BAOSTEEL Wire Rod Service Manual

Contents

4 线材简介 Introduction to Wire Rod

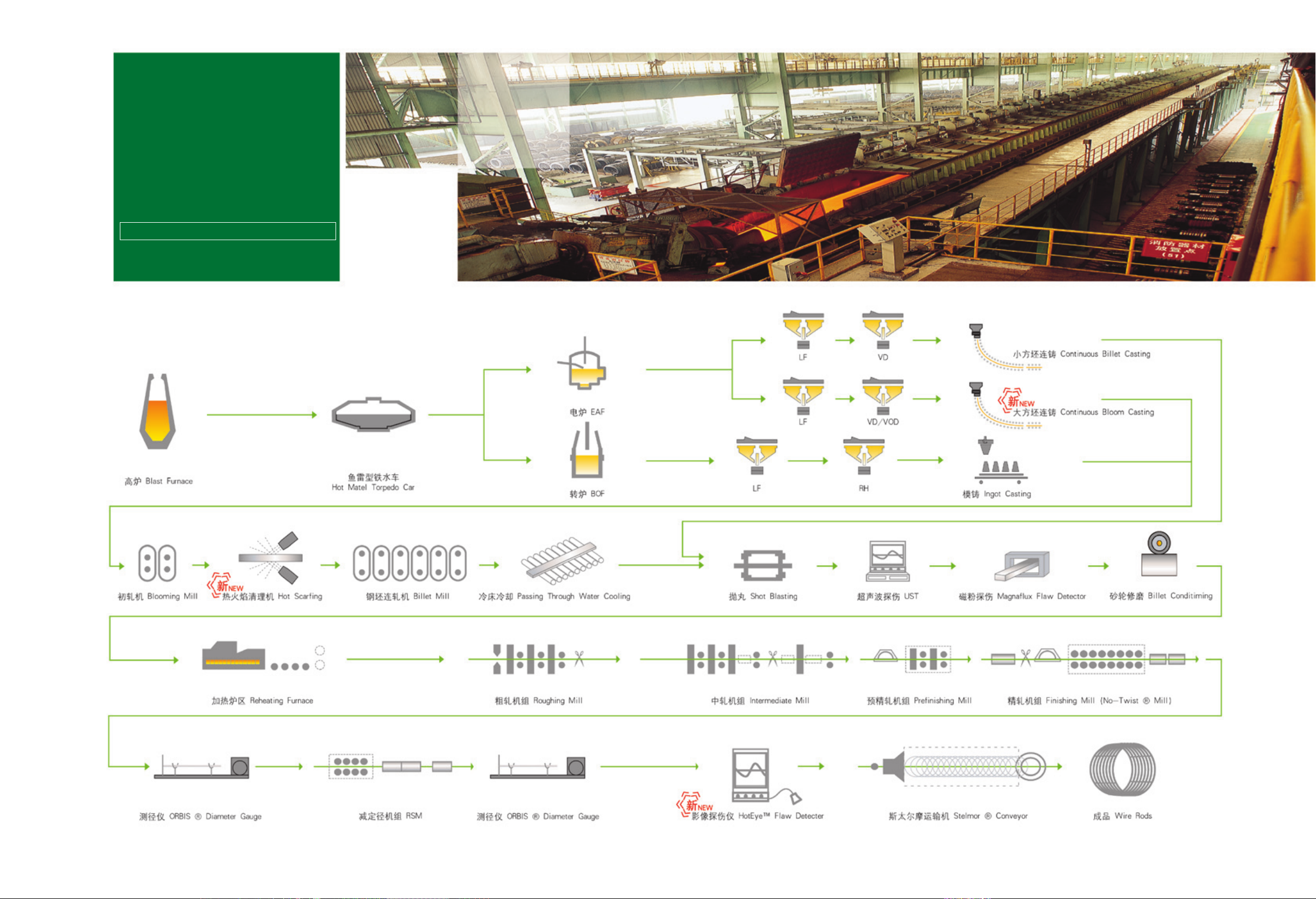

6 生产工艺流程图 Process Flowchart

8 产品牌号 Available Steel Grades

21 线材相近牌号对照 Comparison of Steel Grades

22 产品规格及偏差 Sizes and Tolerances

24 最终用途示例 Examples of Final Use

28 包装与标志 Packaging and Marking

30 认证 Certications

线材简介

Introduction to Wire Rod

宝钢 股 份 宝钢 分 公 司高 速 线 材轧

机于1999年3月 投产,目前年生产 量约

57万 吨 。 产 品规ø5.0-ø26.0mm。 主

要品 种 有帘 线 钢、 弹 簧 钢 、 冷 镦 钢、

桥梁 缆 索用 镀 锌钢 丝 、 高 碳 钢 和 焊接

用钢等。

线 材 原 料 采 用 高 炉 铁 水 和 优 质

废钢 , 经过 转 炉或 电 炉 及 精 炼 工 序的

纯 净 钢 冶 炼 技 术 生 产 , 确 保 钢 质 纯

净。 钢 坯精 整 线对 钢 坯 表 面 存 在 缺陷

进行 清 理, 确 保钢 坯 表 面 质 量 。 随着

2008年5月电炉大方坯连铸投产,线材

原料 水 平得 到 大幅 度 改 善 , 将 进 一步

提升线材实物质量。

线材 生 产 线的 主 要 设备 从 美 国摩

根公司引进,单线无扭连续生产,最大

轧制 速 度 为 120m/s。 采 用 控 制轧制和

控制冷却工艺,通过对冷却水箱水量和

斯太尔摩线冷却速度的控制可获得产品

所期 望 的组 织 和性 能 。 为 保 证 产 品表

面质量和尺寸精度,在精轧机组和减定

径机组后分别设置了影像探伤仪和测径

仪,产品尺寸精度可达 0.1mm。

宝钢 分 公 司质 量 管 理采 用 一 贯质

量管理方式,对产品系列从原料入厂直

至产品出厂进行以质量为中心的全过程

最优化控制,并借助先进的质量控制方

法不断改进产品质量。

宝 钢 分 公 司 生 产 的 汽 车 用 帘 线

钢、弹簧钢、冷镦钢以及桥梁缆索用镀

锌钢丝在国内知名企业和重大工程中广

泛获得应用,多次获得上海市和国家科

技进步奖。

The high-speed wire rod mill of Baosteel

Branch (the largest branch of Baosteel

Co., Ltd) began production in March 1999

and rolls plain rod from 5.0mm to 26mm

with production capacity of up to 570,000

tonnes per year. The major products involve wire rod for tire cord, spring steel

wire rod, steel wire rod for cold heading

and cold forging, galvanized wire for bridge

cables, high carbon steel wire rod, wire rod

for welding, etc.

Raw materials for wire rod include blast

furnace hot metal and high quality scraps.

Rening processes after BOF or EAF ensures the cleanliness of steel. The flaws

are cleaned up on the billet conditioning

line in order to obtain high surface quality.

With the commissioning of new continuous

bloom casting process in May 2008, the

practical quality could be further upgraded

due to the great improvement of the raw

materials for wire rod.

The main rolling equipments of mill are

supplied by Morgan Construction Company and the rolling line is single-strand with

maximum nishing speed of 120 meters

per second. Perfect microstructures and

mechanic properties are gained through

controlling water boxes and Stelmor Cooling System. In order to ensure accurate

diameter with a tolerance of +/-0.1mm and

high surface quality, one HotEye flaw detector and two ORBIS diameter gauges

are located after the No-Twist Finishing

Mill and Reducing/Sizing Mill.

Integrating Quality Control is applied

throughout the entire manufacturing processes from the handling of raw materials

to the delivery of nished products to guarantee full customer satisfaction. At each

stage of production from steelmaking to

rolling of wire rod, improvements of product quality are ensured.

