BAOSTEEL SLAB PRODUCTS Service Manual

CC

C

CC

AA

A

AA

TT

ALAL

OG OF SLOG OF SL

T

AL

OG OF SL

TT

ALAL

OG OF SLOG OF SL

http://www.baosteel.com

AB PRAB PR

AB PR

AB PRAB PR

ODUCTODUCT

ODUCT

ODUCTODUCT

SS

S

SS

Customer satisfaction is enterprises soul

Contents

1

2

3

4

4.1

4.2

4.3

5

5.1

5.2

5.3

5.4

5.5

5.6

5.7

Corporation Profile

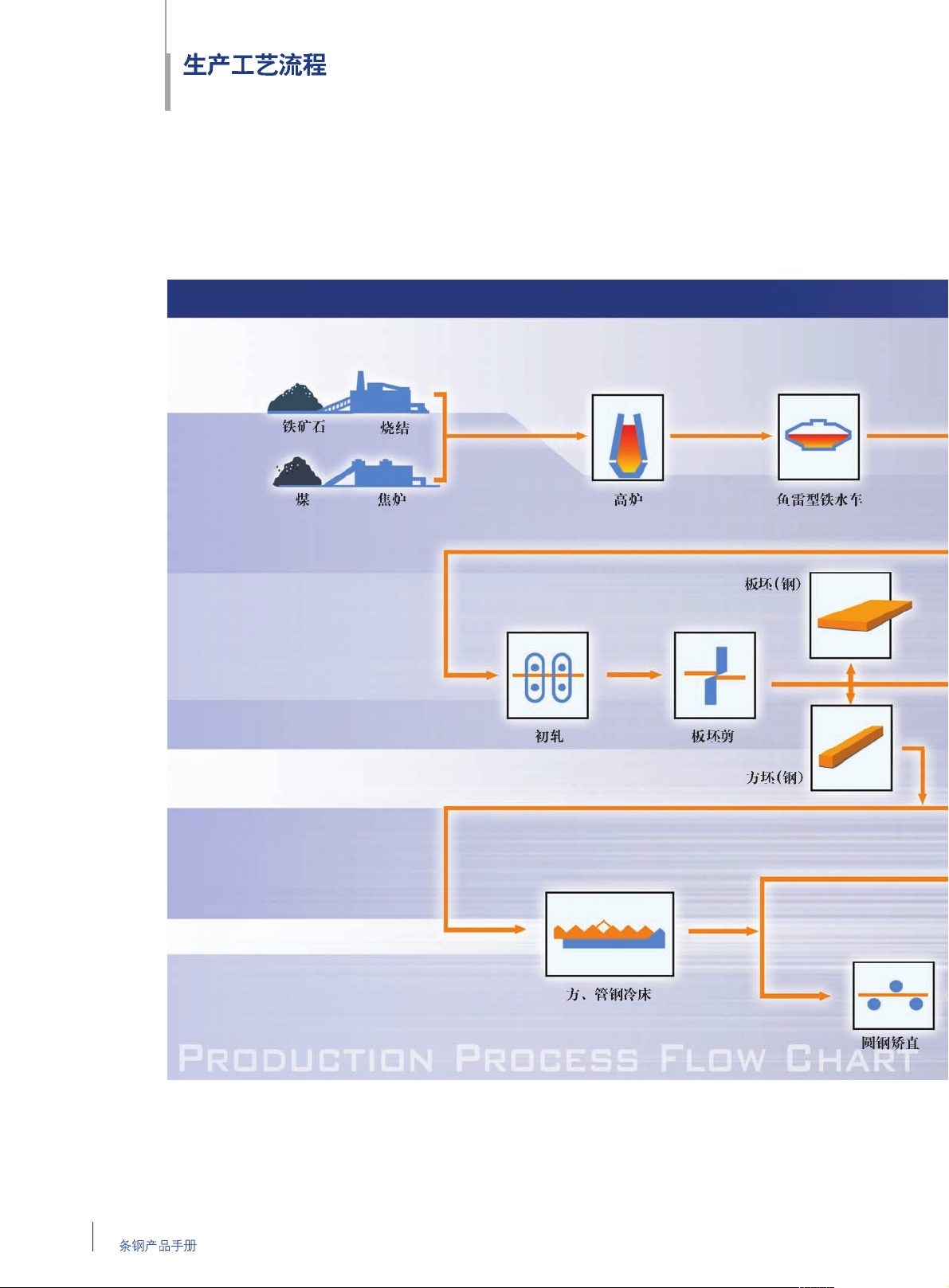

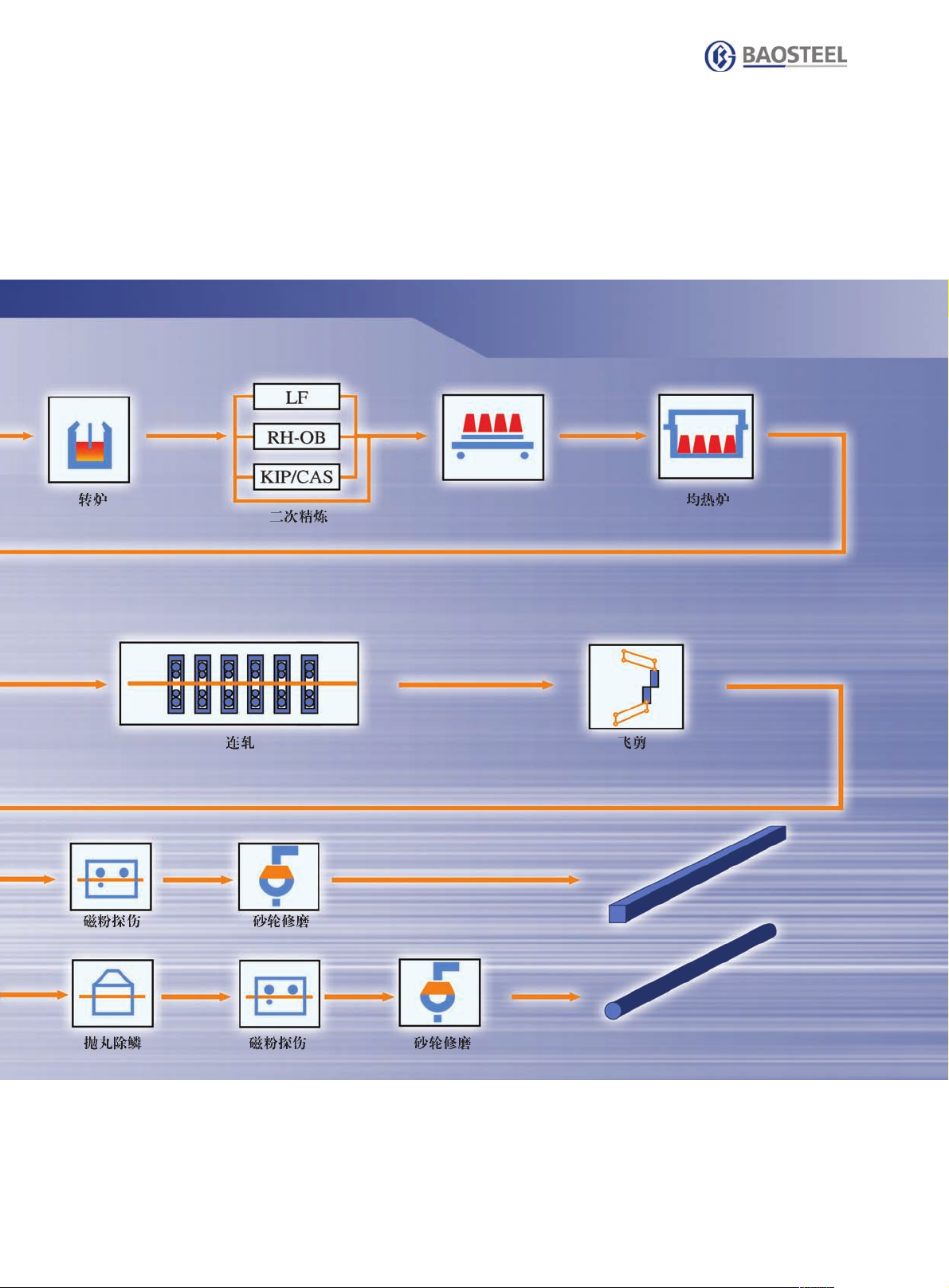

Production Process Flow Chart

Introduction to Long Steel Products

