Page 1

BAPI-Slim™ Wireless Temperature Transmitter

28936_ins_WFC

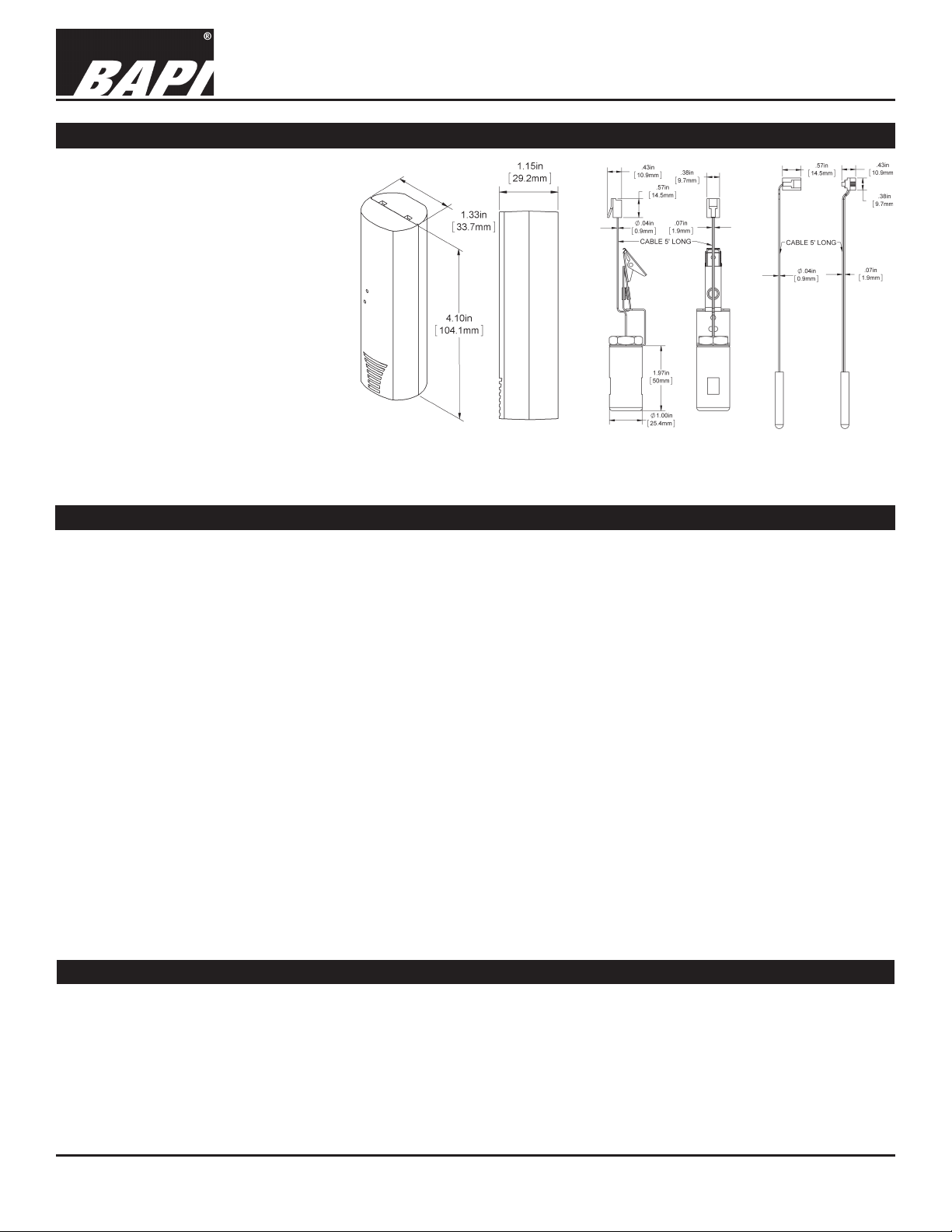

Identication and Overview

The BAPI-Slim Wireless Temperature

Transmitter is designed to monitor

temperature inside refrigerator and

freezer cases. The BAPI-Slim mounts

on the outside of freezer units and

can be mounted either inside or

outside of refrigerator units. The unit

is available with an internal sensor or

an RJ11 jack external sensor.

