Page 1

Wallplate with Semiconductor Sensor (BA/592-SP/AP)

10KΩ uncertainty Table

Tolerance

Temperature uncertainty

0.1%

±8.64°F

1%

±13.47°F

5%

±34.93°F

Table 2: 592 2-Wire Sensors

Table 3: 592 3-Wire Sensors

1. Install a 10KΩ 0.1% resistor from the controller's

analog input to the controller's ground or common.

1. All BAPI BA/592-10K, 3-wire, sensors have a built

in 10KΩ 0.1% resistor.

2. If you are using a separate DC power supply,

connect the power supply's negative terminal to the

controller's ground or common..

2. If you are using a separate DC power supply,

connect the power supply's negative terminal to the

controller's ground or common..

3. Connect the 592 sensor's black wire to the

controller's analog input.

3. Connect the 592 sensor's black wire to the

controller's ground or common.

4. Connect the 592 sensor's red wire to 5 to 30

VDC.

4. Connect the 592 sensor's white wire to the

controller's analog input.

5. Connect the 592 sensor's red wire to 5 to 30

VDC.

Installation & Operating Instructions

16558_ins_592_SP_AP

592 Theory of Operation

The 592 Semiconductor sensor is a two terminal integrated-circuit temperature sensor. The 592 provides an output

current directly proportional to absolute temperature. When the temperature of the 592 sensor changes one-Kelvin (onedegree Celsius), then the current through the 592 changes by 1uAmp. 77° Fahrenheit (25° Celsius) is 298.2 Kelvins and

the output current from the 592 sensor is 298.2uAmp. Initial accuracy of the 592 temperature sensor is ± 8.1° Fahrenheit

(± 4.5° Celsius) at 77° Fahrenheit (25° Celsius).

Since most meters that eld technicians use cannot accurately measure currents this low, BAPI recommends that a 10KΩ

0.1% resistor be placed between the sensor output and ground. The 10KΩ resistor changes the current into a voltage

that varies 0.01 volts per one degree Celsius temperature change; the

voltage at 77°F is 2.982 VDC. Resistors with other tolerances can be

used, but you will have greater temperature uncertainty, see the 10KΩ

uncertainty table;

