Page 1

Non-Room Thermistors and RTDs

2.2KΩ Brown/White 1KΩ Orange/Orange

3KΩ Yellow/Black

3.25KΩ Brown/Green 1KΩ Green/Green

3.3KΩ Yellow/Brown

10K-3Ω Yellow/Red

10K-3(11K)Ω Yellow/Blue 100Ω Red/Red/Black*

20KΩ White/White 1KΩ Orange/Orange/Black*

47KΩ Yellow/Orange

Table 3: Temperature Sensor Lead Wire Colors

Additional sensors are available so your sensor may not be listed on this table.

Installation & Operations

9502_ins_therm_rtd_nrm

Termination

BAPI recommends using twisted pair of at least 22AWG and sealant lled connectors for all wire connections. Larger

gauge wire may be required for long runs. All wiring must comply with the National Electric Code (NEC) and local

codes. Do NOT run this device’s wiring in the same conduit as AC power wiring of NEC class1 or NEC class 2, NEC

class 3 or with wiring used to supply highly inductive loads such as motors, contactors and relays.

BAPI’s tests show that uctuating and inaccurate signal levels are possible when AC power wiring is present in

the same conduit as the signal lines. If you are experiencing any of these difculties, please contact your BAPI

representative.

rev. 10/12/15

BAPI does not

recommend wiring the

sensor with power

Thermistors Platinum RTDs - 2 Wire

1.8KΩ Orange/Red 100Ω Red/Red

applied as accidental arcing

may damage the product and

will void the warranty.

