Page 1

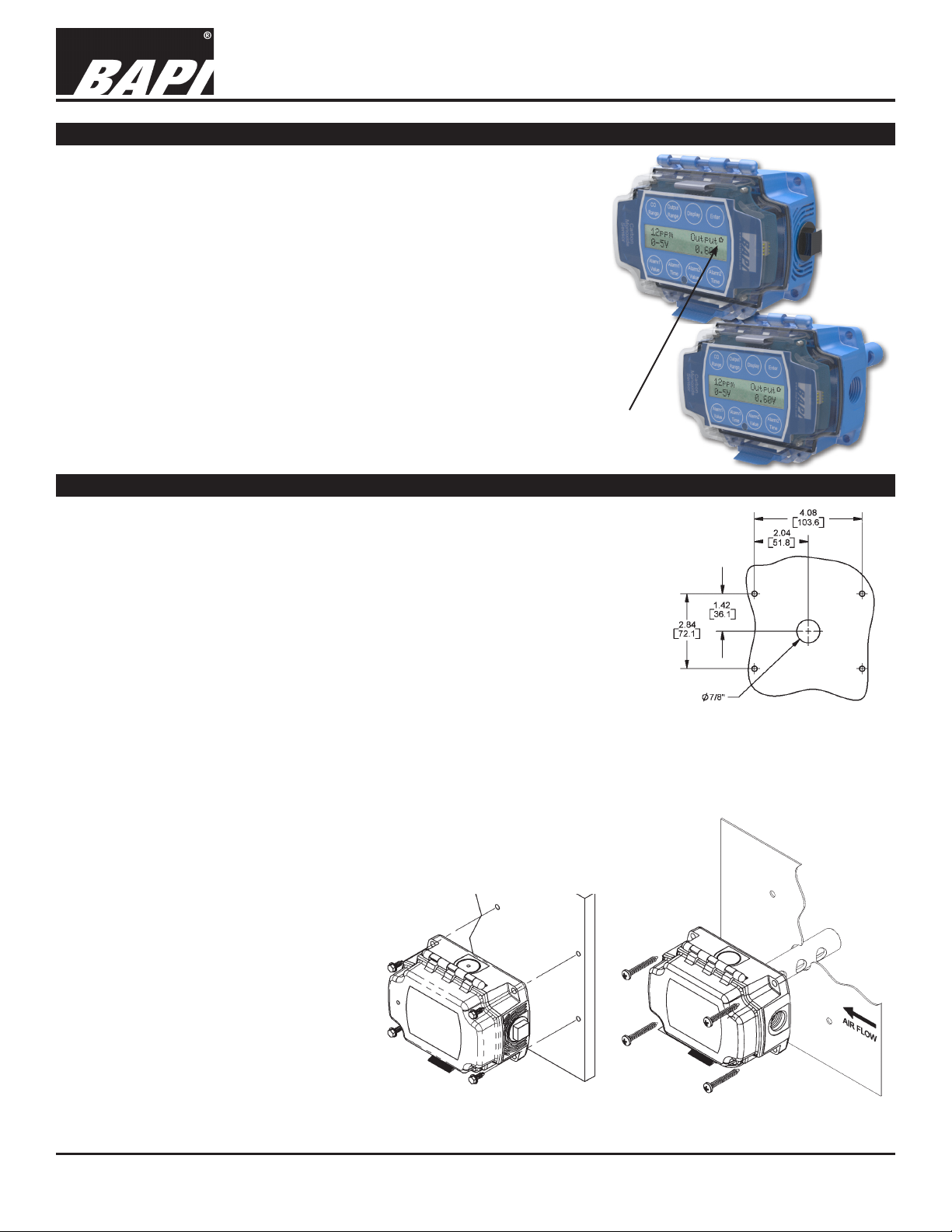

Duct and Rough Service Carbon Monoxide Sensor

34612_ins_CO_V_BB

Product Identication and Overview

BAPI’s Carbon Monoxide Sensor offers enhanced electrochemical sensing

with outstanding accuracy at low concentrations. The Duct unit samples duct

air using an aspiration tube. The Rough Service unit features a ventilated

BAPI-Box and is ideal for parking ramps, equipment rooms and warehouses.

