www.baolong.biz

www.digitire.com

TM

TPMSTPMS

DIGITIRE

TPMS-201TPMS-201

User s GuideUser s Guide

用户手册(简体中文)用户手册(简体中文)

71,Maosheng Rd.,Dongjing ,Songjiang,Shanghai 201619,China

T el: +86-21-57690000 Fax: +86-21-57690035

Shanghai Baolong Industries Corporation

E-mail:sbic@chinabaolong.net

Part Nr.

TPMS-201A

TPMS-201B

TPMS-201C

Shanghai Baolong Industries Corporation reserves the right to change the

contents of this manual at any time and without notice. The information contained

in this manual is proprietary and must not be reproduced without prior written

consent from Shanghai Baolong Industries Corporation.

PSI Bar Kpa

29~35

36~42

43~51

2.0~2.4

2.5~2.9

3.0~3.5

200~249

250~299

300~350

Standard cold inflation pressure

This product requires a trained technician to install or

remove. Ensure that you follow the User's Guide closely. Any

incorrect installation or removal may damage the product.

Whenever you hear “ Beep-Beep” or “ Beep-BeepBeep” beeping sound, or see an or an on the

display, you must pull the vehicle over to a safe area where

you can check and correct the problem.

Dear customers,

Please use the serial number shown below to register

on our website www.digitire.com. This will help you to

use the following services:

1. Timely after-sale service;

2. Promotional information on all our products;

3. Communication among the Digitire TPMS users.

1 Brief introduction

CONTENT

2 How the system works

3 Installation manual (For professional user only)

3.1 Installation of sensor

3.2 Installation of antenna

3.3 Installation of receiver

3.4 Installation of display

3.5 How to remove the sensor

4 Key functions and operation guidelines

4.1 Key functions

4.2 Data display

4.3 Warning signals

4.4 Resetting the system

4.5 ID Module checkout

4.6 Changing wheel positions

4.7 Replacing a sensor

5 Trouble shooting

6 Specifications of the product

7 The authentication announcement for Europe and

North America, and the corporation's declarations

7.1 FCC's authentication announcements

7.2 European regulations announcements

7.3 Product Application and warnings

8 Others

9 Warranty

1

2

3

3

7

7

8

9

10

10

11

12

14

14

16

17

18

19

20

20

21

22

23

24

1 Brief Introduction

Thank you very much for choosing Digitire TPMS. As a

reliable vehicle proactive safety device, it provides real-time

monitoring of all the tires, including air pressure and

temperature. It will give warnings about abnormal conditions

such as slow leakage, rapid leakage, low pressure, high

pressure and high temperature. In addition, Digitire TPMS

can identify its corresponding components easily after wheel

change or sensor change.

