Page 1

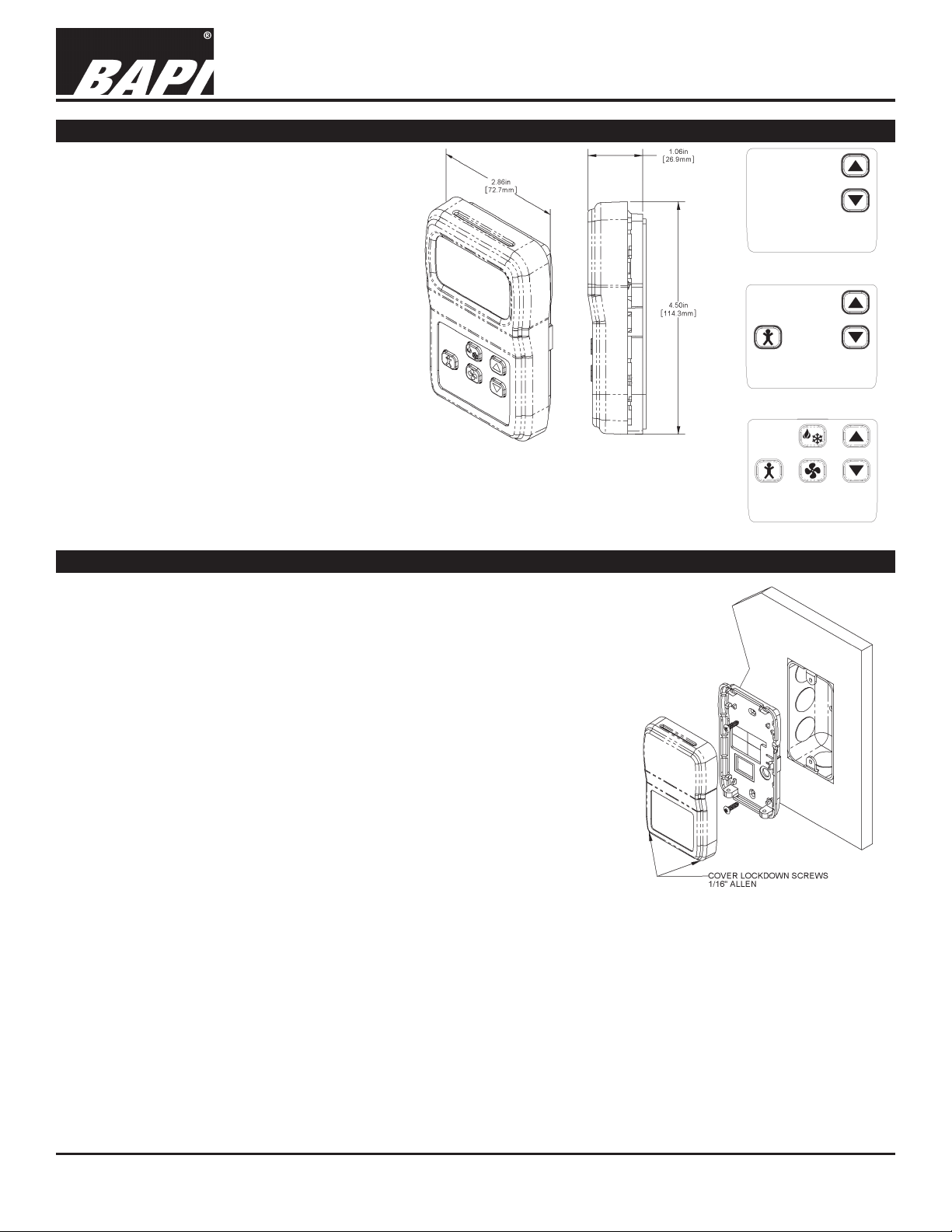

BAPI-Stat 4 Sensor, w/Display, Button Setpoint, Fan or System Mode Control

Product Identication and Overview

The BAPI-Stat 4M room temperature sensor

features a large format LCD and pushbutton

setpoint adjustment. Additonal options include

pushbutton override, fan speed and mode

adjustments.

The setpoint is available as a resistance or

voltage output. The override is a momentary

closure signal that can be congured in parallel

with the sensor or setpoint, or as a separate

momentary or latching contact output. A 3.5mm

(1/8”), RJ11 or RJ22 communication jack can

also be mounted in the unit’s base to provide

direct access to the network.

BA/BS4M Temperature Sensor

Installation & Operating Instructions

rev. 01/18/1625188_ins_BS4M

Fig. 2: 2 Button Unit

Fig. 1: BAPI-Stat 4M

with optional Setpoint,

Override, Fan and Mode

Control.

Note: BAPI-Stat 4M shown with

ve buttons. Two, three or ve

buttons may be present. See “Front

Panel & Control” section.

Mounting

JUNCTION BOX

1. Pull the wire through the wall and out of the junction box, leaving about 6 inches free.

2. Pull the wire through the hole in the base plate.

3. Secure the base to the box using the #6-32 x 1/2 inch mounting screw provided.

4. Terminate the unit according to the guidelines in the Termination section.

5. Attach Cover by latching it to the top of the base, rotating the cover down

and snapping it into place.

