Page 1

RµPS Room Unit with External Sensor

13406_ins_rups_ext_sen

Overview and Identication

The RµPS Room Unit with an External Sensor displays the temperature

where the external sensor is located. The unit can also provide a setpoint

adjustment value and occupancy override value to a controller. The unit

does NOT provide a temperature sensor value to the controller. A second

temperature sensor is required for the controller (see Figs 2 & 4).

The setpoint adjustment is a vertical slide pot with an analog output and a

Warm/Cool legend imprinted on the unit’s base. Optional setpoint indication

is available. The setpoint values can be a resistance or a voltage for easy

conguration with the controller. The occupancy override is available as a

separate output or in parallel with the Sensor or Setpoint. An optional LED

indicator is available on the face of the RµPS unit and is energized from

the controller. An optional 3.5mm (1/8”) or RJ11 communication jack can

be mounted in the base to provide direct access to the network. The sensor

and setpoint outputs can be congured for “common ground” or “differential

ground” controller inputs.

Mounting (on two sides of the same wall)

Installation and Operating Instructions

rev. 06/26/15

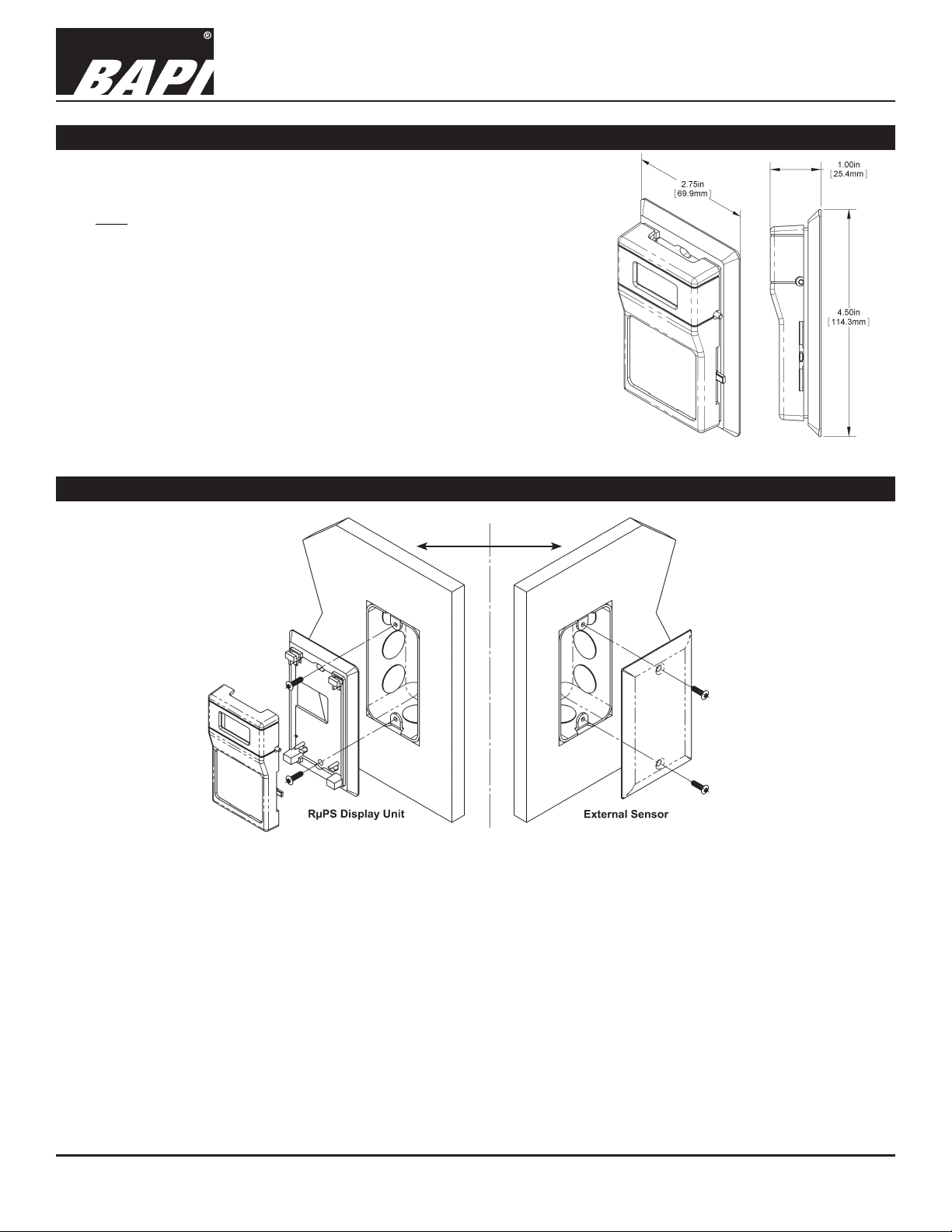

Fig 1: RµPS Display Unit Dimensions

24 Inch Limit

Fig 2:

RuPS Display

Unit and External

Sensor mounted

on opposite sides

of the same wall.

Note: The External

Sensor could be a Wall

Plate sensor (shown) or

a Return Air Sensor.

(All external sensors are

ordered seperately.)

1. Mount two junction boxes on opposite sides of the same wall. One side of the wall is the wall plate external sensor

and the other side of the wall is where the RuPS display unit will be installed. Place the boxes close enough together

that the wire on the wall plate and the display unit can reach one another.

2. Secure the RuPS display unit base to the junction box using the #6-32 x 1/2 inch mounting screws provided.

3. Run the wires from the wall plate through the junction box into the junction box for the RuPS display unit. Secure the

wall plate to the junction box with the #6-32 x 1/2 inch mounting screws provided making sure the foam on the back of

the wall plate makes a good seal with the wall.

4. Terminate the unit according to the Termination guidelines on page 1.

5. Attach RuPS Cover by latching it to the top of the base, rotating the cover down and snapping it into place.

6. Secure the RuPS cover by backing out the lock-down screws using a 1/16” Allen wrench until they are ush with the

bottom of the cover.

Specications subject to change without notice.

