Page 1

CO2 Room Sensor in the BAPI-Stat 3 Enclosure

with Common Ground Conguration

26141_ins_room_CO2

Identication and Overview

The BAPI CO2 Sensor is an accurate and reliable way of incorporating demand controlled ventilation into a building’s HVAC strategy. It

measures the CO

output of 0 to 5 or 0 to 10 VDC.

The non-dispersive infrared (NDIR) technology has been optimized

to reduce drift. The sensor is also altitude compensated for longterm accuracy and stability. Changing air pressure, due to altitude

or weather patterns, can change the output of most CO

as much as 17%. The BAPI unit has a built-in barometric sensor that

continuously compensates the output for accurate readings despite

inclement weather or the altitude of the installation.

The unit can be ordered as CO

sensing, temperature setpoint, occupant override and humidity sensing. The large format display is easy to read and alternates between

the measured values (CO

also eld adjustable between °F or °C and all the displayed values

may be turned on or off by an HVAC technician.

Optional indication of the CO

able as a three-color LED on the unit or as an arrow on the display.

in a range of 0 to 2,000 ppm with a eld selectable

2

sensors by

2

alone, or with optional temperature

2

, Temperature or Humidity). The display is

2

level as “Good, Fair or Poor” is avail-

2

Installation and Operating Instructions

rev. 04/27/18

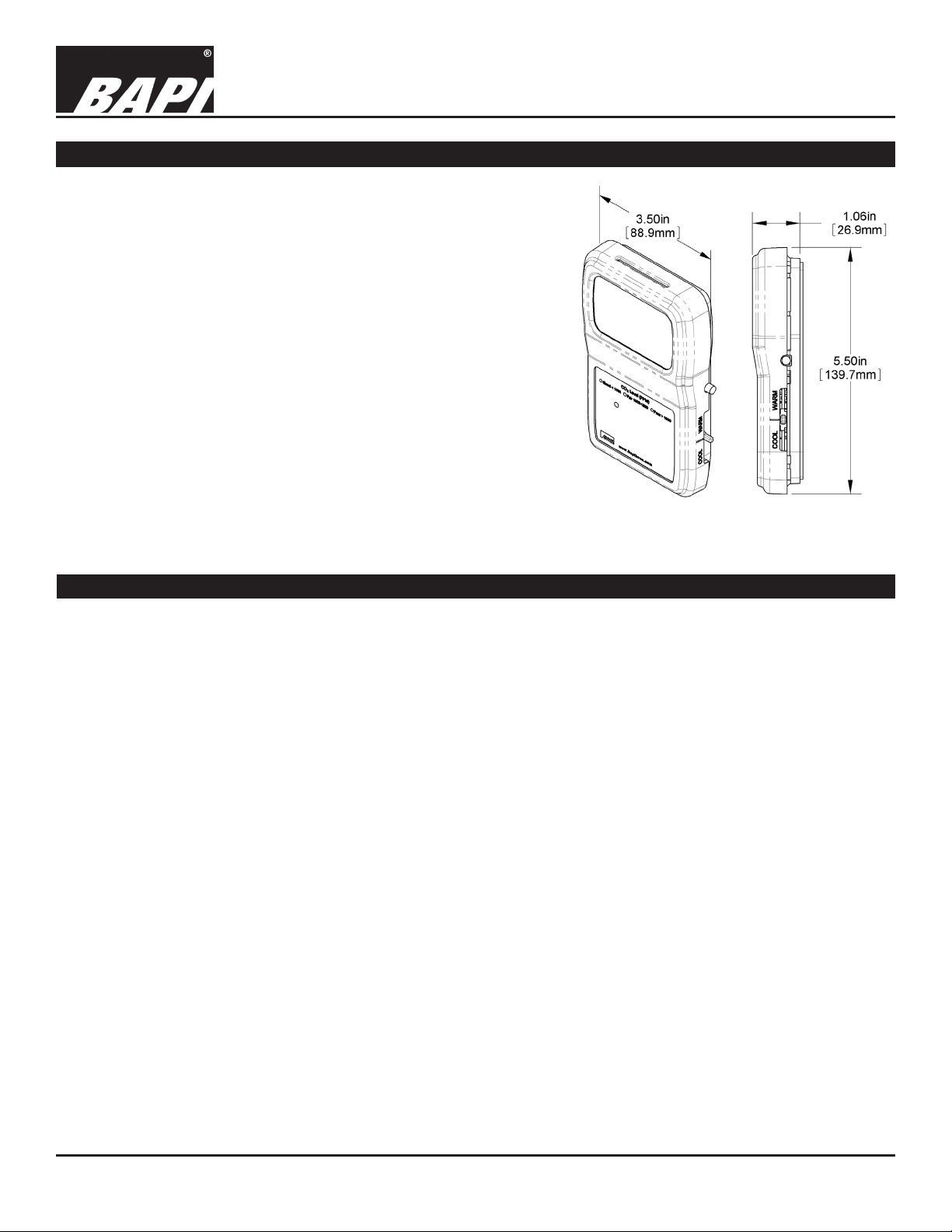

Fig. 1: BAPI-Stat 3 Room CO2 Sensor

Specications

Power for 0 to 5 VDC Outputs:

9 to 35 VDC @ 240mA (9 to 24 VDC recommended)

Power for 0 to 10 VDC Outputs:

15 to 35 VDC @ 240mA (15 to 24 VDC recommended)

Sensing Elements:

– Single Beam Non-Dispersive Infrared (NDIR)

CO

2

or Dual Channel NDIR for “24/7” Model

Humidity – Capacitive Polymer ±2% RH Accuracy

Temperature Sensor:

Thermistor, RTD or Semiconductor

Operating Environment:

32 to 122°F (0 to 50°C)

0 to 95%, RH non-condensing

Material ABS Plastic, Material Rated UL94V-O

Detection Range: 0 – 2000 ppm

CO

2

Start-Up Time: <2 Minutes

Response Time:

<2 Minutes for 90% step change typical (after start-up)