The sensor has eld selectable CO ranges of 0 to 100, 0 to 200, 0 to 300 and

0 to 500 ppm. It also has eld selectable outputs of 0 to 5, 1 to 5, 0 to 10, 2 to

10 VDC and 3-wire 4 to 20 mA output. The large LCD is backlit for 10 seconds

after any button push.

Two independent SPDT alarm contacts switch at eld selectable CO

concentrations of 25, 35, 50, 100 and 200 ppm. An alarm timer can hold the

output relays on for one to ten minutes after the CO level has fallen below

80% of setpoint. This allows additional fan run time to be sure that the CO

has been purged. The eld replaceable sensor element lasts approximately 7

years and is self tested daily.

Note: There is a small heart symbol in the top right corner of the display that blinks

every ½ second. This heartbeat indicates that the unit is operating correctly.

Mounting

Installation & Operating Instructions

rev. 10/11/17

Rough

Service

(top)

and

Duct CO

Sensors

Rough Service Ventilated Unit

1. Mount the unit on a solid, non-vibrating surface 3 to 5 feet above oor level. Mount

in a horizontal orientation with the enclosure hinge at the top as shown in Fig 2.

Failure to do so may degrade the life of the sensor element. Do not mount near

supply or return diffusers.

2. Use BAPI recommended #10 (M5) screws on the four mounting feet of the

enclosure. A pilot-hole makes mounting easier. Use the enclosure mounting feet to

mark the pilot-hole locations.

3. Snug up the screws so that the foam backing is depressed but do not over-tighten

or strip the screw threads.

4. Place the provided #6 screws into the holes on each site of the lid latch to make the

cover tamper resistant.

Duct Aspiration Tube Unit

1. BAPI recommends placing the sensor in the middle of the duct wall, away from

stratied air, to achieve the best reading. The unit should also be a minimum of 3

duct diameters from an elbow, damper or other duct restriction.

2. Drill a 1” hole for the aspiration probe. Position the box so that airow is directly into

the holes on one side of the aspiration probe. The air direction is not important.

4. Mount the enclosure to the duct using

BAPI recommended #10 screws

through a minimum of two mounting

feet on opposite corners. A 1/8” pilot

hole makes mounting easier. Use the

mounting feet to mark the pilot-hole

locations.

5. Snug the screws until the foam backing

is compressed about 50% to prevent

air leakage but do not over-tighten.

6. Use the provided #6 screws to secure

the cover for IP66 rating.

7. BAPI recommends sealing the conduit

opening with berglass insulation.

Specications subject to change without notice.

Fig. 2: Rough Service

Unit mounting

Fig. 1: Screw Hole Template.

