SureCross™ DX80 Quick Start Guide

A setup guide for the SureCross™ DX80 wireless systems

Introducing the SureCross™ DX80 Wireless System

The SureCross™ DX80 wireless system provides reliable monitoring without the burden

of wiring or conduit installation, and can operate independently or in conjunction with a

PLC and/or PC software.

The SureCross DX80 network is a deterministic system—the network identifies when

the radio signal is lost and drives relevant outputs to user-defined conditions. Once the

radio signal is reacquired, the network returns to normal operation.

Each wireless system consists of one Gateway and one or more Nodes that ship with

factory predefined inputs and outputs. Devices may be all discrete I/O, mixed discrete

and analog I/O, and FlexPower™.

A Gateway device acts as the master device within each radio network system. The

Gateway initiates communication and reporting with the Nodes.

A radio network contains only one Gateway, but can contain many Nodes. Each Node

device can be connected to a sensor or output device and reports I/O status to the

Gateway.

A Gateway and Node can be arranged to extend the range of the network or to avoid

obstacles in the transmission path. The Gateway receives a transmission from one

Node and forwards it to another Node positioned to avoid the obstacle.

Table of Contents

Overview ................................................1

Features and Components ..................... 2

Menu System .........................................4

QuickStart

Step 1: Set NID & Device Address

Step 2: Apply Power (Gateway) .....

Step 3: Apply power (Node) ...........

Step 4: Verify Communications ......

Step 5: Site Survey ........................

Step 6: Installation .......................

Maintenance/Parts Replacement ......... 13

Host Network .......................................15

Product Dimensions .............................17

Troubleshooting ................................... 18

Accessories.......................................... 20

Agency Certifications ........................... 21

FCC Certification.................................. 22

WARNING…

Never use these products for personnel protection. Doing so could lead to serious injury or death.

These products do NOT include the self-checking redundant circuitry necessary to allow their use in personnel safety applications.

A failure or malfunction can cause either an energized or de-energized product output condition. Consult your current Banner Safety

Products catalog for safety products that meet OSHA, ANSI, and IEC standards for personnel protection.

10

Not to be used for personnel protection

Host-connected systems can contain up to 15 nodes within a single network and may

be all discrete or a mix of discrete and analog I/O. Host-connected systems allow for

logic and calculations to be applied to the I/O. Inputs from Nodes within the network

are transmitted to the Gateway, which communicates the information to a host device

for processing. While the Gateway is the master device within the radio network, the

Gateway is a slave to the Modbus network.

FlexPower devices allow for a true wireless solution as the Node can be powered

by line power (10 to 30V dc) or battery power (3.6 to 5.5V dc). A SureCross DX81

battery pack and unique power management system runs the Node and a device for

6

up to five years, depending upon the power requirements of the device. Battery life is

7

application specific. Contact Banner Engineering’s application engineers for a battery

7

life calculation for your specific application.

8

9

Printed in USA 04/07 P/N 128185 Rev B

SureCross™ DX80 Quick Start Guide

Single-click

Button 1

Single-click

Button 1

Double-click

Button 2

Double-click

Button 2

etc.

Single-click

Button 1

etc.

