Page 1

BAPI-Stat 4 “X-Combo”, Room %RH and Temp. Sensor

BA/BS4XC

Installation & Operating Instructions

rev. 10/28/1627939_ins_BS4XC

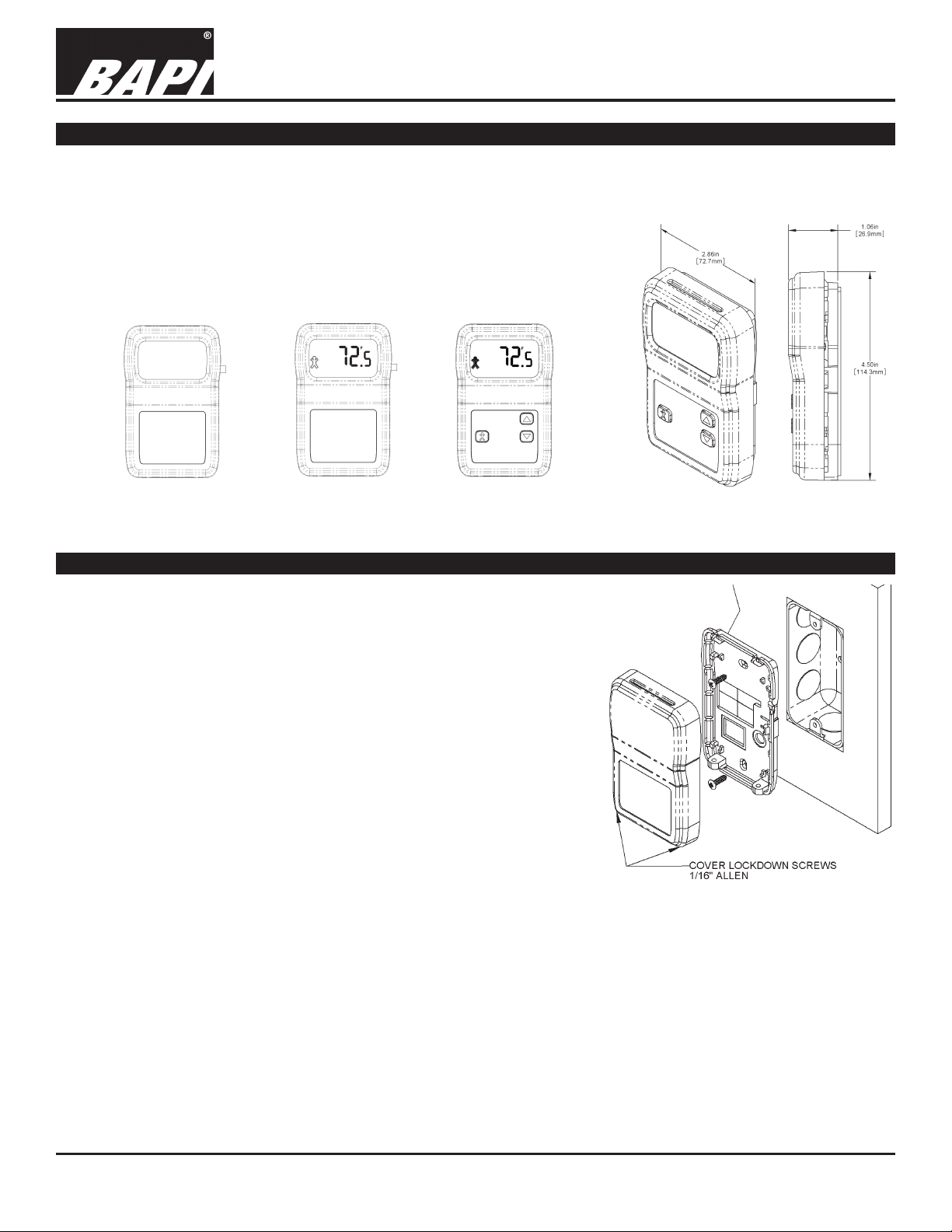

Overview and Identication

The BAPI-Stat 4 “X-Combo” (BA/BS4XC) Room Unit features 4 output channels and optional local indication of

temperature and humidity. Additional options include Temperature Setpoint, Humidity Setpoint and Local Override.

The optional LCD shows room temperature in °C or °F and room humidity in %RH. In addition, the unit has adjustable

offsets for both temperature and humidity and is capable of having the range for

the temp., humidity and setpoints changed in the eld.

The unit has 4 output channels. Channel 1 and 2 can be ordered as voltage

or current, channel 3 as voltage or resistance and channel 4 as a passive

temperature sensor or isolated override contact.