1 of 4

Page 2

RµPS Room Unit with External Sensor

Installation and Operating Instructions

13406_ins_rups_ext_sen

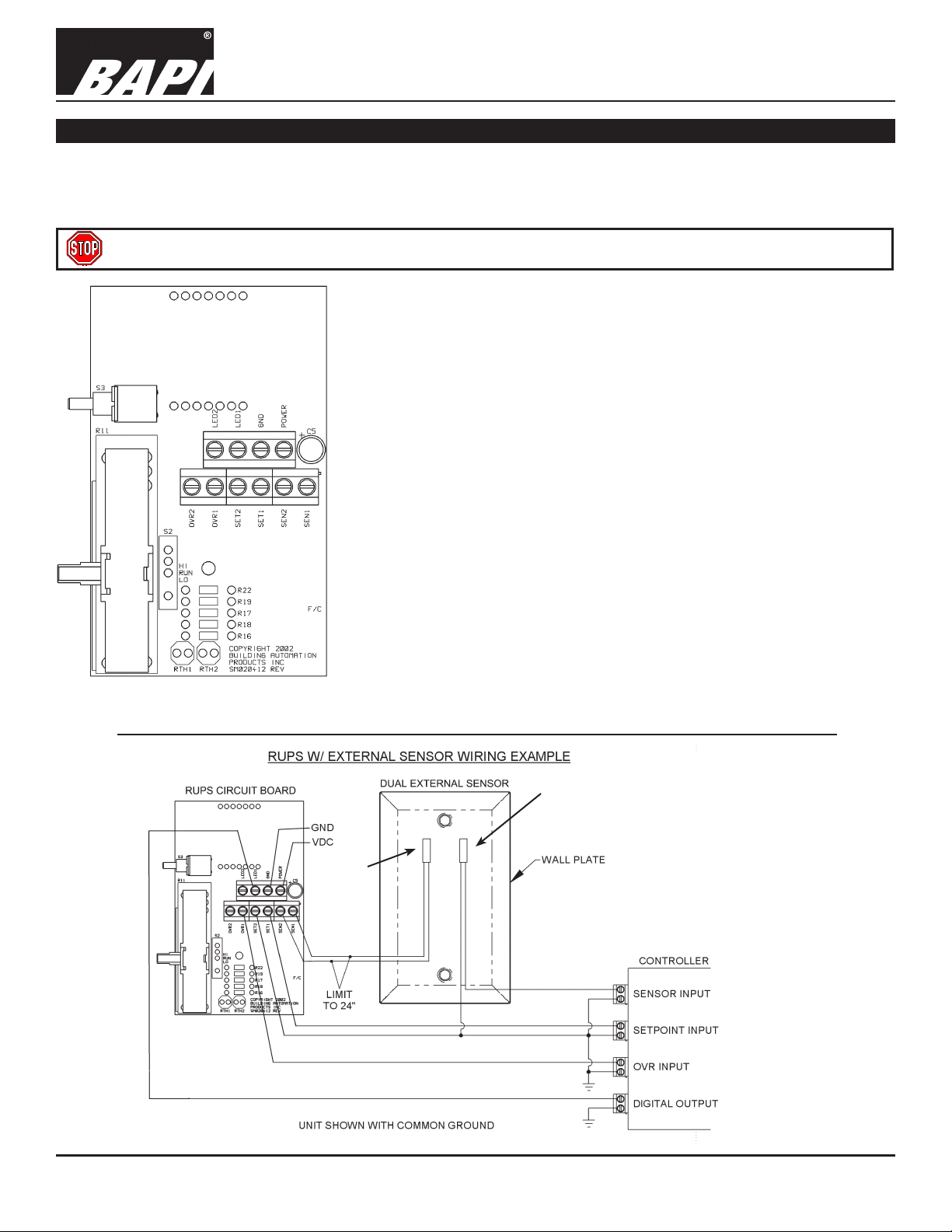

Termination

BAPI recommends using twisted pair of at least 22AWG and sealant lled connectors for all wire connections. Larger

gauge wire may be required for long runs. All wiring must comply with the National Electric Code (NEC) and local codes.

Do NOT run this device’s wiring in the same conduit as AC power wiring of NEC class 1, NEC class 2, NEC class 3 or with

wiring used to supply highly inductive loads such as motors, contactors and relays.

BAPI does not recommend wiring the sensor with power applied as accidental arcing may damage the product

and will void the warranty.

LED1 Short this terminal to Ground or Common to activate the

occupancy override LED on the front of the unit.

LED2 This terminal is only used if the unit is special ordered and the

customer wants to provide both power and ground to light the

occupancy override LED. Call BAPI tech support for more info.

GND Unit Ground or Common. Needs to be the same as the

controller’s Ground or Common.

POWER Unit power. 5 VDC (if 5 VDC option is selected when ordered)

9 to 40 VDC (15 to 24 VDC recommended)

15 to 28 VAC (requires a separate pair of shielded wires)

SEN1 & SEN2 10K-2 Thermistor input to the sensor display. No output to

controller. When unit is congured as Common Ground (CG),

SEN2 is internally shorted to the GND (Common) terminal.

SET1 & SET2 Temperature Setpoint Slider output. When unit is congured

as Common Ground (CG), SET2 is internally shorted to the

GND (Common) terminal.

OVR1 & OVR2 Occupancy Override Pushbutton, dry contact output. When

unit is congured as Common Ground (CG), OVR2 is internally

shorted to the GND (Common) terminal.

Notes:

Fig 3: RµPS Circuit Board

Test and Balance Switch is not available with an external sensor.

Common Ground (CG): GND, SEN2, SET2 & OVR2 are all internally connected.

Differential Ground (DG): GND, SEN2, SET2 & OVR2 are all internally isolated.

rev. 06/26/15

Must be

a 10K-2

Thermistor

Specications subject to change without notice.

Can be any sensor

specied for the

controller.

(This could also be

a Return Sensor)

Fig 4:

Dual External Sensor

Wiring Example with

a Common Ground

(CG) conguration.