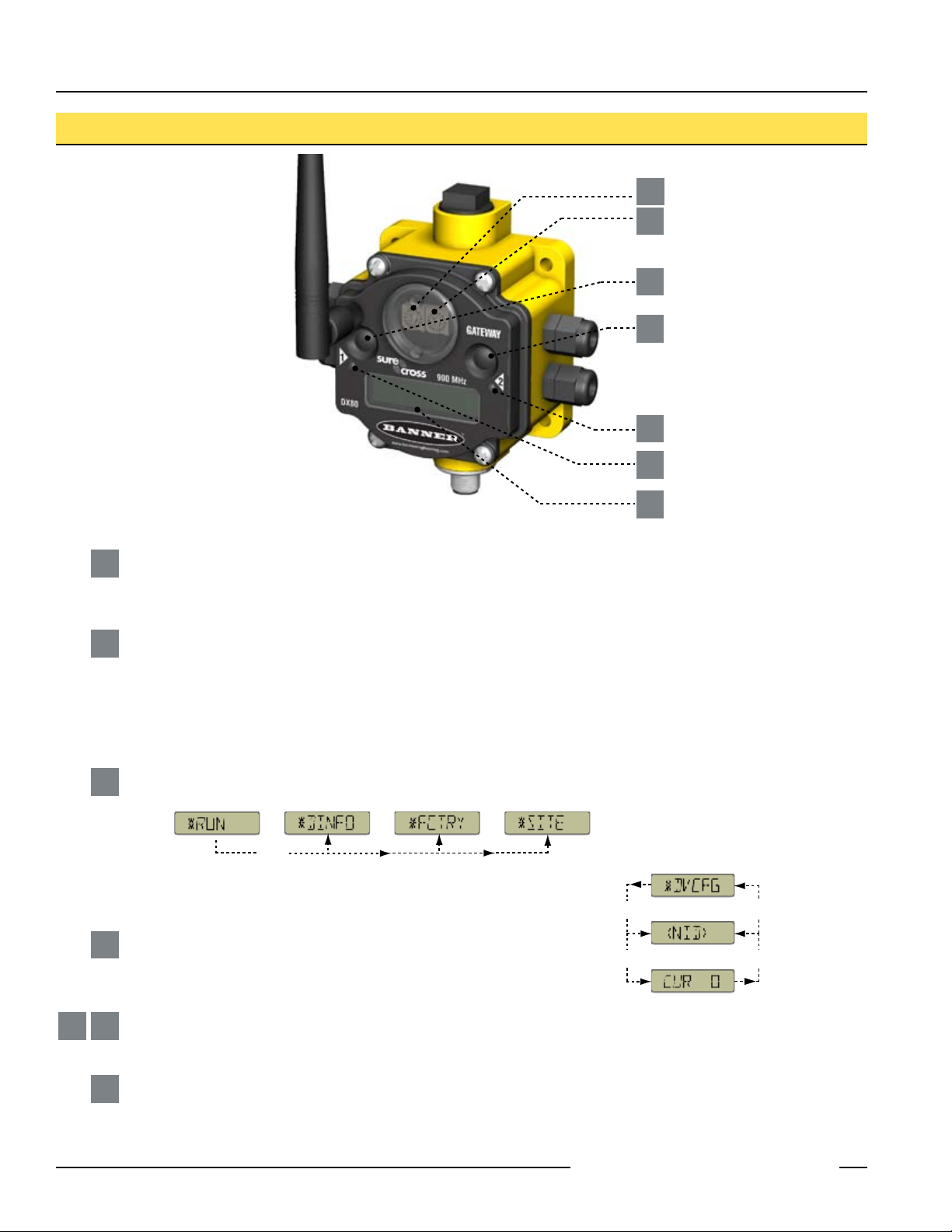

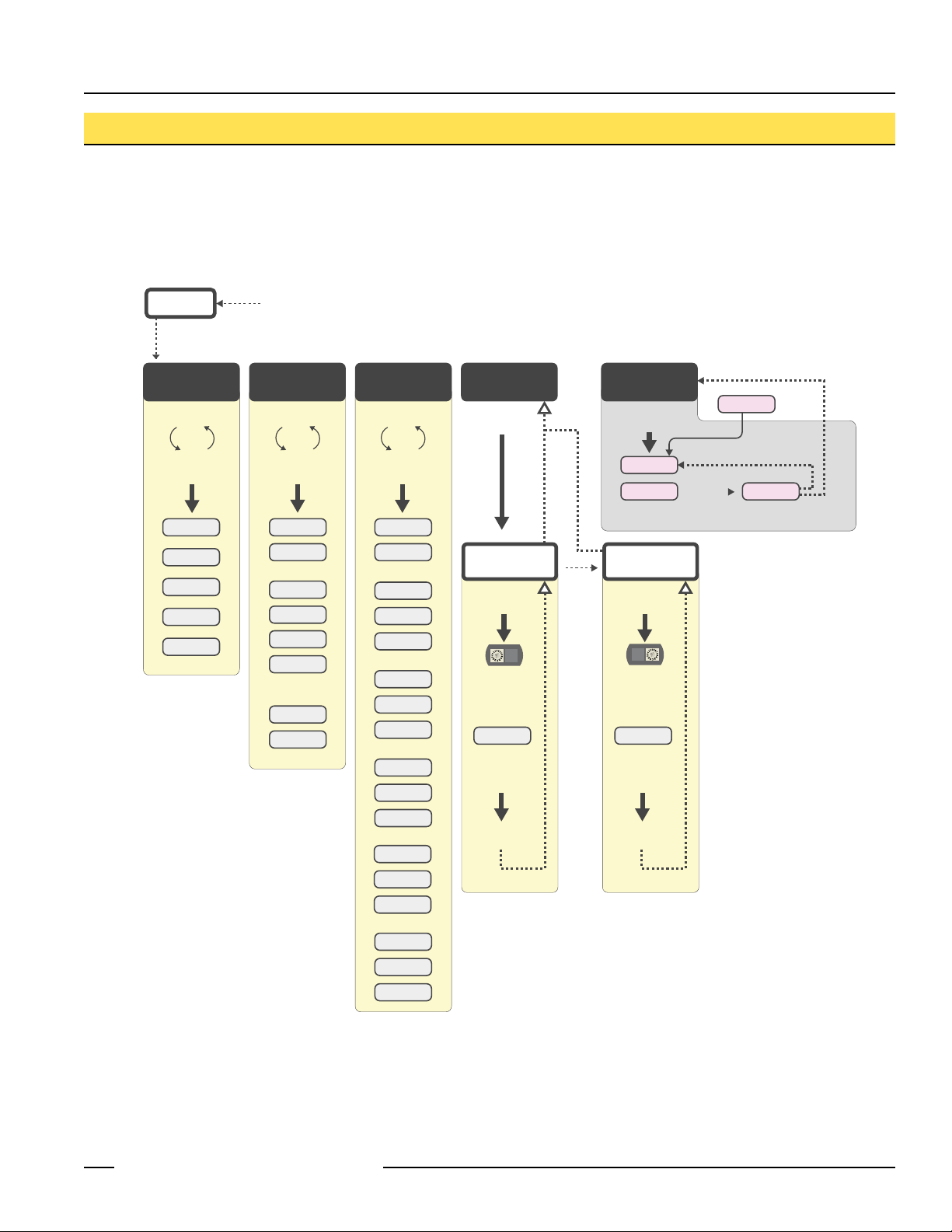

DX80 Gateway and Node Front Panel Interface

Rotary Switches: Used to set Network ID & Device Address

1

2

3

4

5

6

7

Rotary Switch 1 (left)

1

Sets the Network ID (NID) to a hexidecimal value from 0 to F, for a total of 16 Network IDs. A Gateway and its corresponding

Nodes must be assigned the same Network ID.

Rotary Switch 2 (right)

2

On Gateway: Sets the Gateway’s LCD viewing device address. The Gateway is predefined as Device Address 0.

On Node: Sets the Node’s Device Address (hexidecimal 1 to F). Each Node within a network must have a unique Node

Device Address.

Push Buttons: Used to navigate the Gateway and Node menus and program device configurations

Push Button 1

3

Single-click to advance across all top-level DX80 menus.

Single-click to move down interactive menus, once a top-level menu is chosen.

Push Button 2

4

Double-click to select a menu and to enter manual scrolling mode.

Double-click to move up one level at a time.

5 6

2 P/N 128185 Rev B

LED 1 and 2

Provide real-time feedback to the user regarding RF link status, serial communications activity, and the error state.