Fig. 2: Unit with

Override but No

Display or Setpoint

Fig. 3: Unit with

Override and Display

but No Setpoint

Fig. 4: Unit with

Override, Display

and Setpoint

Fig. 1: BAPI-Stat 4

X-Combo Dimensions

Mounting

JUNCTION BOX

1. Pull the wire through the wall and out the junction box, leaving about six

inches free. Pull the wire through the hole in the base plate.

2. Secure the base to the box using the #6-32 x 5/8 inch mounting screws

provided.

3. Terminate the unit according to the guidelines in the Termination section.

4. Attach Cover by latching it to the top of the base, rotating the cover down

and snapping it into place.

5. Secure the cover by backing out the lock-down screws using a 1/16” Allen

wrench until they are ush with the bottom of the cover.

DRYWALL MOUNTING

1. Place the base plate against the wall where you want to mount the sensor.

Mark the two mounting holes and the area where the wires will come

through the wall.

2. Drill two 3/16” holes in the center of each marked mounting hole. Insert a

drywall anchor into each hole.

3. Drill one 1/2” hole in the middle of the marked wiring area. Pull the wire

through the wall and out of the 1/2” hole, leaving about six inches free.

4. Pull the wire through the hole in the base plate.

5. Secure the base to the drywall anchors using the #6 x 1 inch mounting screws provided.

6. Terminate the unit according to the guidelines in the Termination section.

7. Attach Cover by latching it to the top of the base, rotating the cover down and snapping it into place. Secure the cover by

backing out the lock-down screws using a 1/16” Allen wrench until they are ush with the bottom of the cover.

Fig. 5: Mounting hardware is provided for

both junction box and drywall installation

(junction box installation shown).

NOTE: In a wall-mount application, the mixing of room air and air from within the wall cavity can lead to erroneous readings,

condensation, and premature failure of the sensor. To prevent this condition, plug the conduit hole with insulation in the

junction box.

Specications subject to change without notice.