6. Secure the cover by backing out the lock-down screws using a 1/16” Allen

wrench until they are ush with the bottom of the cover.

DRYWALL MOUNTING

1. Place the base plate against the wall where you want to mount the sensor.

2. Using a pencil, mark out the two mounting holes and the area where the

wires will come through the wall.

3. Drill two 3/16” holes in the center of each marked mounting hole. Insert a

drywall anchor into each hole.

4. Drill one 1/2” hole in the middle of the marked wiring area.

5. Pull the wire through the wall and out the 1/2” hole, leaving about 6” free.

6. Pull the wire through the hole in the base plate.

7. Secure the base to the drywall anchors using the #6 x 1 inch mounting screws provided.

8. Terminate the unit according to the guidelines in the Termination section.

9. Attach Cover by latching it to the top of the base, rotating the cover down and snapping it into place. Secure the cover

by backing out the lock-down screws using a 1/16” Allen wrench until they are ush with the bottom of the cover.

Fig. 5: Mounting hardware is provided

for both J-Box and drywall installation

(J-Box installation shown)

Fig. 3: 3 Button Unit

Fig. 4: 5 Button Unit

NOTE: In a wall-mount application, the mixing of room air and air from within the wall cavity can lead to erroneous

readings, condensation, and premature failure of the sensor. To prevent this condition, plug the conduit hole with

insulation in the junction box.

Specications subject to change without notice.

1 of 8

Page 2

BAPI-Stat 4 Sensor, w/Display, Button Setpoint, Fan or System Mode Control

BA/BS4M Temperature Sensor

Installation & Operating Instructions

rev. 01/18/1625188_ins_BS4M

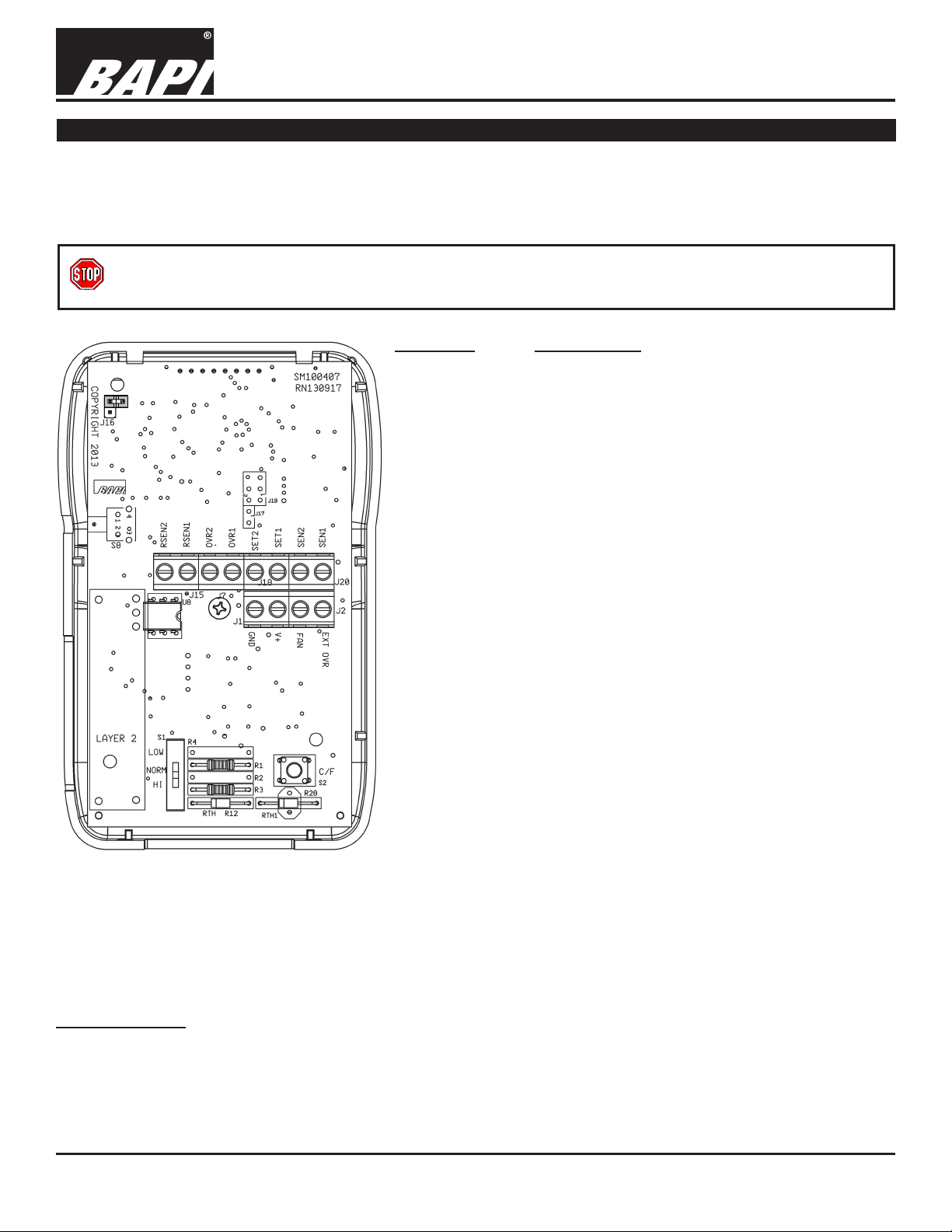

Termination

BAPI recommends using twisted pair of at least 22AWG and sealant lled connectors for all wire connections. Larger

gauge wire may be required for long runs. All wiring must comply with the National Electric Code (NEC) and local codes.