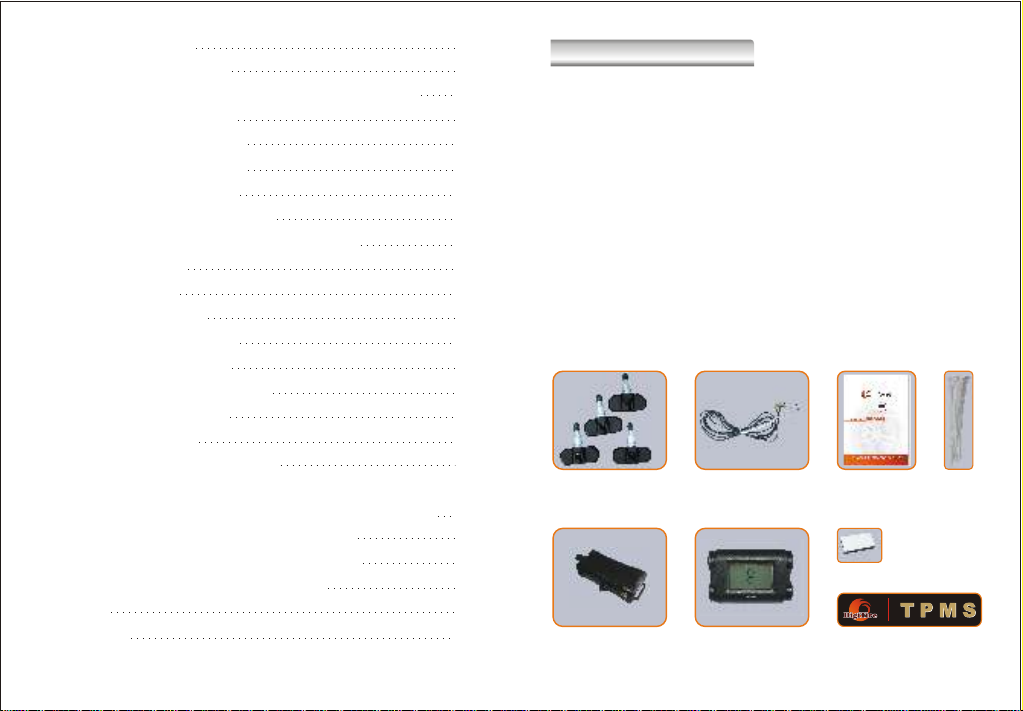

The whole package consists of the components as follows:

Four sensors Two antennas

A display

A receiver

User's guide

Two double-sided

sticky tapes

A sticker

Strips

1

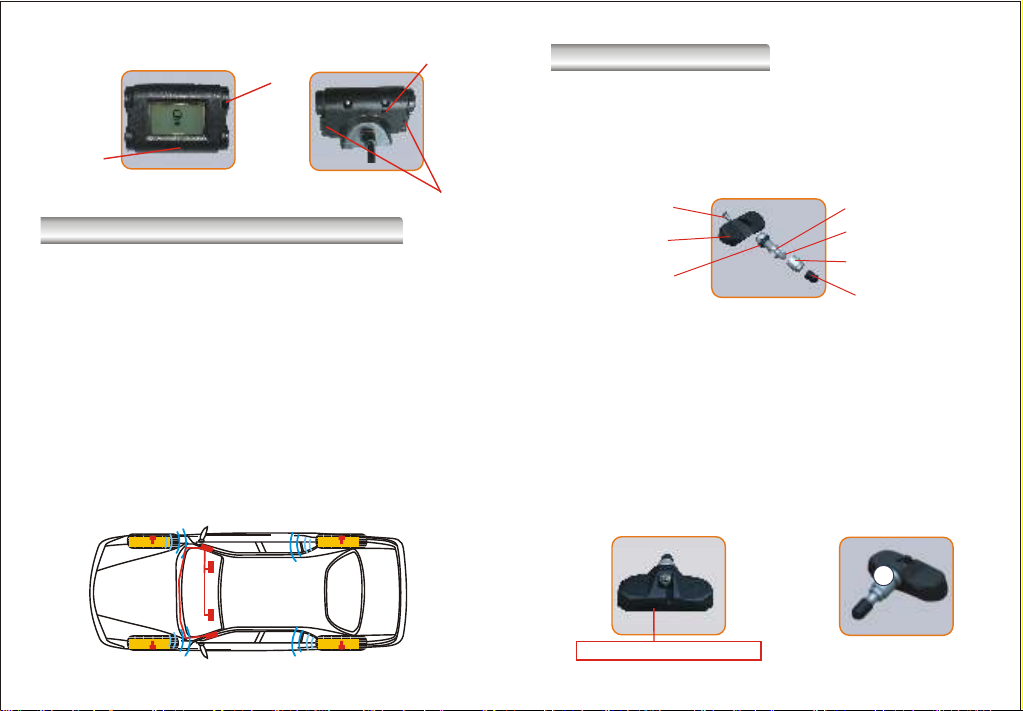

Display detailed key :

C

ID module

RESET Key

3 Installation Manual

(For professional technicians only, end users can skip this section and go directly

to #4, Key Functions and Operation Guidelines)

Key button

Front surface Reverse side

Holding key

2 How the system works

A sensor is installed with the valve stem in each wheel,

monitoring the pressure and temperature conditions inside

each wheel of the vehicle, and wirelessly sends the data it

collects to the receiver through two antennas. The receiver

then transfers the data by wire to the display, which is

installed on the dashboard and digitally displays the pressure

and temperature.