1 of 8

Page 2

BAPI-Stat 4 “X-Combo”, Room %RH and Temp. Sensor

BA/BS4XC

Installation & Operating Instructions

rev. 10/28/1627939_ins_BS4XC

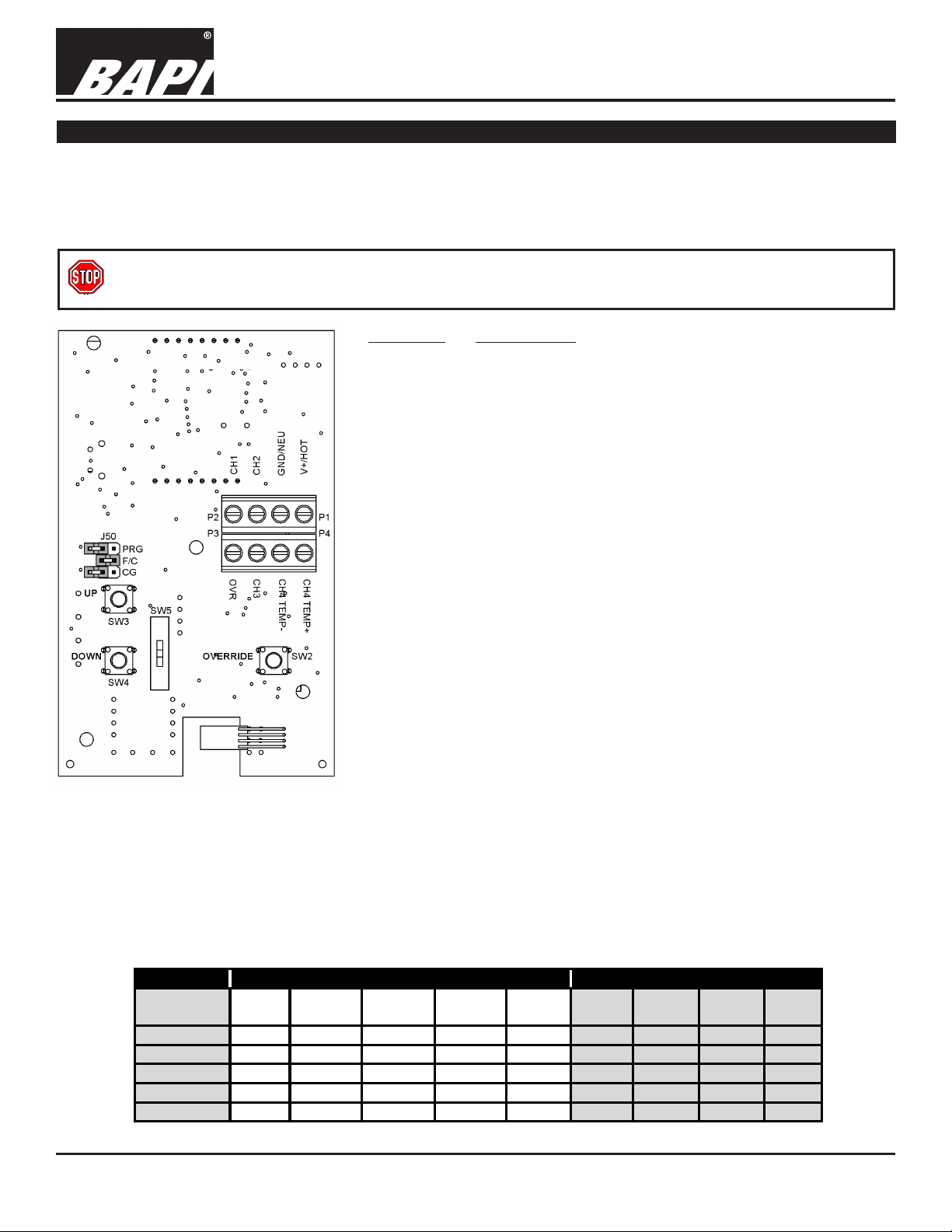

Termination

BAPI recommends using twisted pair of at least 22AWG and sealant lled connectors for all wire connections. Larger

gauge wire may be required for long runs. All wiring must comply with the National Electric Code (NEC) and local

codes. Do NOT run this device’s wiring in the same conduit as AC power wiring. BAPI’s tests show that uctuating and

inaccurate signal levels are possible when AC power wiring is present in the same conduit as the signal lines. If you are

experiencing any of these difculties, please contact your BAPI representative.

BAPI recommends wiring the product with power disconnected. Proper supply voltage, polarity, and wiring

connections are important to a successful installation. Not observing these recommendations may damage the

product and will void the warranty.

Terminal Description

GND/NEU

........Power Supply Common Ground (Ground to the Controller)

Fig. 6: X-Combo Circuit Board

Circuit Board Note: If a display unit is

ordered with Setpoint Adjustment, then

Switches 3 & 4 will NOT be present

on the BACK of the circuit board. If a

display unit is ordered with Override,

then Switch 2 will NOT be present on

the back of the circuit board.

V+/HOT

CH1

...........Power Supply Hot (See specications for voltage details)

.................Ch. 1 Signal, Voltage or 4 to 20mA*, referenced to

Common Ground

CH2

.................Ch. 2 Signal, Voltage or 4 to 20mA*, referenced to

Common Ground

CH3

.................Ch. 3 Signal, Voltage or Resistance, referenced to

Common Ground

CH4 TEMP+

....Channel 4 + Signal, Passive Temp Sensor and/or

Override Contact, referenced to “CH4 TEMP -”

(**See “Grounding Note” below)

CH4 TEMP- .....Channel 4 - Signal, Passive Temp Sensor and/or Override

Contact (**See “Grounding Note” below).

OVR

.................Override input to turn on the Occupied BAPI-Man on the

Display, referenced to Common Ground

*4-20mA Note:

This current output is NOT a loop powered output. It sources the power

for the loop per the specication.

**Grounding Note:

Common Ground (-CG) or Differential Ground (-DF) are selected

per order but can be changed in the eld (see Optional Technician

Adjustments section). In -DF Mode, the “CH4 TEMP–” and “CH4 TEMP+”

terminals are isolated from the rest of the sensor. In -CG Mode, the “CH4

TEMP–” terminal is internally connected to the power ground terminal

GND/NEU.

Channel Output Variable Output Type

Terminal Temp Humidity Temp Humidity Override Voltage Current Resistive 592/334

Name Setpoint Setpoint Sourcing

CH1 X X X X X X

CH2 X X X X X X

CH3 X X X X <50KΩ

CH4 TEMP + X X Sensor V +

CH4 TEMP - X X Sensor V -

Specications subject to change without notice.

2 of 8

Page 3

BAPI-Stat 4 “X-Combo”, Room %RH and Temp. Sensor

Resistance Value

Resistance Value

10K-2 Thermistor 30.1KΩ (34.9°F) 4.75Ω (109.1°F)

10K-3 Thermistor 26.7KΩ (35.9°F) 5.11KΩ (108.4°F)

