Page 1

Replaceable Sensor Probes

BA/#-P-x, BA/#xP, BA/HxS

Installation & Operations

20912_ins_Repl_Probe_Passive

Overview

• The BA/#-P-x is a Stainless Steel Replacement probe for use with any BAPI Immersion, or Duct temperature

sensor. They come in a variety of lengths and with TFE insulated plenum cable. The BA/#-P-x sensor is

available in multiple types of thermistor’s or RTD temperature sensors as shown in the specifications. The

probe comes without a box and is made to insert into an existing duct or immersion box fitting as a replacement. It is ideal to replace a damaged probe or to change the length of an existing probe installation.

• The BA/#-HxP is a Humidity Replacement probe w/sintered filter for use with any BAPI Duct or OSA RH

transmitter. They come pre-calibrated and ready to install and use. The BA/#-HxP probe is available with

multiple types of thermistor’s or RTD temperature sensors as shown in the specifications. The replacement

probe comes without a box and is made to thread into an existing duct or OSA enclosure. It is ideal to

replace a damaged probe or worn-out sensor in an existing installation. Replacement 100 micron SS

sintered filters as well as wash down caps are also available. No field calibration is required.

• The BA/#-HxS is a Humidity Sensor Replacement for BAPI room RH transmitters. They come pre-cali-

brated and ready to install and use. No field calibration is required.

Identification

10/1/09 rev.