The system continuously analyzes the data to detect any

abnormal conditions. It will trigger different alarm settings to

report various abnormal conditions.

Sensor

Sensor Sensor

Antenna

Receiver

Dispiay

Antenna

Sensor

3.1 Installation of sensor

①Self-lock screw

②Electronic module

③Valve stem

④Plastic washer

⑤metal washer

⑥Nut

⑦Valve cap

Before installation, make sure you identify each sensor (A, B,

C and D) respectively. Each sensor has its own electronic

module and nut. For example, you can easily distinguish the

“C” electronic module because the letter “ C” is at the

very end of the S/N. (e.g. T5200-SM5300-050816-015B-C).

Each nut also has an engraved letter that show which

sensor it belongs to.

T5200-SM5300-050816-015B-C

32

Each sensor has a corresponding ID module. With four ID

7

12

modules mounted on two sides, the display resembles a

vehicle with four wheels. The ID modules should be placed

in the same positions on the display as the corresponding

sensors are installed on the vehicle. For instance, if the

“C” sensor is installed in the left rear wheel position, then

the corresponding “C” ID module has to be placed in the

“left rear wheel” position on the display. The manufacturer

has set as the default that A, B, C and D ID modules are

placed respectively on the Left Front Wheel (LFW), Right

Front Wheel (RFW), Left Rear Wheel (LRW) and Right Rear

Wheel (RRW).

3.1.1 Use a self-locking screw ① to join

electronic module ② and valve stem ③

together. The assembly is adjustable to fit the

various angles of the rims.

3.1.2 Insert the valve stem through the rim hole

from inside. Adjust the angle between the valve

stem and the electronic module to fit the rim

properly, and then screw tight the valve stem.

3.1.3 Place plastic washer ④,metal washer

⑤ and nut ⑥ on the valve stem, and tighten

with 3.5~4.5Nm (30~40inch pounds) torque.

A

B

A

B

3.1.4 Lock the rim on the tire changer. (If the

mounting head of the tire changer is

positioned at 12 o'clock, then the valve

C

C

D

D

should be at the 7 o'clock position.) Apply

lubricant on both tire bead and rim. Mount the

lower tire bead on the rim. Ensure that the tire bead does not

touch the electronic module during mounting.

54

3.1.5 Mount the upper tire bead the

5

12

Recciver

same way. (If the mounting head of the

tire changer is positioned at 12 o'clock,

then the valve should be at the 5

o'clock position.) Inflate the tire to

nominal pressure.

3.1.6 Apply soapsuds on the valve tip. If

no leakage is found, put on the valve

cap ⑦.Otherwise determine the reason

for the leakage and reinstall this sensor.

3.1.7 Dynamic balance the wheel

before it is put back on the vehicle.

3.2 Installation of antenna

3.2.1 Installing the antenna

Place the two antennas underneath the

rubber layers of the two 'A' posts along

the fringe of the Dashboard.

3.2.2 Place the cable of the antenna

along the front edge of the dashboard.

3.3 Installation of receiver

3.3.1 Tighten the connecting nut of

the antenna cable to the receiver only

finger tight. Do not twist the cable.

Connecting nut

Use the same procedures to install the other three

sensors. Please install A, B, C, and D sensors on the

Left Front Wheel (LFW), Right Front Wheel (RFW), Left

Rear Wheel (LRW) and Right Rear Wheel (RRW)

respectively.

3.3.2 Remove the cover on the side of

the dashboard or below the dashboard.

Align all receiver cables. Fasten the

receiver on the metal frame inside the

dashboard with a strap or double-sided tape.

76

11

12

-

12

3.3.3 Now, if correctly connecting the

+

red wire and the blue wire from the

receiver with the positive power cable

out of battery and the negative

ground in the circuit board of the car

respectively, the screen background

will be lighted up in blue and

displaying “000”at the four corners

in the display. Then, the joint

connecting wires should be safely

wrapped with friction tape.

3.3.4 Tie up all the cables with a strap and put in the

compartment. Then replace the dashboard cover.