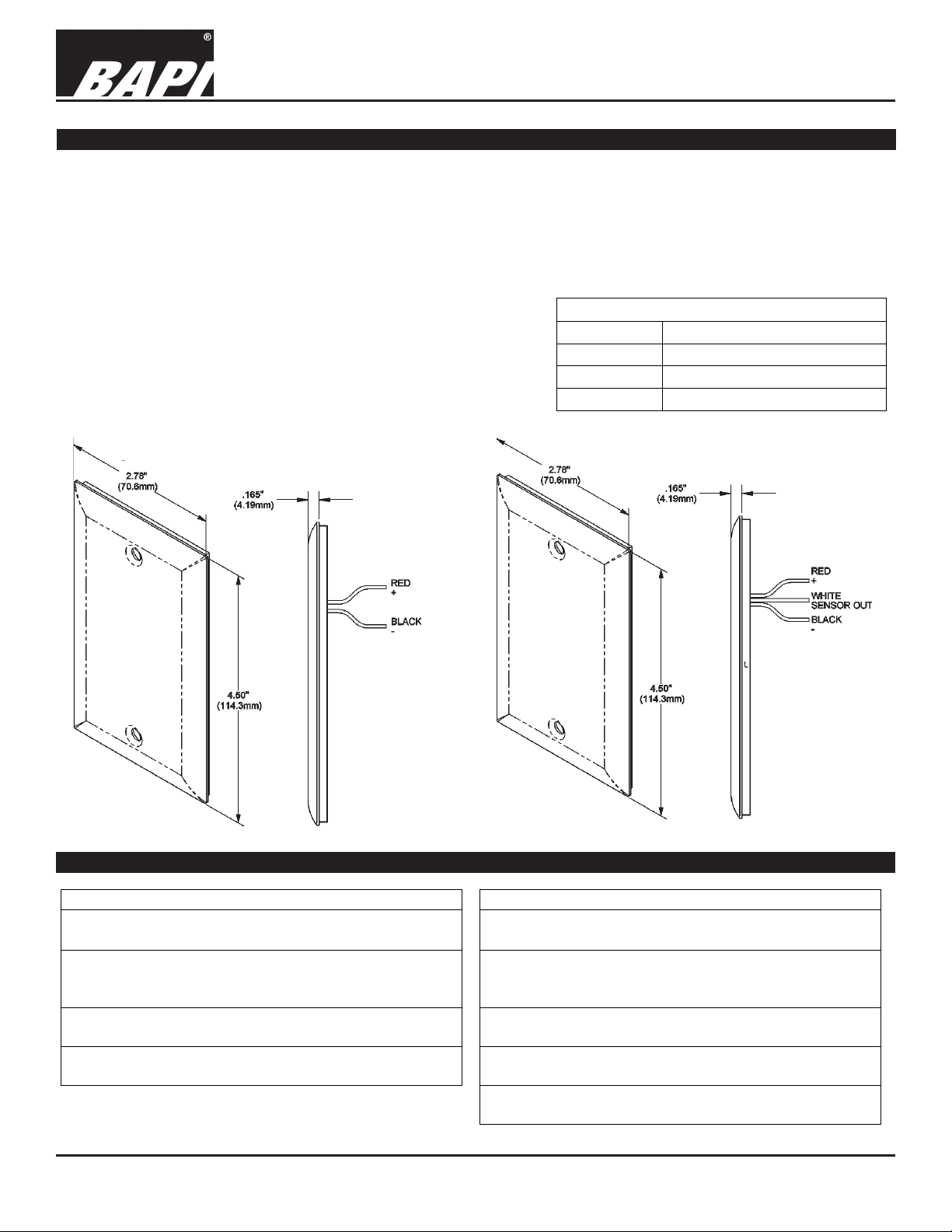

BAPI provides two styles of 592 sensor, one with and one without the

10K ohm, 0.1% resistor. The one with the resistor has three wires –

red, black and white. The one without the resistor has two wires – red

and black.

rev. 08/01/18

Fig. 1:

592 Semiconductor

2-wire unit

Termination

Specications subject to change without notice.

Fig. 2:

592 Semiconductor

3-wire unit

1 of 3

Page 2

Wallplate with Semiconductor Sensor (BA/592-SP/AP)