Drill center 7/8” hole for rear

conduit entry on Rough Service

Unit. Drill 1” hole for Aspiration

Tube on Duct Unit

Fig. 3: Duct Unit mounting

1 of 10

Page 2

Duct and Rough Service Carbon Monoxide Sensor

Installation & Operating Instructions

34612_ins_CO_V_BB

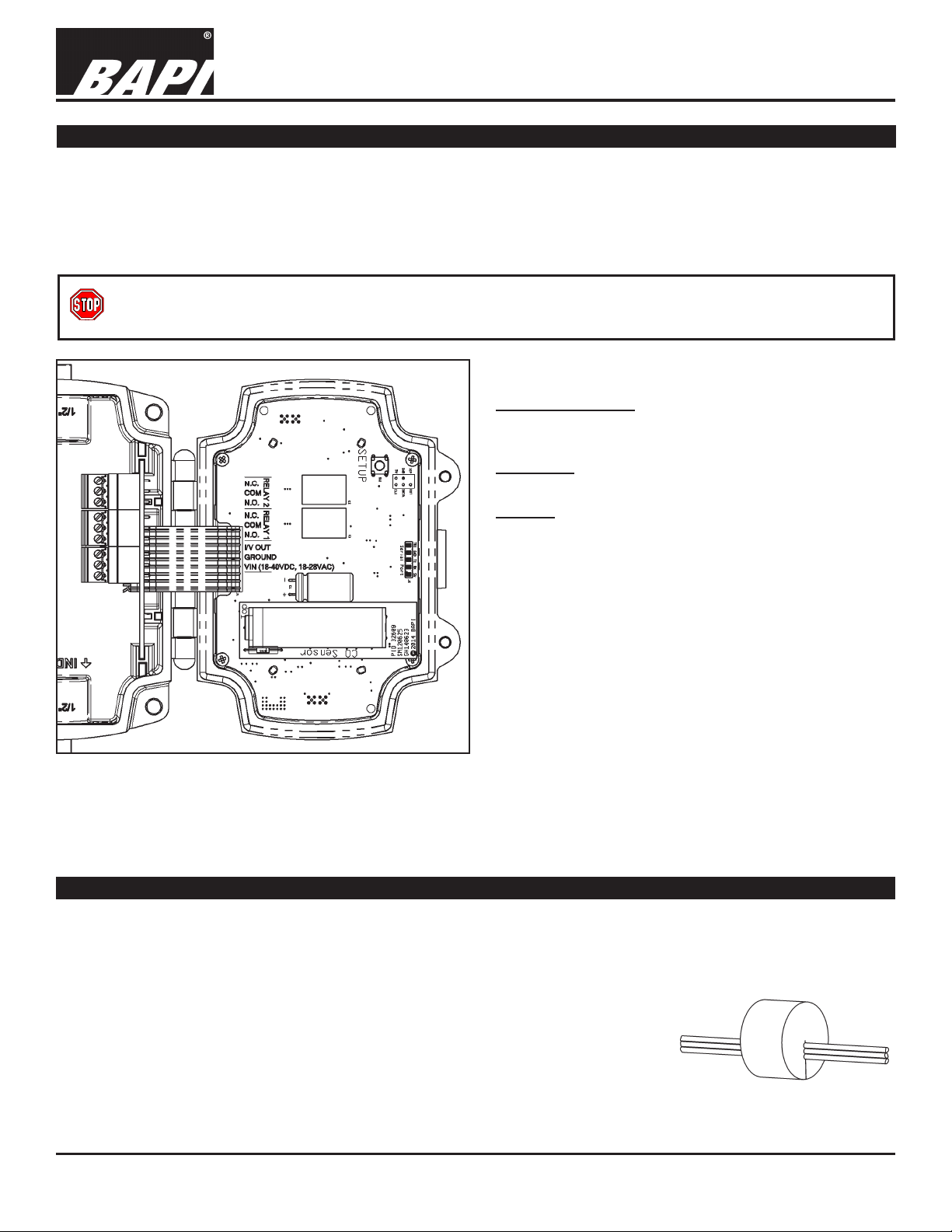

Termination

BAPI recommends using twisted pair of at least 22AWG and sealant lled connectors for all wire connections. Larger gauge

wire may be required for long runs. All wiring must comply with the National Electric Code (NEC) and local codes.

Do NOT run this device’s wiring in the same conduit as AC power wiring of NEC class 1, NEC class 2, NEC class 3 or with

wiring used to supply highly inductive loads such as motors, contactors and relays. BAPI’s tests show that uctuating and

inaccurate signal levels are possible when AC power wiring is present in the same conduit as the signal lines. If you are

experiencing any of these difculties, please contact your BAPI representative.

BAPI recommends wiring the product with power disconnected. Proper supply voltage, polarity and wiring

connections are important to a successful installation. Not observing these recommendations may damage the

product and void the warranty.

