AC

Sensing Element: Thermistor, RTD or Semiconductor

Wiring: 2 to 4 pair of 16 to 22AWG*

Comm. Jack: Optional 3.5 mm Phono Jack, RJ11 or RJ22 Jacks

Mounting: Standard 2” by 4” J-box or drywall

mount (mounting screws provided)

Environmental Operation Range:

Temperature: 32 to 122

o

F (0 to 50 oC)

Humidity: 0 to 95%, non-condensing

Enclosure Material & Rating: ABS Plastic, UL94 HB

Specications subject to change without notice.

4

Loading...

Loading...