Page 1

BA/*-LP, Low Prole “Button” Wall Sensor

Installation and Operating Instructions

23961_ins_LP

Overview and Identication

The Low Prole “Button” Wall Sensor is

ideal for locations where aesthetics are as

important as the temperature measurement.

The inconspicuous sensor mounts easily by

pushing through a 1/2” hole and secured with

a peel off tape strip. The only visible portion is

a ush 7/8” dot on the wall.

The Low Prole Wall Sensor is available in

multiple thermistor or RTD sensors as shown

in the specications. Other sensor types are

available on request.

Operation/Application

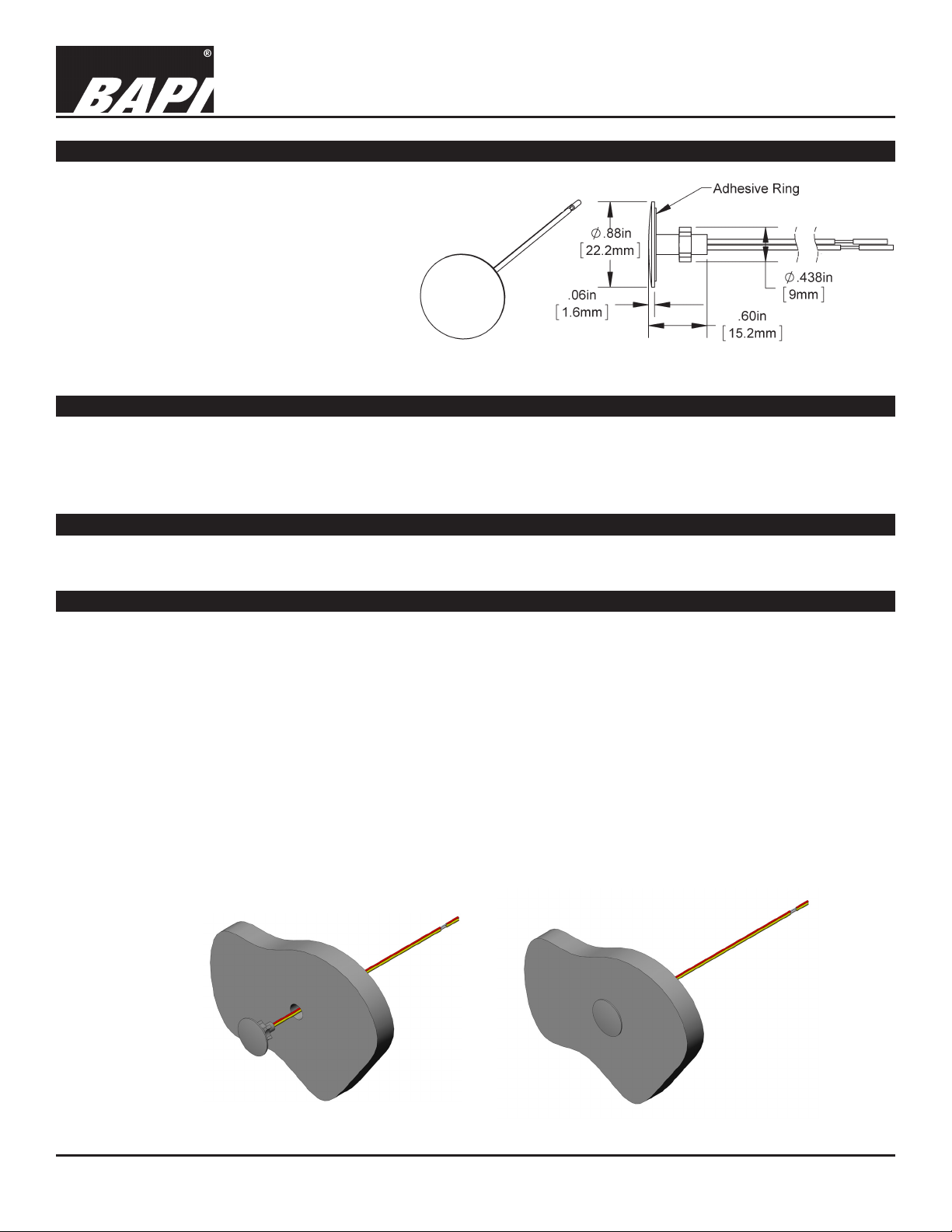

Fig 1: Low Prole “Button” Sensor Dimensions

This sensor is suspended in a round button size enclosure shell so that room air can surround the sensing element

for a fast and accurate temperature reading. The sensor is isolated from the mass wall temperature with internal

insulators. The unit can be painted. The unit should not be covered with any material such as wall paper.