Top quailty wire rod products manufactured

are put into use widely in many well-known

domestic enterprises and local key projects. These products have also won lots of

honors in Shanghai as well as numerous

national science and technology progress

awards were given to the company in honor of these products.

4 〉 Wire Rod

Wire Rod 〈 5

6 〉 Wire Rod

Process Flowchart

生产工艺流程图

8 〉 Wire Rod

Wire Rod 〈 9

产品牌号

1.1、焊接用钢盘条 (Q/BQB 511) Wire Rod for Core Wire of Covered Electrodes (Q/BQB 511)

牌号

Grade

化学成份 (成品) % Chemical Composition (Finished Product) %

C Si Mn P S

其它 Others

SWRY11

≤0.09 ≤0.03 0.35-0.65 ≤0.020 ≤0.023 Cu:≤0.20

ER70S-6 0.06-0.15 0.80-1.15 1.40-1.85 ≤0.025 ≤0.035

H10Mn2 ≤0.12 ≤0.05 1.50-1.90 ≤0.035 ≤0.035

BH10Mn2G ≤0.17 ≤0.05 1.80-2.20 ≤0.030 ≤0.030

Ni:≤0.30,Cr:≤0.20

H08MnA ≤0.10 ≤0.05 0.80-1.10 ≤0.030 ≤0.030

H08Mn2SiA ≤0.11 0.70-0.95 1.80-2.10 ≤0.030 ≤0.030

BH08MnMoTiB ≤0.11 ≤0.25 1.40-1.60 ≤0.030 ≤0.030

Mo:0.30-0.60,Ti:0.03-0.08

B:0.004-0.008

BH08Mn2E ≤0.10 ≤0.07 1.50-1.90 ≤0.025 ≤0.020

Ni:≤0.25,Cu:≤0.20,Cr:≤0.20

BH08MnNiA ≤0.10 0.35-0.60 1.20-1.60 ≤0.025 ≤0.025

Cu:≤0.20,Cr:≤0.20

Ni:0.30-0.60

H08MnSiCuCrNi ≤0.10 0.35-0.65 0.90-1.30 ≤0.025 ≤0.025

Cu、Cr、Ni:0.20-0.50

1.2、焊接用钢盘条 (协议) Wire Rod for Core Wire of Covered Electrodes (Agreement)