Do NOT run this device’s wiring in the same conduit as AC power wiring. BAPI’s tests show uctuating and inaccurate

signals are possible when AC power wiring is in the same conduit as the signal lines. If you are experiencing any of these

difculties, please contact your BAPI representative.

BAPI recommends wiring the product with power disconnected. Proper supply voltage, polarity and wiring

connections are important to a successful installation. Not observing these recommendations may damage the

product and void the warranty.

TERMINAL DESCRIPTION

GND ........................Power Supply Ground (Common to the controller)

V+

........................... Power Supply Hot (See specications for voltage

details)

.........................Fan Speed/System Mode (Resistive Output)

FAN

EXT OVR

SEN1 & SEN2

SET1 & SET2 ......... A) Setpoint output per order (resistive). *If the unit

B) Setpoint output per order (voltage). SET1 is

OVR1 & OVR2

Fig. 6: BAPI-Stat 4M Circuit Board

*Grounding Note:

Common Ground (-CG) or Differential Ground (-DF) congurations are selected per order. The Differential Ground

conguration (-DF) indicates that SEN2, SET2, OVR2 and RSEN2 must all be wired separately (No internal common

connection). The Common Ground conguration (-CG) indicates that SEN2, SET2, OVR2 and RSEN2 are connected to

GND internally (All internally common). This is true of all Common Ground units except when ordered with the Override as

a Latching Switch option (-L#). In this case, OVR2 is isolated and not internally connected to SEN2, SET2 and RSEN2.

RSEN1 & RSEN2

................BAPI-Man Occ/Un-Occ indicator Input.

Ground terminal to ll in the BAPI-Man icon for

Occupied.

........Sensor output per order (resistive). No polarity. *If

the unit is a common ground conguration (-CG),

see “Grounding Note” below.

is a common ground conguration (-CG), see

“Grounding Note” below.

“+”, SET2 is “-”. *If the unit is a common ground

conguration (-CG), see “Grounding Note”

below.

........Override output (Dry contact) The contact can be

ordered as a momentary shunt across the sensor

(-N) or as a momentary shunt across the setpoint

(-P) or as a separate momentary contact (-J) or

as a separate latching contact (-L#). *If the unit

is a common ground conguration (-CG), see

“Grounding Note” below.

... Remote sensor option (-ES). No polarity. *If the

unit is a common ground conguration (-CG),

see “Grounding Note” below. A 10K-2 thermistor

sensor must be ordered separately and the

temperature value is displayed on the LCD. Note:

If a temperature reading is needed at the controller,

then a second sensor must be ordered and wired

independently.

Specications subject to change without notice.

2 of 8

Page 3

BAPI-Stat 4 Sensor, w/Display, Button Setpoint, Fan or System Mode Control

Low Temp (40° F)

High Temp (105°F)

3000Ω Thermistor 7.87KΩ (39.8°F) 1.5KΩ (106.8°F)

10K-3(11K) Thermistor 7.32KΩ (43.7°F) 3.65Ω (105.2°F)