3.4 Installation of display

Fix the display unit on the dashboard

with double-sided tape. Do not block

the driver's view. Pay attention to the

viewing angle of the display.

3.5 How to remove the sensor

(When removing or replacing a sensor and taking off

or changing the tire from the rim of the wheel)

3.5.1 Deflate the tire and remove the

>90

wheel weights from the rim. Push the

tire bead away from the rim. Make

sure to always set the bead breaker

at least 90 degrees from the valve stem to avoid

damaging the electronic module.

3.5.2 Firmly fix the wheel on the

turntable clamps. (If the mounting

head of the tire changer is positioned

at 12 o'clock, then the valve stem

should be at the 11 o'clock position.)

Apply lubricant to both tire bead and

rim, and then dismount the upper tire bead.

3.5.3 Use the same procedure to

dismount the lower tire bead. (If the

mounting head of the tire changer is at

the 12 o'clock position, then the valve

should also be at the 12 o'clock

position.)

98

3.5.4 Final inspection: Visually inspect the rim, valve

stem and electronic module to ensure no damage has

occurred.

The little screen is displaying as follows:

LFW pressure

(or T emperature)

Pressure unit Temperature unit

Leakage icon

RFW pressure

(or T emperature)

4 Key Functions and operation guidelines

4.1 Key functions

4.1.1 The sensors continuously monitor the air pressure

and temperature of the tires.

4.1.2 When tire pressures and temperatures are all at

normal settings, the sensor will transmit data to the

receiver at eight-minute intervals. Every time the

display receives the latest data, it will refresh and

display the tire pressures and temperatures of all four

tires.

4.1.3 If the sensor detects any abnormal condition, it

will immediately send the signals to the display. The

display will instantly give an alarm and indicate the

problem.

LRW pressure

(or Temperature)

4.2 Data display

T emperature mode

Pressure mode

Abnormality icon

RRW pressure

(or Temperature)

To read the tire pressure and

temperature of each tire, simply

press the key button on the

display. Press again to switch

between air pressure and

temperature.

When pressing the key button, the

background will light up for 9

seconds before it turns off.

1110

4.3 Warning Signals

Abnormality warning

4.3.1. Hear

When you hear the warning sound “ Beep-Beep” or

“Beep-Beep-Beep”, pull over to a safe area to check the

problem.

4.3.2. Check

When you hear the warning sound, please check the

warning icons on the display. The background will light up

automatically.

a. If you see an , that means one of the tires has a high

temperature or an abnormal pressure (high or low)

b. If you see an , that means one of the tires is leaking

rapidly.

c. If no icon appears, that means one of the tires is leaking

slowly.

4.3.3. Locate

Each number on the display has a square frame. If the frame

has disappeared, this tire is the problem tire.

The warning signals are shown as below:

Low Pressure warning

Pressure is lower than

1.6Bar(23PSI)--------TPMS-201A

1.9Bar(28PSI)--------TPMS-201B

2.3Bar(33PSI)--------TPMS-201C

High Pressure warning

Pressure is higher than

3.2Bar(46PSI)----TPMS-201A

3.8Bar(55PSI)----TPMS-201B

4.3Bar(62PSI)----TPMS-201C

High Temperature warning

The temperature inside the

tire is higher than 80 C(176 F)

Rapid Leakage warning

Changes of pressure is greater

than 0.08 Bar/15 seconds

Slow Leakage warning

Changes of pressure is greater

than 0.15 Bar within 10 days

1312

4.4 Resetting the system

The system has to be reset to re-identify

the ID module in the following situations.

1) Replace the ID module;

2) Interchange the positions of the ID

modules and sensors;

Or, if the display continues to show some

RE-SET Key

incomprehensible codes or “---” , or the

data does not refresh, you may press the reset button on the

back of the display to restart.

If the 6-digit ID number shown on the display matches the

corresponding 6-digit ID number on the ID module, the

system is working Properly. Otherwise it isn't. In this case,

pull out the ID module and put it back properly. If the

problem still exists, the sensor and its ID module need to be

replaced.

Press and hold the button again for 3 seconds and the

system will resume normal working condition.