The external sensor’s ribbon cable

can easily t between the door seal

or through hole with FEP cable

without affecting appliance efciency.

The temperature is then transmitted

at 30-second intervals to the receiver

with a remote probe measurement

range of -40 to 185˚F (-40 to 85˚C).

Fig. 1: BAPI-Slim Wireless

Temperature Transmitter

(Battery Operated)

Installation and Operating Instructions

rev. 06/03/16

Fig. 2: External

Hanging Bracket

Sensor

Fig. 3:

External Probe

Sensor

Specications

Supply Power:

Activation: Starts to transmit when battery is installed (or

battery tab removed) and training button

pushed

Training: A button on the inside of the case. (Pushed

with paper clip through a pin hole in case)

LED: Transmit LED Inside Cover (Visible through

the lower pin hole in the case.)

Battery: 4 Year Replaceable, 1/2 AA, (3.6 VDC)

Battery Ambient: -67° to 185ºF (-55° to 85ºC)

Sensor: Thermistor, 10K-2

Internal: Located at Bottom of Case

External: RJ11 Jack

2” SS Sensor w/ Ribbon Cable or FEP Cable

2” Thermobuffer w/ Ribbon Cable or FEP Cable

Measurement Range: -40 to 185˚F (-40 to 85˚C)

Accuracy: ±0.5ºF (±0.28ºC) from -40 to 185ºF (-40º to 85ºC)

Environmental Operation:

Stainless Steel Probe: -40 to 185˚F (-40 to 85˚C)

Electronics: -22 to 122ºF (-30 to 50ºC)

Humidity: 0 to 95% RH Non-condensing

One 3.6 VDC Lithium Thionyl Chloride Battery

Case Material: ABS Plastic

Ext. Probe Material: 304 Stainless Steel (SS)

Transmitter Mounting:

Keyhole Screw Mounts (Screws not included)

Double-Sided Mounting Tape (Included)

Sensor Mounting:

Remote Probe: Plastic Holder (BA/FPB)

Thermobuffer: Hanging Rack Clip (Included)

Radio Frequency: 418 MHz @ 1mW

Transmitter Interval: Factory selectable from 10 sec to

10 minutes in 5 second intervals (30 seconds default)

Antenna: Spiral Type Built into Case

Transmission Range:

Up to 100 Ft Open Air (418 MHz @ 1mW)

Up to 1,000 Ft Open Air with Repeater (900MHz @ 100mW)

Warranty: 2 Years from Date of Manufacture

Agency:

RoHS

Industry Canada (IC:9067A-SM061025)

Flammability: UL 94 V-O

FCC Approval: FCC ID# T4FSM061025 (418MHz Only)

FCC Compliance

Compliance: This device complies with Part 15 Subpart B of the FCC rules Operation is subject to the following conditions.

1. This device may not cause harmful interference.

2. This device must accept any interference received, including interference that may cause undesired operation.

FCC Radio Frequency Interference Statement:

This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to Part 15,

Subpart B, of the FCC Rules. This equipment generates, uses, and can radiate radio frequency energy. If not installed

and used in accordance with the instructions, it may cause interference to radio communications.

Specications subject to change without notice.

