Page 1

592/592-10K Room/Setpoint/Override/Comm Jack

T ermination and Troubleshooting

11/9/04

8586_ins_592_rm_set_or_cj

Termination

BAPI recommends using twisted pair of at least 22AWG and sealant filled connectors for all wire connections. Larger

gauge wire may be required for long runs. All wiring must comply with the National Electric Code (NEC) and local codes.

Do NOT run this device’s wiring in the same conduit as AC power wiring of NEC class 1, NEC class 2, NEC class 3 or with

wiring used to supply highly inductive loads such as motors, contactors and relays. BAPI’s tests show that fluctuating and

inaccurate signal levels are possible when AC power wiring is present in the same conduit as the signal lines. If you are

experiencing any of these difficulties, please contact your BAPI representative

BAPI does not recommend wiring the sensor with power applied as accidental arcing may

damage the product and will void the warranty

rev.

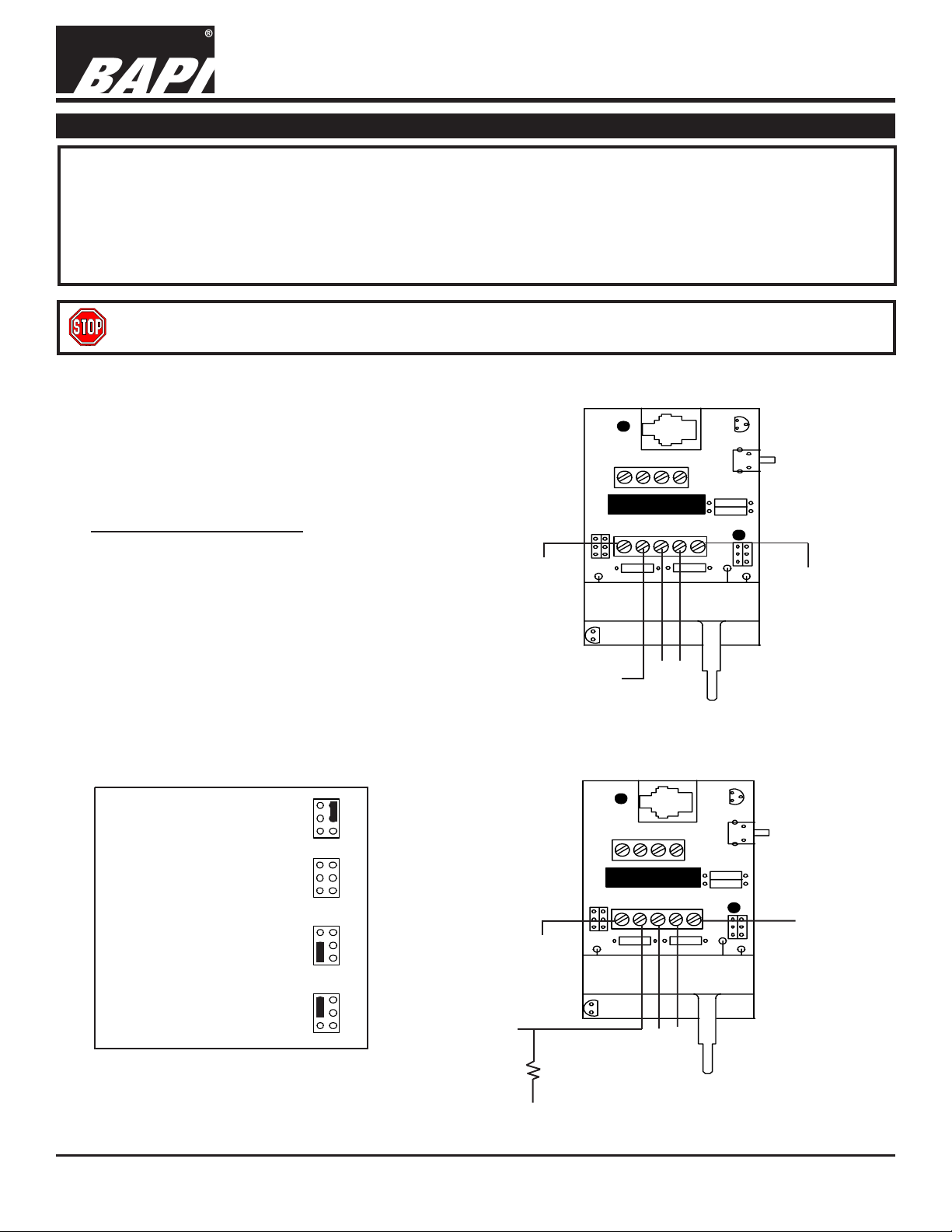

1. For 592-10K units, sensor is measured at Sen +Gnd.

For 592 units, a 10K ohm 0.1% resistor must be

installed between the controller input and ground.

2. Override (O/R) and Setpoint (Set) are with reference

to Gnd.