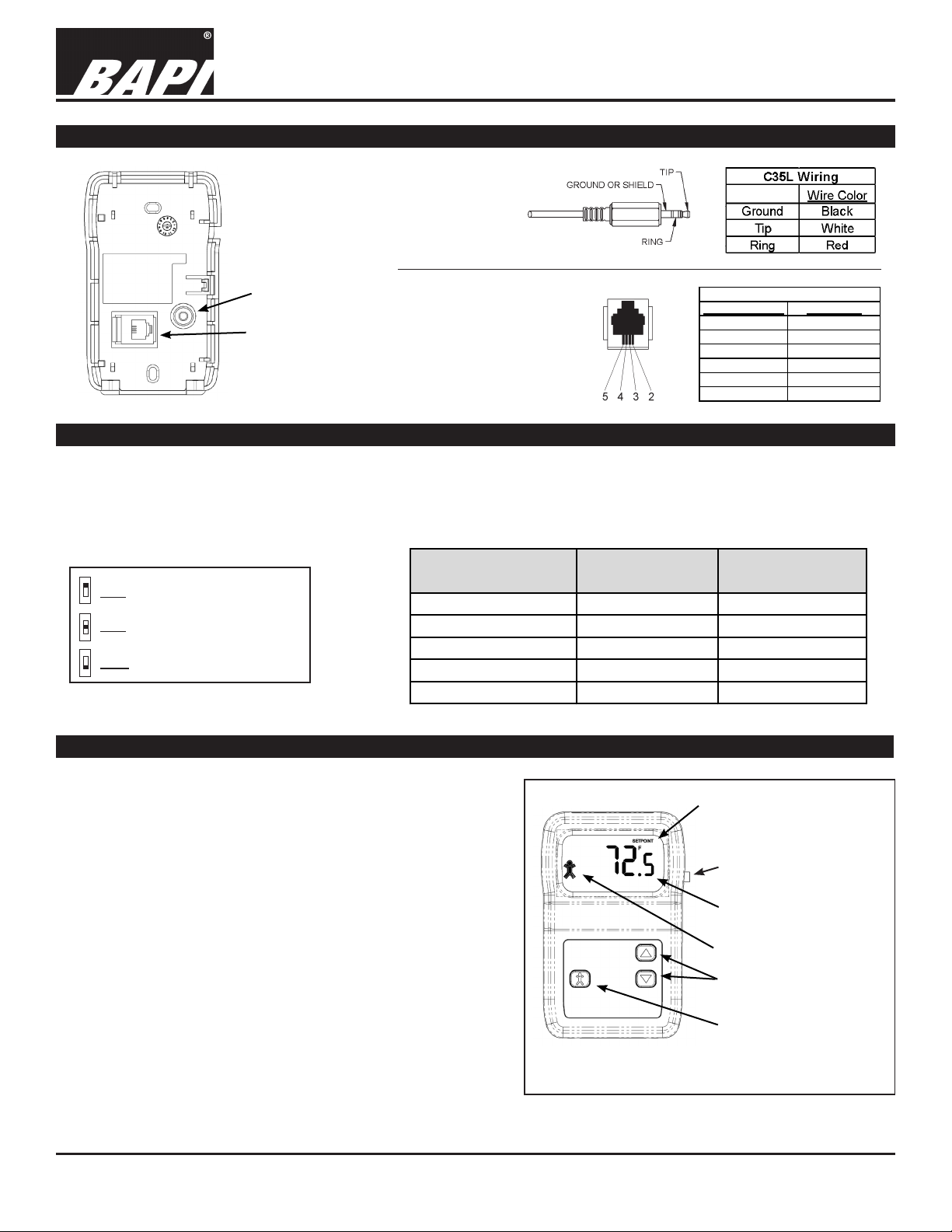

Optional Communication Jack Wiring

Fig. 7: Back

Plate of the

BAPI-Stat 4

BA/BS4XC

Installation & Operating Instructions

rev. 10/28/1627939_ins_BS4XC

Fig. 8: C35L

Comm. Jack

(male jack

shown for clarity)

C35L

C11L/

C22L

Comm Jack Pin Wire Color

Fig. 9: C11L/C22L

Comm. Jack

C11L/C22L Wiring

1 Not Connected

2 Black

3 Red

4 Yellow

5 Green

6 Not Connected

Optional Test and Balance Switch (SW5)

The test and balance switch is used by the balancer to equalize the ow of air or water per the design prints. This

switch can also be used by the commissioning technician to verify sensor termination in a point to point checkout of the

control system. The “Run” position allows the real sensor to be monitored. The “High” position forces the output to a

very hot reading and the “Low” position forces the output to a very cold output. The table below shows the most common sensor output readings.

High Temp (105°F)

Low: Sets the sensor value low

Sensor Type

Low Temp (40° F)

1000Ω RTD 1.02KΩ (41.20°F) 1.15KΩ (101.5°F)

Run: Sensor operates normally

High: Set the sensor value high

3000Ω Thermistor 7.87KΩ (39.8°F) 1.5KΩ (106.8°F)

10K-3(11K) Thermistor 7.32KΩ (43.7°F) 3.65Ω (105.2°F)

Display and Front Panel Button Operation

The “X-Combo” is available with optional LCD, override and

setpoint buttons. See Fig. 10 for a fully featured sensor.

NUMERICAL DISPLAY:

The default numerical display shows current temperature, and

toggles to humidity display at an adjustable rate of 1 to 20

seconds. When the up/down buttons are pushed, the display

will show and adjust the current setpoint and hold that display

for 3 seconds. The unit can also be programmed to “setpoint

only” display or setpoint lockout. See pages 4-5.