HCF 5KΩ 10KΩ 15KΩ 20KΩ 25KΩ 30KΩ

Option Heat Cool Auto Off

Option OFF AUTO LO MED HI ON

XLD 5KΩ 10KΩ 15KΩ 20KΩ 25KΩ

X02 2KΩ 4KΩ 6KΩ 8KΩ 10KΩ

X06 6.5KΩ 8.5KΩ 10.5KΩ 12KΩ

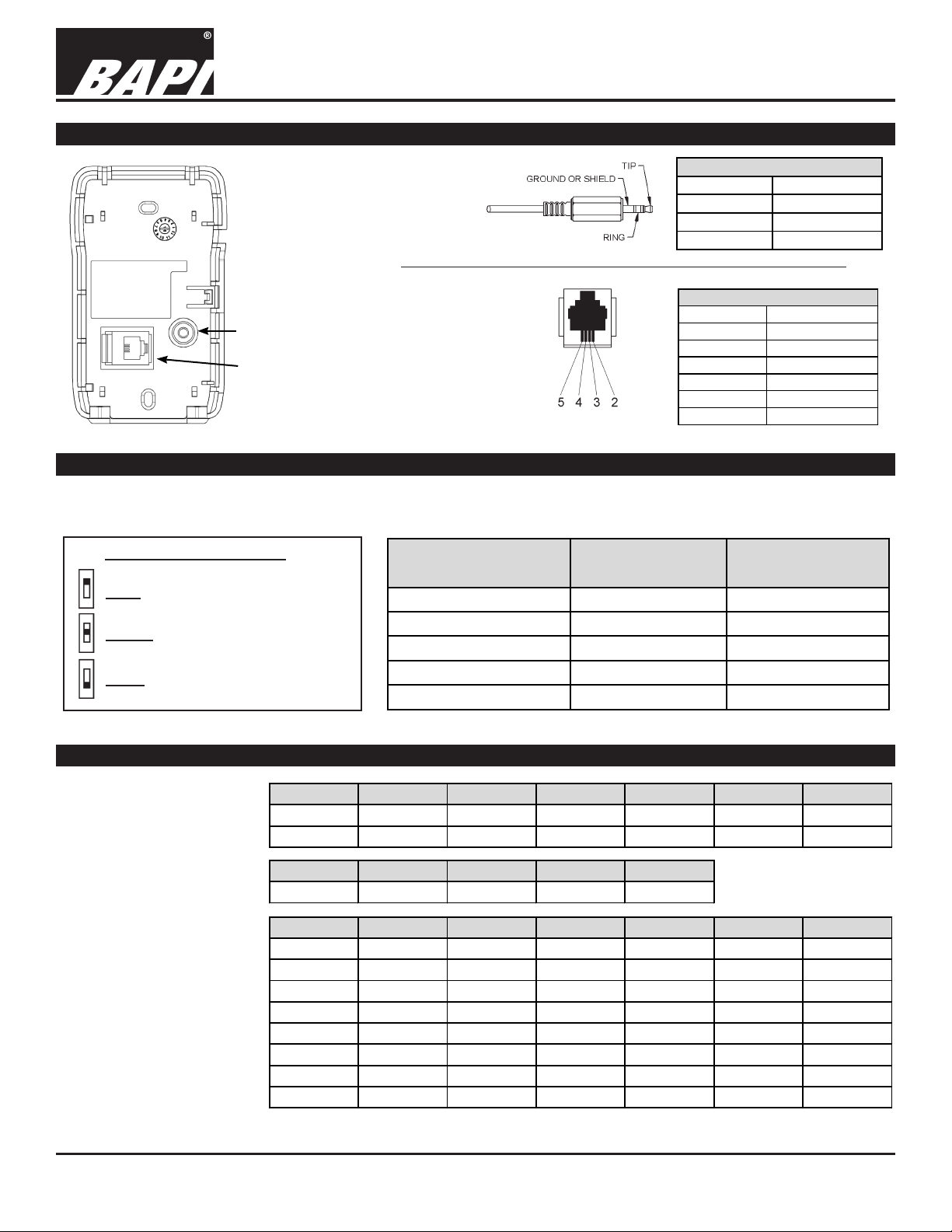

Optional Communication Jack Wiring

BA/BS4M Temperature Sensor

Installation & Operating Instructions

rev. 01/18/1625188_ins_BS4M

Fig. 7:

Back Plate

Comm.

Jack

Locations

C35L

C11L/

C22L

Fig. 8: C35L

Comm. Jack

(3.5mm plug

shown for

clarity)

Fig. 9:

C11/C22

Comm.

Jack

C35L Comm. Jack Wiring

Location WIRE COLOR

Ground Black

Tip White

Ring Red

C11L/C22L Comm. Jack Wiring

PIN # WIRE COLOR

1 Not Connected

2 Black

3 Red

4 Yellow

5 Green

6 Not Connected

Optional Test and Balance Switch (S1)

On the Test and Balance Switch, the NORM position allows the real sensor to be monitored. The HIGH position forces the

output to a very hot reading and the LOW position forces a very cold reading (see Table below).

Test and Balance Switch (S1)

LOW: Sets the sensor value low

Sensor Type

Resistance Value

Resistance Value

1000Ω RTD 1.02KΩ (41.20°F) 1.15KΩ (101.5°F)

NORM: Sensor operates normally

HIGH: Sets the sensor value high

Optional Fan Speed and System Mode Control

The unit is available with

optional Fan Speed and

Option Heat/Auto Off /Auto Cool/Auto Heat/On Off/On Cool/On

System Mode Control.

The resistive outputs for

H01 0Ω 2KΩ 4KΩ 6KΩ 8KΩ 10KΩ

the various options is

shown in the table at right.

The option is selected at

H02 5KΩ 10KΩ 15KΩ 20KΩ

the time of order and the

resistive value is output to

the FAN terminal.

X01 4.89KΩ 2.33KΩ 10.63KΩ 13.24KΩ 16.33K

X03 5KΩ 10KΩ 15KΩ

X05 4.89KΩ 2.33KΩ 15.8KΩ

X07 5KΩ 15KΩ

X08 12.68KΩ 11.86KΩ 13.86KΩ

10K-2 Thermistor 30.1KΩ (34.9°F) 4.75Ω (109.1°F)

10K-3 Thermistor 26.7KΩ (35.9°F) 5.11KΩ (108.4°F)

Specications subject to change without notice.

3 of 8

Page 4

BAPI-Stat 4 Sensor, w/Display, Button Setpoint, Fan or System Mode Control

Front Panel & Control Descriptions

A display is standard for all BA/BS4M

units. It is available with an optional

override button, setpoint buttons, fan

control or system control buttons or any

option combination. Fig. 10 shows a fully

featured sensor.