rev. 12/02/16

Customer Provided Tools and Materials

Requires a 1/2” drill bit and wire splice connectors. Crimp on sealant lled connectors recommended for protection

from in wall moisture. (BA/SFC1000-100)

Mounting and Wire Termination

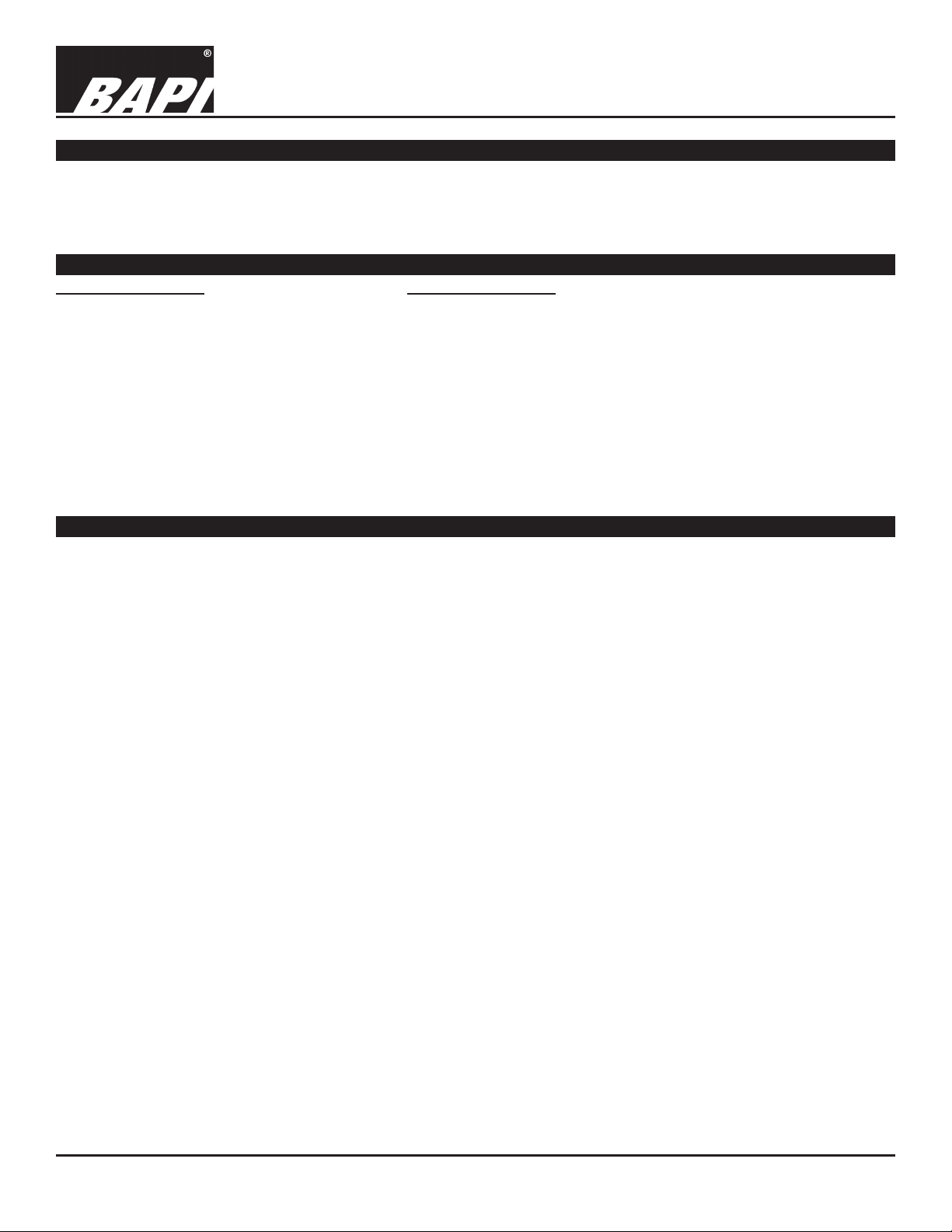

1. Select a location with a at surface on an interior wall approximately 5’ (1.5m) off the oor.

2. Drill a 1/2” hole where you want the sensor mounted.

3. Pull your zone wire through the hole and terminate the sensor using a ying lead connector (crimp or wire nut).

A crimp-on sealant lled connector is recommended for protection from in wall moisture, (BA/SFC1000-100).

