Page 1

Powers Style Room Units with Thermistor, RTD or

Semiconductor Sensor (BA/-RSS)

Termination and Troubleshooting

32062_ins_temp_rss.pdf rev. 07/16/15

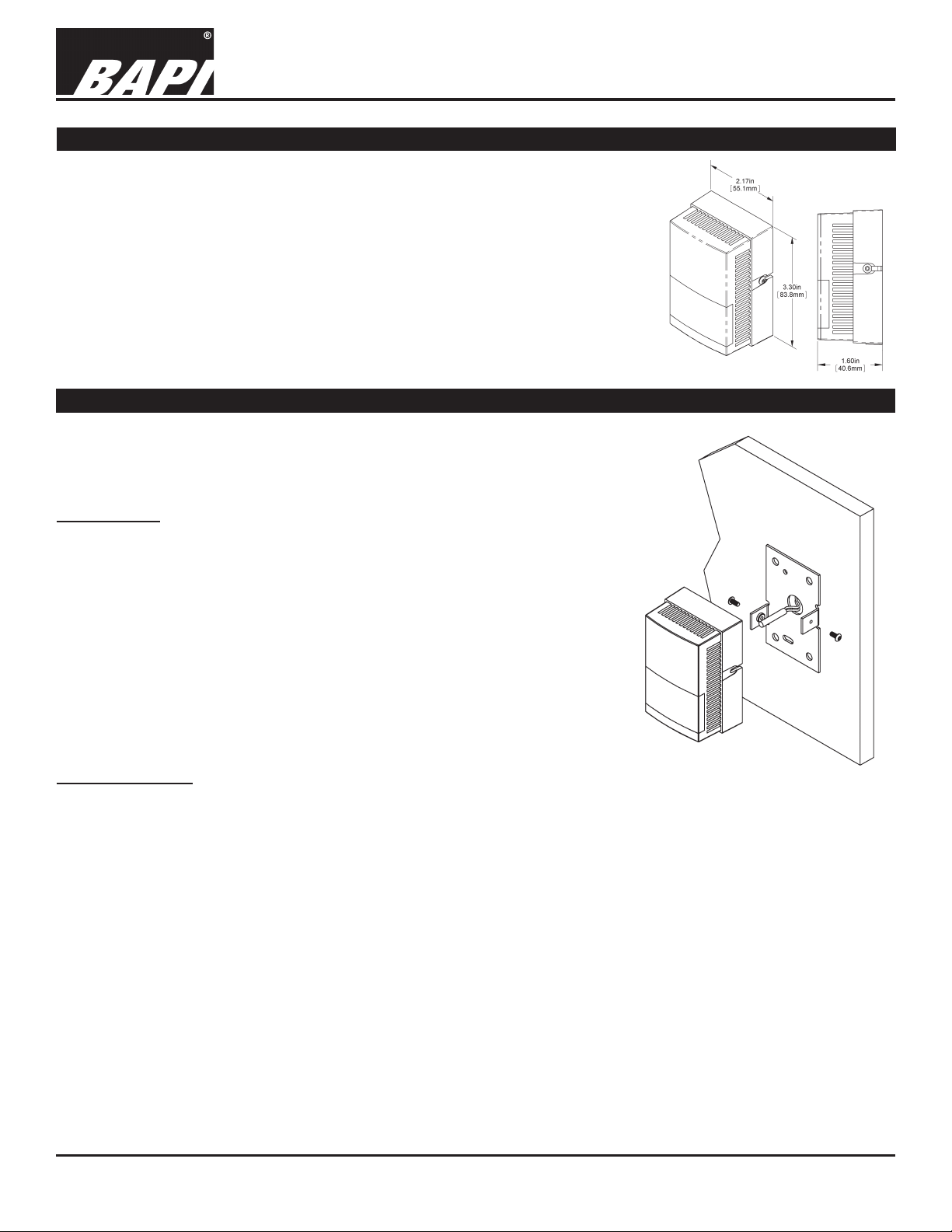

Product Identication

The Powers Style Room Sensor is available with a wide selection of temperature

sensing elements. An optional Bi-Metal Indicator can display room temperature;

accurate to ±1 °F. The display is protected by a view plate and comes standard

with a 50 to 80 °F Legend. This legend is printed in dark brown on a tan

background.

Fig. 1: Powers Style

Room Sensor

Mounting

Mounting hardware is provided for only the drywall installation Junction Box

installation of the Powers Style room unit will require a BAPI Adaptor Plate.

Order Part Number BA/ADP-525-7-Color Code.

Junction Box

1. Pull the wire through the wall and out of the junction box, leaving about six

inches free.

2. Pull the wire through the hole in the adaptor plate and then through the

hole in the base plate.

3. Secure the adaptor plate to the wall (following the adaptor plate

instructions) and then secure the base plate to the to the adaptor plate

using the #6-32 x 1/2 inch mounting screws provided.

4. Terminate the unit according to the guidelines in Termination on page 2.

5. Attach Cover by locating it over the top of the base plate, and then

attaching it by tightening the side security screws with a 1/16” Allen

wrench.