Per OrderPer Order

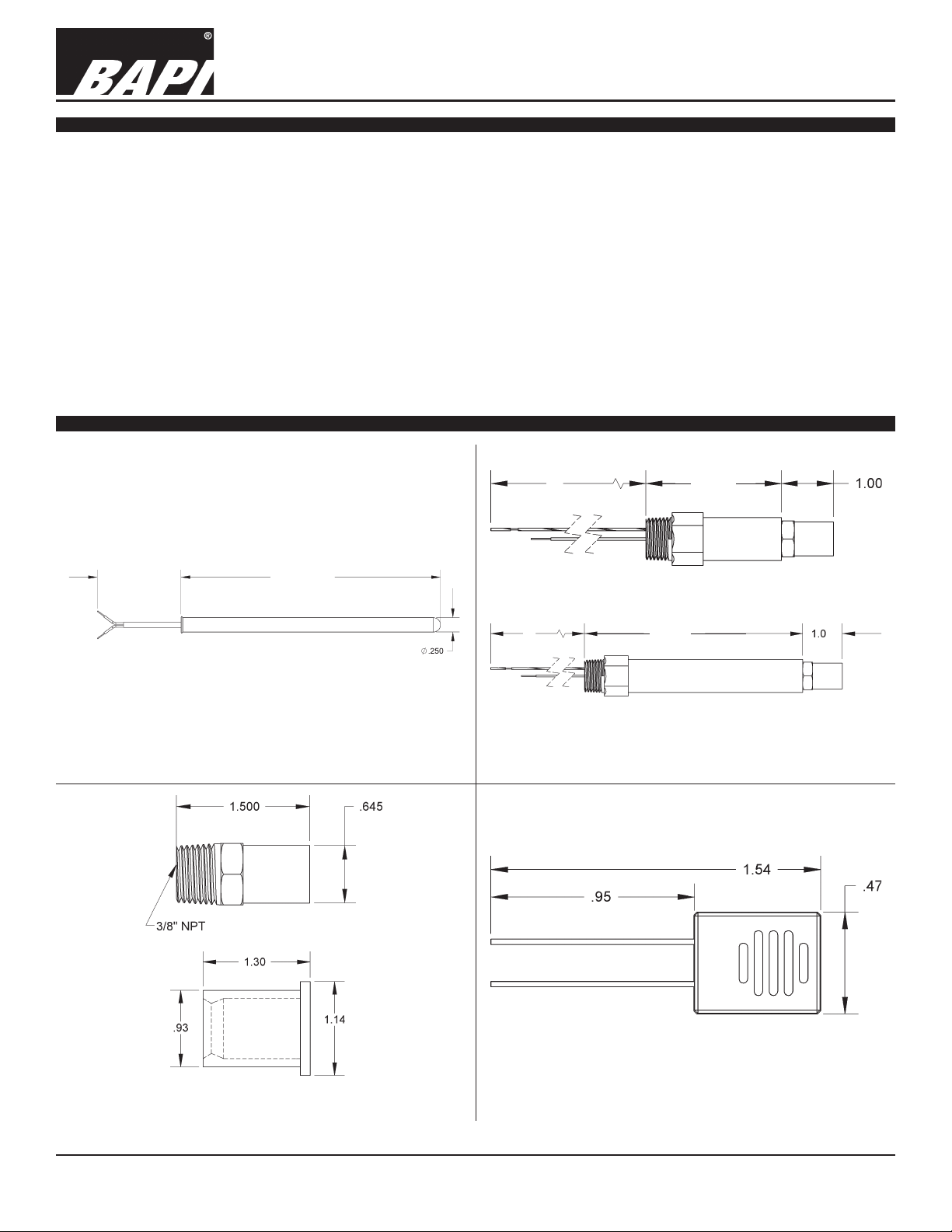

Fig 1: SS Replacement Sensor Probe (BA/#-P-X)

FILTER

6”

6”

2.125”

OSA

5.25”

DUCT

Fig 2: Replacement RH Probe (BA/#-HxP)

CAP

Fig 3: Replacement Sintered Filter & Washdown Cap

(BA/HDOFS), (BA/VFC)

Specifications subject to change without notice.

Fig 4: Replacement Room RH Sensor (BA/#-HxS)

1 of 4

Page 2

20912_ins_Repl_Probe_Passive

Mounting

•

Replaceable Sensor Probes

BA/#-P-x, BA/#xP, BA/HxS

Installation & Operations

10/1/09 rev.