WIRING TERMINALS

VIN – Input Power

18 to 28 VAC, 7.2 VA Max

18 to 40 VDC, 180 mA Max.

GROUND:

N.C.

COM

N.O.

N.C.

COM

N.O.

OUT

GND

VIN

Power and Analog Output Ground

I/V OUT

Three wire voltage or current signal

RELAYS

Relay contacts are galvanically isolated. They are

not connected to each other, or to circuit power or

ground in the carbon monoxide transmitter.

N.O. – Normally Open Contact

COM – Common Contact

N.C. – Normally Closed Contact

rev. 10/11/17

Fig. 4: Field Wiring Terminals

NOTE: The connectors that plug into the jacks on the board use a rising block screw terminal to hold the wires. If the

block is in a partially up position, the wire may be inserted under the block and the wire will not be held when the screw

is tightened. To avoid improper wiring, turn the male connector screws counterclockwise until the block is below the wire

opening before inserting the wire. Lightly tug on each wire after tightening to verify proper termination.

Keeping the Enclosure Air Tight After Termination

For the sensor to work correctly, the wiring entrance must remain air tight. If the CO transmitter is mounted to

a hollow wall and wired through its back, or wired with conduit, it is possible that a draft of clean air may ll the

enclosure through the wiring opening. This draft may prevent the unit from measuring ambient Carbon Monoxide.

BAPI recommends either a liquid-tight tting or plugging the conduit at the enclosure.

• Liquid-Tight Fitting – BAPI’s Liquid-Tight Fitting (BA/LTF) allows wire cables

of 0.1 to 0.3 inch outside diameter to enter the box. Tightening the collar onto the

wire cable keeps the wiring entrance air tight.

• Conduit – Included with the Carbon Monoxide transmitter is a foam plug to seal

the ½ inch EMT. Place the wires into the plug as shown in Fig. 5 and then insert

the plug into the conduit sealing the conduit.

Fig. 5:

Wires Through Foam Plug

Specications subject to change without notice.