LCD Display

7

Six-character display provides run mode user information and shows enabled I/O point status. This display allows the user

to conduct a Site Survey (RSSI) and modify other DX80 configuration parameters without the use of a PC or other external

software interfaces. On the Node, after 15 minutes of inactivity, the LCD goes blank. Press any button to refresh the display.

Banner Engineering Corp. • Minneapolis, MN U.S.A.

www.bannerengineering.com • Tel: 763.544.3164

SureCross™ DX80 Quick Start Guide

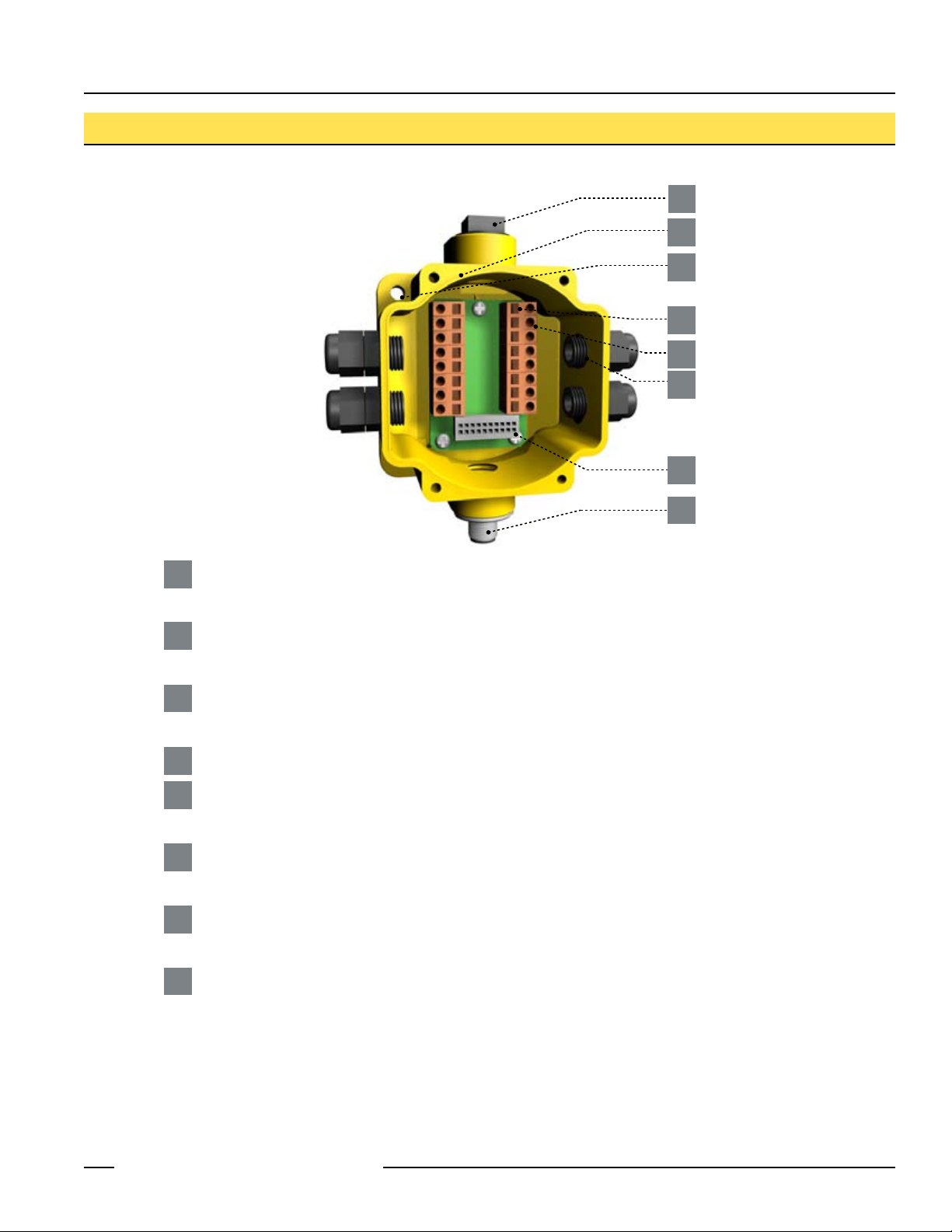

DX80 Gateway and Node Wiring Chamber

1

2

3

4

5

6

7

8

Port, NPT Gland, or Plug

1

If unused, install the provided plug into the 1/2 NPT threaded port. Use PTFE tape if an IP67 seal is required.

Housing

2

The rugged, industrial DX80 housing meets IEC IP67 standards.

Mounting Hole, #10/M5 Clearance

3

Mounting Holes accept metric M5 or UNC/UNF #10 hardware -- DIN rail mount adapter bracket available

Wiring Terminal Strip

4

Wiring Terminal

5

The 16 spring-clip type wiring terminals accept wire sizes: AWG 12-28 or 2.5 mm

Port, PG-7 Gland or Blank

6

The PG-7 threaded ports can accept provided cable glands or blanks.

Ribbon Connector

7

Ribbon cable connects wiring base to LCD/radio.

5-Pin M12 Euro-style quick-disconnect fitting

8

2

Banner Engineering Corp. • Minneapolis, MN U.S.A.

www.bannerengineering.com • Tel: 763.544.3164

P/N 128185 Rev B 3

SureCross™ DX80 Quick Start Guide

NOD XX

M XX

R XX

Y XX

G XX

*

DINFO

*

FCTRY

*

SITE

*

DVCFG

*

DERR

*

RUN

AUTO

DISPLAY

LOOP

AUTO

DISPLAY

LOOP

AUTO

DISPLAY

LOOP

(DE V)

GATE WY

(NI D)

XX

(SL ID)

XX

(BA UD)

XX

(PR TY)

XX

(DE V)

GATE WY

(RA DIO

MICRO)

V 00.0 A

(LC D

MICRO)

V 00.0 A

(DX 80

S/N)

(0000)

(DX 80

MODEL)