4.5 ID Module checkout

If you see one or more “---” on display,

ID module may not be properly plugged

into the display. Press and hold the

button on the display for 3 seconds and

the system will begin the checkout

process. Each ID module has a 6-digit

ID code. The display will show the first 3

digits. Press again and it will show the

last 3 digits.

Before pulling out the ID module, firmly

push the holding key on the back of the

display. Otherwise the ID module may

be damaged.

Holding key

Important:

When plugging the ID module into the display, make sure the

“needle plugs” on the ID module line up with the slot form

on the side of the display. Otherwise the ID module could be

damaged when plugged in by force.

1514

4.6 Changing wheel position

Each sensor and its corresponding ID module have the

same ID code. With four ID modules mounted on two sides,

the display resembles a vehicle with four wheels. The ID

modules should be placed in the same positions on the

display as the corresponding sensors are installed on the

vehicle. Therefore when you change a wheel position, the ID

module position should also be changed.

For example, if you interchanged the LFW (Left Front Wheel)

and the LRW (Left Rear Wheel), you should also

interchange the positions of the upper left ID module and the

lower left ID module.

4.7 Replace sensor

When you replace a sensor, first install the new sensor in the

wheel. Then plug the ID module came with the sensor in the

corresponding position of the display. For example, if you

replaced a sensor in the RRW (Right Rear Wheel), then you

should plug the new ID module in the lower right position of

the display.

1716

5 Trouble shooting

Problem Probable reason Solution

“- - -”shows

on the display

1.Data does not

refresh;

2.Back light does

not turn off;

3.The display

continues to show

incomprehensible

codes.

Nothing shown on

the display

1. ID module is not

properly connected

with the display

2. System failure

3. Receiver did not

receive the signal

from the sensor

System failure

Display power cord is

not properly plugged in

ID Module checkout. See

4.5.

Press RESET key to

restart the system

Contact your distributor

Press RESET key to

restart the system

Contact your distributor

6 Parameters of the product

Sensor

Weight :36 g ( 1.26 oz. )

Dimensions : 1.5 X 2.8 X 6.4 cm ( 0.59 x 2.50 x 1.11 inch )

Operating Temp. Range : -40 C to 125 C

(-40 F to 257 F)

Pressure Accuracy: 0.05 Bar (0.73 PSI)

Temperature Accuracy : 2 C (3.6 F)

Battery life : 5 years (Theoretically estimation: 10 years )

Maximum range : 5.4 Bar (78 PSI)

Frequency : 433.92MHz

Receiver

Power Consumption: Max : 220mW

Power Supply : DC12 Volt

Weight : 48 g (1.7 oz.)

Dimensions : 2.3 X 3.7 X 8.8 cm ( 0.91 x 3.47 x 1.46 inch )

Operating Temp. Range : -40 C to 85 C (-40 F to 185 F)

Display

Power Consumption ;Regular : 130 mW Max : 230mW

Power Supply : DC12 Volt

Weight : 75 g ( 2.65 oz. )

Dimensions : 2.2 X 4.9 X 7.7 cm ( 0.87 x 3.03 x 1.93 inch )

Operating Temp. Range : -20 C to 70 C (-4 F to 158 F)

Pressure resolution : 0.01Bar (0.2PSI)

Temperature resolution : 1 C(2 F)

1918

7 The authentication announcement for

Europe and North America, and the

corporation's declarations.

7.1 FCC's authentication announcement

This device complies with Part 15 of the FCC Rules.

Operation is subject to the following two conditions: (1) this

device may not cause harmful interference, and (2) this

device must accept any interference received, including

interference that may cause undesired operation.

This equipment has been tested and found to comply with

the limits for a Class B digital device, pursuant to Part 15 of

the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference in a

residential installation. This equipment generates uses and

can radiate radio frequency energy and, if not installed and

used in accordance with the instructions, may cause harmful

interference to radio communications. However, there is no

guarantee that interference will not occur in a particular

installation. If this equipment does cause harmful

interference to radio or television reception, which can be

determined by turning the equipment off and on, the user is

encouraged to try to consult the dealer for help.