2 of 4

Page 3

13406_ins_rups_ext_sen

Optional Communications Jack

(Male Jack shown for clarity)

C11L or C22L Wiring

RµPS Room Unit with External Sensor

Installation and Operating Instructions

rev. 06/26/15

Comm.

Jack

Fig. 5:

C35L Comm Jack

Fig. 6:

C35L Comm Jack in Unit’s Base.

(Front of unit base is shown at left, back of base at right)

Fig. 7:

C11L or C22L Comm

Jack

Fig. 8:

C11L or C22L Comm Jack in Unit’s Base.

(Front of unit base is shown at left, back of base at right)

Communications Jack Diagnostics

Possible Problems:

Comm. Jack has no connection to controller

Comm. Jack information received through wires is garbled

Possible Solutions:

- Conrm connection from patch cable to remote computer

- Make sure wires are tightly pressed in

- Check wiring for proper termination

- Check wiring for proper termination

- Verify that no wires are shorted together

Optional Settings for the RuPS Unit

OPTIONAL SETTINGS

Overrides: Override in parallel with the sensor or override as a separate input

External Sensor: 10K-2 Thermistor required

Setpoint: Resistive (Potentiometer) or 0 to 5VDC or 5 to 0VDC per order.

Comm.

Jack

CONTACT FACTORY WITH ANY DIFFERENT RANGE INQUIRIES

Common Ground (CG): Unit can be set up at factory (CG)

Differential Ground (DF): Unit can be set up at factory (DG)

Specications subject to change without notice.

3 of 4

Page 4

13406_ins_rups_ext_sen

Diagnostics

RµPS Room Unit with External Sensor

Installation and Operating Instructions

rev. 06/26/15

Possible Problems:

Unit will not operate

Temperature sensor in front end

software is reading is incorrect

LCD is not working

Sensor reading is signicantly off

from the LCD temperature

Possible Solutions:

- Check power supply/controller voltage supply

- Disconnect sensor power wires and check for power to sensor

- Verify the input is set up correctly in the front end software

- Check to see if the thermistor is damaged

- Check wiring for proper termination

- Compare temperature reading to the appropriate sensor table (See Note below)

- Verify that the unit has the proper voltage across the “Power” and “GND” circuit

board terminals. See power specications below proper power.

- Conrm that the sensor is wired correctly

- If outputs are correct but display is not operating, contact BAPI technical

support.

- Conrm that the sensor is wired correctly

- Compare temperature reading to appropriate sensor table (See Note below)

- Make sure the specied thermistor is correct

Note: To compare a reading to the appropriate sensor table, measure the physical

temperature at the temperature sensor’s location using an accurate temperature

standard. Disconnect the temperature sensor wires and measure the temperature

sensor’s resistance with an ohmmeter. Compare the temperature sensor’s

resistance to the appropriate temperature sensor table on the BAPI website. If the

measured resistance is different from the temperature table by more than 5%, call

BAPI technical support. BAPI’s website is found at www.bapihvac.com. Click on

the left menu link “Sensor Specs” and then click on the type of sensor you have.

Specications

Power:

5 VDC (only if 5 VDC option is selected when ordered)

9 to 40 VDC (15 to 24 VDC recommended)

15 to 28 VAC (Requires a separate pair of shielded wires)

Power Consumption:

10 mA max DC, .2 VA max AC

External Sensor Element and Accuracy:

Thermistor: 10K-2, ± 0.36ºF (±0.2ºC)

Wiring:

2 to 5 pair of 16 to 22 AWG

Communication Jack:

Option C35: 3.5mm (1/8”) phone jack

Option C11: RJ11

Option C22: RJ22

Specications subject to change without notice.

Mounting:

Standard 2” x 4” J-box or drywall (Mounting screws

provided)

Ambient:

32 to 122ºF (0 to 50ºC) 0 to 95% RH, Non-condensing

Material:

ABS plastic, UL94 HB

Override:

Contact N.O. as a separate closure or contact N.O. in

parallel with the setpoint

Setpoint:

Resistance (Potentiometer) or Voltage 0 to 5VDC or 5

to 0VDC

4 of 4

Loading...

Loading...