(0000-00)

(PR OD

DATE)

(00-00)

Single-click

Button 2

Single-click

Button 2

Single-click

Button 2

Double-click

Button 2

ADJUST RIGHT

ROTARY SWITCH

TO SURVEY

RESPECTIVE NODE

Single-click

Button 2

Double-click

Button 2

Double-click Button 2

NOD XX

EC XX CLE AR

ERR

ERA SED

ERR

DIS ABL

*

ERR OR

DIS ABL IGN ORE

Nex t

Dev ice

Single-click Button 1 to advance through menu

AUTO

DISPLAY

LOOP

Single-click

Button 2

Single-click

Button 2

Single-click

Button 2

Single-click

Button 2

Single-click

Button 2

Single-click

Button 2

New Error

Detected

ADJUST RIGHT

ROTARY SWITCH

TO SURVEY

RESPECTIVE NODE

(DE V)

I/O XX

GATE WY

NID XX

ON/OFF

(DE V)

I/O XX

GATE WY

NID XX

ON/OFF

Eve n

Non e

Odd

Single-click

Button 2

Single-click

Button 2

SAVES

DISPLAYED

VALUE

Single-click B1

192 00

960 0

384 00

Single-click

Button 2

Single-click

Button 2

SAVES

DISPLAYED

VALUE

NEW XX

Single-click

Button 2

Single-click

Button 2

ADJUST LEFT

ROTARY SWITCH

TO SET

NETWORK ID

SAVES NEW

VALUES

CUR XX

Single-click

Button 2

Single-click

Button 2

ADJUST ROTARY

SWITCHES

TO SET

SLAVE ID

SAVES NEW

VALUES

(NID) (SLID) (BAUD) (PRTY)

Network ID Slave ID Baud Rate Parity

Single-click B1

NEW XX

Single-click

Button 1

Single-click

Button 1

Single-click

Button 1

Single-click

Button 1

Single-click Button 1 to advance through menu

(NA ME)

GATEWY

KIT

XX

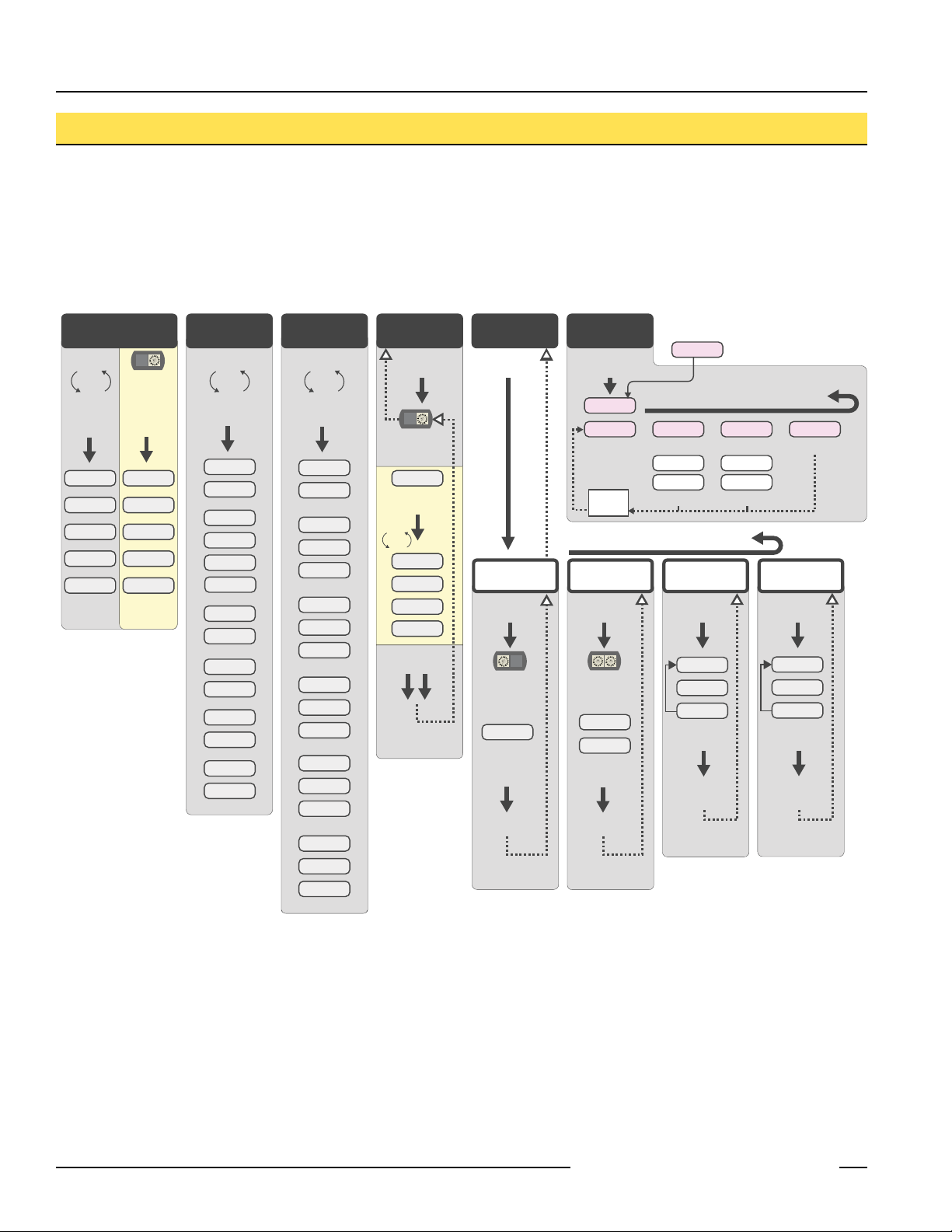

SureCross™ DX80 Gateway Setup Menu

When power is applied, the DX80 immediately begins running. The display screen autoscrolls through the *RUN menu and

communication begins between the Gateway and Node(s). Autoscrolling through the *RUN menu is the normal operating mode for all

devices on the wireless network.