•

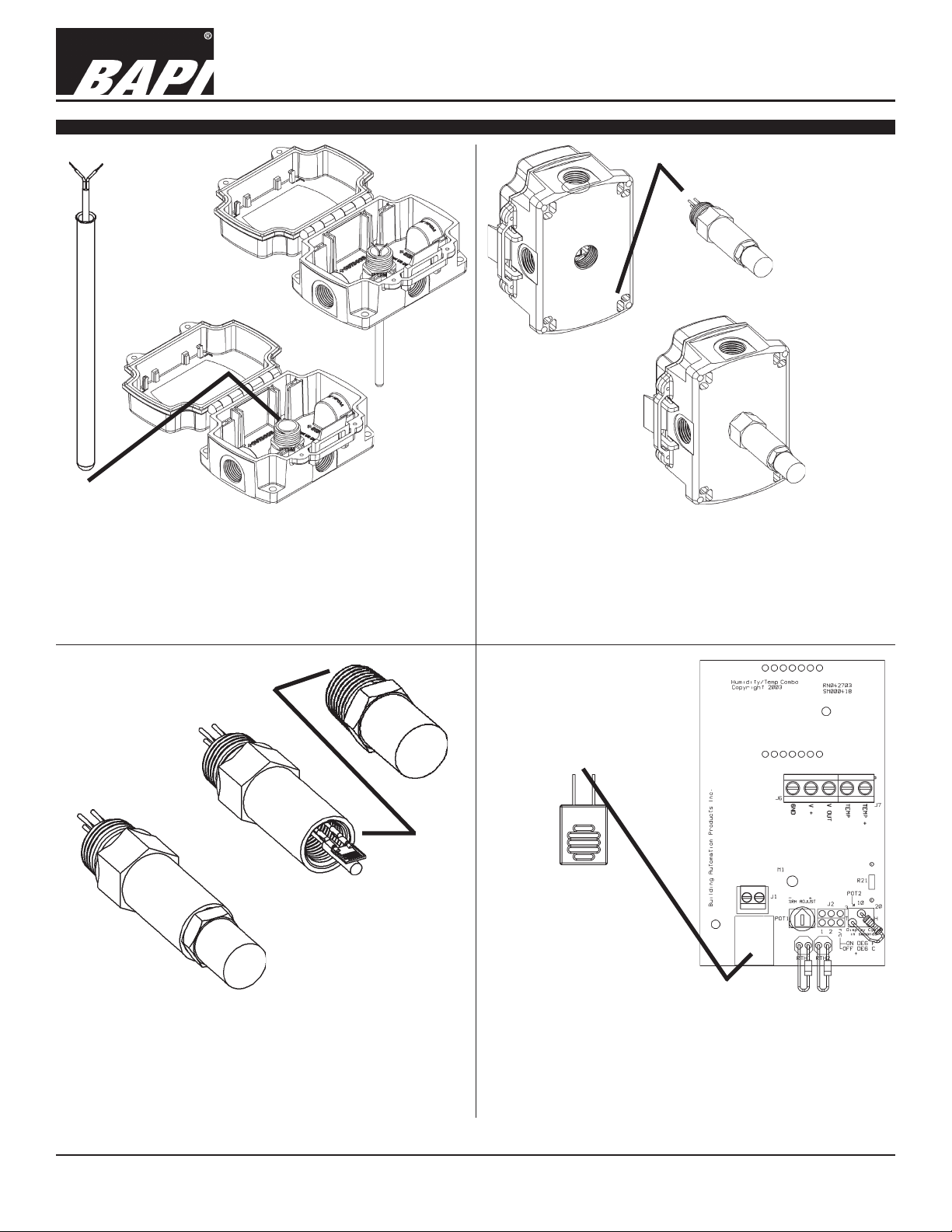

Fig 5: Typical Temperature Sensor probe replacement

1. Open the box and disconnect the wires.

2. Push the old probe into the box and out through the plastic fitting.

3. Push the new probe into the box and into the plastic fitting all the

way to the flared end.

4. Pull the probe to full extension and re-connect per termination

section.

•

Fig 6: Typical Humidity Transmitter Probe Replacement

1. Un-install the box and disconnect the wires from the transmitter.

Note color code.

2. Un-screw (CCW) the old 1/2” NPT probe from the back of the box.

3. Screw in (CW) the new 1/2” NPT probe into the back of the box.

4. Install and re-connect the wires per the color code and termination

section.

NOTE: No callibration is needed.

•

Fig 7: Typical Humidity Probe Filter Replacement

1. Un-screw (CCW) the old 1/2” stainless steel filter.

2. Fully screw in (CW) the new 1/2” stainless steel filter.

NOTE: The old filter can be cleaned for future use with

soap & water and then rinse thoroughly.

Specifications subject to change without notice.

Fig 8: Typical Room RH Sensor Replacement

1. Take the sensor cover off using a 1/16” Allen wrench.

2. Un-screw terminals J1 and remove the old blue RH sensor.

3. Install new sensor leads in the terminals with vents facing up.

4. Install the sensor cover.

NOTE: No calibration is required.

2 of 4

Page 3

20912_ins_Repl_Probe_Passive

Temperature Probe Termination

Sensor

Replaceable Sensor Probes

BA/#-P-x, BA/#xP, BA/HxS

Installation & Operations

10/1/09 rev.

Fig 9: 2 Wire Thermistor or RTD

RH Probe Termination

To Controller Analog

Input or Transmitter

(AI) (No Polarity)

Sensor

Fig 10:

To 3 Wire Transmitter

3 Wire RTD

Fig 11: 4-20mA RH Probe With or Without RTD Temp. Transmitter

RH Probe Termination

Voltage Sensor Output

Ground

Power

Fig 13: Voltage RH Probe With or Without Passive Sensor

Specifications subject to change without notice.