1 of 4

Page 2

28936_ins_WFC

Mounting

BAPI-Slim™ Wireless Temperature Transmitter

Installation and Operating Instructions

rev. 06/03/16

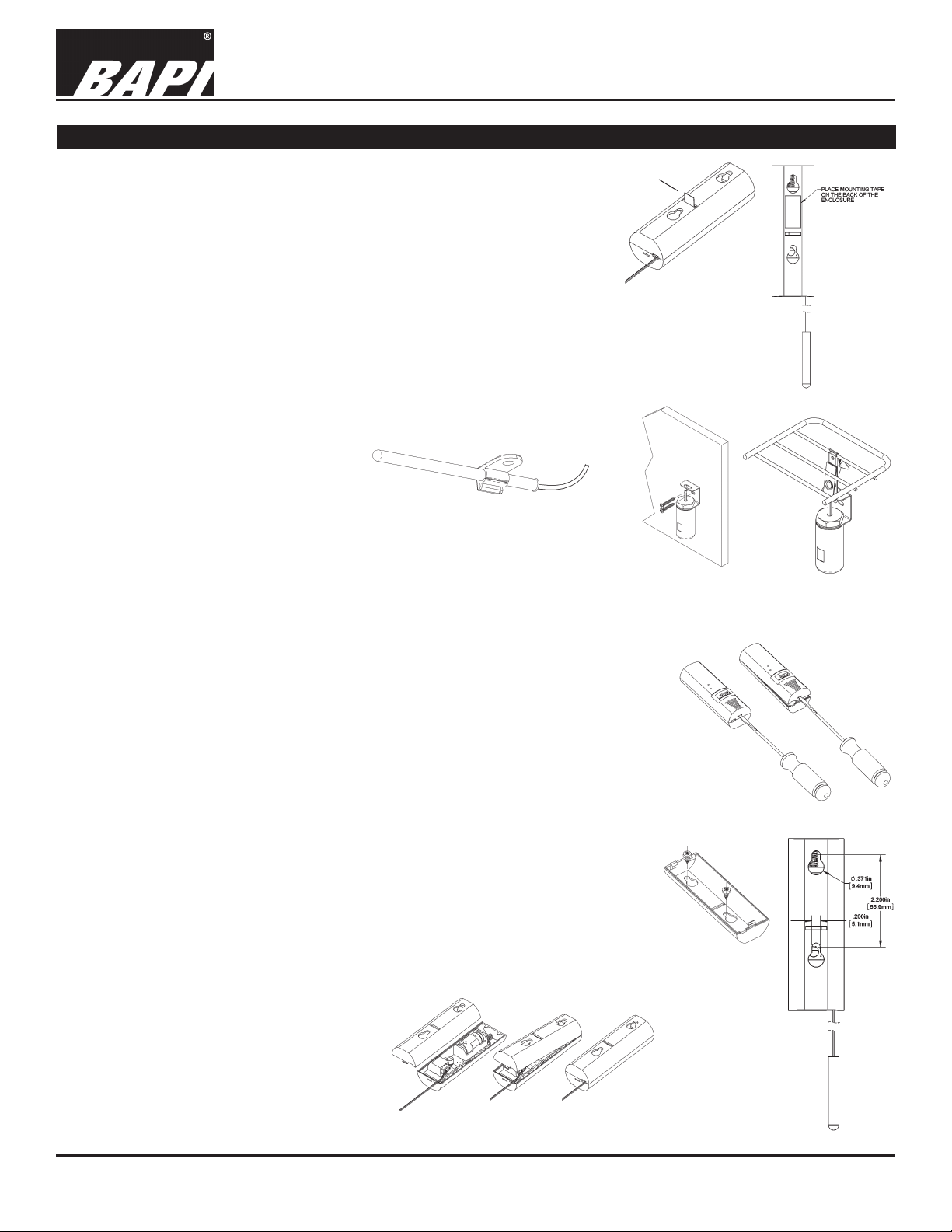

There are two ways to mount the wireless transmitter. One uses a keyhole

screw mount and the other uses double stick mounting tape. Both techniques

BATTERY

TAB

can be used together if desired.

TRANSMITTER MOUNTING WITH TAPE

1. Remove the battery tab by pulling the tab straight out to start the transmitter

(Fig. 4). The battery will last about 4 years before replacement is required.