From the *RUN Menu (or any menu), single-click button 1 to advance through the top-level menus.

To return to the top level menus and autoscrolling mode, double-click button 2 twice.*** To enter manual scrolling mode, double-click

button 2 at the top level menu. The device autoscrolls through the *RUN, *DINFO, and *FCTRY menus if paused on those menu

headings. If the device is paused on the *SITE, *DVCFG, or *DERR menu options, the display does not autoscroll.

**

** The Network ID (NID) can be set at any time from the left rotary switches. Once changed, allow five seconds for the devices to

update to the new NID.

*** At any point in the menu system, double-clicking Button 2 twice returns to the top level menu.

Navigating the menu:

* indicates a top level menu option

( ) indicates a sub-menu item

No characters indicate the value of the previous item

4 P/N 128185 Rev B

Banner Engineering Corp. • Minneapolis, MN U.S.A.

www.bannerengineering.com • Tel: 763.544.3164

SureCross™ DX80 Quick Start Guide

*

DINFO

*

RUN

*

FCTRY

*

DVCFG

*

DERR

AUTO

DISPLAY

LOOP

AUTO

DISPLAY

LOOP

AUTO

DISPLAY

LOOP

(DEV)

NOD XX

(NAME)

NODE XX

KIT

XXXXX

(NID)

XX

(DEV)

NOD XX

(RADIO

MICRO)

V 00.0 A

(DX80

S/N)

0x0000(2)

(LCD

MICRO)

0x0000(2)

(PROD

DATE)

(00-00)

Single-click

Button 2

NEW XX

Single-click

Button 2

Single-click

Button 2

SAVES NEW

VALUES

(NID)

Network ID

Single-click

Button 2

Double-click Btn 2

Double-click Btn 2

NEW XX

Single-click

Button 2

Single-click

Button 2

SAVES NEW

VALUES

(NADR)

Node Address

NOD XX

**

EC XX IGNORE

*

ERROR

Single-click Button 1

** LCD will display ‘NO ERR’ if no error is detected.

Single-click

Button 2

Single-click

Button 2

New Error

Detected

Single-click Button 2

OFF

Press and hold Button 1 from any top level menu to power down the Node.

Press and hold Button 1 from power down mode to enter RUN mode.

ADJUST LEFT

ROTARY SWITCH

TO SET

NETWORK ID

ADJUST RIGHT

ROTARY SWITCH

TO SET

NODE ADDRESS

Single-click

Button 1

(DEV)

I/O XX

NOD XX

NID XX

ON/OFF

Single-click

Button 1

Single-click

Button 1

Single-click

Button 1

(DX80

MODEL)

0x0000(2)

SureCross™ DX80 Node Setup Menu

When power is applied, the DX80 immediately enters *RUN mode. *RUN mode is the normal operating mode for all devices on the

wireless network.

From the *RUN Menu (or any menu), single-click button 1 to advance through the top-level menus.

To return to the top level menus and autoscrolling mode, double-click button 2 twice.*** To enter manual scrolling mode, double-click

button 2 at the top level menu. The device autoscrolls through the *RUN, *DINFO, and *FCTRY menus if paused on those menu

headings. If the device is paused on the *DVCFG or *DERR menu options, the display does not autoscroll.

** The Network ID (NID) and Node Address

(NADR) can be set at any time from the

rotary switches. The left rotary switch sets

the Network ID and the right rotary switch

sets the Node Address.

*** At any point in the menu system,

double-clicking Button 2 twice returns to

the top level menu.

** **

Navigating the menu:

* indicates a top level menu option

( ) indicates a sub-menu item

No characters indicate the value of the previous item

Node LCD Timeout: After 15 minutes of inactivity, the LCD screen stops displaying information. Press any button to refresh the display if

the Node has entered this energy-saving mode.

Banner Engineering Corp. • Minneapolis, MN U.S.A.