10K-2Ω Yellow/Yellow 2KΩ Brown/Blue

50KΩ White/Blue

100KΩ Yellow/White

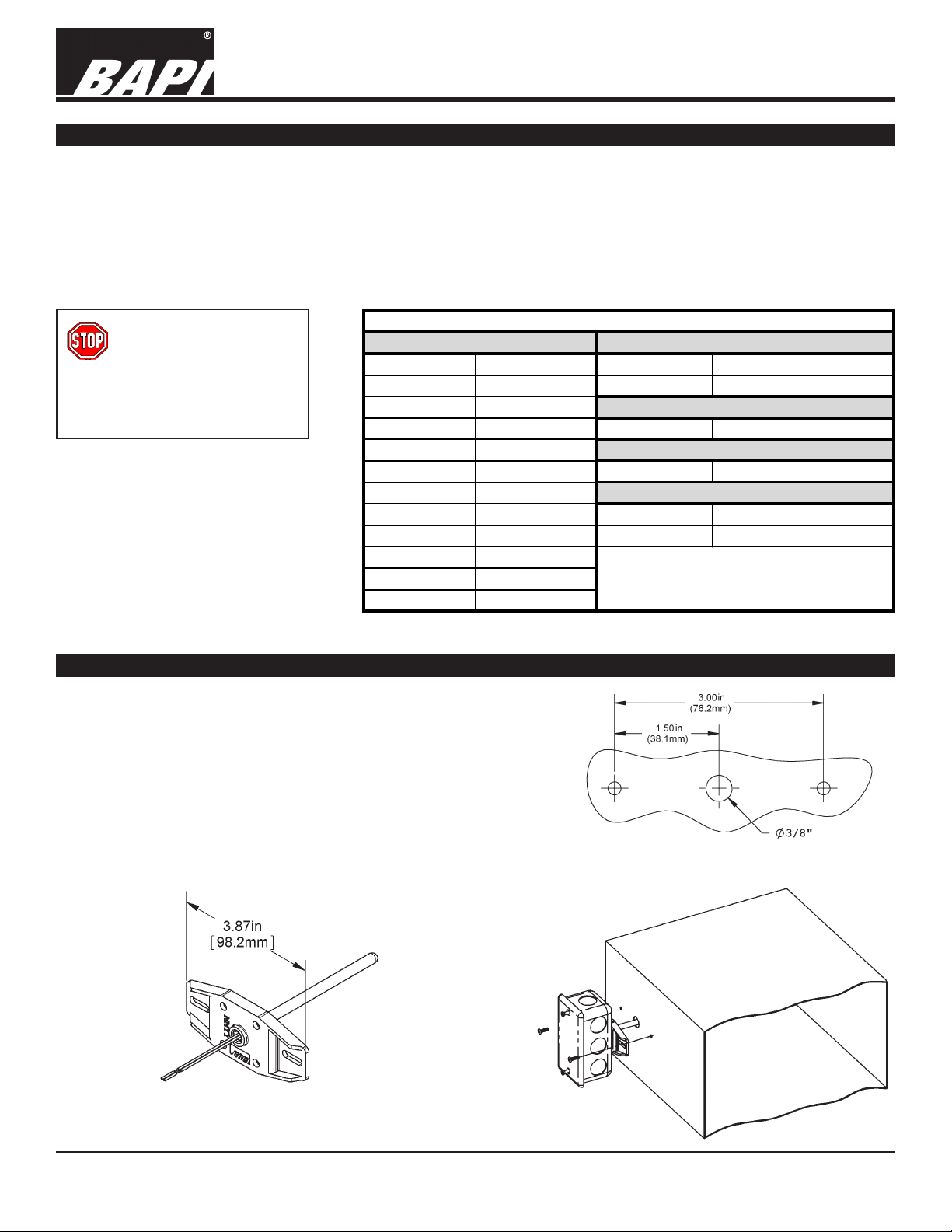

Junction Box (JB) and No Box (NB) Mounting Indoors

The junction box mount is intended for indoor mounting in

equipment rooms, plenums or occupied spaces. The gures

below show a typical junction box mounting in an air duct.

BAPI recommends using #8 sheet metal screws that need 1/8inch pilot holes to attach the sensor to the duct.

After placing the sensing element in the duct, secure the

mounting ange to the duct; center the plastic tting holding

the probe in the mounting hole. Make sure that the foam seals

the hole; do not over tighten the screws. No box units use the

same mounting holes as Junction Box units.

Nickel RTD

Silicon RTD

Platinum RTDs - 3 Wire

*In the 3-Wire RTD sensors listed above,

the two wires of similar color are

connected together.

Fig. 1: Junction Box (JB) or No Box (NB)

mounting holes

Fig. 3: No Box (NB)

Probe

Specications subject to change without notice.