NUMERICAL DISPLAY:

The default display shows current

temperature. When the up/down buttons

are pushed, then the display will show

and adjust the current setpoint and hold

the display for 3 to 4 seconds. The unit

can also be set up to display setpoint

only or for setpoint lockout. See “Optional

Technicians Adjustments” section.

BAPI-MAN ICON:

The BAPI-Man Icon shows the status of

the room – Solid for Occupied, Hollow for

“Unoccupied” (Fig. 11).

Note: The unit must receive a

conrmation (ground) signal on the “EXT OVR”

terminal for the BAPI-Man to remain visible on the

screen. Pressing the Override button will light the

BAPI-Man icon; however, if no conrmation signal is

received, then the BAPI-Man will go blank (disappear)

after 5 seconds.

Upon receiving a rst conrmation (ground) signal

on the “EXT OVR” terminal, the BAPI-Man will show

occupied (Solid). The BAPI-Man will then show

unoccupied (Hollow) whenever the conrmation signal

is removed and occupied when the signal is returned.

The only way to blank the BAPI-Man from the display

at this point is to cycle power.

Fan and Speed Indicator

Occupied or Unoccupied Icon

Automatic System Mode

BA/BS4M Temperature Sensor

Heat Mode

Cool Mode

System Mode Button

Override Button

Fan Speed Button

Fig. 10: BAPI-Stat 4M unit with Override, Setpoint, Fan

Note: BAPI-Stat 4M shown with ve buttons. Two,

three or ve buttons may be present.

Solid

equals

“Occupied”

Fig. 11: BAPI-Man Icon

Installation & Operating Instructions

& System Buttons.

Hollow

equals

“Unoccupied”

rev. 01/18/1625188_ins_BS4M

Engineering Units

Temperature Display

in .5 Increments

Override On

Override Off

Setpoint Up/Down

Buttons

Fan Speed

Low

Fan Speed

Medium

Fan Speed

High

Fig. 12: Fan Speed

Indicator

FRONT PANEL BUTTONS

SETPOINT:

When pressed, the setpoint will display for three to four seconds. When pressed again, the setpoint will change

in one degree increments. It will only change within the setpoint range that was ordered.

OVERRIDE:

When the override button is pressed, the BAPI-Man will be displayed as “Solid” for 3-5 seconds and the override

output will shunt or short for 3 seconds depending on the override option selected. (-N Option = Momentary

Temperature Sensor Shunt to <15Ω, -P Option = Momentary Setpoint Shunt to <15Ω, -J Option = Momentary Override as

a Separate Shorting Contact Output, -L# Option = Override as a Latching Switch, See “Latching Override Operation” on

pg. 5.) If the occupied input (EXT OVR) terminal is grounded, then the BAPI-Man will stay lled in, indicating an occupied

state. If the input is open, then the BAPI-Man will revert to hollow, indicating unoccupied (or the icon will disappear

completely if there has never been a ground on the EXT OVR terminal).

MODE:

Cycles through ‘HEAT’, ‘OFF’ and ‘COOL’.

FAN:

Cycles through ‘AUTO’, ‘ON’ and Fan Speed (see Fig. 12).

Specications subject to change without notice.

4 of 8

Page 5

BAPI-Stat 4 Sensor, w/Display, Button Setpoint, Fan or System Mode Control

BA/BS4M Temperature Sensor

Installation & Operating Instructions

rev. 01/18/1625188_ins_BS4M

Optional Technician Adjustments (The sensor set-up is factory set per your order. Set-up adjustments are not required)

The unit is shipped ready to install per the order and does not requires any special setup or programming. The following

Setup or Program Menu Changes are available if the installer decides to change the factory settings. Pushing the button

(S2) on the lower right side of the termination board allows the user to change the display from Celsius to Fahrenheit and

back again (See Fig. 6).

ENTERING PROGRAM MODE AND MAKING CHANGES:

1. Remove cover and install the shunt jumper across the J16 pins (see Fig. 13).

2. Use the Up and Down Setpoint Pushbuttons on the front of the sensor to advance

to the parameter you wish to adjust. (Moves up or down from page to page or from

setting to setting.)

3. Push the Override Pushbutton on the front of the unit to select the menu adjust

Jumper Off

Run Mode

parameter. This selects the currently displayed menu.

4. Use the Up and Down pushbuttons to adjust the parameter

Fig. 13: J16 Program

5. Push the Override Pushbutton to select the newly adjusted parameter value.

6. You can quit by removing J16 or move to the next parameter using the Up/Down Setpoint buttons.

Note: If your unit does not have the necessary front Up/Down/Override buttons for

adjustment you can remove the board from the housing and use the three

buttons that are on the back of the board. Removing the board requires

removing the centered board mounting screw. The buttons are identied as S3

= Enter (Override), S5 = Up Adjust and S6 = Down Adjust. (See Fig. 14) After

adjustment, place the board back into the cover and insert the center mounting

screw. Do not over tighten.