www.bannerengineering.com • Tel: 763.544.3164

P/N 128185 Rev B 5

SureCross™ DX80 Quick Start Guide

NODE

GATEWAY

GATEWAY

GATEWAY

NODE

NODE

NODE

NODE

NODE

7

NID

8

NID

9

NID

NID: 9

Device: 1

NID: 7

Device: 2

NID: 8

Device: 2

NID: 8

Device: 1

NID: 7

Device: 1

NID: 9

Device: 2

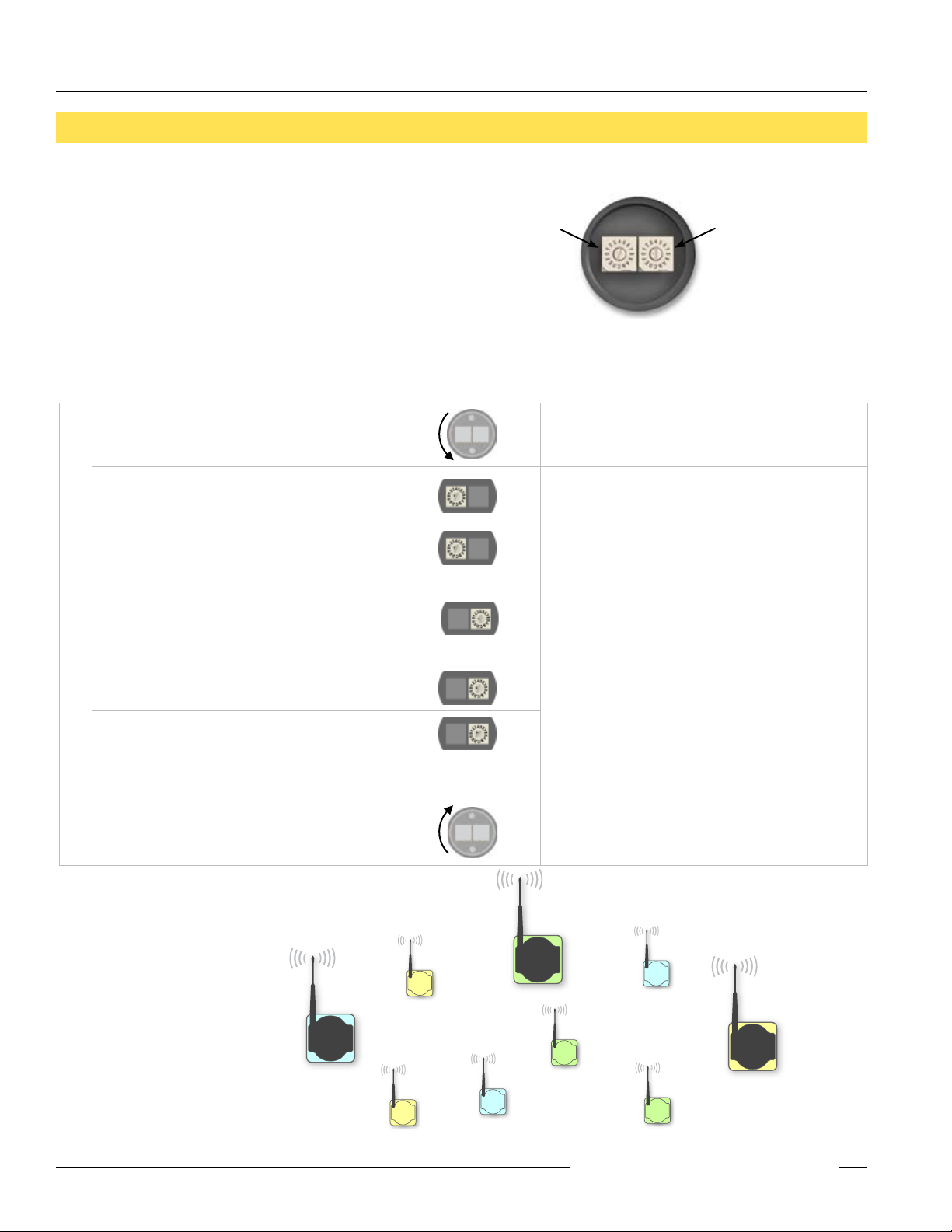

Quick Start: STEP 1

The wireless RF network is defined by the Network ID (NID)

assigned to the Gateway and its Nodes. Each device within

this common network must have a unique Device Address

assigned.

For factory configured kits, the Network ID and Device

Addresses have been assigned. Otherwise, use the Rotary

Switches (shown right) to define both the NID and Device

Address for each device. Follow the steps below to set up

your DX80 network.

User Action

Remove rotary switch access covers.

On the Gateway, set the Left Rotary Switch to 1.

SET NETWORK ID

On all Nodes (within the same network), set the Left

Rotary Switch to 1.

On the Gateway, set the Right Rotary Switch to 0.

On the first Node (Device Address = 1), set the Right

Rotary Switch to 1.

On the second Node (Device Address = 2), set the Right

Rotary Switch to 2.

SET DEVICE ADDRESS

Continue setting the Device Address for each additional

Node using a unique number (..3,4,5).

> Set Network ID & Device/Node Address

Network ID (NID) Device Address

Rotary Switches on

Gateway and Node

Display/Status

Turn counterclockwise to remove and clockwise to

tighten

The factory default NID setting on all devices is 1. Set

to another Network ID when operating more than one

network in the same area.

Assign the same NID to all devices within a single

network (hexidecimal 0-F).

A Device Address of 0 on the Gateway will display

settings for the Gateway itself. To view settings for

another device on the network, adjust the Right Rotary

Switch on the Gateway to the respective Device

Address.

Do not change the Device ID for preconfigured kits as

this would affect the factory mapping of the I/O.

Notes

Install rotary switch access covers. Please refer to the

installation section for IP67 instructions.

Multiple Networks

When more than one network is

operating in the same space, assign

a unique Network ID (NID) to each

network (shown right).

6 P/N 128185 Rev B

A successful RF link is identified by a blinking green LED

1 on each node.

Banner Engineering Corp. • Minneapolis, MN U.S.A.