Installation & Operating Instructions

16558_ins_592_SP_AP

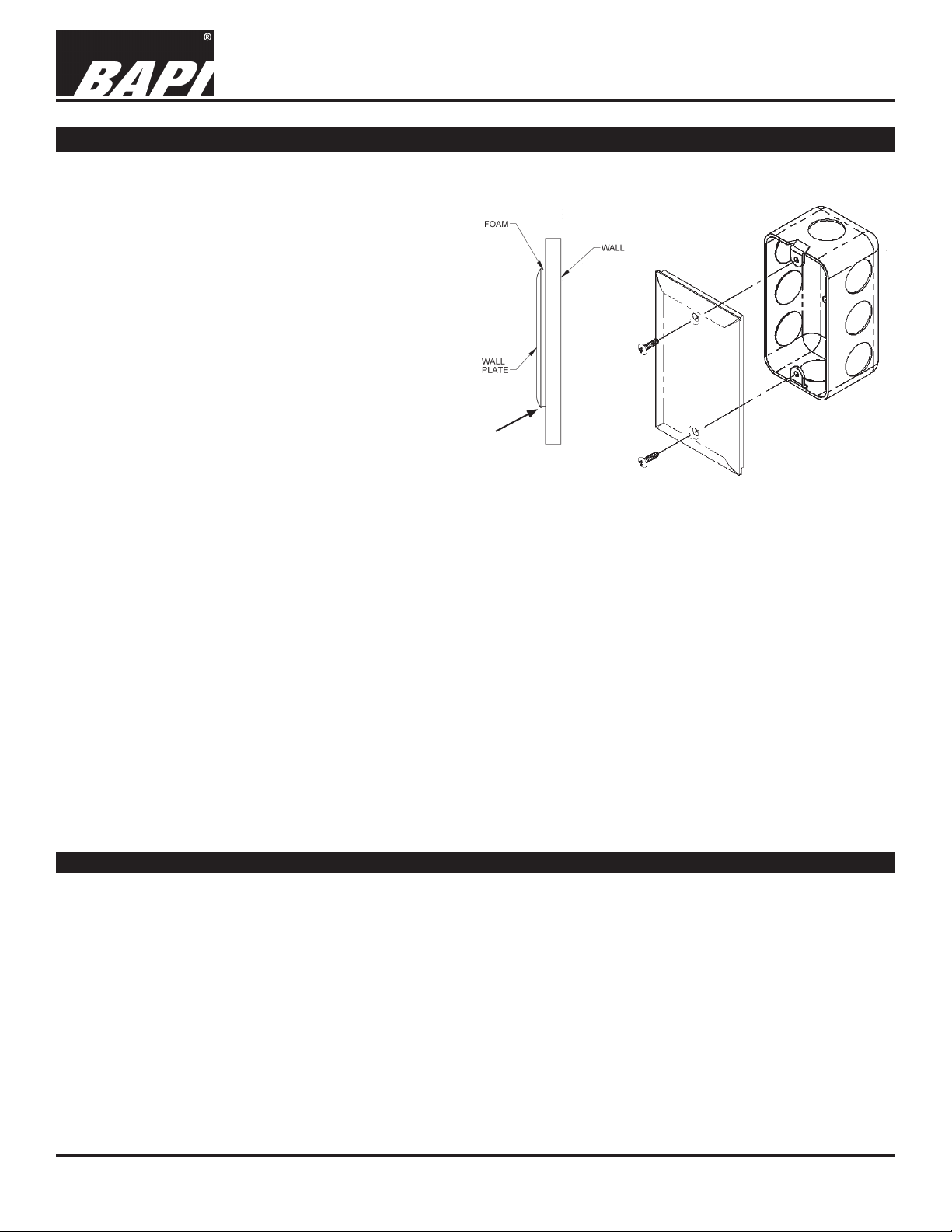

Mounting

Ensure the plate does not touch the wall when it is mounted as this will lead to slower response

rates when the environment changes.

Mounting hardware is provided for both

junction box and drywall installation.

Junction Box

1. Pull the wire through the wall and out of

the junction box, leaving about 6” free.

2. Terminate the unit according to the

guidelines in Termination on page 1.

3. Secure the plate to the box using the

#6-32 x 1/2” mounting screws provided

or with security screws which are

sold separately. (Call BAPI or visit the

Accessories section of our website for

security screw ordering.)

4. Tighten screws until the foam gasket on

the back plate is compressed about 50%.

Ensure the plate doesn’t touch the wall

(Fig 5).

Verify visible

air gap

between plate

and wall.

Fig 5:

Side View of

Mounted Plate

J-Box Mounting

rev. 08/01/18

Fig 6:

Note: Louvered wall plates require a mounting adapter bracket for J-Box mounting. The bracket is not shown in the

diagram above but is included with any louvered wall plates ordered from BAPI.

Drywall Mounting

1. Place the plate against the wall where you want to mount the sensor and mark out the two mounting holes.

2. Drill two 3/16” holes in the center of each marked mounting hole. Insert a drywall anchor into each hole.

3. Cut hole between the mounting holes that clears the apparatus mounted on plate. Pull the wire through the wall hole

cut in step 2, leaving about 6” free.

4. Terminate the unit according to the guidelines in Termination on page 1.

5. Secure the plate to the drywall anchors using the #6 x 1” mounting screws provided. Tighten screws until the foam

gasket on the back plate is compressed about 50%. Ensure the plate doesn’t touch the wall.