Drywall Mounting

1. Place the base plate against the wall where you want to mount the

sensor.

2. Using a pencil mark out the two mounting holes and the area where the wires will come through the wall.

3. Drill two 3/16” holes in the center of each marked mounting hole. Insert a drywall anchor into each hole.

4. Drill one 1/2” hole in the middle of the marked wiring area.

5. Pull the wire through the wall and out of the 1/2” hole, leaving about six inches free.

6. Pull the wire through the hole in the base plate.

7. Secure the base to the drywall anchors using the #6 x 1 inch mounting screws provided.

8. Terminate the unit according to the guidelines in Termination on page 2.

9. Attach Cover by locating it over the top of the base plate, and then attaching it by tightening the side security

screws with a 1/16” Allen wrench.

Powers Style Dyrwall Mounting

Fig. 2

NOTE: In a wall-mount application, the wall temperature and the temperature of the air within the wall cavity can

cause erroneous readings. The mixing of room air and air from within the wall cavity can lead to condensation,

erroneous readings and premature failure of the sensor. To prevent these conditions, seal the conduit leading to the

junction box and seal the hole in the drywall with berglass insulation

Specications subject to change without notice.

1 of 3

Page 2

Powers Style Room Units with Thermistor, RTD or

Semiconductor Sensor (BA/-RSS)

Termination and Troubleshooting

32062_ins_temp_rss.pdf rev. 07/16/15

Termination

BAPI recommends using twisted pair of at least 22AWG and sealant lled connectors for all wire connections.

Larger gauge wire may be required for long runs. All wiring must comply with the National Electric Code (NEC) and

local codes.

Do NOT run this device’s wiring in the same conduit as AC power wiring of NEC class 1, NEC class 2, NEC class 3

or with wiring used to supply highly inductive loads such as motors, contactors and relays. BAPI’s tests show that

uctuating and inaccurate signal levels are possible when AC power wiring is present in the same conduit as the

signal lines. If you are experiencing any of these difculties, please contact your BAPI representative.

Sensor Termination

Pin 1 .....Sensor, To Analog Input of Controller

(Resistive Output)

Pin 2 .....Sensor, To Analog Input of Controller

(Resistive Output)

Figure 3:

Powers Circuit Board

Specications

Environmental Operation Range:

Temperature: 32 to 122 oF (0 to 50 oC)

Humidity: 0 to 95%, non-condensing

Material: ABS Plastic

Material Rating: UL 94, HB

Agency: CE Compliant (

All Passive Thermistors 10KΩ and smaller are CE compliant.)

Pin 3 .....Not Used for Two Wire Sensors

(Three Wire Sensors use Pin 2 and Pin 3 as Common.

The odd wire connects to Pin 1.)

Specications subject to change without notice.

2 of 3

Page 3

Powers Style Room Units with Thermistor, RTD or

Semiconductor Sensor (BA/-RSS)

Termination and Troubleshooting

32062_ins_temp_rss.pdf rev. 07/16/15

Diagnostics

POSSIBLE PROBLEMS:

General troubleshooting

Temperature reading is

incorrect

POSSIBLE SOLUTIONS:

- Determine that the input is set up correctly in the controller software and building

automation software.

- Check wiring for proper termination

- Check for corrosion at either the controller or the sensor. Clean off the corrosion,

re-strip the interconnecting wire and reapply the connection. In extreme cases,

replace the controller, interconnecting wire and/or sensor.

- Label the terminals that the interconnecting wires are connected to at the sensor

end and the controller end. Disconnect the interconnecting wires from the

controller and the sensor. With the interconnecting wires separated at both ends

measure the resistance from wire-to-wire with a multimeter. The meter should

read greater than 10 Meg-ohms, open or OL depending on the meter you have.

Short the interconnecting wires together at one end. Go to the other end and

measure the resistance from wire-to-wire with a multimeter. The meter should

read less than 10 ohms (22 gauge or larger, 250 feet or less). If either test fails,

replace the wire.

- Determine that the temperature sensors wires are connected to the correct

controller input terminals and are not loose.

- Check the wires at the sensor for proper connections.

- Measure the physical temperature at the temperature sensor’s location using an

accurate temperature standard. Disconnect the temperature sensor wires and

measure the temperature sensor’s resistance across the sensor output pins with

an ohmmeter. Compare the temperature sensor’s resistance to the appropriate

temperature sensor table on the BAPI website. If the measured resistance

differs from the temperature table by more than 5% call BAPI technical support.

Find BAPI’s website at www.bapihvac.com; click on “Resource Library” and

“Sensor Specs”, then click on the type of sensor you have. Don’t forget to

reconnect the wires.

- Make sure that the sensor leads are not touching one another.

- Determine if the sensor is exposed to an external air source different from room

environment, such as a conduit draft. If so, ll the junction box with berglass

insulation or plug the conduit.

Specications subject to change without notice.

3 of 3

Loading...

Loading...