Fig 12: RH Probe With Thermistor Transmitter

Sensor Terminals

•

Sensor

•

Fig 6: Room Replacement RH Sensor

3 of 4

Page 4

Replaceable Sensor Probes

BA/#-P-x, BA/#xP, BA/HxS

Installation & Operations

20912_ins_Repl_Probe_Passive

Diagnostics

Problems:

Controller reports higher or lower than

actual temperature

Humidity not reading - Check power supply/controller voltage supply

Humidity Sensor/Transmitter Check: - Reconnect all the wires as shown in the wiring details for your

Specifications

Temperature Sensor:

Thermistor NTC, 2 wire

RTD PTC, 2 or 3 wire

Thermistor Thermal resistor

Temp. Output Resistance

Accuracy (std) ±0.36ºF, (±0.2ºC)

Accuracy (Hi) ±0.18ºF, (±0.1ºC), [XP] option

Stability < 0.036ºF/Year, (<0.02ºC/Year)

Heat dissipation 2.7 mW/ºC

Temp. Drift <0.02ºC per year

Probe range -40º to 221ºF (-40º to 105ºC)

RTD Resistance Temperature Device

Platinum (PT) 100Ω or 1KΩ @0ºC, 385 curve,

Platinum (PT) 1KΩ @0ºC, 375 curve

PT Accuracy (std) 0.12% @Ref, or ±0.55ºF, (±0.3ºC)

PT Accuracy (Hi) 0.06% @Ref, or ±0.277ºF,

(±0.15ºC), [A]option

PT Stability ±0.25ºF, (±0.14ºC)

PT Self Heating 0.4 ºC/mW @0ºC

PT Probe range -40º to 221ºF (-40º to 105ºC)

Nickel (Ni) 1000Ω@70ºF, JCI curve

Ni Probe range -40º to 221ºF (-40º to 105ºC)

Sensitivity bapihvac.com click “Sensor Specs”

Thermistor Non-linier

RTD (PT) 3.85Ω/ºC for 1KΩ RTD

0.385Ω/ºC for 100Ω RTD

Nickel (Ni) 2.95Ω/ºF for the JCI RTD

Lead wire 22awg stranded

Wire Insulation FEP jacketed plenum rated cable

Probe Rigid, 304 Stainless Steel, 0.25" OD

Mounting Inserted into Plastic Fitting

Agency RoHS, CE

PT= DIN43760, IEC Pub 751-1983,

JIS C1604-1989

Possible Solutions:

- Confirm the input is set up correctly in the front end software

- Check wiring for proper termination & continuity. (shorted or open)

- Disconnect wires and measure sensor resistance and verify “Sensor”

output is correct.

- Disconnect humidity transmitter and check for correct power

- Connect power and then check signal wiring with a meter.

- Check for proper signal wiring to the controller.

- Open one of the blue wire connections. The transmitter should

read 0% RH, if not the transmitter may be bad.

- Short out the blue wires. The transmitter should read 100% RH.

If not the transmitter may be bad.

sensor type and power up the transmitter. You should be

reading the relative humidity at the output. Check this reading

with a trusted hygrometer reference. If it’s off by more than the

added ± accuracy of the hygrometer accuracy plus the trans

mitter accuracy the combined sensor/transmitter is bad or

needs factory calibration. (±2% + ±3% = ±5% total accuracy)

RH Sensor and Probe:

Sensor:

Humidity Resistive (Impedance)

Temp. Per sensor spec above

Filter: 100 micron sintered stainless steel

Wiring:

Duct Probe RH- 4 flying leads, Opt. Temp.-

2 flying leads

OSA Probe RH- 4 flying leads, Opt. Temp.-

2 flying leads

Room Board mounted Terminals

Probe Termination Required:

Sealant filled crimp connectors, (BA/SFC1000-100)

Accuracy:

H2P, H2S 2%, from 15% to 95%RH @77ºF

H3P, H2S 3%, from 15% to 95%RH @77ºF

Probe Material:

Duct ABS Plastic, UL94V-HB

OSA Polycarbonate, UV resistant,

UL94V-HB

Environmental Ambient Range:

-22º to 158ºF, (-30º to 70ºC)

0% to 100% RH

10/1/09 rev.

Specifications subject to change without notice.

4 of 4

Loading...

Loading...