Changes or modifications to this device without the express

approval of Shanghai Baolong Industries Corporation may

void the user's authority to use this device.

7.2 European regulations announcements

This device complies with all European Electromagnetic

compatibility regulations (95/54/EC and EN300 220-1). The

equipment has been tested and found to comply with the

above regulations, and in addition it meets the requirements

for low powered transmitters/receivers as defined by the

relevant radio approval authority. The regulations are

designed to provide reasonable protection against harmful

interference or susceptibility. Changes made to this device

without the express approval of Shanghai Baolong Industries

Corporation. may void the user's authority to use this device.

2120

7.3 Product Application and Warnings

7.3.1 Product Function

This is a monitoring device. It provides real-time monitoring

on each tire for pressure and temperature, and gives

warning to any abnormal condition. The driver should react

promptly to the warning and correct the problem.

7.3.2 Important Notice about Installation

This product should only be installed by a trained technician

according to the manufacturer's instructions. All instructions

are in the user's manual and/or CD.

7.3.3 Application

We recommend to use in cars or light trucks with 4 tubeless

tires. We have 3 types of TPMS for different vehicles with

different cold inflation pressure. Please refer to the

application chart as follows:

Part Nr.

TPMS-201A

TPMS-201B

TPMS-201C

Standard cold inflation pressure

PSI Bar Kpa

29~35

36~42

43~51

2.0~2.4

2.5~2.9

3.0~3.5

200~249

250~299

300~350

If you need the TPMS beyond above pressure ranges, we

can custom it according to your requirement.

7.3.4 Warning

When you observe any warning, immediately reduce speed

and pull the vehicle to a safe place, where you can inspect

and repair the tire.

8 Others

8.1 When you park the vehicle, the tire temperature will

decrease and thus the tire pressure will also decrease. If the

system gives rapid leakage warning within half an hour after

parking the vehicle, this might be the reason and should be

considered as normal.

8.2 If the display unit does not receive signals properly

from a sensor, the system will detect it within an hour and

show “---” on the corresponding location in the display.

8. 3 Sometimes you may see “ ---” when the vehicle is

parked. This might be caused by the surrounding

interference. This is normal. The display will show correct

data when you start the vehicle.

8.4 Try to avoid parking the vehicle under strong sunlight.

The LCD screen may be damaged after one hour of

exposure to 70°C (158°F) in-car temperature.

2322

9 Warranty

Type: TPMS-201;

Voltage: DC 3.6V;

Frequency: 433.92MHz;

Temperature: -40℃ to 125℃;

Transmitting Block

This block is made up of Li-cell, Senor, CPU and Radio circuit.

Through the supply of the Li-cell, the sensor accurately monitors

the data. The CPU will operate the data and transmit the Radio,

which including the pressure data, the temperature data and

ID.

Receiving Block

This block is made up of power supply, radio receiving, CPU and

display.

Power supply is in charge of the supply to the whole block, the

management of the radio receiving from the transmitter and

transmission to the CPU. CPU operates the data, and then

transmits them to the display. CPU will trigger the warning

system in case abnormality happens.

This Warranty covers substantial manufacture's defects in

workmanship and materials. It does not cover any unit that

is damaged beyond normal usage, not properly installed,

subject to chemical contact, or other acts not sanctioned

by the Owner's Manual.

All components are covered for one(1) year and unlimited

mileage following the date of purchase.

The Digitire Warranty will be honored by any authorized

Digitire Dealer. The owner is required to provide dated

proof of the purchase. The authorized dealer will

determine if there is warrantable condition associated with

materials and/or manufacturing workmanship. If a

warrantable condition exists, the component will be

replaced free of charge and shipping prepaid. The owner

is responsible for any labor and installation charges.

The warranty does not include any further obligation

whatsoever, including but not limited to actual installation

of the replacement unit on the customer’s vehicle.

All other Warranties, explicit or implied, are disclaimed. All

collateral agreements, which purport to modify this limited

Warranty are of no effect. The absolute limit of liability is the

purchase price of the unit. Digitire System inc. is not liable

for any direct, consequential, indirect or punitive damages of

any kind.

2524

Loading...

Loading...