Semi-Finished Products

Rolled Slab

Rolled Square Billet

Round Billet for Seamless Tube

Steel for Special Application

Bloom for Train Axle

Bloom for gas cylinder

Mould and Die Steel

Round Billet for Gear

Steel for Driving Shaft

Mandrel Bar

Steel for Drill Rod Joint

2

4

6

8

9

11

13

14

15

17

19

23

26

27

28

6

7

8

Ordering Information

Standardization Association

Unit Conversion

30

32

33

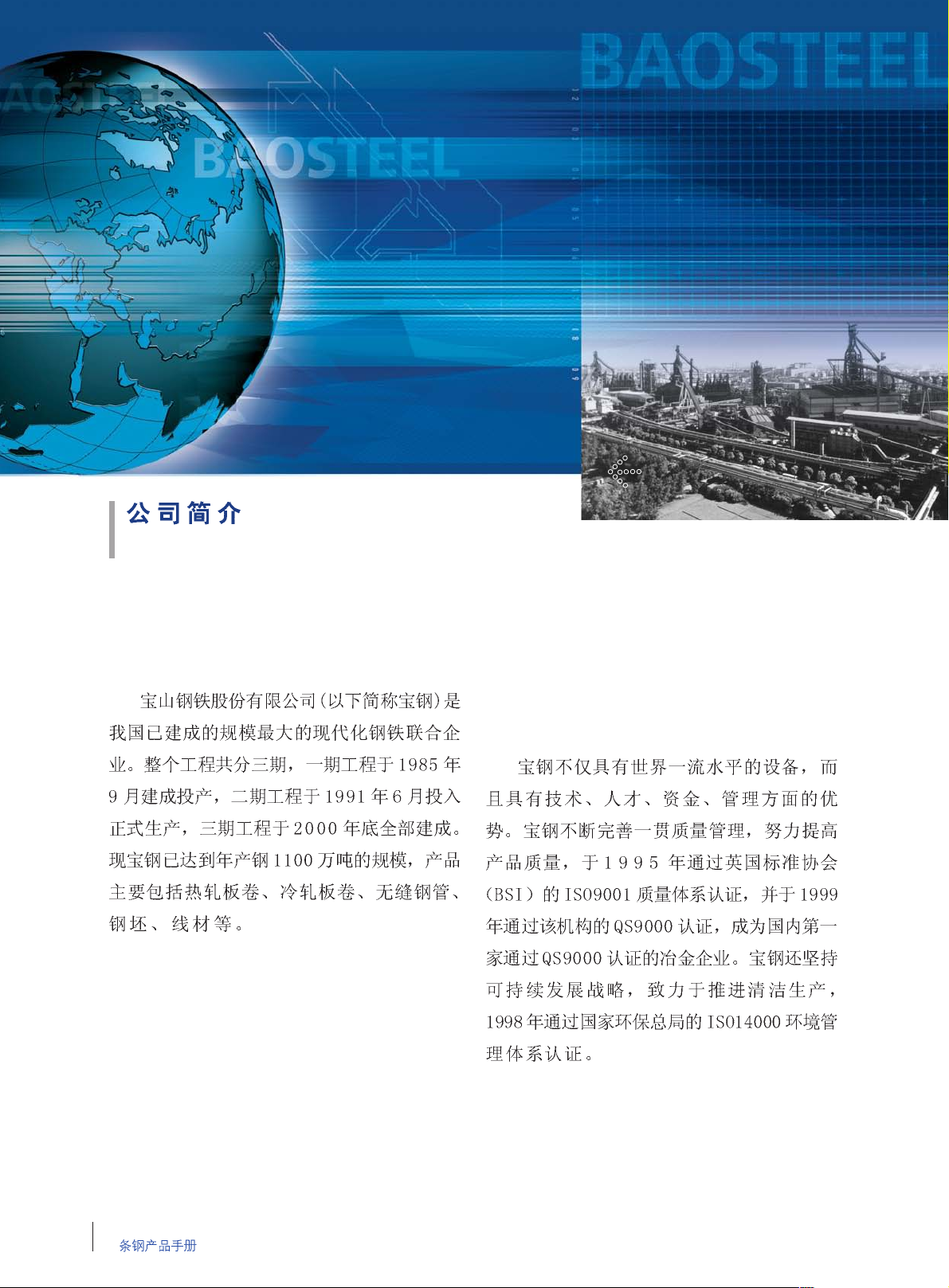

Corporation Profile

3

2

LONG STEEL PRODUCTS

Corporation Profile

Baoshan Iron & Steel Co., Ltd. (Baosteel) is the largest modern

iron and steel enterprise in China. Its construction has experienced

three phases projects: Phase I was completed and put into operation

in Sep. 1985; Phase II started the production in Jun. 1991 and Phase

III got completely built up by the end of 2000. Now, it has reached

the capacity of 11 million of steel. Its main products cover: hot rolled

sheet, cold rolled sheet, seamless steel tube, billet and bloom and wire

rod as well.