2 of 10

Page 3

Duct and Rough Service Carbon Monoxide Sensor

Installation & Operating Instructions

34612_ins_CO_V_BB

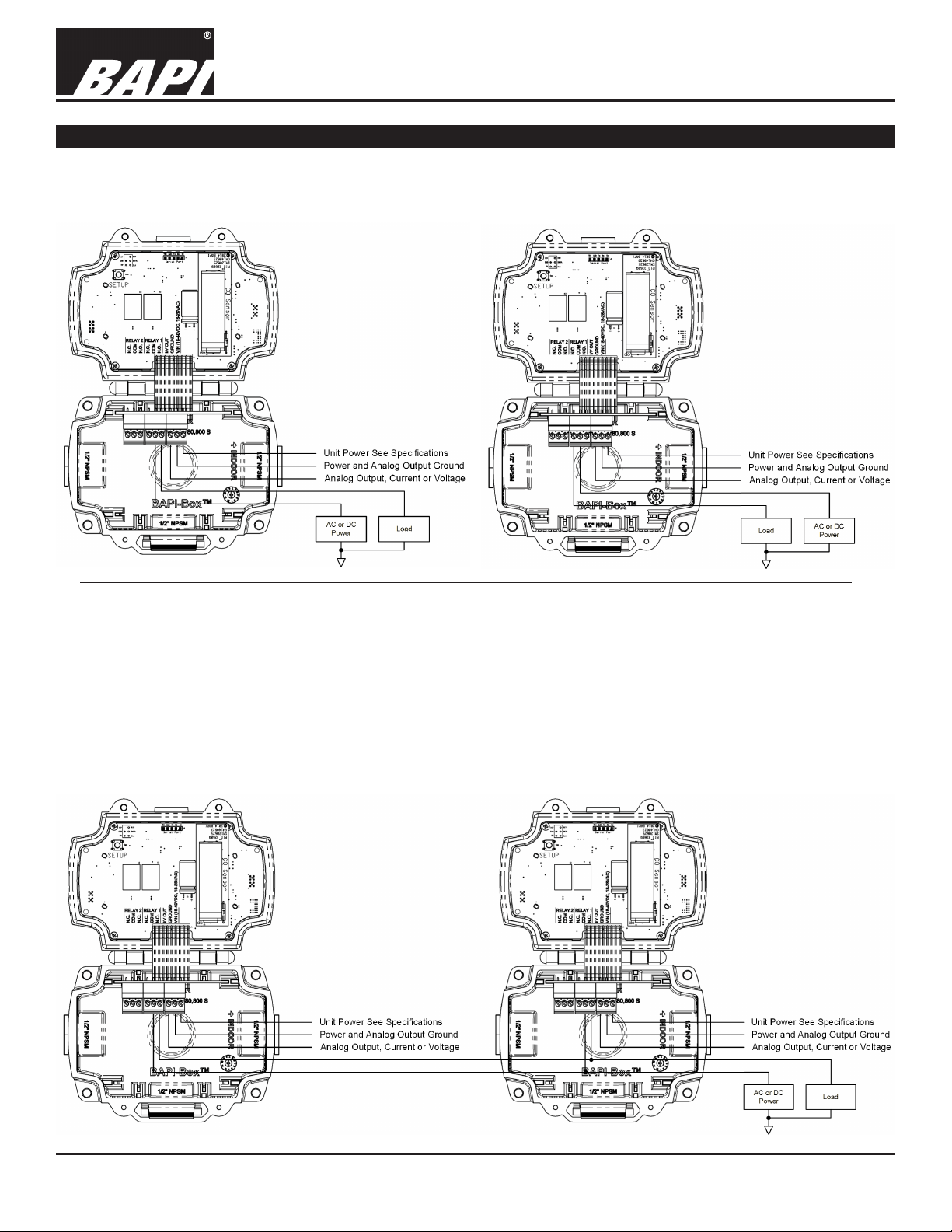

Relay Load Termination

The Alarm Relays may be used to switch a load on or off. Fig. 6 shows a circuit that may be used to switch on a

load under alarm conditions. Fig. 7 shows a circuit that may be used to switch off a load under alarm conditions.

For clarity only Alarm Relay 1 is shown, Alarm Relay 2 may be used in the same way.

Fig. 7:

Fig. 6:

Turn “On”

a load

under alarm

conditions

Turn “Off”

a load

under alarm

conditions

rev. 10/11/17

Fig. 8 shows how two or more Carbon Monoxide Transmitters may be interconnected to switch a load. This example

shows how to turn on a load under alarm conditions. Similar circuitry may be used to turn off a load under alarm

conditions. Fig. 8 connects together the Normally Open terminals of Alarm Relay #1 in both units and connects them

to the load. Fig. 8 also connects together the Common terminals of Alarm Relay #1 in both units and then connects

them to the load’s power. This wiring circuit will drive the load whenever any one of the Carbon Monoxide Transmitters is in an alarm condition. Note: Be sure to only connect similar terminals from each unit (Normally Open terminal

to Normally Open terminal, etc.). Cross connecting any of the terminals (Normally Closed to Common, etc.) may

damage the units and may void the warranty.

For clarity only Alarm Relay 1 is shown in the example below. Alarm Relay 2 may be used in the same way.

Fig. 8:

Turn “On” a

load when

either unit

enters an alarm

condition

Specications subject to change without notice.

3 of 10

Page 4

Duct and Rough Service Carbon Monoxide Sensor

Installation & Operating Instructions

34612_ins_CO_V_BB

Relay Load Termination continued...