Mounting: 2”x4” J-Box or drywall – screws provided

Override Output:

Contact

Sensor

Setpoint

....SPST, 24V AC/DC, 0.5A max

.....Shorts Out direct temperature sensor

...Contact in parallel, resistive setpoint only

LCD Display:

Main Display: 0.76” 4-digit Numeric Values

Minor Display: 0.34” 3-digit Alpha-Numeric

(PPM, %RH, °F, °C)

Occupancy BAPI Man Icon: (Blk=Occupied)

Measurement Offsets: (Field Adjustable)

±5° (F or C) in 0.1° increments

±5% RH in 0.1% RH increments

Accuracy:

CO

2

(Single Channel Automatic Background Calibration model)

400 to 1,250 ppm: ±30ppm or 3% of reading,

whichever is greater

1,250 to 2,000 ppm: ±5% of reading + 30ppm

Accuracy:

CO

2

(“24/7” Dual Channel Model)

75ppm or 10% of reading (whichever is greater)

CO

Drift Stability (Dual Channel DCD “24/7” Units):

2

<5% of full scale over life of product.

LED CO

Level Indicator:

2

Good, Green < 1,000 PPM

Fair, Orange = 1,000 to 1,500 PPM

Poor, Red > 1,500 PPM

Certications: RoHS

Warranty Period: 5 Years from manufacture date

Specications subject to change without notice.

1 of 6

Page 2

CO2 Room Sensor in the BAPI-Stat 3 Enclosure

with Common Ground Conguration

Installation and Operating Instructions

26141_ins_room_CO2

Mounting

Mounting hardware is provided for both junction box and drywall installation (junction box installation shown).

Note: Screw the 1/26” Allen lock-down screw into the base to open the

case, less chance of losing it this way. Back out the lock-down screw

to secure the cover.

Junction Box

1. Pull the wire through the wall and out of the junction box, leaving

about six inches free.

2. Pull the wire through the hole in the base plate.

3. Secure the plate to the box using the #6-32 x 5/8 inch mounting

screws provided.

4. Terminate the unit according to the guidelines in the Termination

section. (page 3)

5. Mold the foam on the unit’s base to the wire bundle to prevent

drafts. (see note below)

6. Attach Cover by latching it to the top of the base, rotating the cover

down and snapping it into place.

7. Secure the cover by backing out the lock-down screw using a

1/16” Allen wrench until it is ush with the bottom of the cover.