Jumper On

Program Mode

Jumper

MODE MENUS:

The setup mode consists of menu pages P1 through P6 for conguring the sensor.

The following adjustments can be done with the program jumper J16 installed.

P1 = Temperature offset: Adjust Up or Down, -5 to 5° in 0.1° increments

P2 = Setpoint Lockout: Adjust the value to dene the Setpoint mode

0 = Enable Setpoint adjustment (Normal mode)

1 = Disable Setpoint adjustment (No setpoint adjust)

Enter

2 = Display Setpoint Only (No room temperature displayed)

3 = No Setpoint Displayed (Rarely used with pushbutton setpoint units)

P3 = Latching Display (see Fig. 15)

-1 = Override Disabled

0 = Momentary Contact, Hollow Man/Solid Man (Typically the normal setting)

1 = Latching Contact: Off/On, No Fan/Fan, Solid Man

2 = Latching Contact: Off/On, No Fan/Fan, No BAPI-Man

3 = Latching Contact: Off/On, Solid Man

4 = Latching Contact: Off/On, No BAPI-Man

Fig. 14: Setup Switch

locations on the circuit board.

5 = Latching Contact: On/Off, Fan/No Fan, Solid Man

6 = Latching Contact: On/Off, Fan/No Fan, No BAPI-Man

7 = Latching Contact: On/Off, Solid Man

8 = Latching Contact: On/Off, No BAPI-Man

9 = Latching Contact: Hollow Man/Solid Man

10 = Non-Latching

See “Latching Override Operation” and “Momentary Override Operation” descriptions for further details.

P4 = Temperature Display: Adjust value to the display increments desired

0 = Display in whole digits only

1 = Display in 0.5° increments, F or C as chosen on switch S2

2 = Display in 0.1° increments, F or C as chosen on switch S2

P5 = Setpoint Display Low: Adjust the Low temperature of the desired setpoint range between -9 to 99°.

P6 = Setpoint Display High: Adjust the High temperature of the desired setpoint range between -9 to 99°.

