Page 1

Duct and Outside Air Humidity (H200-H300)

4 to 20mA or 0 to 5V Humidity Output with Optional Temperature Sensor

Installation and Operating Instructions

9938_ins_hum_temp_duct_out_5_20

Overview

The BA/(H200, H300) is a humidity transmitter which comes in 2% or 3% accuracies and an optional temperature sensor.

The temperature sensor can be either a Thermistor or RTD. It can be ordered for either Duct or Outside Air applications with

Weatherproof (WP), Weather Tight (EU), BAPI-Box (BB), or BAPI-Box 2 (BB2) Enclosures. The transmitter can be wired for

either a 0 to 5VDC output or a loop powered 4 to 20mA output.

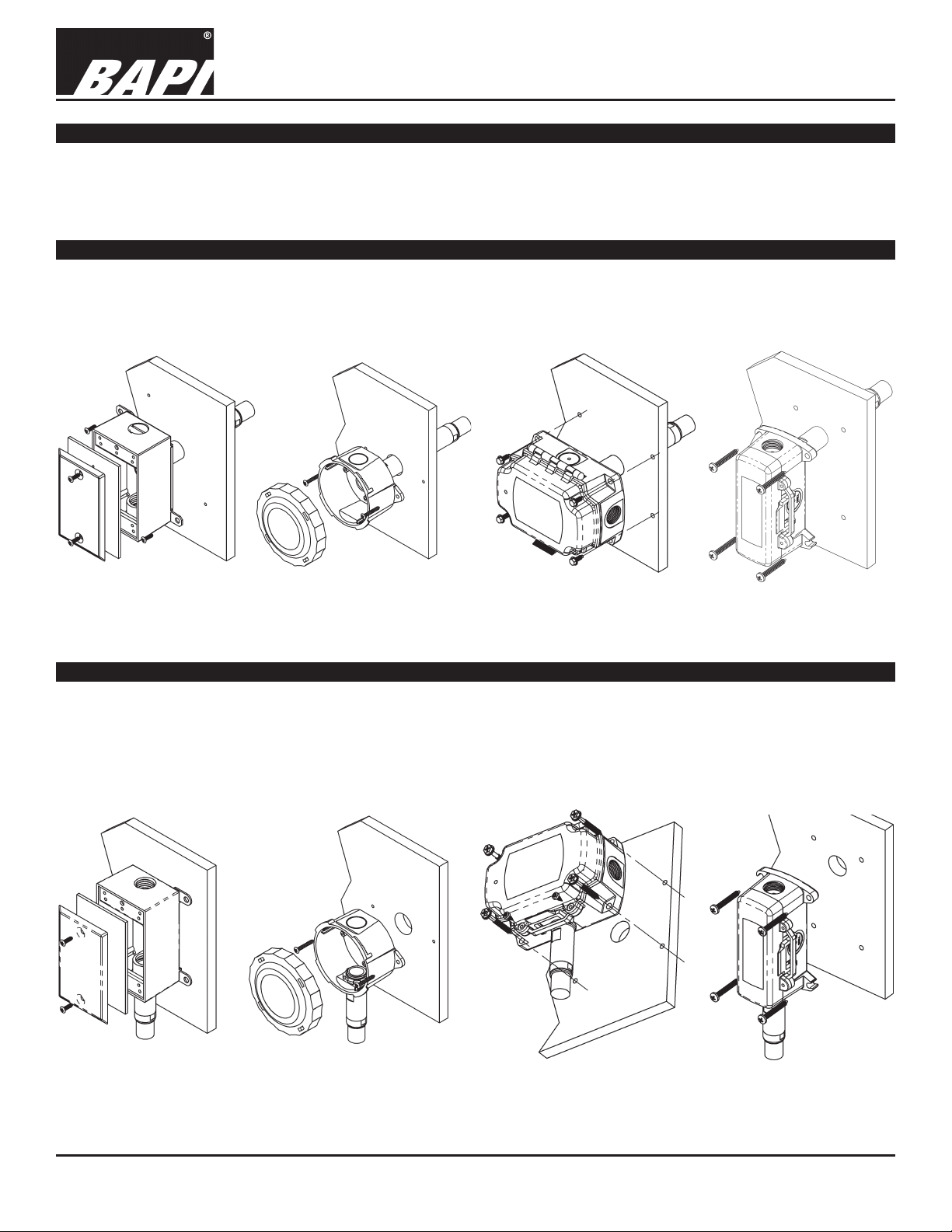

Duct Unit Mounting

Mount at least 3 duct diameters from humidiers in the center of the duct wall. Drill a 1 inch hole for the probe in the duct

and use two number 8 sheet metal screws to attach the sensor to the duct. Center the probe in its mounting hole. Be sure

that the foam seals the hole, do not over tighten the screws.