Some circuits require a switched ground to operate, such as audible alarms, visual alarms, or large AC motor controllers. Fig. 9 shows how to apply ground under an alarm condition. Fig. 10 shows how to remove ground under

an alarm condition. For clarity only Alarm Relay 1 is shown. Alarm Relay 2 may be used in the same way.

rev. 10/11/17

Fig. 9:

Applying

ground

under alarm

conditions

Fig. 10:

Removing

ground

under alarm

conditions

Power Up

During the rst 60 seconds after applying power, the Carbon Monoxide Transmitter performs the following functions:

• Front panel capacitive button test;

• Displays the transmitter’s software version number;

• Displays the transmitter’s serial number;

• Displays the transmitter’s run time;

• Displays the CO Module’s software version number;

• Displays the CO Module’s serial number;

• Displays the CO Module’s run time;

• Performs a CO Module self-test;

When the CO Module self-test is complete, the transmitter is operational.

Operation

The eight buttons

on the face of the

unit sense the user’s

ngertip when pressed

against the plastic

cover. The buttons

allow the user to

review or select

unit conguration

parameters. The top

line of the display

continues to show

the CO measurement

when reviewing or

selecting parameters.

Parameter Button Function

Review or select Carbon Monoxide measurement range used for analog output

Review or select analog output range

Review or select display on or display off

View hidden values, verify edit mode, save edited configuration parameters, or end configuration parameter edit

Review or select CO concentration to enable Alarm 1 relay

Review or select number of minutes that Alarm 1 relay stays on after CO dissipates

Review or select CO concentration to enable Alarm 2 relay

Review or select number of minutes that Alarm 2 relay stays on after CO dissipates

Specications subject to change without notice.

4 of 10

Page 5

Duct and Rough Service Carbon Monoxide Sensor

Installation & Operating Instructions

34612_ins_CO_V_BB

Operation continued...

Display On and Display Off Modes

The top line of the display shows the CO measurement when the Display Mode is set to “On” . If the Display Mode

is set to “Off,” the top line of the display shows the word “On” rather than the CO measurement. If the CO measurement is below Alarm 1 or Alarm 2 levels, the LED will be green.

Fig. 11:

Display During

Normal Operation

(Reading is below

CO alarm value)

rev. 10/11/17

Display “On” Mode

Display “Off” Mode

Displaying the CO Measurement, Analog Output Range and Analog Output Value

Touching the Enter button displays the Current Reading, the Analog Output Range and Analog Output Value for 10

seconds. The current reading is replaced by the word “On” if the display is set to “Off”.

4 to 20 mA Output Mode

(Display set to “On”)

Fig. 12: Display showing the Current Reading, the Analog Output Range and Analog Output Value

0 to 5 Volt Output Mode

(Display set to “On”)

0 to 5 Volt Output Mode

(Display set to “Off”)

CO Sensor Failure Display

The CO sensor element is tested for proper operation daily. If

the sensor fails:

• The top line of the display displays “Replace Sensor,”

• The analog output is set to 100% of range

• Both relays turn on,

• The LED ashes yellow.

Note: The sensor failure display is the same whether the

display is set to “On” or “Off”.

Specications subject to change without notice.

Fig. 13: CO Sensor Failure

5 of 10

Page 6

Duct and Rough Service Carbon Monoxide Sensor

34612_ins_CO_V_BB

Operation continued...

Alarm Condition 1 Display

If the CO measurement exceeds the

Alarm 1 setpoint:

• The CO measurement or the word

“On” is displayed on the rst line

• The alarm condition is display on

the second line

• The LED will be red

• The backlight ashes

Alarm Condition 2 Display

If the CO measurement exceeds the

Alarm 2 setpoint;

• The CO measurement or the word

“On” is displayed on the rst line

• The alarm condition is displayed on

the second line

• The LED will be red

• The back light ashes

Note: The Alarm 2 Setpoint may be

equal to, greater than or less than the

Alarm 1 Setpoint.