Baosteel is well-known not only for its worldwide top class

equipment, but also for its advantage in technology, talent, fund and

management. It has kept perfecting its through-going quality control,

striving to improve its product quality. In 1995, it passed the certifica-

tion of ISO9001 conducted by BSI and in 1999, it got the certification

of QS9000 of the same mechanism, thus becoming the first domestic

steel-maker with certificate of QS9000. Yet, Baosteel persistently ap-

plies the strategy of sustainable development, devotes itself to the

clean production. In 1998, it passed the certification of ISO14000 en-

vironment management system of the State Environment Protection

Bureau.

2

PRPR

ODUCTION PRODUCTION PR

PR

ODUCTION PR

PRPR

ODUCTION PRODUCTION PR

OCESS FLOCESS FL

OCESS FL

OCESS FLOCESS FL

OO

W CHARW CHAR

O

W CHAR

OO

W CHARW CHAR

TT

T

TT

Iron Ore

Coal Coke Oven Blast Furnace

Sintering

Hot Matel Torpedo Car

Slabs

Slab ShearBlooming Mill

Billet

Cooling Bed for Square and

Round Billet

Bar Straightening

5

4

LONG STEEL PRODUCTS

PRPR

PR

PRPR

ODUCTIONODUCTION

ODUCTION

ODUCTIONODUCTION

Converter

PR PR

PR

PR PR

Secondary Refinery

OCESS FLOCESS FL

OCESS FL

OCESS FLOCESS FL

OO

O

OO

W CHARW CHAR

W CHAR

W CHARW CHAR

Soaking Furnace

TT

T

TT

Magnetic Powder Inspection

Throw Shot Cleaning

Tandem Mill

Sand Wheel Grinding

Magnetic Powder Inspection Sand Wheel Grinding

Fly Shear

3

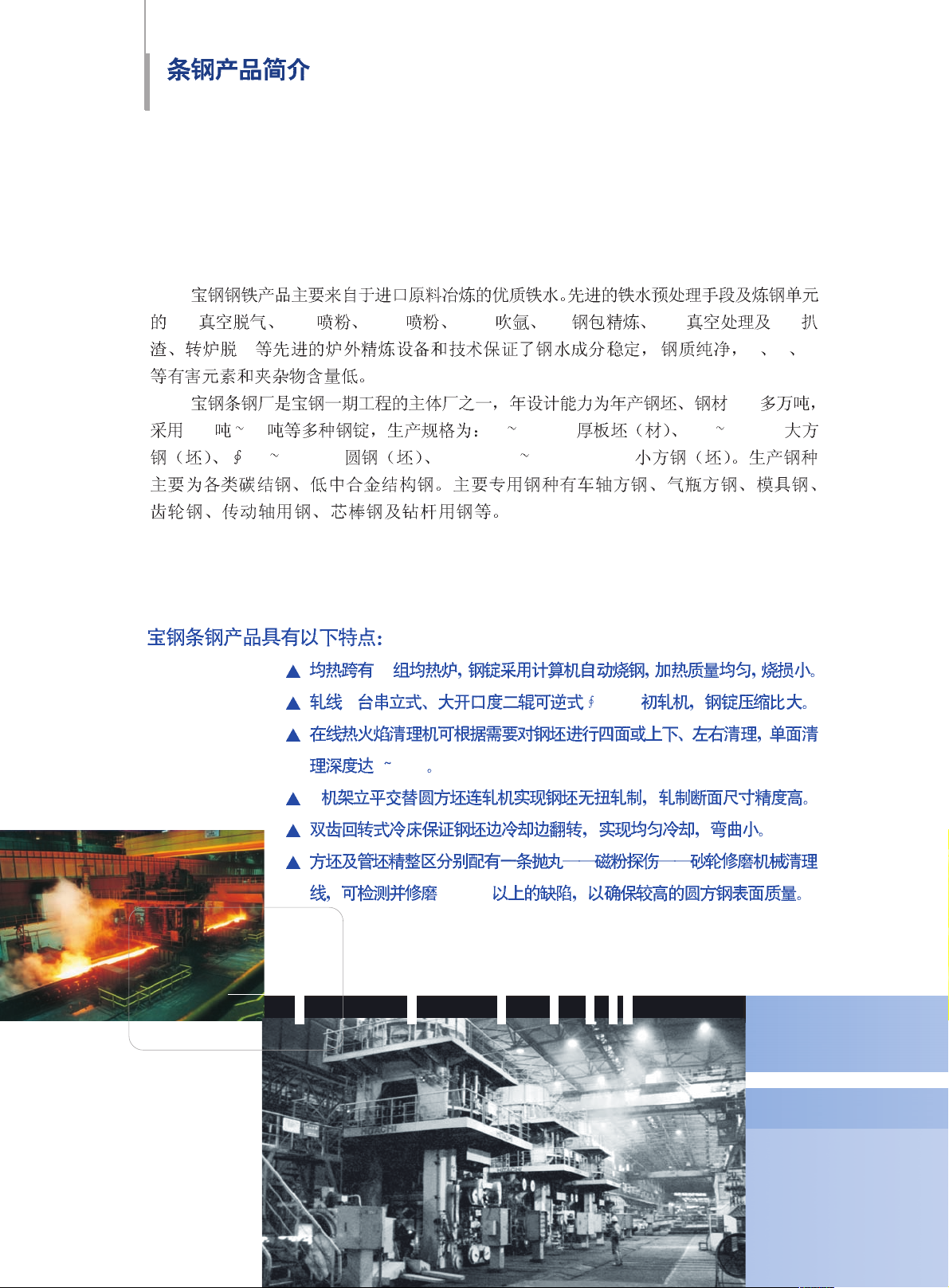

BRIEF INTRODUCTION OF

LONG STEEL PRODUCTS

RH KIP KST CAS LF VD DS

P S P N

300

6.5 28 50 500mm 180 280mm

75 185mm 90*90mm 175*175mm

10

2 1300

1 3mm

6

0.3mm

Baosteel's iron and steel products are mainly made from high-quality hot metal melted by imported raw materials.

Advanced hot metal pre-treatment means and sophisticated secondary refining equipment and technologies including