Fig. 2: Mounting to a Junction Box

Drywall Mounting

1. Place the base plate against the wall where you want to mount the sensor.

2. Using a pencil, mark out the two mounting holes and the area where the wires will come through the wall.

3. Drill two 3/16” holes in the center of each marked mounting hole, DO NOT punch the holes or the drywall anchors will not hold. Insert a drywall anchor into each hole.

4. Drill one 1/2” hole in the middle of the marked wiring area.

5. Pull the wire through the wall and out of the 1/2” hole, leaving about six inches free.

6. Pull the wire through the hole in the base plate.

7. Secure the base to the drywall anchors using the #6 x 1 inch mounting screws provided.

8. Terminate the unit according to the guidelines in the Termination section. (page 3)

9. Mold the foam on the unit’s base to the wire bundle to prevent drafts. (see note below)

10. Attach cover by latching it to the top of the base, rotating the cover down and snapping it into place.

11. Secure the cover by backing out the lock-down screw using a 1/16” Allen wrench until it is ush with the bottom

of the cover.

rev. 04/27/18

NOTE: In any wall-mount application, the wall temperature and the temperature of the air within the wall cavity can

cause erroneous readings. The mixing of room air and air from within the wall cavity can lead to condensation, erroneous readings and sensor failure. To prevent these conditions, BAPI recommends sealing the conduit leading to

the junction box, lling the junction box with berglass insulation or sealing the wall cavity.

Specications subject to change without notice.

2 of 6

Page 3

CO2 Room Sensor in the BAPI-Stat 3 Enclosure

with Common Ground Conguration

Installation and Operating Instructions

26141_ins_room_CO2

Termination

BAPI recommends using twisted pair of at least 22AWG and sealant lled connectors for all wire connections. Larger

gauge wire may be required for long runs. All wiring must comply with the National Electric Code (NEC) and local codes.

Do NOT run this device’s wiring in the same conduit as AC power wiring. BAPI’s tests show uctuating and inaccurate

signals are possible when AC power wiring is in the same conduit as the signal lines. If you are experiencing any of these

difculties, please contact your BAPI representative.

BAPI recommends wiring the product with power disconnected. Proper supply voltage, polarity and wiring

connections are important to a successful installation. Not observing these recommendations may damage the

product and void the warranty.

Terminal Function

OVR

............. Override Output (Dry Contact Switch). When

Override switch is pushed this terminal is connected

to the GND terminal.

SET

.............. Setpoint output. Referenced to GND terminal.

.............. External occupied LCD indicator is activated by logic

EXT

LOW or ground at this terminal, referenced to the

GND terminal.

TP+ & TP-

... Temperature Sensor Output (Resistive Output).

When a jumper is on J16, TP- is connected to the

GND terminal. When the jumper is off of J16, the

temperature sensor is oating.

(Semiconductor TP+ = +, TP- = -)

CO2 / VOC ....Voltage output CO2 Signal (0 to 2,000 ppm)

referenced to the GND terminal.

RH

...............Voltage output Humidity Signal referenced to the

GND terminal.

GND

............. To controller Ground [GND or Common]

............ Power, referenced to GND

PWR

9 to 35 VDC @ 240mA

(9 to 24 VDC recommended) for 0 to 5 VDC Outputs

15 to 35 VDC @ 240mA

(15 to 24 VDC recommended) for 0 to 10 VDC Outputs

rev. 04/27/18

Fig. 3: Circuit Board

POWERING WITH A BAPI VC350A

VOLTAGE CONVERTER

The CO2 unit requires 240mA of current

to operate correctly. If this is more

current than can be provided by the

controller power output, then the unit

can be powered by a BAPI VC350A or

VC350A-EZ Voltage Converter.

Note: For proper operation, the

jumper on PRG connector of J19

must be connected by only one leg.

VC350A or VC350A-EZ

Voltage Converter

(VC350A shown below)

CO2 Sensor

Specications subject to change without notice.

Note: Unit is not ready for

operation until the 10 minute

start-up time has elapsed.