www.bannerengineering.com • Tel: 763.544.3164

SureCross™ DX80 Quick Start Guide

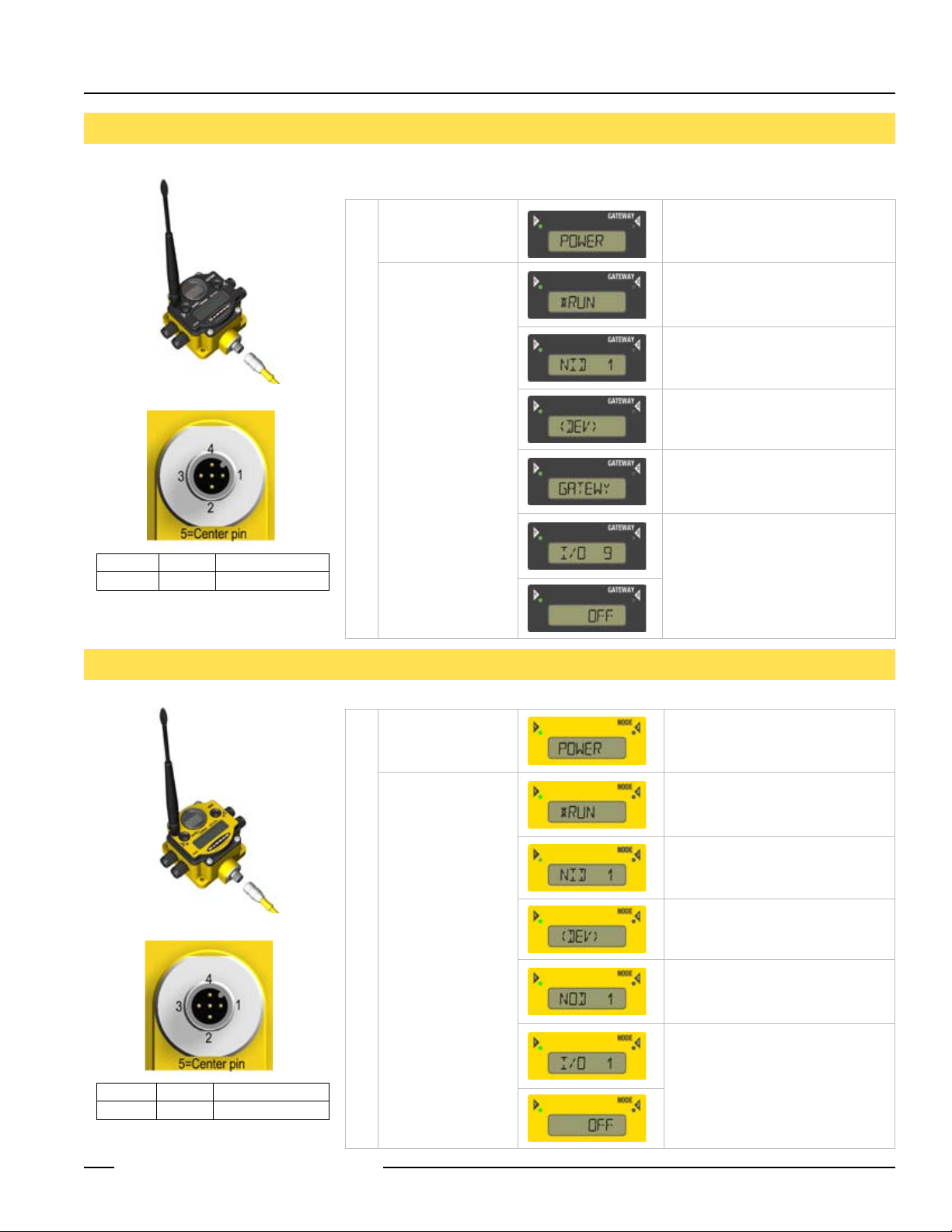

Quick Start: STEP 2

To apply power to the Gateway, connect the 10-30V dc cable as shown.

User Action

Apply power...

The LCD display

shows the current I/O

status of the Gateway.

> Apply Power, Gateway

Gateway Pinout Diagram

Brown 1 10-30V dc Input

Blue 3 dc common

On the Gateway, the other pins are used for

RS485 communications

Display/Status

Notes

This reading occurs only when power is

applied to the Gateway.

The Gateway starts in *RUN mode.

Displays current Network ID (NID)

Device is ...

... Gateway (Device Address = 0)

Indicates the current status of the I/O.

The display cycles through each I/O

point of the device, then returns to

*RUN.

Quick Start: STEP 3

To apply power to the Node, connect the 10-30V dc cable or DX81 Battery Module as shown.

Apply power...

The LCD display

shows the current I/O

status of the Node.

Line Powered Node Pinout Diagram

Brown 1 10-30V dc Input

Blue 3 dc common

Note: Terminal block GND = dc common

Banner Engineering Corp. • Minneapolis, MN U.S.A.

www.bannerengineering.com • Tel: 763.544.3164

P/N 128185 Rev B 7

> Apply Power, Node

This reading occurs only when power

is applied to the Node.

The Node starts in *RUN mode.

Displays current Network ID (NID)

Device is ...

... Node 1 (Node Address = 1)

Indicates the current status of the I/O.

The display cycles through each I/O

point of the device, then returns to

*RUN.

SureCross™ DX80 Quick Start Guide

Quick Start: STEP 4

Verify LED 1 is on and green.

Status LED 1 LED 2

Power ON Green ON —

System Error Red Flash Red Flash

Modbus Communication Active — Yellow Flash

Modbus Communication Error — Red Flash

Verify LED 1 is flashing Green and LED 2 is off. Until communication is established with

the Gateway, the Node’s LED 2 flashes Red. When communication is established, the

Node’s LED 1 flashes Green.

> Verify Communications, Gateway

> Verify Communications, Node

Status LED 1 LED 2

System Error Red Flash Red Flash (1 per sec)

RF Link Ok Green Flash (1 per sec) —

RF Link Error — Red Flash (1 per 3 sec)

If testing the Gateway and Node before installation, verify the Gateway and Node are at

least two meters apart or the communications may fail.

8 P/N 128185 Rev B

Banner Engineering Corp. • Minneapolis, MN U.S.A.

www.bannerengineering.com • Tel: 763.544.3164

SureCross™ DX80 Quick Start Guide

Quick Start: STEP 5

> Site Survey (optional)

A site survey analyzes the radio signal between a Gateway and a specified Node and reports the number of data packets missed or

received. Perform the Site Survey before permanently installing your network to ensure reliable communication. Use the Gateway to

perform a site survey analysis.

User Action

Remove Gateway rotary switch access cover.

To check the status of Node 1, change the

Gateway’s right rotary switch setting to 1

Single-click Gateway push button 1 Device Information menu

Single-click Gateway push button 1 Factory Settings menu

Display/Status

The Gateway is now enabled to read the status of

Node 1; the display scrolls through the Node’s I/O

status.

Notes

SITE SURVEY MENU

Single-click Gateway push button 1 Site Survey menu

Single-click Gateway push button 2 Site Survey will be conducted with Node 1

Single-click Gateway push button 2

Examine reception readings (M,R,Y,G) of the

Gateway at various locations. Note that the numbers

displayed are a percentage. M displays the percent

of missed packets while R, Y, and G display the

SURVEY READINGS

percent of received packets.

The Gateway analyzes the quality of the signal from

the selected Node by counting the number of data

packets it receives from the Node.

M = Percentage of missed packets

R = RED marginal signal

Y = YELLOW good signal

G = GREEN excellent signal

When possible, install all devices in positions that

optimize the percentage of YELLOW and GREEN data

packets received.