rev. 02/15/18

Fig. 1: Duct Humidity

in a Weatherproof

(WP) Enclosure

Fig. 2: Duct Humidity

in a Weather Tight (EU)

Enclosure

Fig. 3: Duct Humidity

in a BAPI-Box (BB)

Enclosure

Fig. 4: Duct Humidity

in a BAPI-Box 2 (BB2)

Enclosure

Outside Air Mounting

Mount in a permanently shaded area away from windows and doors. Do not mount in direct sunlight. Mount with the sensor probe pointed down. Drill a hole large enough for your sensor cable through your mounting surface. Mount the unit to

the surface with the wiring knock out centered over the wiring hole. Pull the wiring into the unit and terminate using sealant lled connectors. Best practice is to seal the wiring hole with caulk after the wiring is installed. Be sure that the foam

on the back of the unit makes a good weather tight seal.

Fig. 5: Outside Humidity

in a Weatherproof (WP)

Enclosure

Fig. 6: Outside Humidity

in a Weather Tight (EU)

Enclosure

Specications subject to change without notice.

Fig. 7: Outside Humidity

in a BAPI-Box (BB)

Enclosure

Fig. 8: Outside Humidity

in a BAPI-Box 2 (BB2)

Enclosure

1 of 4

Page 2

Duct and Outside Air Humidity (H200-H300)