Fig. 4: Powering with

a BAPI VC350A

3 of 6

Page 4

CO2 Room Sensor in the BAPI-Stat 3 Enclosure

Table 1: C35 Wiring

10K-3(11K) Thermistor 7.32K (43.7°F) 3.65K (105.2°F)

26141_ins_room_CO2

Optional Test and Balance Switch (SW1)

Optional Communications Jack Wiring

C35

Communication

Jack

(Male jack

shown for clarity)

with Common Ground Conguration

Installation and Operating Instructions

rev. 04/27/18

Sensor Type Low Temp High Temp

1000 RTD 1.02K (41.2°F) 1.15K (101.5°F)

3000

Thermistor 7.87K (39.8°F) 1.50K (106.8°F)

10K-2 Thermistor 30.1K

10K-3 Thermistor 26.7K

Wire Color

Ground Black

Tip White

Ring Red

C11

(34.9°F) 4.75K (109.1°F)

(35.9°F) 5.11K (108.4°F)

C35

Table 2: C11 Wiring

Comm Jack Pin Wire Color

C11

Communication

Jack

1 Not Connected

2 Black

3 Red

4 Yellow

5 Green

6 Not Connected

User Operation

The display indicates CO2 in PPM, temperature in °F or °C,

%RH, temperature setpoint in degrees °F or °C and override

using the BAPI Man icon. The three triangle icons are used

with the –ARW option to show CO

levels.

2

The main display indicates the numeric value of the quantity

being displayed. The minor display indicates the engineering

units of the value, such as PPM, °F, °C or %RH.

Temperature Setpoint Slidepot: Moving the slidepot enough

to change the setpoint by one degree will display the setpoint

on the main LCD display if equipped with display. The setpoint

display will hold for ve seconds after moving the slide pot.

Override Button: When the override button is pressed on

display units, the BAPI Man icon will display. A dry resistance

of less than 1 ohm appears from the override output (OVR) to

the Ground terminal (GND). Latching the Icon to show that

the system is in override requires that a dry contact on your

controller be used to connect terminal EXT to ground.

Optional CO

CO

level indication is available via a black arrow on the display

2

Level Indication via Arrow or 3-Color LED

2

or a three-color LED on the logo plate with green for good,

yellow for fair and red for poor.

Fig. 5: Communication Jack Locations

BAPI Man

Icon

“ON” Icon

Arrow

Indicators

& Legend

LED

Indicator

& Legend

Note: Both

indicators are

not available

together

Fig. 6: CO

Unit Indicators

2

(Shown above with all

optional indicators)

Specications subject to change without notice.

4 of 6

Page 5

CO2 Room Sensor in the BAPI-Stat 3 Enclosure

with Common Ground Conguration

Installation and Operating Instructions

26141_ins_room_CO2

Optional Technician Adjustments

BAPI’s CO2 room sensor comes calibrated and ready to operate. In some

installations the sensor may not match local instrumentation. The technician

adjustment procedure allows °F or °C display units, temperature or humidity

offsets or display information to be changed at any time.

Removing Ground from Temperature Sensor

Some installations may experience erratic temperature readings. A

remedy may be to oat the temperature sensor as shown in Figs 7 and 8. Run

wires directly from TP+ and TP- to the controller’s analog input. The VOC/CO

and RH jumpers are omitted for clarity.

°F or °C Display Units

Figs 9 and gure 10 show the jumper positions for displayed values of Celsius

or Fahrenheit degrees. The jumpers on pins PRG and BNK are omitted for

clarity.

Parameter Offsets & Display Information

Figs 11 and 12 show how to place the unit into eld setup mode. Take the

jumper from the BNK terminals and place it on the PRG terminals. The F/C

jumper is omitted for clarity.

The major display should read P1 and the minor display should read DSP.

Use the UP/DN buttons (See Fig 13) to select the desired page.

Press and release the ENT button to select the desired page.

Use the UP/DN buttons to adjust the desired value

Press and release the ENT button to save the change and return to the page

display.

Adjust another page or place the jumper into normal operation.

possible

2

Fig. 7: Temp.

Grounded

Fig. 9: °F

Sensor

rev. 04/27/18

Fig. 8: Temp.