BAPI-MAN INDICATOR (FIG. 11):

The BAPI-Man on the display indicates whether the room is in

the “Occupied” (solid) or “Un-occupied” (hollow) status.

Note: The unit must receive a conrmation (ground) signal on

the “OVR” terminal for the BAPI-Man to remain visible on the

screen. Pressing the Override button will light the BAPI-Man

indicator; however, if no conrmation signal is received, then

the BAPI-Man will go blank (disappear) after 5 seconds.

Continued on next page....

Specications subject to change without notice.

“Setpoint” word Indicates

that the Setpoint is being

displayed.

Override Pushbutton for

Units without Setpoint

Temperature Display in

.5 Degree Increments

“BAPI-Man” Indicator

Setpoint Up/Down

Buttons

Override Pushbutton

Fig. 10: X-Combo with LCD, Setpoint and Override

3 of 8

Page 4

BAPI-Stat 4 “X-Combo”, Room %RH and Temp. Sensor

BA/BS4XC

Installation & Operating Instructions

rev. 10/28/1627939_ins_BS4XC

Display and Front Panel Button Operation continued...

Upon receiving a rst conrmation (ground) signal on the “OVR” terminal, the

BAPI-Man will show occupied (solid). The BAPI-Man will then show un-occupied

(hollow) whenever the conrmation signal is removed and occupied when the signal

is returned. The only way to blank the BAPI-Man from the display at this point is to

cycle power.

OVERRIDE BUTTON:

When the override button is pressed, the BAPI-Man will be displayed (solid) for 3-5

Solid equals

“Occupied”

Fig. 11: BAPI-Man Indicator

seconds and the override output will shunt or short for 5 seconds depending on the

override option selected. Momentary closure of the selected channel goes to its

minimum value for 5 seconds (Voltage goes to 0, 1, or 2 volts, current goes to 4mA, resistance goes to ~10Ω or the

channel 4 value goes to <1Ω on terminals “CH4 TEMP+” to “CH4 TEMP-”). If an override conrmation (ground) signal

is received on the “OVR” terminal, then the BAPI-Man will stay lled in, indicating an occupied status. If no conrmation

signal is received, then the BAPI-Man will revert to a hollow man display, indicating an un-occupied status. (See “BAPIMan Indicator” above for more information.)

TEMPERATURE SETPOINT:

Press the Setpoint Up/Down buttons once to enter the Setpoint Adjustment Mode. View the display to see whether

you are in Temperature or %RH Setpoint mode. If needed, press the Override Button once to toggle to Temperature

Setpoint mode. The current temperature setpoint will display for 5 seconds. When the Setpoint Up/Down buttons are

pressed in this mode, the temperature setpoint will change in one degree increments. It will only change within the

setpoint range that was ordered. After 5 seconds of no buttons being pushed, the sensor will go into the standard

display or toggle mode.

%RH SETPOINT:

Press the Setpoint Up/Down buttons once to enter the Setpoint Adjustment Mode. View the display to see whether you

are in Temperature or %RH Setpoint mode. If needed, press the Override Button once to toggle to the %RH Setpoint

Adjustment Mode. The current %RH Setpoint will display for 5 seconds. Pressing the UP/Down buttons will change the

selected setpoint by 1% increments. After 5 seconds of no buttons being pushed, the sensor will go into the standard

display or toggle mode.

Hollow equals

“Un-occupied”

Optional Technician Adjustments (The sensor set-up is factory set per your order. Set-up adjustments are not required)

The unit is shipped ready to install per the order and does not require any special setup or programming. The following

Set-up or Program Menu Changes are available if the installer decides to change the factory settings. Program Menu

changes require a display on the sensor. Non-display sensors must be factory congured.

Note: The Setpoint Up/Down Buttons and Override Button are used to make Menu changes. If the unit is ordered

without Setpoint Adjustment or Override, then buttons will be located on the back of the PCB inside the sensor. See

Figure 6 on page 2. These buttons will not be present on the PCB if the unit has been ordered with Setpoint and

Override.

SET-UP JUMPER (J50) CONFIGURATION: (FACTORY SET PER ORDER)

Label Description Setting

PRG Program Mode Program Mode = Jumper installed for Program Mode (See Program Menu below)

or Run Mode Run Mode = Jumper removed for Run Mode (Place jumper on one pin only)

F/C ˚C Indication ˚C = Jumper installed for °C Indication

or ˚F Indication ˚F = Jumper removed for °F Indication (Place jumper on one pin only)

CG Common Ground Common Ground = Jumper installed for Common Ground

or Differential (“CH4 TEMP-” terminal connected to ground)

Differential Ground = Jumper removed for Differential Ground

(“CH4 TEMP-” terminal isolated from ground)

Continued on next page....

Specications subject to change without notice.