TERMINAL CONNECTIONS

V+ = +7 to 30 VDC input

Sen = Sensor out

O/R = Override

Set = Setpoint output, voltage(see

product label for span)

Gnd = Common for O/R and Set

TB1 = Comm jack power (+5 Volts)

TB2 = Comm +

TB3 = Comm TB4 = Comm Jack Ground

Jumper configurations (both units)

J1: Selects AD 592 sensor

J2: Override as seperate input

J2: Override//setpoint

5 to 30VDC

Sensor

Output

(10mV/°K)

5 to 30VDC

592-10K Room Sensor

TB1

J1

1

+V

Sen

4

O/R

Set

Gnd

(Override)

(Setpoint)

592 Room Sensor

TB1

O/R

Set

4

Gnd

J2

1

J1

+V

Sen

J2

Ground

Ground

J2: Override//sensor

Sensor Output

(10mV/°K)

10K ohm 0.1%

resistor

Ground

Specifications subject to change without notice.

(Setpoint)

(Override)

1

Page 2

592/592-10K Room/Setpoint/Override/Comm Jack

8586_ins_592_rm_set_or_cj

Offsetting

All BA592 sensors will have the following information provided on a label:

T ermination and Troubleshooting

11/9/04

rev.

Thermistor Reading_______

The actual temperature reading

according to a thermometer that

is certified traceable to

recognized standards by the

National Institute of Standards and

Technology (NIST).

To correct the Sensor Reading, simply add the offset value to the sensor reading so that it equals the thermometer reading.

e.g. Therm Reading 74.6 Sensor Reading 73.0 Offset +1.6

Correction: Add (+1.6) °F to the sensor for an accurate reading: 73 + 1.6 = 74.6°F

e.g. Therm Reading 75.4 Sensor Reading 77.2 Offset -1.8

Correction: Add (-1.6) °F to the sensor for an accurate reading: 77.2 + (-1.8) = 75.4°F

Sensor Reading ______

The temperature reading according

to the AD592 sensor, using the

output in either uA or V and

converting the output to a

Fahrenheit temperature.

Troubleshooting

Offset_______

The difference between the

Thermometer Reading and the

Sensor Reading.