2. Peel off one side of the mounting tape and apply the mounting tape to the

back (Fig. 5).

Fig. 4: Transmitter

Activation & Battery

3. Select a location you would like monitored or within reach of the remote

sensor. Any orientation is acceptable although vertical will enhance the

transmitter distance.

4. Peel off the mounting tape, position the sensor and rmly push it into place.

5. For units with an internal sensor the mounting process is complete.

6. For remote sensors, string the wire

through the freezer door and place

the sensor in the best location to

measure the required temperature.

7. Mount the External Probe using a

Flexible Probe Bracket (Fig. 6) or

use the clip or screw hole on the

Fig. 6: External Probe Mounting with

a Flexible Probe Bracket (BA/FPB)

Hanging Bracket Sensor (Fig. 7)

TRANSMITTER MOUNTING WITH SCREWS

1. Remove the battery tab to start the transmitter (Fig. 4). The battery will last

about 4 years before replacement is required.

2. Remove the back plate by inserting a small thin screwdriver in the bottom slot and

pushing gently. Then swing the cover up and off (Fig. 8).

3. Select a location within reach of the remote sensor. Any orientation is acceptable

although vertical mount will enhance the transmitter distance.

4. Mark the mounting holes by using the transmitter backplate as a template (Fig. 9).

Drill holes and use hardware appropriate for the application (hardware not included).

6. For units with an internal sensor, the mounting process is complete. Place the

transmitter over the back plate by hooking at the top of the back plate and swinging

down until it snaps into place (Fig. 10).

7. For remote sensors, string the wire through the freezer door and place the sensor

in the best location to measure the required temperature. Sensor removal from the

transmitter may be necessary. See Fig. 11.

8. Mount the External Probe using a Flexible Probe Bracket (Fig. 6) or use the clip or

screw hole on the Hanging Bracket Sensor (Fig. 7). Reconnect the remote sensor if

necessary (Fig. 11)

9. Place the transmitter over the back plate by hooking the transmitter at the top of

the back plate and swinging down until it snaps into place. Be sure the remote

sensor wire is lined up with the bottom slot (Fig. 10).

Tab Removal

Mounting

Application

Fig. 7: External Hanging Bracket

Sensor Mounting

FLATHEAD

SCREWDRIVER

Fig. 8:

Transmitter

Cover Removal

Fig. 9:

Mounting Hole

Location and

Mounting of

Unit

Fig. 5:

Tape

Fig. 10: Cover

Replacement

Specications subject to change without notice.

2 of 4

Page 3

BAPI-Slim™ Wireless Temperature Transmitter

Installation and Operating Instructions

28936_ins_WFC

Remote Sensor Connection

If the transmitter has an internal sensor then there is no external wiring. If a remote

sensor is used, then it is terminated using an RJ11 connector inside the transmitter case.

Remote Sensor Connection

1. Remove the back plate by inserting a small thin screwdriver in the bottom slot and

pushing gently. Then swing the cover up and off (Fig. 8).

2. An RJ11 connector is located at the bottom of the board. Insert the sensor RJ11 plug

(tab down) into the connector until it is fully seated (Fig. 11).

3. Place the transmitter over the base plate by hooking the transmitter at the top of the

back plate and swing down. Be sure the remote sensor wire is lined up in the bottom

slot and swing the cover down until it snaps into place (Fig. 10).

Battery Replacement

New transmitter installations are powered by a pre-installed battery.

To activate the unit, nd the battery tab insulator in the back of the

unit, pull it out and discard the tab (Fig. 4) and push the training

button (Fig. 14). The transmitter will start to transmit approximately

every 30 seconds.

Battery Replacement

1. Replacement requires the removal of the back plate by inserting

a small thin screw driver in the bottom slot and gently push then

swing the cover up and off (Fig. 8).