Fig. 2: Junction

Box (JB) duct

installation

1 of 5

Page 2

Non-Room Thermistors and RTDs

Installation & Operations

9502_ins_therm_rtd_nrm

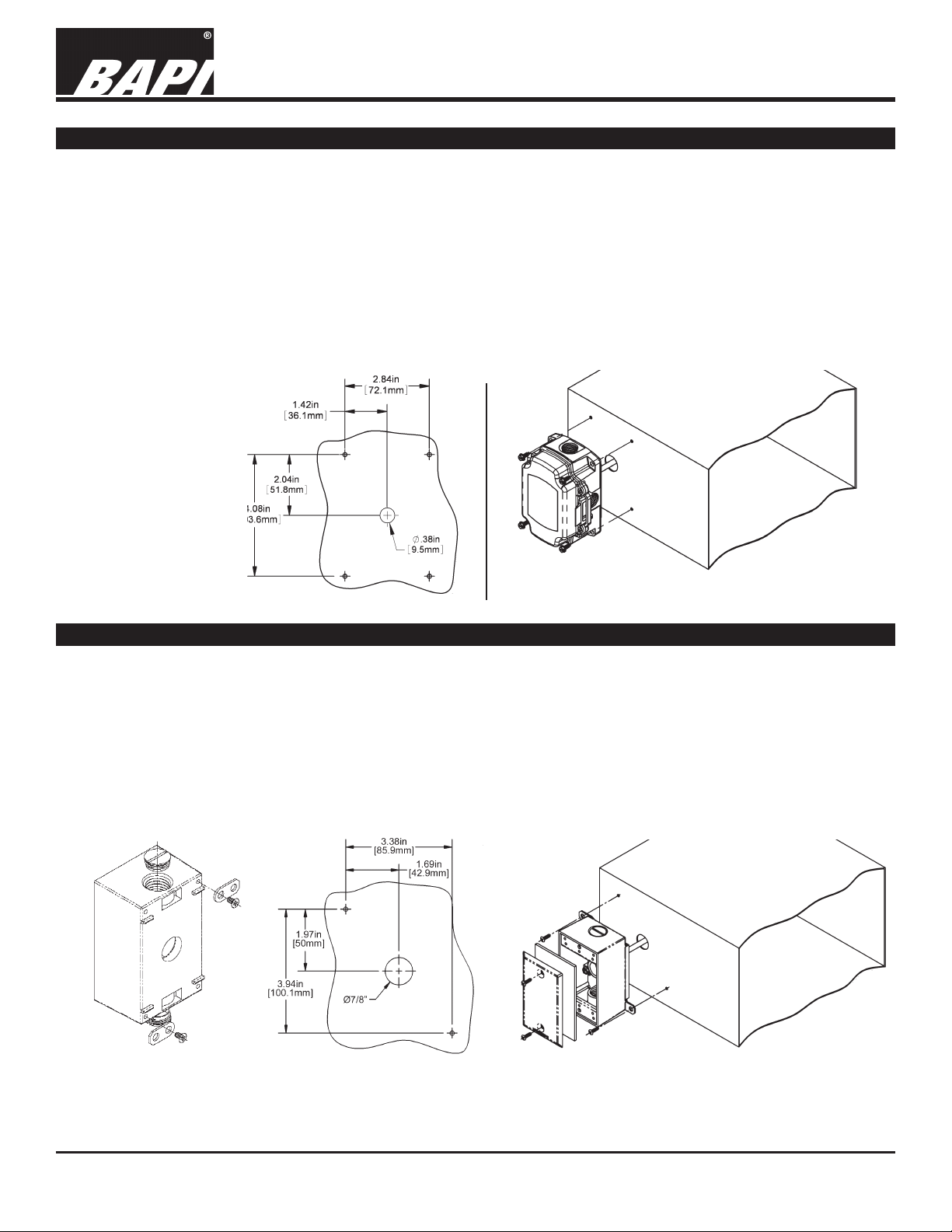

BAPI-Box (BB) Mounting Indoors

The BAPI-Box Enclosure is watertight and carries an IP66 rating which is similar to a NEMA 4X rating when the

included 6-32 screws are fastened on either side of the latch. The BAPI-Box Enclosure is made of high impact, UV

resistant polycarbonate and features a gasketed cover for a waterproof seal, a hinged cover to simplify installation,

horizontal or vertical mounting with multiple knockouts and a window in the cover for an LCD display.

Enclosure is available for the full line of BAPI duct, immersion, outside air and pressure sensors.

Mount the unit to its mounting surface with four #10 scres through the holes in the mounting feet. #10 sheet metal

screws require 5/32” (4mm) pilot holes. For concrete or cinder block, drill four 5/32” (4mm) holes, 1-3/4 inch (45mm)

deep. Make sure that all screws are started in their holes before tightening evenly. If unit has a foam gasket, only

squeeze to about 1/2 of its original thickness.

Be sure to seal conduit connector threads and holes in mounting surface to maintain the integrity of the box.

Fig 4: BAPI-Box (BB)

enclosure mounting

holes, rotate 90° for

horizontal mounting

The BAPI-Box

rev. 10/12/15

-

Fig. 5: BAPI-Box (BB) duct installation

Weatherproof (WP) Enclosure Mounting Indoors

The weatherproof box is intended for outdoor or equipment room mounting. Use the mounting tabs provided to

mount the weatherproof box as shown in the gure below. DO NOT drill screw holes through the back wall of the

box, this destroys the integrity of the box and may void the warranty.

The gures below show a typical weatherproof box mounting in an air duct. BAPI recommends using #8 sheet

metal screws that need 1/8-inch pilot holes to attach the sensor to the duct. After placing the sensing element in

the duct, secure the mounting tabs to the duct; center the plastic tting holding the probe in the mounting hole. Be

sure that the foam seals the hole; do not over tighten the screws. Place the foam gasket between the cover and the

box before securing the cover in place with the screws provided. T

threads of the box plugs or conduit connectors with caulk before screwing them into the waterproof box.

o keep water out of the box, be sure to coat the

Fig. 6:

Weatherproof (WP)

enclosure mounting tabs

Fig. 7:

Weatherproof (WP)

enclosure mounting holes

Specications subject to change without notice.

Fig. 8:

Weatherproof (WP) enclosure

duct installation

2 of 5

Page 3

Non-Room Thermistors and RTDs

Installation & Operations

9502_ins_therm_rtd_nrm

Weather Tight (EU) Enclosure Mounting Indoors

The Weather Tight (EU) enclosure is made from ABS plastic for indoor applications and a UV light stabilized

plastic for outdoor applications or indoor applications exposed to direct sun light. The gures below show a typical

Weathertight enclosure mounting in an air duct.

BAPI recommends using #8 sheet metal screws that need 1/8-inch pilot holes. After placing the sensing element in

the duct, secure the mounting feet to the duct; center the plastic tting holding the probe in the mounting hole. Do

not over tighten the screws but be sure that the foam insulation makes an airtight seal. T

when you are nished making terminations.

Fig. 10: Weather

Tight (EU) duct

installation

Fig. 9: Weather

Tight (EU)

enclosure

mounting holes

ighten the lid to two clicks

rev. 10/12/15

Weather Tight (EU) and Weatherproof (WP) Enclosure Mounting Outdoors

Do not mount in direct sunlight, preferably mount on the north side of the

building. Install with the sensor probe pointed down. For best correlation with

the local weather bureau’s temperature, position the end of the probe between

four feet and six and one-half feet above the ground. Drill a hole through your

mounting surface as shown in the gures below. Mount the unit to the surface

with a wiring knock out centered over the wiring hole. Pull the wiring into the

unit and terminate using sealant lled connectors. Best practice is to caulk the

wiring hole after the wiring is installed. Be sure that the foam on the back of

the unit makes a good weather tight seal. Use the mounting tabs provided to

mount the weatherproof box as shown in the gure below.