Installation & Operating Instructions

rev. 10/11/17

Alarm Condition 1

(Display set to “On”)

Fig. 14: Display when the measurement exceeds Alarm Condition 1 Setpoint

Alarm Condition 2

(Display set to “On”)

Fig. 15: Display when the measurement exceeds Alarm Condition 2 Setpoint

Alarm Condition 1

(Display set to “0ff”)

Alarm Condition 2

(Display set to “Off”)

Alarm Condition 1 & 2 Display

If the CO measurement exceeds the

Alarm 1 & 2 setpoint;

• The CO measurement or the word

“On” is displayed on the rst line

• The alarm condition 1 and 2 is

displayed on the second line

• The LED will be red

• The back light ashes

Note: The Alarm 2 Setpoint may be

equal to, greater than or less than the

Alarm 1 Setpoint.

Alarm Condition 1 & 2

(Display set to “On”)

Fig. 16: Display when the measurement exceeds Alarm

Condition 1 & 2 Setpoint

Specications subject to change without notice.

Alarm Condition 1 & 2

(Display set to “Off”)

6 of 10

Page 7

Duct and Rough Service Carbon Monoxide Sensor

Installation & Operating Instructions

34612_ins_CO_V_BB

Reviewing Parameter Settings

You can review the parameter settings at any time during normal operation by touching any of the eight buttons on

the face of the unit. The following gures show a typical display when a button is touched. The values will display for

10 seconds and then the display will revert to normal.

rev. 10/11/17

CO Range Output Range (0 to 10 Volts)

Display Mode Alarm 1 Value

Output Range (4 to 20mA)

Alarm 1 Time

Alarm 2 Value Alarm 2 Time

Specications subject to change without notice.

7 of 10

Page 8

Duct and Rough Service Carbon Monoxide Sensor

Installation & Operating Instructions

34612_ins_CO_V_BB

Parameter Setup and Default Settings

If eld personnel wish to change any parameter settings, they must remove the tamper resistant screws, open the

cover, and press the switch on the board labeled “Setup.” Follow Fig. 17 below to change parameters.

rev. 10/11/17

Fig. 17:

Parameter Setup Flow Chart

(Default settings are shown with gray shading)

Specications subject to change without notice.

8 of 10

Page 9

Duct and Rough Service Carbon Monoxide Sensor

34612_ins_CO_V_BB

Calibration

Every BAPI Carbon Monoxide Transmitter is factory calibrated. Each unit

is ready for operation after installation and the 60 second start-up time.

BAPI’s factory calibrated CO sensing element is not capable of eld

calibration. BAPI recommends replacing the sensor whenever the

Replace Sensor alarm is active, or every 7 years, or at the recalibration

intervals required by the local jurisdiction. The sensing element comes

supplied factory equipped with calibration certicate.

To replace the CO Module (Fig. 18), follow these steps;

• Remove the tamper resistant screws and open the lid

• Unplug the power connector

• For the next two steps, hold the sensor by the body, not the endcaps.

• Remove the CO Module by pulling it straight off the transmitter

• Plug in the new sensor by pushing the sensor board straight into the

transmitter

• Plug in the power connector

• Close the lid until it clicks, and replace the tamper resistant screws

Installation & Operating Instructions

rev. 10/11/17

Maintenance

The BA/CO sensor/transmitter unit should be vacuumed clean once a year

or more, depending on the rate of accumulation of any dust or dirt. T

o

avoid sensor damage, the unit MUST NOT be submerged in any liquids.

Hosing or splashing of the unit with any liquids must also be avoided and

may void the warranty.

The sensor in the Carbon Monoxide Transmitter typically has a life of over

Inserting or Removing the

Fig. 18:

Sensor Module

7 years. When the sensor reaches the end of its useful life, the transmitter

will alarm when a replacement is required. Factory calibrated replacement sensors are available from BAPI.