Fig. 12:

J50 Jumper

4 of 8

Page 5

BAPI-Stat 4 “X-Combo”, Room %RH and Temp. Sensor

BA/BS4XC

Installation & Operating Instructions

rev. 10/28/1627939_ins_BS4XC

Optional Technician Adjustments continued....

PROGRAM MODE MENU PAGES: (DISPLAY REQUIRED)

Note: The J50 jumper “ ˚F/˚C “ selection determines what engineering unit is used for the following program mode.

Make sure to selected the desired ˚F or ˚C before adjusting the program values below.

ENTERING PROGRAM MODE AND MAKING CHANGES:

1. Install the J50 “PRG” jumper onto both pins to enter Program Mode.

2. Press the Up/Down Buttons to advance to the desired program parameter from P1 through P17.

(Parameters described below).

3. Press the Override Button to select the specic program parameter to change.

4. Change the parameter value as described in the Mode Menus section below.

5. Press the Override Button again to set the selected parameter.

6. Press the Up/Down Buttons to proceed to the next parameter (as in Step 3 above).

7. When done making changes, remove the J50 “PRG” jumper (and place over one pin) to end the programming

mode and store all the values. The sensor is now in the run mode.

MODE MENUS

P1 - Display Selection (Move the Setpoint Up/Down Arrows to change the display mode. Factory default setting is

“03”)

00 = No display (Blank)

01 = Temp display only

02 = %RH display only

03 = Temp and %RH display, toggling

04 = Temp Setpoint display only

05 = Temp and Temp Setpoint display, toggling

06 = %RH and Temp Setpoint display, toggling

07 = Temp, %RH and Temp Setpoint display, toggling

08 = %RH Setpoint only

09 = Temp and %RH Setpoint display, toggling

10 = %RH and %RH Setpoint display, toggling

11 = Temp, %RH and %RH Setpoint display, toggling

12 = Temp Setpoint and %RH Setpoint display, toggling

13 = Temp, Temp Setpoint and %RH Setpoint display, toggling

14 = %RH, Temp Setpoint and %RH Setpoint display, toggling

15 = Temp, %RH, Temp Setpoint & %RH Setpoint display, toggling

P2 - Display Toggle Rate (Factory default is 5 seconds)

Move the Up/Down arrows in 1 second increments up to 20 seconds between variables as selected in P1.

P3 - Temperature Span Low Limit (Factory set per order)

Move the UP/Down arrows in 1˚ increments between -40 to 140 span. (˚F or ˚C must be selected rst on

Jumper J50.)

P4 - Temperature Span High Limit (Factory set per order)

Move the UP/Down arrows in 1˚ increments between -40 to 140 span. (˚F or ˚C must be selected rst on

Jumper J50.)

Continued on next page....

Specications subject to change without notice.

5 of 8

Page 6

BAPI-Stat 4 “X-Combo”, Room %RH and Temp. Sensor

BA/BS4XC

Installation & Operating Instructions

rev. 10/28/1627939_ins_BS4XC

Optional Technician Adjustments continued....

MODE MENUS Continued....

P5 - %RH Span Low Limit: (Factory set per order)

Move the UP/Down arrows in 1% increments between 0% to 100% span.

P6 - %RH Span High Limit: (Factory set per order)

Move the UP/Down arrows in 1% increments between 0% to 100% span.

P7 - Fixed Temperature Setpoint (Must be within the Temperature spans set in menu page P3 and P4.)

This function is used for Temperature Setpoint Lockout Only. Move the UP/Down arrows in 1˚ increments

between -40 to 140 span. (˚F or ˚C must be selected rst on Jumper J50.)

P8 - Temperature Setpoint Span Low Limit (Must be within the Temp spans set in menu page P3 and P4.)

Move the UP/Down arrows in 1˚ increments between -40 to 140 span. (˚F or ˚C must be selected rst on

Jumper J50.)

P9 - Temperature Setpoint Span High Limit (Must be within the Temp spans set in menu page P3 and P4.)

Move the UP/Down arrows in 1˚ increments between -40 to 140 span. (˚F or ˚C must be selected rst on

Jumper J50.)

P10 - %RH Setpoint (Must be within the RH spans set in menu page P5 and P6.)

This function is used for %RH Setpoint Lockout Only. Move the UP/Down arrows in 1% increments between 0%

to 100% span.

P11 - %RH Setpoint Span Low Limit (Must be within the RH spans set in menu page P5 and P6.)

Move the UP/Down arrows in 1% increments between 0% to 100% span.

P12 - %RH Setpoint Span High Limit (Must be within the RH spans set in menu page P5 and P6.)

Move the UP/Down arrows in 1% increments between 0% to 100% span.

P13 - Temperature Offset

Move the UP/Down arrows in 0.1˚ increments between -5 to +5 ˚F or °C. This affects both the display and signal

output values.