Note: In any wall-mount application, the wall temperature and the temperature of the air within the wall cavity can cause

erroneous readings. The mixing of room air and air from within the wall cavity can lead to condensation, erroneous

readings and premature failure of the sensor. To prevent these conditions, seal the conduit leading to the junction box or

ll the box with insulation.

Temperature Measurement Offsetting

All BA/592 sensors will have the following information provided on a label:

Therm Reading_______

The actual temperature reading according to

a thermometer that is certied traceable to

recognized standards by the National Institute of Standards and Technology (NIST).

Sensor Reading ______

The temperature reading according to

the AD592 sensor. The output is dropped

across a 10KΩ 0.1%, read in mV and

converted to a Fahrenheit temperature.

Offset_______

The difference between the

Thermometer Reading and

the Sensor Reading

To correct the Sensor Reading, simply add the offset value to the sensor reading so that it equals the thermometer reading.

e.g. Therm Reading = 74.6, Sensor Reading = 73.0, Offset = +1.6

Correction: Add (+1.6) °F to the sensor for an accurate reading: 73 + 1.6 = 74.6°F

e.g. Therm Reading = 75.4, Sensor Reading = 77.2, Offset = -1.8

Correction: Add (-1.6) °F to the sensor for an accurate reading: 77.2 + (-1.8) = 75.4°F

Specications subject to change without notice.