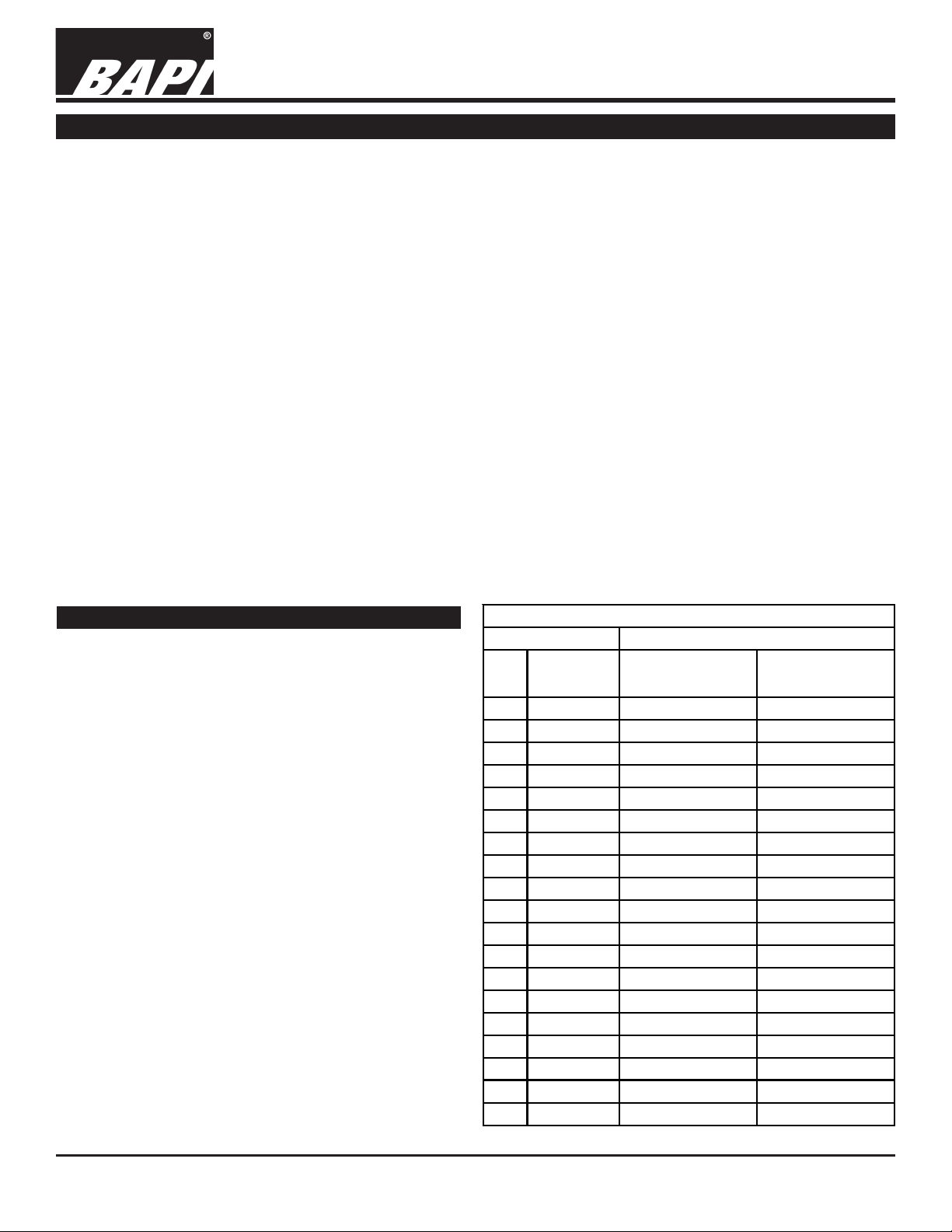

592 Output Table

Temperature 592 Semiconductor

If the unit you installed does not respond properly,

please go through the following steps:

°F °C

Output Current uAOutput Voltage

across 10KΩ

50 10.00 283.2 2.832

1. Set your meter to the V setting.

2. Measure the voltage between the “Sen” and

“GND.” See diagrams above in the Termination

section.

3. Compare the voltage reading to the voltage listed

in the output table.

4. If the sensor reads significantly lower or 0, then

your sensor may be shorted.

5. If the sensor reads significantly higher then the

sensor may be open.

6. If the sensor reads properly, verify that the

controller is operating correctly.

60 15.56 288.8 2.888

62 16.67 289.9 2.899

64 17.78 291.0 2.910

66 18.89 292.1 2.921

68 20.00 293.2 2.932

70 21.11 294.3 2.943

72 22.22 295.4 2.954

74 23.33 296.5 2.965

76 24.44 297.6 2.976

77 25.00 298.2 2.982

78 25.56 298.8 2.988

80 26.67 299.9 2.999

82 27.78 301.0 3.010

84 28.89 302.1 3.021

86 30.00 303.2 3.032

88 31.11 304.3 3.043

90 32.22 305.4 3.054

100 37.78 311.0 3.110

Specifications subject to change without notice.

2

Page 3

8586_ins_592_rm_set_or_cj

Mounting

Fig. 2

592/592-10K Room/Setpoint/Override/Comm Jack

T ermination and Troubleshooting

11/9/04

rev.

Mounting hardware is provided for both junction box and drywall installation (junction box installation shown).

Junction Box

1. Pull the wire through the wall and out of the junction box, leaving about six inches free.

2. Pull the wire through the hole in the base plate.

3. Secure the plate to the box using the #6-32 x 1/2 inch mounting screw provided.

4. Terminate the unit according to the guidelines in Termination on page 1.

5. Attach Cover by latching it to the top of the base, rotating the cover down and snapping it into place.

6. Secure the cover by backing out the lock-down screws using a 1/16" allen wrench until they are flush with the bottom

of the cover.

Drywall Mounting

1. Place the base plate against the wall where you want to mount the sensor.

2. Using a pencil mark out the two mounting holes and the area where the wires will come through the wall.

3. Drill two 3/16" holes in the center of each marked mounting hole. Insert a drywall anchor into each hole.

4. Drill one 1/2" hole in the middle of the marked wiring area.

5. Pull the wire through the wall and out of the 1/2" hole, leaving about six inches free.

6. Pull the wire through the hole in the base plate.

7. Secure the base to the drywall anchors using the #6 x 1 inch mounting screws provided.

8. Terminate the unit according to the guidelines in Termination on page 1.

9. Attach cover by latching it to the top of the base, rotating the cover down and snapping it into place.

10. Secure the cover by backing out the lock-down screws using a 1/16" allen wrench until they are flush with the bottom

of the cover.

NOTE

In a wall-mount application, the wall temperature and the temperature of the air within the wall cavity can cause erroneous

readings. The mixing of room air and air from within the wall cavity can lead to condensation, erroneous readings and

premature failure of the sensor.

T o prevent these conditions, seal the conduit leading to the junction box and use BAPI’ s adhesive backed, foam insulating

pad centered over the hole(order part number BA/FOAMBACK).

Specifications subject to change without notice.

3

Page 4

The BAPI Family of Sensors for HVAC/R

Temperature & Humidity Sensors

Temperature or Humidity Alone or Combination Sensors

Room Units • Wall Plate Units • Duct Units • Immersion Units

Thermowells • Strap Units • Outside Air Units

Room Units

Wall Plate Units

Outside

Air Units

Zone Pressure Sensors

Differential Pressure

Transmitter

Differential Pressure

Transmitter with

Air Quality Sensors

Display

Duct Units

Duct Averaging Units

Immersion Units

Accessories

Power Supplies & Voltage Converters

Sealant Filled Connectors

Field Mounting Kits & More

Room Mount

Air Quality Sensor

Duct Mount

Air Quality Sensor

VC75 Voltage

Converter

4

Loading...

Loading...