RH vacuum degassing in steel making , KIP powder injection, KST powder injection, CAS argon blowing, LF refining,

VD treatment and de-slagging ensure a stable composition of liquid steel, clean quality of steel and low content of

harmful elements and inclusions such as S, P and N.

Baosteel Long-product Mill is one of the main mills in Baosteel Phase I Project. The designed annual

production capacity is over 3 million tons of steel slab, using various kinds of ingots weighted 6.5 ~ 28 t, with

specifications of 50 ~500mm of heavy plate (product), 180~280mm of bloom,

75~185mm round billet and

90*90mm~175*175mm billet. Steel grades produced are mainly various kinds of carbon structure steel, low

and medium alloy structure steel, Special steel Products are car bloom for train axle, bloom for gas cylinder,

mould and die steel, round billet for gear, steel for driving shaft, mandrel bar and steel for drill rod joint.

Key equipment and features of Long-product Plant are:

Soaking bay has 10 soaking furnaces. Ingot can be controlled for reheating automatically by

computer. Heating quality is even and reheating loss is low.

There are 2 cascade and vertical, large opening and two-roll reversing

1300 blooming mills.

Reduction ratio of ingot is large.

On-line scarfing machine can clean four sides of slab or up and down and right and left with

cleaning depth on single surface up to 1~3mm.

6 stands of vertical and horizontal round and square billet continuous rolling mill can realize non-

twist rolling with high accurate rolling cross-section size.

Double tooth rotary cooler can ensure that while being cooled, slab can rotate, realizing even

cooling and small bending.

In billet and tube billet finishing zone, there is a mechanical cleaning line of shot-blasting -

magnetic powder flaw detection - sand wheel grinding, which can detect and grind defects

above 0.3mm to guarantee high surface quality of round and square billet.