P14 - %RH Offset

Move the UP/Down arrows in 0.1% increments between -5% to +5%. This affects both the display and the

signal output values.

P15 - Test & Balance Channel 1:

This only applies to the active Ch. 1 output. The passive sensor must use the (-TB) option and a board

mounted 3 position switch.

Move the UP/Down arrows to “+1” to output a high temp output. Move the UP/Down arrows to “0” to output

the normal temp value on the output. Move the UP/Down arrows to “-1” to output a low temp output. On exit

from programming mode, the active Test & Balance will no longer be active, so the output changes to the live

variable.

P16 - Setpoint Lockout (Move the UP/Down arrows to change the lockout mode desired.)

00 = No Setpoint Lockout (Default)

01 = Temperature Setpoint Lockout Only. (See P7 for lockout value)

02 = Temperature Setpoint Lockout and %RH Setpoint Lockout. (See P7 and P10 for lockout value)

03 = %RH Setpoint Lockout Only. (See P10 for lockout value)

P17 - Temperature Display Resolution (Move the UP/Down arrows to change the resolution to the desired value.)

01 = .1 Degree Temperature Resolution

02 = .5 Degree Temperature Resolution (Default)

03 = 1 Degree Temperature Resolution

Specications subject to change without notice.

6 of 8

Page 7

BAPI-Stat 4 “X-Combo”, Room %RH and Temp. Sensor

Diagnostics - Temperature Output

Problems:

Temperature

Reading is

Incorrect

Possible Solutions

- Check for proper wire terminations and determine that the temperature input is set up correctly in the

controller and in the building automation software.

- Check the wiring between the sensor and controller. Label the terminals at the sensor end and the

controller end. Disconnect the interconnecting wires from the controller and the sensor. With the

wires disconnected, measure the resistance from wire-to-wire with a multimeter. The meter should

read greater than 10 Meg-ohms, open or OL depending on the meter. Short the interconnecting

wires together at one end. Go to the other end and measure the resistance from wire-to-wire with a

multimeter. The meter should read less than 10 ohms (22 gauge or larger, 250 feet or less). If either

test fails, replace the wire.

- Check the sensor temperature output against a reference. Measure the temperature at the sensor’s

location using an accurate temperature standard. Disconnect the temperature channel wires and

measure the temperature signal with a multi-meter and compare to the reference temperature. For

resistive output units, use the “Sensor Specs” tables in the “Resource Library” section of the BAPI

website (www.bapihvac.com) for the reference. For voltage or current output units, use the equations

below for the reference. If the output and reference differ by more than 5%, call BAPI technical support.

- Make sure that the Test and Balance switch is in the correct position.

- Make sure that the temperature sensor element leads are not touching one another.

- Determine if the sensor is exposed to an external source different from the room environment (conduit

draft). Plug the conduit or ll the handy box as necessary. DO NOT use silicon caulk.

BA/BS4XC

Installation & Operating Instructions

rev. 10/28/1627939_ins_BS4XC

Setpoint

reading is

incorrect

- Make sure that the setpoint output is correct. Remove the

setpoint output wire (Channel 1, 2 or 3. See product label for

conguration.) and check

the output for the correct

resistance, current or

voltage output. Call BAPI

technical support if the

value doesn’t match the

label.

Diagnostics - Humidity Output

Problems:

Humidity

Reading is

Incorrect

Possible Solutions

- Check for proper wire terminations and determine that the humidity input is set up correctly in the

controller and in the building automation software.

- Check the wiring between the sensor and controller (as described above).

- Check the sensor humidity output against a reference. Measure

the humidity at the sensor’s location using an accurate standard.

Disconnect the humidity channel wires and measure the humidity

signal with a multi-meter and compare to the reference, using the

equations at right for the reference. If the output and reference differ

by more than 5%, call BAPI

technical support.

- Determine if the sensor

is exposed to an external

source different from the room

environment (conduit draft).

Plug the conduit or ll the

handy box as necessary. DO

NOT use silicon caulk.

4-20mA Temperature Equation

T = TLow + (A -4) x (TSpan)

16

T = Temperature at sensor

TLow = Low temperature of span

THigh = High temperature of span

TSpan = THigh - TLow

A = Signal reading in mA

4-20mA Humidity Equation

RH = RHLow + (A -4) x (RHSpan)

16

RH = %RH at sensor

RHLow = Low %RH of Span

RH

High = High %RH of Span

RH

Span = RHHigh - RHLow

A = Signal reading in mA

Voltage Temperature Equation

T = TLow + (V-VLow) x (TSpan)

VSpan

T = Temperature at sensor

TLow = Low temperature of span

THigh = High temperature of span

TSpan = THigh - TLow

VLow = Low transmitter voltage

usually=(0, 1 or 2v)