DO NOT drill screw holes through the back wall of the box, this destroys the

integrity of the box and may void the warranty. Note: Air temperature units

are shown. To keep water out of the box, be sure to coat the threads of the

box plugs or conduit connectors with caulk before screwing them into the

weatherproof box.

Weatherproof (WP) enclosure

mounting holes and outside

Fig. 11:

air installation

Fig. 12: Weather Tight (EU)

enclosure mounting holes and

outside air installation

Specications subject to change without notice.

3 of 5

Page 4

9502_ins_therm_rtd_nrm

Immersion Sensor Mounting

Place the thermowell into the pipe nipple

using Teon tape and/or pipe dope. Tighten

securely but do not over torque. Insert the

immersion sensor into the well with the plastic

tting screwing into the opening on the well.

Tighten the immersion sensor snugly by hand

without too much torque. Make sure that the

tip of the immersion sensor is in contact with

the bottom of the well.

The unit is designed so that the temperature

probe moves slightly into the junction box as

the sensor hits the bottom of the well. Figure

13 shows a junction box, but Weatherproof,

Weather Tight or BAPI-Box enclosures may

be used as well.

Non-Room Thermistors and RTDs

Installation & Operations

rev. 10/12/15

Fig. 13:

Cross section of

immersion unit

installation

Spring-Loaded Strap Mounting

The spring-loaded strap sensor is used when a large

section of insulation cannot be removed from a pipe.

The unit accommodates insulation of up to two inches

thick. Cut a 1.25” diameter hole in the insulation

and remove the insulation from the hole down to the

bare pipe. Be sure to remove all insulation and debris

from the hole. Place the copper pad on the end of

the spring-mounted foam into the hole; make sure it

makes good physical contact with the pipe. Tighten

the straps until the strap-mounting bracket contacts

the insulation. The spring-loaded strap on sensor is

sized for pipe diameters of 5 to 12.5”, including the

insulation.

Clamp On Strap Mounting

Place the clamp-on sensor on bare pipe, or a section

of pipe with the insulation removed. Make sure that

the copper pad on the foam is in good physical contact

with the pipe. Snug the straps so that the assembly

does not rotate around the pipe when moderate

pressure is applied to the junction box. Do not over

tighten. You may place pipe insulation over the whole

assembly. The clamp-on strap sensor is sized for bare

pipes of 2 to 4.5” in diameter. Add another pipe clamp

if needed.

Fig. 14:

Spring-Loaded Strap installation

Specications subject to change without notice.

Fig. 15:

Clamp-On Strap installation

4 of 5

Page 5

Non-Room Thermistors and RTDs

9502_ins_therm_rtd_nrm

Remote Sensor (RPFEP and FEP) Mounting Indoors

Mount the Weatherproof or the Weather Tight enclosures as shown

in the gures below. Mount with the wire connector down. Route

the temperature probe to the spot where you wish to measure the

temperature. Best practice is to tie down the wire every two feet. Make

sure to caulk the upper screw in plug on the Weatherproof enclosure.

Center mounting hole shown is only used if you are wiring through the

mounting surface.

Fig. 16:

Weatherproof (WP) enclosure

mounting holes and remote

probe installation

Installation & Operations

rev. 10/12/15

Fig. 17:

Weather

Tight (EU)

enclosure

mounting

holes and

remote

probe

installation

Diagnostics

Problems:

Controller reports temperature that is different

from the actual temperature of the location

Specications subject to change without notice.

Possible Solutions:

- Conrm the input is set up correctly in the front end software

- Verify that the wires are not physically shorted or open

- Check wiring for proper termination

- Disconnect wires and measure the sensor resistance with an

Ohmmeter to verify that the sensor output is correct. (See note

below)

Note: Measure the temperature at the sensor’s location using

an accurate temperature standard. Disconnect the temperature

sensor wires and measure the temperature sensor’s resistance

with an ohmmeter. Compare the temperature sensor’s

resistance to the appropriate temperature sensor table on

the BAPI website. If the measured resistance varies from

the temperature table by more than 5%, call BAPI technical

support. BAPI’s website is found at www.bapihvac.com; click on

“Resource Library” and “Sensor Specs”, then click on the type of

sensor you have.

5 of 5

Loading...

Loading...