2 of 3

Page 3

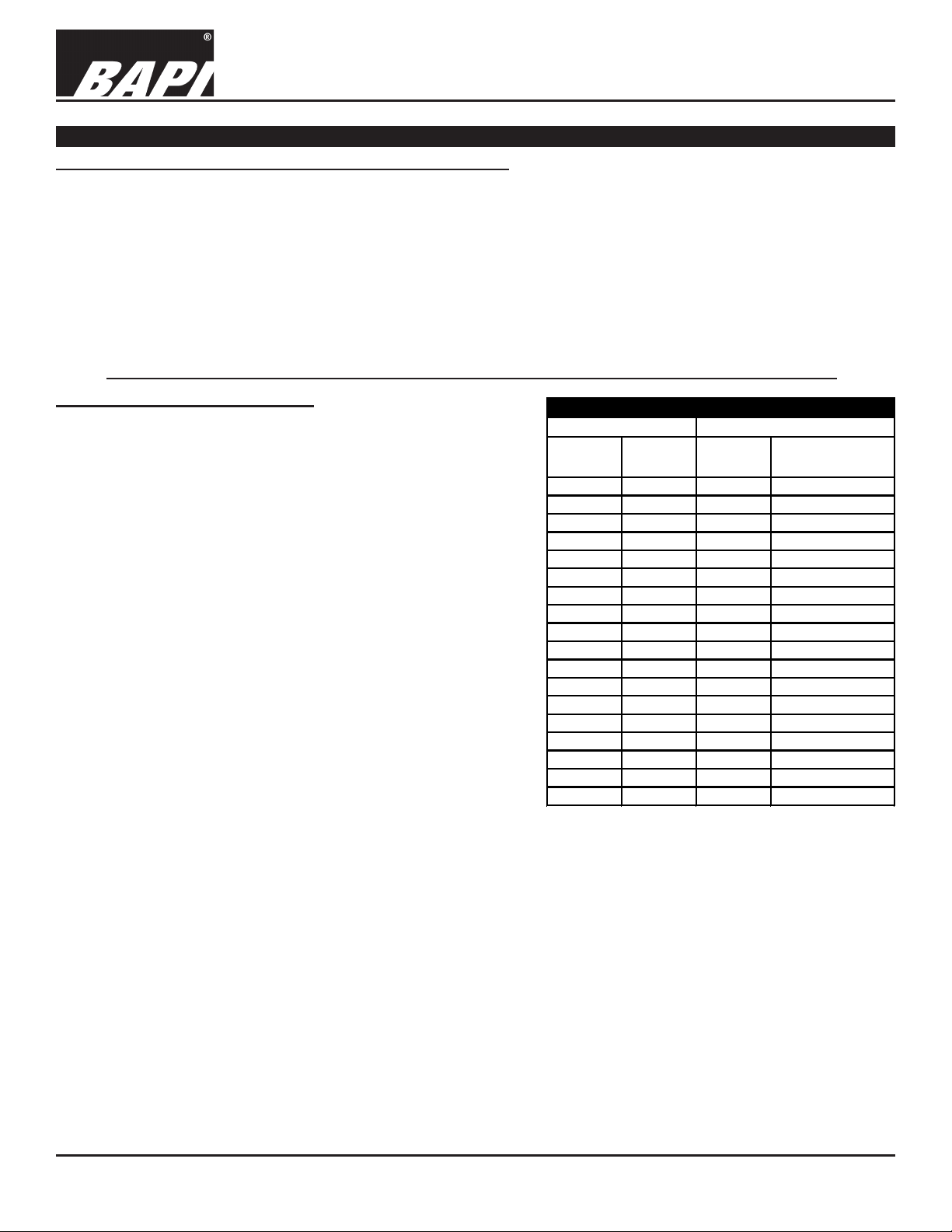

Wallplate with Semiconductor Sensor (BA/592-SP/AP)

°F °C

Output

Current uA

Output Voltage

across 10KΩ

50 10 283.2 2.832

60 15.56 288.8 2.888

62 16.67 289.9 2.899

64 17.78 291 2.91

66 18.89 292.1 2.921

68 20 293.2 2.932

70 21.11 294.3 2.943

72 22.22 295.4 2.954

74 23.33 296.5 2.965

76 24.44 297.6 2.976

78 25.56 298.8 2.988

80 26.67 299.9 2.999

82 27.78 301 3.01

84 28.89 302.1 3.021

86 30 303.2 3.032

88 31.11 304.3 3.043

90 32.22 305.4 3.054

100 37.78 311 3.11

Table 4: 592 Output

Temperature

592 Semiconductor

Installation & Operating Instructions

16558_ins_592_SP_AP

Diagnostics

GENERAL TROUBLESHOOTING AND POSSIBLE SOLUTIONS

- Determine that the input is set up correctly in the controller’s and building automation software.

- Check wiring for proper termination

- Check for corrosion at either the controller or the sensor. Clean off the corrosion, re-strip the interconnecting wire and

reapply the connection. In extreme cases, replace the controller, interconnecting wire and/or sensor.

- Label the terminals that the interconnecting wires are connected to at the sensor end and the controller end. Discon-

nect the interconnecting wires from the controller and the sensor. With the interconnecting wires separated at both ends

measure the resistance from wire-to-wire with a multimeter. The meter should read greater than 10 Meg-ohms, open

or OL depending on the meter you have. Short the interconnecting wires together at one end. Go to the other end and

measure the resistance from wire-to-wire with a multimeter. The meter should read less than 10 ohms (22 gauge or

larger, 250 feet or less). If either test fails, replace the wire.

592 SENSOR TROUBLESHOOTING

Note: The BAPI crimp-on sealant lled connectors have a

convenient hole opposite the wire opening to insert a meter probe

for measurements.

1) Measure the sensible temperature at the sensors location

using an accurate temperature standard.

2) Set your meter to the Volts setting.

3) Measure from the controller ground (black sensor lead) to the

592’s power lead (red sensor lead) for +5 to +30 VDC.

4) Set your meter to the mV setting.

a) For two wire units place a 10KΩ resistor between the

sensors black lead and the return wire to the controller.

Measure and record the voltage across the resistor.

b) For three-wire units measure and record the voltage from

the black lead to the white lead.

5) Using Table 4, if the sensor voltage is greater or less than

0.050VDC from the expected voltage measurement, call BAPI

technical support.

6) If the sensor reads properly, verify that the controller is

operating correctly.

7) If the sensor reads improperly, determine if the sensor is

exposed to an external source different from the measured

environment (conduit draft).

rev. 08/01/18

Specications subject to change without notice.

3 of 3

Loading...

Loading...