VHigh = High transmitter voltage

usually=(5 or 10v)

VSpan = VHigh - VLow

V = Signal reading in volts

Voltage Humidity Equation

RH = RHLow + (V-VLow) x (RHSpan)

VSpan

RH = %RH at sensor

RH

Low = Low %RH of Span

RH

High = High %RH of Span

RH

Span = RHHigh - RHLow

VLow = Low transmitter voltage

usually=(0, 1 or 2v)

VHigh = High transmitter voltage

usually=(5 or 10v)

VSpan = VHigh - VLow

V = Signal reading in volts

7 of 8

Page 8

BAPI-Stat 4 “X-Combo”, Room %RH and Temp. Sensor

BA/BS4XC

Installation & Operating Instructions

rev. 10/28/1627939_ins_BS4XC

Specications

Supply Voltage: ................ 16 to 30 VDC or 18 to 30 VAC

Supply Power: .................. VDC = 50mA

Temperature Sensor: ....... Semiconductor Band gap, ±0.5ºC

%RH Sensor:

Available Outputs: ........... 3 Congurable, 1 Passive Sensor

Channels 1 & 2 ................Voltage or Current

Channel 3......................... Voltage or Resistance

Channel 4......................... Passive Sensor, Dedicated override contact

Output Signals: ................ Direct or reverse acting available

Voltage ............................. VDC 0 to 5V, 1 to 5V, 0 to 10V, 2 to 10V, Impedance>10KΩ, (ref. to common ground)

Current (Sourcing) .......... 4 to 20mA, 500Ω @11.5 VDC (referenced to common ground)

Resistance (Setpoint) ...... Available on Ch. 3 Only

Passive Sensor (Ch. 4) .... Thermistor, RTD or Solid State,

-CG Units, “TEMP-” terminal is Common Ground,

-DF Units, “TEMP” terminals are isolated

Thermistor, ±0.36ºF (±0.2ºC),

High Accuracy Thermistor [XP], ±0.18ºF (±0.1ºC)

Platinum RTD, ±0.12%, [A] ±0.06%

Nickel RTD, 1000Ω @70ºF, JCI curve

Solid State, AD592 or LM334

Digital Input (DI): .............. Occupied dry DI input (lights BAPI-Man on display)

Program Controls: ........... Requires display. See “Program Mode” section

Offset ............................... Temperature or Humidity

Range Setup.................... Temperature, Humidity or Setpoint - Limits: -40 to 140°F or °C or 0 to 100%RH

Display Setup ..................Temp./%RH/Setpoint with adjustable toggle rate

Display Units.................... °F, °C, %RH, Setpoint, BAPI-Man

Field Conguration: ........ J50 Jumper Pins

Channel 4 Ground .......... CG = Jumper installed, “TEMP-” is Common Ground

DF = Jumper removed, terminals Isolated (DF Mode)

˚F/˚C Indication ................ ˚C = Jumper installed, ˚F = Jumper removed

Program Mode ................ ON = Jumper installed for Program Mode

PRG = Jumper removed for Run Mode

Optional Faceplate Controls:

Setpoint ...........................Up/Down Buttons (requires display)

Override (BAPI-Man) ....... Momentary occupied request button (5 sec), or setpoint mode change if in Setpoint Mode

Test & Balance ................. 3-position switch for passive sensor

Optional Override: ........... Shunt on any one of 4 Channels

Face Button ..................... Used on Setpoint units

Side Button ...................... Used on Non-Setpoint units

Optional Comm. Jack: ..... Located in base: -C11 = RJ11, 4 wires • -C35 = 3.5mm, 3 wire • -C22 = RJ22, 4 wires

Optional Colored Plate: .... -WMW = Warm White plate • -GRY = Gray plate

Test & Balance: ................ 3 Temp. Positions: High/Run/Low

Active type ...................... Program Mode, Ch. 1, (Prog. page P15)

Passive Sensor ............... Optional for Ch. 4 w/ 3-Way Internal Switch

Optional Display: ............. LCD-Temp, RH, Setpoint, Override

Display size ....................2.04”W x 1.33”H

Digits................................ ±999.9 Digits @0.6”H

Resolution........................ 0.5 displayed value, 0.1 for offset adjust

Units ................................˚F, ˚C, %, BAPI-Man, Setpoint

Value Displayed ............... Always shows the value regardless of the output range

Termination: ..................... 8 Terminals, 16 to 22 AWG

Mounting: ......................... Standard 2x4” J-Box or Drywall

Enclosure Material: .........ABS Plastic, UL94V-0

Ambient (Enclosure): ...... 32 to 122ºF (0 to 50ºC), 0 to 95% RH, Non-condensing

Agency: ............................RoHS

.................... 2% Accuracy from 20 to 80%, Capacitive

Specications subject to change without notice.

8 of 8

Loading...

Loading...