4. Test the sensor at the controller to be sure of your connections and sensor operation.

Note: Once installed the sensor is difcult to remove and may damage the wall.

5. Be sure the wall interior is insulated behind the sensor. In-wall drafts can affect the temperature reading.

6. Clean the wall surface from any dust or lings to make a clean mounting surface.

7. Remove the peel off strip from the mounting tape on the back of the sensor rim and push the sensor rmly into the

1/2” hole until the double stick tape adheres rmly to the wall.

Specications subject to change without notice.

1 of 2

Page 2

BA/*-LP, Low Prole “Button” Wall Sensor

Installation and Operating Instructions

23961_ins_LP

Maintenance

Clean any debris out from around the center sensor. It is important that air space is all around the inner sensor. Painting is OK as long as excess paint does not build up between the sensor and the mounting shell. Wall paper should not

cover the sensor. Either cut out around the mounting shell or pull the sensor out of the wall and remount after the wall

papering is completed.

Diagnostic

Possible Problems: Possible Solutions:

Controller reports incorrect temperature - Conrm the input is set up correctly in the front end software.

- Verify that the wires are not physically shorted.

- Check wiring for proper termination.

- Verify the “Sensor” output is correct.

- Determine if the sensor is exposed to an external H/C source.

Over Base board heat.

Under a supply air diffuser.

Extreme back wall draft temperatures.

- Fill wall cavity with Fiberglass, or Polyester ll.

rev. 12/02/16

Specications

Sensor .................... Passive

Thermistor ............. NTC, 2 wire

RTD ....................... PTC, 2 or 3 wire

Thermistor .............. Thermal resistor

Temp. Output ......... Resistance

Accuracy (Std) ...... ±0.36ºF, (±0.2ºC)

Accuracy (High) ..... ±0.18ºF, (±0.1ºC),

[XP] option

Stability ................. < 0.036ºF/Year, (<0.02ºC/Year)

Heat dissipation .... 2.7 mW/ºC

Temp. Drift ............. <0.02ºC per year

Probe range .......... -40º to 221ºF (-40º to 105ºC)

RTD ......................... Resistance Temperature Device

Platinum (PT)......... 100Ω or 1KΩ @0ºC, 385 curve,

Platinum (PT)......... 1KΩ @0ºC, 375 curve

PT Accuracy (Std) ..

PT Accuracy (Hi) ...

0.12% @Ref, or ±0.55ºF, (±0.3ºC)

0.06% @Ref, or ±0.277ºF, (±0.15ºC),

[A] option

PT Stability ........... ±0.25ºF, (±0.14ºC)

PT Self Heating .... 0.4 ºC/mW @0ºC

PT Probe range .... -40º to 221ºF, (-40 to 105ºC)

Lead wire: 2 or 3 conductor, 22 AWG stranded wire

Wire Insulation: Etched Teon, Plenum rated

Wiring: Two 22 AWG wires (non-polar)

Mounting: 1/2" hole, push in plastic sheath

with peel off tape strip.

Dimensions: ........... Plastic Sheath

Insertion ................. 1.0" depth, into a 7/16" hole

Sleeve.................... 0.438" Diameter

Bezel...................... 0.875" Diameter

Encl. Type: Round Flush Sensor Sheath

Enclosure Ratings: NEMA 1

Encl. Material: Plastic, UL94

Ambient (Encl.)

0 to 100% RH, Non-condensing

-40ºF to 185ºF, (-40º to 85ºC)

Agency

RoHS, CE* (Thermistor’s <10KΩ)

PT= DIN43760, IEC Pub 751-1983,

JIS C1604-1989

Nickel (Ni) ............. 1000Ω @70ºF, JCI curve

Ni Probe range ..... -40º to 221ºF (-40 to 105ºC)

Sensitivity

Thermistor ...Non-linear

Go to bapihvac.com “Sensor Specs”

RTD (PT) .....3.85Ω/ºC for 1KΩ RTD

3.75Ω/ºC for 1KΩ RTD

0.385Ω/ºC for 100Ω RTD

Nickel (Ni) ....2.95Ω/ºF for the JCI RTD

Specications subject to change without notice.

2 of 2

Loading...

Loading...