TRANSMITTER SERIAL NUMBER

(ON BATTERY HOLDER AND ON

STICKER ON BACK OF UNIT)

Fig. 11: Remote

Sensor Connection

TRAINING

BUTTON

HOLE

TRANSMIT

LED HOLE

rev. 06/03/16

2. Remove the old battery and install a new battery (BA/BAT-5AAHIT) so that the negative faces up toward the antenna (Fig. 12).

Push the training button (Fig. 14) and the transmitter will start to

transmit approximately every 30 seconds. The transmission LED

(Fig. 13) will ash once for each transmission.

3. Place the transmitter over the base plate by hooking the

transmitter at the top of the back plate and swing down. Be sure

the remote sensor wire, if used, is lined up in the bottom through

Fig. 12: Transmitter

Internal Components

slot and swing the cover down until it snaps into place (Fig. 10).

Setup and Commissioning

As soon as the batteries are installed (or the insulating battery tab is removed) and

the training button is pressed, the transmitter will start to transmit the temperature

using the serial # code shown on the battery holder (Fig. 12). A small transmit LED

on the circuit board ashes once for each transmission. This happens at 30 second

intervals. This LED is visible through the lower hole on the front cover (Fig. 13).

When using a receiver with one or more Analog Output Modules, the transmitter

will have to be trained to an individual Analog Output Module on the receiver. To do

this, push and hold the Service Button on the Analog Output Module you wish to

train. Then push and release the Training Button on the transmitter with a paper clip

through the top faceplate hole (Fig. 14). The Analog Output Module LED will light up,

indicating a successful training process. The LED on the Analog Output Module will

then ash with each received transmission, approximately every 30 seconds.

Fig. 13: Transmit

LED & Training

Button

PAPER

CLIP

TRAINING

BUTTON

HOLE

Fig. 14: Accessing the

Training Button through

the Front Cover

Specications subject to change without notice.

3 of 4

Page 4

BAPI-Slim™ Wireless Temperature Transmitter

Installation and Operating Instructions

28936_ins_WFC

Diagnostics

Possible Problems: Possible Solutions:

The unit is suspected of not transmitting - Verify that the Transmit LED (Fig. 13) on the transmitter ashes at 30

second intervals. If the LED is not ashing, press the Training Button

(Fig. 14) and recheck if the transmit LED is ashing.

Unit is not talking to the analog output module - If this is a 900MHz system (has a repeater), then be sure the repeater is

within range of the transmitter and within range of the receiver.

- Re-train the analog output module as described in the “Setup and Commissioning” section.

Sensor reads low - Remove the sensor from the case by unplugging the RJ11 plug.

Measure the resistance of the two center terminals and compare

this resistance to the resistance found on the resistance/temperature

chart for the 10K-2 thermistor on the BAPI website. If the measured

resistance is different from the temperature table by more than 5%,

call BAPI technical support. Find BAPI’s website at www.bapihvac.

com; click on “Resource Library” and “Sensor Specs”, then click on the

10K-2 Thermistor sensor.

rev. 06/03/16

Battery may be low - Check the battery voltage to see that it is 2.6 volts or greater. If it is less

than 2.6 volts, replace the battery. The batteries should last for 4 years.

Related Products

Part Number Description

BA/RCV418-WAM-x-EZ ....Wireless 418MHz Wireless Asset Monitoring (WAM) Receiver

BA/RCV418-EZ .................418MHz Wireless Receiver for Analog Output Modules

BA/RCV900-EA-EZ ...........900MHz Wireless Receiver for Analog Output Modules (requires a repeater)

BA/RPT49-EA-EZ .............. 418 MHz to 900MHz Repeater

BA/VOM-10-x-EZ ............... 0 to 10V Voltage Output Module

BA/COM-x-EZ .................... 4 to 20mA Current Output Module

BA/ROM-10x-EZ ................ Resistance Output Module, 10K-2 Thermistor Output

BA/BAT-5AA-HIT .............. Replacement Battery, ½ AA, 3.6V

Specications subject to change without notice.

4 of 4

Loading...

Loading...