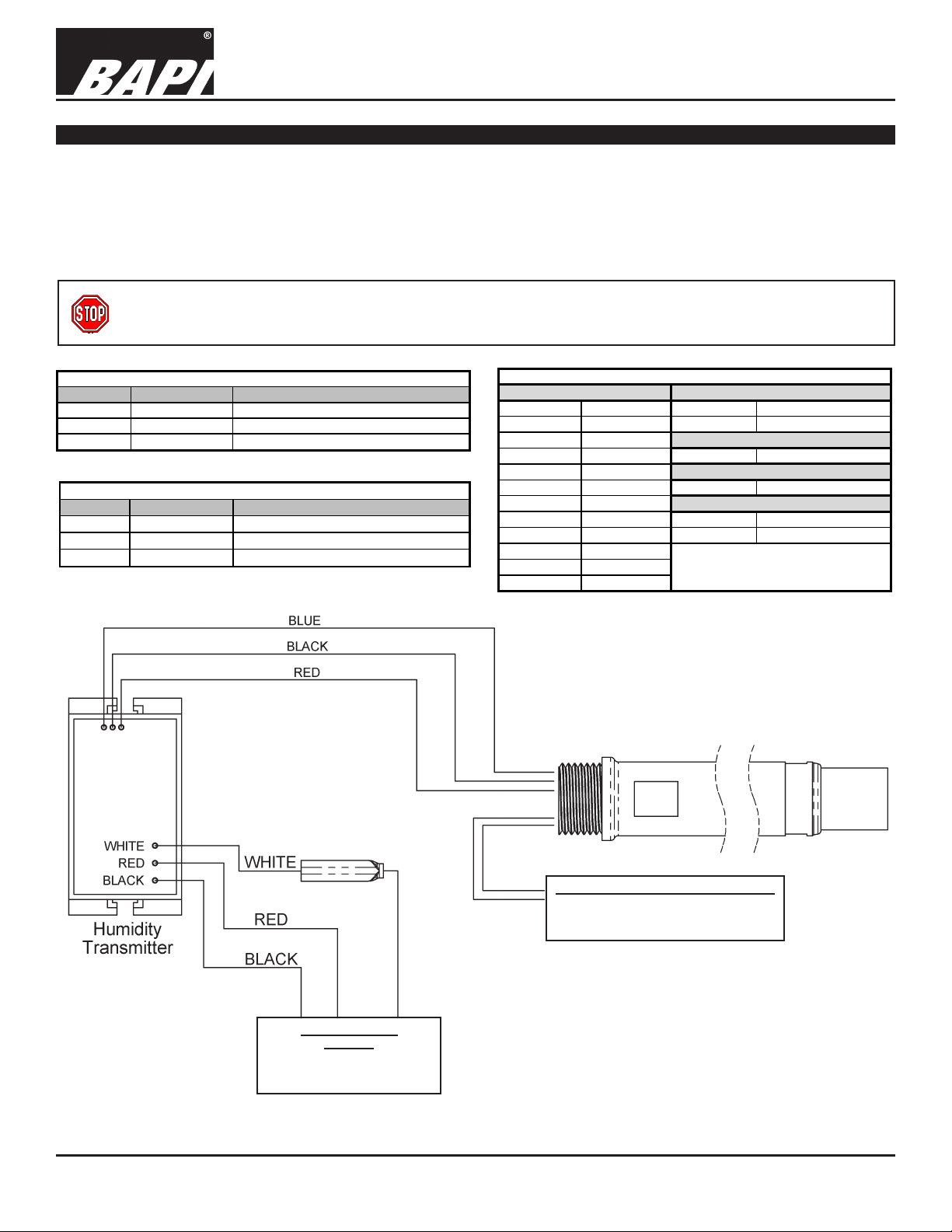

Table 1: Humidty Transmitter with 4 to 20mA Output

Red Power 10 to 35VDC

White

Black GND (Common) Ground for Power and Humidity Output

2.2KΩ Brown/White 1KΩ Orange/Orange

3KΩ Yellow/Black

3.25KΩ Brown/Green 1KΩ Green/Green

10K-3Ω Yellow/Red

10K-3(11K)Ω Yellow/Blue 100Ω Red/Red/Black*

50KΩ White/Blue

100KΩ Yellow/White

Additional sensors are available so your sensor may not be listed on this table.

4 to 20mA or 0 to 5V Humidity Output with Optional Temperature Sensor

Installation and Operating Instructions

9938_ins_hum_temp_duct_out_5_20

Wiring and Termination

BAPI recommends using twisted pair of at least 22AWG and sealant lled connectors for all wire connections. Larger

gauge wire may be required for long runs. All wiring must comply with the National Electric Code (NEC) and local codes.

Do NOT run this device’s wiring in the same conduit as AC power wiring of NEC class 1, NEC class 2, NEC class 3 or with

wiring used to supply highly inductive loads such as motors, contactors and relays. BAPI’s tests show that uctuating and

inaccurate signal levels are possible when AC power wiring is present in the same conduit as the signal lines. If you are

experiencing any of these difculties, please contact your BAPI representative.

BAPI recommends wiring the product with power disconnected. Proper supply voltage, polarity, and

wiring connections are important to a successful installation. Not observing these recommendations may

damage the product and will void the warranty.

Table 3: Temperature Sensor Lead Wire Colors

Wire Color Purpose Note

White Not Used Not Used (Cap Wires)

Black Humidity Output 4 to 20 mA, To Analog Input of Controller

Thermistors Platinum RTDs - 2 Wire

1.8KΩ Orange/Red 100Ω Red/Red

Nickel RTD

rev. 02/15/18

Table 2: HumidityTransmitter with 0 to 5VDC Output

Wire Color Purpose Note

Humidity Output 0 to 5VDC, To Analog Input of Controller

Red Power 10 to 35VDC or 12 to 27 VAC

3.3KΩ Yellow/Brown

10K-2Ω Yellow/Yellow 2KΩ Brown/Blue

20KΩ W hite/White 1KΩ Orange/Orange/Black*

47KΩ Yellow/Orange

Optional Temperature Sensor Output

See Table 3 above for Wire Colors

(Sensors are not polarity sensitive,

3 wires used for 3-wire RTDs)

*In the 3-Wire RTD sensors listed above,

the two wires of similar color are

Silicon RTD

Platinum RTDs - 3 Wire

connected together.

Humidity Output

& Power

See Tables 1 and 2 above

for Wiring Information

Specications subject to change without notice.

Fig. 9: Wiring Diagram

NOTE: BAPI’s 2% and 3%, humidity transmitters ARE

polarity sensitive as well as reverse polarity protected.

2 of 4

Page 3

Duct and Outside Air Humidity (H200-H300)

4 to 20mA or 0 to 5V Humidity Output with Optional Temperature Sensor

Installation and Operating Instructions

9938_ins_hum_temp_duct_out_5_20

Specications

Power:

10 to 35 VDC For 0 to 5 VDC or 4 to 20 mA Humidity Outputs

12 to 27 VAC For 0 to 5 VDC Humidity Output

Power Consumption:

22 mA max. DC For 0 to 5 VDC or 4 to 20 mA Humidity Outputs

0.53 VA max. AC For 0 to 5 VDC Humidity Output

Sensor: Factory corrected @17 RH points (10 to 90% RH)

Humidity Capacitive Polymer

RH Accuracy ±2% @ 73°F (23°C) from 10 to 90%

Drift 0.5% per year

Response time < 5 seconds in moving air

RH Linearity Negligible, factory corrected linear from 10 to 90%

RH Hysteresis Factory corrected to <1%

Opt. Temp. Passive RTD or Thermistor

Filter: 80 micron sintered stainless steel lter

Calibrated Accuracy: Calibration @17 RH points, (10% to 90%)

RH 2% 2% from 10 to 90% @ 73°F (23°C), Non-condensing

RH 3% 3% from 10 to 95% @ 73°F (23°C), Non-condensing

Thermistor ±0.36ºF (0.2ºC) from 32 to 158ºF (0 to 70ºC) - High accuracy units are available