Specications

Power:

18 to 28 VAC, 7.2 VA Max

18 to 40 VDC, 180 mA Max

Field Selectable Ranges:

0 to 100, 0 to 200, 0 to 300 & 0 to 500 ppm

Sensor Element Life: 7 Years Typical

Alarm Relays:

2 Independent, Dry SPDT (Form C)

2 Amps at 24 VAC/DC, Resistive

140 VA Inrush, 48 VA Holding at 24 VAC

Field Wiring Terminals:

Pluggable Screw Terminals, 14 to 24 AWG

Response Time:

Alarm Relay Setpoints:

25, 35, 50, 100 or 200 ppm

Alarm Timer: 0, 1, 5 & 10 minutes

Field Selectable Outputs:

3-wire 4 to 20 mA

0 to 5 VDC, 1 to 5 VDC

0 to 10 VDC, 2 to 10 VDC

Accuracy:

<200ppm = ±3% FS, 32 to 122°F (0 to 50°C)

201 to 500 ppm = ±5% FS, 50 to 122°F (10 to 50°C)

Environmental Operation Range

14 to 122°F (-10 to 50°C)

5 to 95%RH Noncondensing

<80 seconds from 10% to 90% of range

See BAPI’s Application Notes on our website for further information about coverage area and mounting. Go to

www.bapihvac.com and select “Resource Library”. Click on “Application Notes”, then “Air Quality Related”, and choose

the link titled “Coverage Area and Mounting Recommendations for BAPI Indoor Air Quality Sensors”.

Specications subject to change without notice.

9 of 10

Page 10

34612_ins_CO_V_BB

Diagnostics

POSSIBLE PROBLEMS:

General troubleshooting

Duct and Rough Service Carbon Monoxide Sensor

Installation & Operating Instructions

rev. 10/11/17

POSSIBLE SOLUTIONS:

- Determine that the input is set up correctly in the controller’

automation software.

- Check wiring for proper termination

- Check for corrosion at either the controller or the sensor. Clean off the corrosion,

re-strip the interconnecting wire and reapply the connection. In extreme cases,

replace the controller, interconnecting wire and/or sensor.

- Label the terminals that the interconnecting wires are connected to at the sensor

end and the controller end. Disconnect the interconnecting wires from the

controller and the sensor. With the interconnecting wires separated at both ends,

measure the resistance from wire-to-wire with a multimeter. The meter should read

greater than 10 Meg-ohms, open or OL depending on the meter you have. Short

the interconnecting wires together at one end. Go to the other end and measure

the resistance from wire-to-wire with a multimeter. The meter should read less than

10 ohms (22 gauge or larger, 250 feet or less). If either test fails, replace the wire.

s and building

Unit does not operate

- Cycle power.

- Check power for proper polarity.

- Disconnect the power wires at the controller and measure the voltage coming

from the power source. If the voltage is outside the limits specied on page 1,

troubleshoot the power source. Reconnect power wires to controller when nished

- Disconnect the power wires at the sensor and measure the wires for the same

voltage as at the controller. If the voltage is different from that measured at the

source, troubleshoot the wire. Reconnect power wires to sensor when nished.

- Measure the power at the sensor with the power wires connected to the power

source. If the voltage is outside the limits specied on page 9, call your BAPI

representative.

ADDITIONAL DISPLAY MESSAGES AND INDICATION

Display Message LED Indication

Module not found

retrying

mA Output Fault Flashing Red

V Output Fault Flashing Red

Replace Sensor Flashing Yellow Sensor Module failed self-test, replace the sensor module

Self-Test Solid Yellow Sensor Module is performing a self-test

Solid Red Sensor Module is loose or missing. Securely plug in a sensor module

Unit is configured for mA output, but the loop resistance is incorrect.

Troubleshoot connection.

Unit is configured for voltage output, but the output voltage is incorrect.

Troubleshoot connection

Note: If you are experiencing any other problems besides those decribed above, contact your BAPI representative.

Specications subject to change without notice.

10 of 10

Loading...

Loading...