Up

Down

5 of 8

Page 6

BAPI-Stat 4 Sensor, w/Display, Button Setpoint, Fan or System Mode Control

BA/BS4M Temperature Sensor

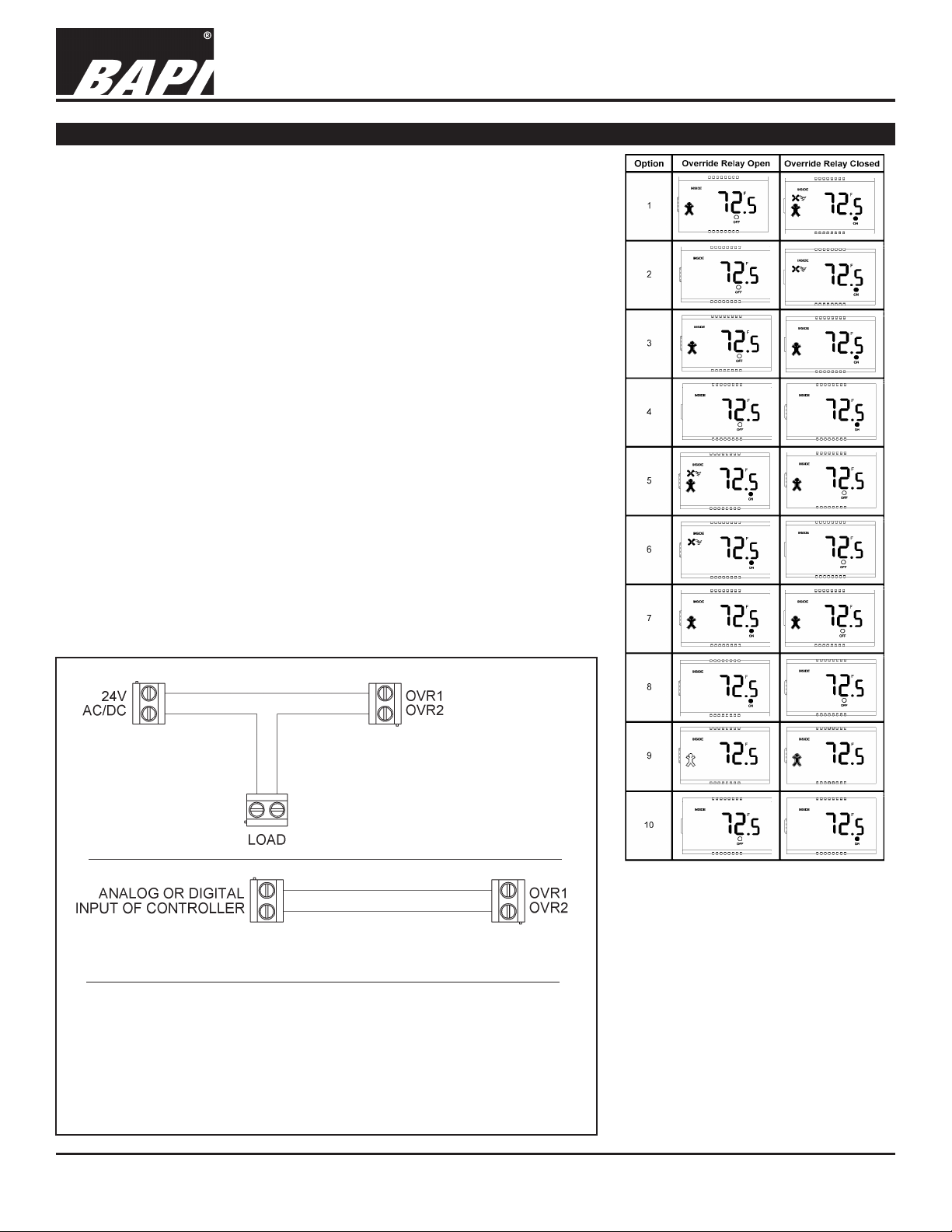

Latching Override Operation

The unit can be ordered with an “Override as a Latching Switch” by selecting

the -L# option. The # (1-10) represents the display the user may want to use

and is shown below. This can be changed by a technicians adjustment.

In the “Override as Latching Switch” Option, pressing the Override button

closes the override relay contacts (Terminals OVR1 & OVR2). They will remain

closed until the “Override” button is pressed again, then they will open and

remain open until the Override button is pressed again. See Fig. 16 below for

examples of “Override as a Latching Switch” circuits.

Ten display options (Fig. 15) are available to indicate when the latching relay

is open and when the latching relay is closed. Note: If one of the “Fan Speed/

Mode” options is selected from the ordering grid, then you MUST use the

latching display Option 9.

BAPI-MAN ICON

On Options 2, 4, 6, 8 & 10, the BAPI-Man Icon is disabled and will not show on

the display, even when the Override button is pushed.

On Options 1, 3, 5 & 7, the BAPI-Man Icon is lled or solid for 3 to 5 seconds

after the Override button is pushed, but it will only remain solid or lled when

there is a ground signal to the EXT OVR terminal of the unit.

For Option 9, the BAPI-Man Icon stays lled or solid when the relay is closed

and hollow when the relay is open.

For Option 10, the BAPI-Man Icon is disabled but the “ON” or “OFF” Dot on the

display is controlled by the EXT OVR terminal. When there is a ground signal at

the EXT OVR terminal, the “ON” dot is lit. Otherwise the “OFF” and hollow dot

are lit. Note: The Override Terminals OVR1 and OVR2 are NOT latching in

Option 10. These terminals close MOMENTARILY in this option.

Installation & Operating Instructions

rev. 01/18/1625188_ins_BS4M

Latching Switch with

External Load Circuit

Latching Switch as Direct Controller Input Circuit

Fig. 16: Latching Switch Wiring Diagrams

In the “Override as Latching Switch” conguration, terminals OVR1 &

OVR2 act as a latching switch with a maximum capacity of 24 VAC/VDC

at 800 mA resistive. Pressing the Override button latches or unlatches

the OVR1 & OVR2 terminals. These diagrams show how to wire the

latching switch with an External Load and as a Direct Controller Input

Fig. 15: Latching Switch Display Options

The 10 “Override as a Latching Switch”

display options are shown above for

when the relay is open and when the

relay is closed.

Note 1: If the unit is ordered with “Fan

Speed/Mode” Options, then you must

use the latching display Option 9.

Note 2: On Options 1, 3, 5 & 7, the

BAPI-Man Icon is lled or solid for 3 to

5 seconds after the Override button is

pushed, but it will only remain solid or

lled when there is a ground signal to

the EXT OVR terminal of the unit.

6 of 8

Page 7

BAPI-Stat 4 Sensor, w/Display, Button Setpoint, Fan or System Mode Control

BA/BS4M Temperature Sensor

Installation & Operating Instructions

rev. 01/18/1625188_ins_BS4M

Momentary Override Operation (Non-Latching)

When the Override pushbutton is pressed, the BAPI-Man (Fig. 11) will be displayed as “Solid” for 3-5 seconds and the

override output will shunt or short for 3 seconds depending on the override option selected. The various options are

described below.

-N Option = Momentary Temperature Sensor Shunt to < 15Ω

-P Option = Momentary Setpoint Shunt to <15Ω

-J Option = Momentary Override as a Separate Shorting Contact Output on OVR1 & OVR2

BAPI-MAN ICON:

The BAPI-Man Icon shows the status of the room – Solid for Occupied, Hollow for “Unoccupied” (Fig. 11). The unit must

receive a conrmation (ground) signal on the “EXT OVR” terminal for the BAPI-Man to remain visible on the screen.

Pressing the Override button will light the BAPI-Man icon; however, if no conrmation signal is received, then the BAPIMan will go blank (disappear) after 5 seconds. Upon receiving a rst conrmation (ground) signal on the “EXT OVR”

terminal, the BAPI-Man will show occupied (Solid). The BAPI-Man will then show unoccupied (Hollow) whenever the

conrmation signal is removed and occupied when the signal is returned. The only way to blank or remove the BAPI-Man

from the display after receiving a conrmation signal is to cycle power.