RTD ±0.55ºF (0.31ºC) @ 32ºF (0ºC) - High accuracy units are available

Output: Selectable via wiring detail

Humidity 0 to 5VDC or 4 to 20mA at 0 to 100% RH

Opt. Temp. Resistance RTD or Thermistor

Humidity Output Impedance:

Current 700W@ 24VDC, Voltage drop is 10VDC

(Supply Voltage DC – Transmitter voltage drop 10VDC) / 0.02 Amps = Max load Impedance

Voltage 10KW

Probe Length:

Duct 5.3” (13.5cm) Duct Insertion, 1” diameter

Outside Air 2.4” (6.1cm) Below Enclosure, 1” diameter

Dimensions: W x H x D

Weatherproof (WP) 2.75” x 4.5” x 2.2”, (70 x 114 x 55 mm)

Weather Tight (EU) 4.1”x 3.8” x 2.1”, (105 x 97 x 54 mm)

BAPI-Box (BB) 4.15” x 5” x 2.5”, (105.4 x 127 x 63.5mm)

BAPI-Box 2 (BB2) 4.9” x 2.8” x 2.35”, (124.8 x 71.6 x 59.7mm)

Termination: Open wire

Crimp 18 to 26 AWG with Sealant Filled Crimp Connector (BA/SFC1000-x00)

Wire Nut 26 to 16 AWG with Sealant Filled Wire Nut (BA/SFC2000-x00)

Enclosure Material:

Weatherproof (WP) Cast Aluminum

Weather Tight (EU) ABS plastic, UV resistant

BAPI-Boxes (BB, BB2) Polycarbonate, UV resistant

Enclosures Ratings:

Weatherproof (WP) NEMA-3R

Weather Tight (EU) IP66, UL94V-0

BAPI-Boxes (BB, BB2) NEMA-4, IP66, UL94V-0

Environmental Operation Range: -40º to 158ºF (-40º to 70ºC) • 0% to 100% RH

Approvals: RoHs

rev. 02/15/18

Specications subject to change without notice.

3 of 4

Page 4

Duct and Outside Air Humidity (H200-H300)

4 to 20mA or 0 to 5V Humidity Output with Optional Temperature Sensor

Installation and Operating Instructions

9938_ins_hum_temp_duct_out_5_20

Filter Care

A sintered lter protects the humidity sensor from various airborne particles and may need periodic cleaning. To do this,

gently unscrew the lter from the probe. Rinse the lter in warm soapy water and rinse until clean. A

nylon brush may be

used if necessary. Gently replace the lter by screwing it back into the probe. The lter should screw all the way into the

probe. Hand tighten only. If a replacement lter is needed, call BAPI.

BA/HDOFS3 Stainless Steel Sintered Filter Replacement for Outside Air Units

Humidity Diagnostics

Possible Problems:

Unit will not operate

Possible Solutions:

- Check for proper supply power. (See page 2 for wiring diagram and power

specications)

rev. 02/15/18

Humidity output is at its maximum

value of 5V or 20mA

Humidity output is at its minimum

value of 0V or 4mA

Humidity reading in controller’s

software appears to be off by

more than the specied accuracy

Output Humidity Formula

4 to 20mA %RH =(mA-4)/0.16

0 to 5VDC %RH = V/0.05

Temperature Diagnostics

Possible Problems:

Controller reports Incorrect

temperature

- Make sure the humidity sensor is wired properly.

- Make sure the humidity sensor is wired properly.

- Check all software parameters

- Determine if the sensor is exposed to an external air source different from the

intended measured environment or reference device.

- Check the Humidity transmitter output against a calibrated reference such as a

2% accurate hygrometer. Measure the humidity at the sensor’s location using the

reference meter, then calculate the humidity transmitter output using the humidity

formula at left. Compare the calculated output to the actual humidity transmitter

output (see the wiring diagram on page 2 for the humidity transmitter output wire

colors). If the calculated output differs from the humidity transmitter output by more

than 5%, contact BAPI technical support.

Possible Solutions:

- Conrm the input is set up correctly in the controller’s software

- Verify that the sensor wires are not physically shorted or open

- Check wiring for proper termination

- Measure the temperature at the temperature sensor’s location using an

accurate temperature standard. Disconnect the temperature sensor wires and

measure the temperature sensor’s resistance with an ohmmeter. Compare the

temperature sensor’s resistance to the appropriate temperature sensor table on

the BAPI website. If the measured resistance is different from the temperature

table by more than 5%, call BAPI technical support. BAPI’s web site is found at

www.bapihvac.com; click on “Resource Library” and “Sensor Specs” then click on

the type of sensor you have.

Specications subject to change without notice.

4 of 4

Loading...

Loading...