牌号

Grade

化学成份 (成品) % Chemical Composition (Finished Product) %

C Si Mn P S

其它 Others

ER70S-G

≤0.10 0.65-0.85 1.40-1.60 ≤0.025 0.008-0.020

Ti:0.08-0.25,Cu:≤0.10,TAl:≤0.10

BH550NQ-II ≤0.10 ≤0.60 1.2-1.60 ≤0.025 ≤0.020

Cu:0.10-0.40,Cr:0.40-0.80

Ni:0.20-0.60,Ti:0.035-0.080

BH600-II ≤0.10 ≤0.70 1.30-1.60 ≤0.020 ≤0.012

Ni:0.20-0.38,Mo:0.20-0.38

Ti:0.05-0.12,Cu:≤0.12

Cr:≤0.12,TAL:≤0.020

BH700-II ≤0.11 ≤0.70 1.50-1.80 ≤0.020 ≤0.012

Ni:0.60-0.90,Mo:0.20-0.38

Ti:0.08-0.16,Cu:≤0.12

Cr:0.10-0.30,TAL:≤0.020

BH500J-Ⅲ

0.08-0.15 ≤0.20 1.80-2.20 ≤0.020 ≤0.012 Ni:0.08-0.25

BH500NHY3-Ⅲ

≤0.11 ≤0.25 1.20-1.50 ≤0.020 ≤0.012

Ni:0.28-0.46,Mo:0.10-0.30

Ti:0.02-0.08,Cu:0.05-0.20

Cr:0.66-0.90,TAL:≤0.020

ER55-D2-Ti 0.05-0.10 0.40-0.80 1.20-1.60 ≤0.025 ≤0.025

Ti:0.05-0.15,Mo:0.20-0.35

Cu:≤0.20

BH70GX-Ⅲ 0.06-0.10 0.15-0.35 1.50-1.70 ≤0.015 ≤0.005

Ti:≥0.081,B:35-65 ppm

Cu:≤0.10,Mo:0.30-0.40

N:≤80 ppm

ER80S-B2 ≤0.12 0.60-0.90 1.00-1.50 ≤0.025 ≤0.020

Mo:0.45-0.65,Cr:1.00-1.20

Ni:≤0.25,Cu:≤0.15

ER69-3 ≤0.12 0.40-0.80 1.25-1.80 ≤0.020 ≤0.020

Mo:0.20-0.55,Ti:≤0.20

Ni:0.60-1.10,TAl:≤0.10

,

Cu:≤0.35

BH08Mn2SiTiB ≤0.10 0.55-1.10 1.65-1.95 ≤0.025 ≤0.009

Cu:≤0.10,N:≤80 ppm

Ti:0.08-0.18,B:0.0035-0.0060

Available Steel Grades

10 〉 Wire Rod

Wire Rod 〈 11

3.1、高碳钢盘条 (Q/BQB 512) High Carbon Steel Wire Rod (Q/BQB 512)

牌号

Grade

化学成份% Chemical Composition %

C Si Mn P S

SWRH32

0.29-0.36 0.15-0.35 0.30-0.60 ≤0.030 ≤0.030

SWRH42A 0.39-0.46 0.15-0.35 0.30-0.60 ≤0.030 ≤0.030

SWRH42B 0.39-0.46 0.15-0.35 0.60-0.90 ≤0.030 ≤0.030

SWRH47A 0.44-0.51 0.15-0.35 0.30-0.60 ≤0.030 ≤0.030

SWRH47B 0.44-0.51 0.15-0.35 0.60-0.90 ≤0.030 ≤0.030

SWRH52A 0.49-0.56 0.15-0.35 0.30-0.60 ≤0.030 ≤0.030

SWRH52B 0.49-0.56 0.15-0.35 0.60-0.90 ≤0.030 ≤0.030

SWRH57A 0.54-0.61 0.15-0.35 0.30-0.60 ≤0.030 ≤0.030

SWRH57B 0.54-0.61 0.15-0.35 0.60-0.90 ≤0.030 ≤0.030

SWRH62A 0.59-0.66 0.15-0.35 0.30-0.60 ≤0.030 ≤0.030

SWRH62B 0.59-0.66 0.15-0.35 0.60-0.90 ≤0.030 ≤0.030

2、低碳钢盘条 (Q/BQB 513) Low Carbon Steel Wire Rod (Q/BQB 513)

牌号

Grade

化学成份% Chemical Composition %

C Si Mn P S

SWRM6

≤0.08 ≤0.03 ≤0.60 ≤0.035 ≤0.035

SWRM6-1* ≤0.06 ≤0.03 ≤0.60 ≤0.035 ≤0.035

SWRM8 ≤0.10 ≤0.03 ≤0.60 ≤0.035 ≤0.035

SWRM10 0.08-0.13 ≤0.03 0.30-0.60 ≤0.035 ≤0.035

SWRM12 0.10-0.15 ≤0.03 0.30-0.60 ≤0.035 ≤0.035

SWRM15 0.13-0.18 ≤0.03 0.30-0.60 ≤0.035 ≤0.035

SWRM17 0.15-0.20 ≤0.03 0.30-0.60 ≤0.035 ≤0.035

SWRM20 0.18-0.23 ≤0.03 0.30-0.60 ≤0.035 ≤0.035

注 Notes:*按照协 议供货

*Accordin g to t he technial agree ment r eached by the Sel lers a nd the Buyers.

Loading...

Loading...