LONG STEEL PRODUCTS

76

Steel Slab

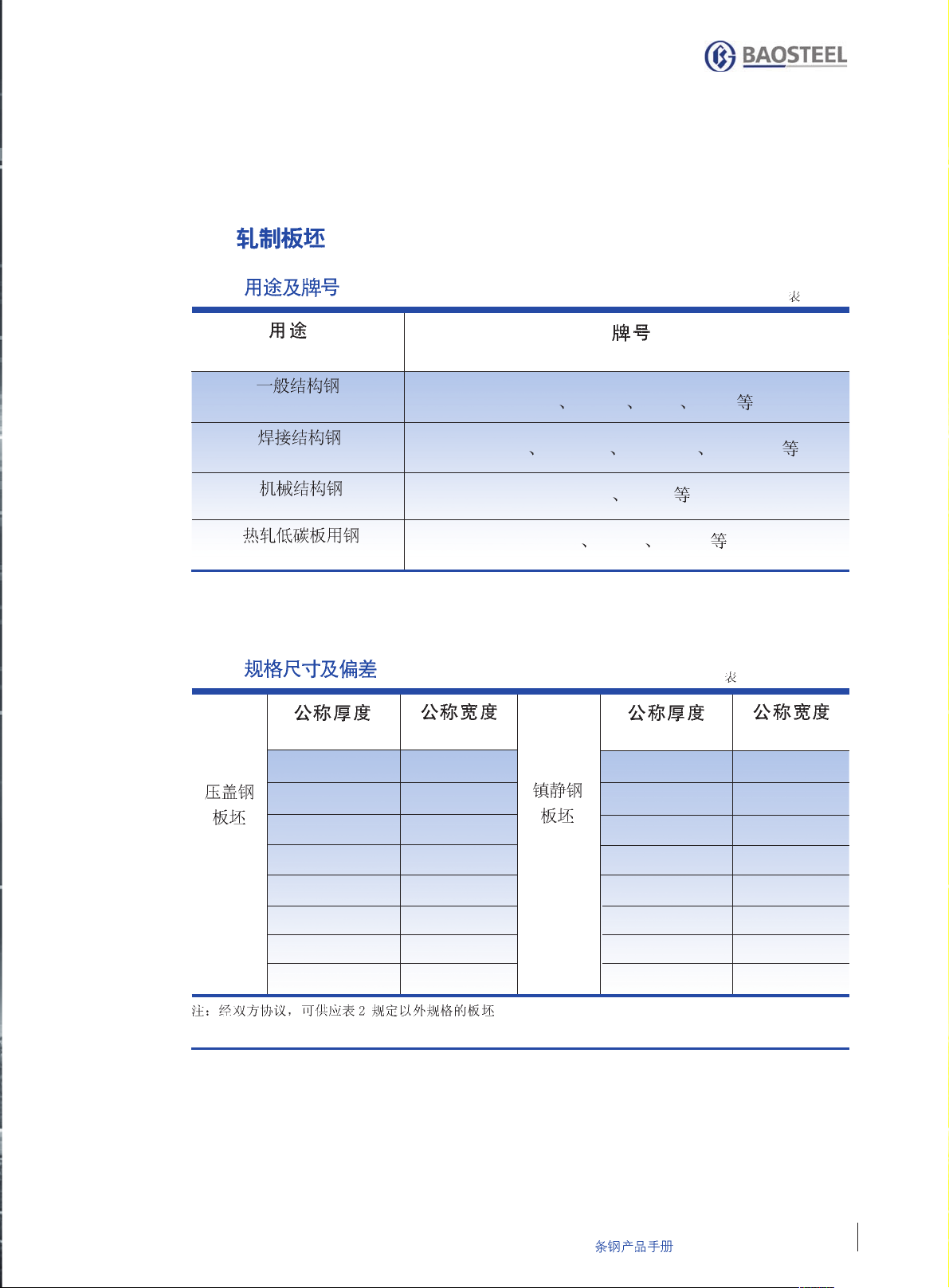

4.1. Slab

4.1.1. Applications and Grades

Application

Normal structural steel

Welding structural steel

Mechanical structural steel

Hot rolled low carbon steel

SS400 SS490 St37 St44

SM490A SM490B SM50B-1 SM502B

SPHC SPHD SPHE

Grade

S20C S35C

4.1.2. Specifications and dimension

Nominal thickness

Nominal width

Nominal thickness

(Table) 1

(Table) 2 Unit: mm

Nominal width

120

150-180

180-200

Gland

steel billet

240

250

250

250

250

Note: The billet beyond the specifications in Table2 can also be supplied through mutual agreement.

650-800

900-1150

900-1150

1500-1600

650

700-800

900-1000

1350-1450

Killed steel

billet

120

150-180

180-210

220

230

240

250

900-1150

900-1150

900-1150

1050, 1100, 1150

1350-1600

900-1100

1350

LONG STEEL PRODUCTS

9

8

Loading...

Loading...