General Diagnostics

POSSIBLE PROBLEM: POSSIBLE SOLUTIONS:

Temperature reading is incorrect - Verify that the input is set up correctly in the controller’s and building

automation software.

- Check wiring for proper termination and check for opens or shorts.

- Measure the room temperature at the sensor’s location using an accurate

temperature standard. Disconnect the temperature sensor wires and

measure the temperature sensor’s resistance across the sensor output

pins with an ohmmeter. Compare the temperature sensor’s resistance

to the appropriate temperature sensor table on the BAPI website. If the

measured resistance varies by more than 5% from the temperature table,

call BAPI technical support. To view the temperature table, go to the BAPI

website (www.bapihvac.com), click on “Resource Library” and “Sensor

Specs”, then click on the type of sensor you have.

- If the unit has a test and balance switch, make sure that it is in the correct

position.

Setpoint reading is incorrect - Make sure that the setpoint output is correct. Remove the setpoint output

wire and check the output for the correct resistance or voltage output. See

the product label for your specic range.

Override is not working correctly - Check that the resistance across the override output is less than 5Ω when

the override is pushed.

Fan Mode not correct - Make sure that the fan mode output is correct. Remove the fan mode

output wire and check the output for the correct resistance. See the

product label for your specic range and compare it to the resistance chart

at the bottom of page 3. Don’t forget to reconnect the wire.

Specications subject to change without notice.

7 of 8

Page 8

BAPI-Stat 4 Sensor, w/Display, Button Setpoint, Fan or System Mode Control

BA/BS4M Temperature Sensor

Installation & Operating Instructions

Specications

Power for 5 VDC Power Units:

0 to 5 VDC Setpoint or Resistive Setpoint ....5V ±1% (5 VDC nominal, Input regulation affects accuracy)

Power for 24 VDC Power Units:

0 to 5 VDC Setpoint or Resistive Setpoint ...9 to 40 VDC (24 VDC nominal)

0 to 10 VDC Setpoint or Resistive Setpoint ..15 to 40 VDC (24 VDC nominal)

Any Allowed Setpoint ....................................15 to 28 VAC (24 VAC nomimal)

Note: AC power requires a separate pair of shielded wires

Power Consumption: .....................................7 mA max DC; .17 VA maximum AC

Wiring: ................... See Wiring & Termination Section, 22 to 14AWG

Mounting: .............. Standard 2 x 4” box or drywall direct, Screws provided

Outputs:

Passive Sensor....See order grid for thermistor or RTD

Thermistor, ±0.36ºF (±0.2ºC), [XP] ±0.18ºF (±0.1ºC)

Platinum RTD, ±0.12%, [A] ±0.06%

Nickel RTD, 1000Ω @70ºF, JCI curve

External Sensor ...10K-2 thermistor (-ES), (Purchased separately) Wired 25’ maximum from sensor

Setpoint ...............Resistive per order or voltage (0 to 10VDC limit per order)

Isolated Contact ..24VDC @500mA resistive

Inputs: ....................Dry contact (24V, <1mA)

Occupied .............EXT OVR “Grounded”

Unoccupied .........EXT OVR “Open to Ground”

Display: .................LCD, Overall, 2”W x 1.1”H (Temp/Setpoint/Occupied)

LCD ....................3.5 Digits @0.6”H

Occ/Unocc ..........BAPI-Man Icon, (Filled in man is occupied)

Display Limits ......1.0º, 0.5° and 0.1° (F/C) increments, Setpoints in 1º steps

Range .................-40 to 185°F (-40 to 85°C)

Display Setup ......Temp. & Setpoint, Temp. only, or Setpoint only, ºF or ºC

Optional ............... Fan Speed, System Mode, Override

Button Options: .... Factory set options

Setpoint ..............Up & Down buttons

Override .............. Pushbutton

Override .............. Factory set to Momentary shunt across sensor, Momentary shunt across setpoint,

Momentary isolated contact or Latching isolated contact

Fan Speed ...........Off, Auto, Lo, Med, Hi

System Mode ......Heat/Off/Cool, Auto/On Fan

Setup Options:

Offset ...................±5º

Temp Display .......Display in ºF or ºC

Setpoint ...............Disabled or Setpoint display only

Resolution ...........Display in 1.0°, 0.5º or 0.1º increments

Other Options:

Comm. jack .........3.5mm phone jack, 3 wires (-C35) • RJ11 jack, 4 wires (-C11) • RJ22 jack, 4 wires (-C22)

Test & Balance .... Three position switch (-TB), (High Temp/Normal/Low Temp)

Common Ground .Internal common connection (-CG)

Differential GND. .Each output terminal is isolated (-DF)

Environmental Ambient:

Temperature ........32 to 122ºF (0 to 50ºC)

Humidity ..............0 to 95% RH Non-condensing

Storage ................32 to 185°F (0 to 85°C)

Encl. Material: ....... ABS Plastic, UL94V-0

Agency: .................RoHS, CE* (*Units with passive Thermistors 20KΩ and smaller are CE compliant.)

Specications subject to change without notice.

rev. 01/18/1625188_ins_BS4M

8 of 8

Loading...

Loading...