Sensor

Floating

Fig. 10: °C

Table 4: Parameter Offsets & Display Information

Parameter

Display Options P1 DSP

Temperature

Offset

%RH Offset P3 %RH

Offset

CO

2

Altitude P5 ALT

Display

Main Minor

P2 TMP

P4 CO2

Adjustment

Item Display Action

1 Temperature Only

2 % RH Only

CO

3

4 Temperature and %RH (10 second rotation)

5

6

7

8 Setpoint Display Only

±5° in 0.1° increments

±5% RH in 0.1% RH increments

±100 ppm in 1 ppm increments

Effective Pressure Altitude (display only, no adjustment)

Only

2

Temperature and CO

%RH and CO

Temperature, %RH and CO

Specications subject to change without notice.

(10 second rotation)

2

(10 second rotation)

2

(10 second rotation)

2

Fig. 11:

Normal

Operation

Fig. 12:

Programming

Setup

Fig. 13:

Calibration

Buttons

5 of 6

Page 6

CO2 Room Sensor in the BAPI-Stat 3 Enclosure

with Common Ground Conguration

Installation and Operating Instructions

26141_ins_room_CO2

Output Selection

The CO2 outputs may be eld congured for 0

to 5 VDC or 0 to 10 VDC outputs at any time.

Set the jumpers on J16 as shown in Figs 12

and 13.

The humidity outputs may be eld congured

for 0 to 5, 1 to 5, 0 to 10 or 2 to 10 VDC outputs

at any time. Set the jumpers on J16 as shown

in Figs 14 and 15.

Note: The jumpers on the pins not being

described are omitted for clarity on the gures

at right.

Fig. 14:

Output

CO

2

0 to 5 VDC

Fig. 15: CO

Output 0 to

10 VDC

Fig. 16: %RH

2

Output 0 to 5

or 1 to 5 VDC

Fig. 17: %RH

Output 0 to 10

or 2 to 10 VDC

Diagnostics

Possible Problems: Possible Solutions:

General troubleshooting Determine that the input is set up correctly in the controller's and building automation software.

Check wiring at the sensor and controller for proper connections. If there is corrosion, clean off

the corrosion, re-strip the interconnecting wire and reapply the connection. In extreme cases,

replace the controller, interconnecting wire and/or sensor.

Label the terminals that the interconnecting wires are connected to at the sensor end and the

controller end. Disconnect the interconnecting wires from the controller and the sensor. With

the interconnecting wires separated at both ends measure the resistance from wire-to-wire with

a multimeter. The meter should read greater than 10 Meg-ohms, open or OL depending on the

meter you have. Short the interconnecting wires together at one end. Go to the other end and

measure the resistance from wire-to-wire with a multimeter. The meter should read less than 10

ohms (22 gauge or larger, 250 feet or less). If either test fails, replace the wire.

Check power supply/controller voltage supply for proper voltage (see specications)

rev. 04/27/18

Incorrect CO2 Wait 15 minutes after a power interruption.

Check all software parameters

If the sensor is reading consistently high, make sure that the power supply to the unit can provide

Note: If the CO2 sensor has consistently given high PPM readings for over 5 days, it will take up

Incorrect Humidity Check all software parameters

If available, check the sensor against a calibrated instrument such as a hygrometer

Incorrect Temperature Check the wires at the sensor and controller for proper connections.

Check the Temperature Output of the unit. Disconnect the temperature sensor’s wire (Terminals

Determine if the sensor is exposed to an external environment different from the room (conduit or

Determine if the sensor is exposed to an external environment different from the room (conduit draft)

240mA. A low power situation will cause high CO2 readings.

to 14 days for the readings to return to normal.

Determine if the sensor is exposed to an external environment different from the room (conduit draft)

TP+ & TP-) and measure the temperature sensor’s resistance across the sensor output pins with

an ohmmeter. Put the ohmmeter’s black lead on Terminal TP- and the red lead on Terminal TP+.

Compare the temperature sensor’s resistance to the appropriate temperature sensor table on the

BAPI website. (Go to www.bapihvac.com; click on “Resource Library” and “Sensor Specs”, then

click on the sensor type you have.) If the measured resistance differs from the temperature table

by more than 5%, call BAPI technical support.

wall cavity draft)

Specications subject to change without notice.

6 of 6

Loading...

Loading...