Double-click Gateway push button 2 End Site Survey

Change right rotary switch back to 0 (Gateway) Change the device readings back to the Gateway

Double-click Gateway push button 2 Move back to the top level menu

Single-click Gateway push button 1 Return to RUN mode

Single-click Gateway push button 1

Single-click Gateway push button 1

RETURN TO RUN MODE

Install Gateway rotary switch access cover.

Banner Engineering Corp. • Minneapolis, MN U.S.A.

www.bannerengineering.com • Tel: 763.544.3164

P/N 128185 Rev B 9

Refer to the installation instructions to create an IP67

seal.

SureCross™ DX80 Quick Start Guide

Quick Start: STEP 6

Avoid Direct Sunlight

To minimize the damaging effects of

ultra-violet radiation, avoid mounting the

Gateway or Node facing intense direct

sunlight.

Mount the DX80 within a protective

•

enclosure,

Mount the DX80 under an overhang or

•

other source of shade,

Install the DX80 indoors, or

•

Face the unit north when installing

•

outside.

Avoid Collecting Rain

When possible, mount the DX80 where

rain or snow will drain away from the unit.

Mount the units vertically so that

•

precipitation, dust, and dirt do not

accumulate on permeable surfaces.

Avoid mounting the units on flat or

•

concave surfaces, especially if the

display will be pointing up.

> Installation

Ideal Mounting Conditions

Reduce Chemical Exposure

Before installing the DX80 units in a

chemically harsh environment, contact

Banner for more information regarding the

life-expectancy. Solvents, oxidizing agents,

and other chemicals will damage the DX80.

Minimize Mechanical Stress

While the DX80 is very durable, it is a

sophisticated electronic device that is

sensitive to shock and excessive loading.

Avoid mounting the units to an object

•

that may be shifting or vibrating

excessively. High levels of static

force or acceleration may damage the

housing or electronic components.

Do not subject the DX80 to external

•

loads. Do not step on the DX80 or use

it as a handgrip.

Do not allow long lengths of cable to

•

hang from the DX80 glands. Cabling

heavier than 100 grams should be

supported instead of allowed to hang

from the DX80 housing.

10 P/N 128185 Rev B

Banner Engineering Corp. • Minneapolis, MN U.S.A.

www.bannerengineering.com • Tel: 763.544.3164

SureCross™ DX80 Quick Start Guide

Installation - Weather-Proofing Glands and Plugs

Watertight Glands and Plugs

Rotary Switch Access Cover

Check the rotary switch access cover

o-ring every time the access cover is

removed. Replace the o-ring when it is

damaged, discolored, or showing signs of

wear. The o-ring should be:

Seated firmly against the threads

•

without stretching to fit or without

bulging loosely, and

Pushed against the flanged cover.

•

When removing or closing the rotary switch

access cover, manually twist the cover

into position. Do not allow cross-threading

between the cover and the DX80 face.

Watertight 1/2” NPT Plug

Seal the 1/2” NPT port if it is not used. To

install a watertight NPT plug:

Wrap 12 to 16 passes of PTFE

1.

tape evenly across the length of the

threads.

Manually thread the plug into the

2.

housing port until reaching some

resistance.

Using a 9/16” crescent wrench, turn

3.

the plug until all the plug’s threads are

engaged by the housing port.

If the DX80 is mounted outdoors or will be

exposed to moisture, dirt, or dust, follow

these steps to weatherproof the units.

Watertight Glands

To make the glands watertight:

Wrap four to eight passes of

1.

polytetrafluoroethylene (PTFE) tape

around the threads as close as

possible to the hexagonal body of the

gland.

Manually thread the gland into the

2.

housing hole. Never apply more than

10 in-lbf of torque to the gland or its

cable clamp nut.

Note, these instructions apply both to the

PG-7 glands and the 1/2” NPT gland.

Watertight PG-7 Plug

Seal any unused PG-7 (small) access

holes with one of the supplied black plastic

plugs. To install a watertight PG7 plug:

Wrap four to eight passes of PTFE

1.

tape around the plug’s threads, as

close as possible to the flanged

surface.

Carefully thread the plastic plug

2.

into the vacant hole in the DX80

housing and tighten using a slotting

screwdriver. Never apply more than

10 in-lbf torque to the plastic plug.

Once the cover is in place and manually

tightened, use a small screwdriver (no

longer than five inches total length) as a

lever to apply enough torque to bring the

rotary switch access cover even with the

DX80 cover surface.

Banner Engineering Corp. • Minneapolis, MN U.S.A.

www.bannerengineering.com • Tel: 763.544.3164

P/N 128185 Rev B 11

SureCross™ DX80 Quick Start Guide

A wireless network can be hindered by

radio interference and obstructions in the

path between a receiver and transmitter.

To achieve the best radio performance,

carefully consider the installation locations

for the Gateways and Nodes.

Quick Tips

Clear Communication Paths

Orient the external antenna vertically for

optimal RF communication. If necessary,

consider changing the height of the DX80

position to improve reception levels.

Increase Height of DX80 Units

12 P/N 128185 Rev B

Banner Engineering Corp. • Minneapolis, MN U.S.A.

www.bannerengineering.com • Tel: 763.544.3164

SureCross™ DX80 Quick Start Guide

Maintenance and Parts Installation

Main Body Gasket

Check the main body gasket every time the

DX80 is opened. Replace the gasket when

it is damaged, discolored, or showing signs

of wear. The gasket must be:

Fully seated within its channel along

•

the full length of the perimeter, and

Positioned straight within the channel

•

with no twisting, stress, or stretching.

Rotary Switch Access Cover O-Ring

Check the rotary switch access cover

o-ring every time the access cover is

removed. Replace the o-ring when it is

damaged, discolored, or showing signs of

wear. The o-ring should be:

Seated firmly against the threads

•

without stretching to fit or without

bulging loosely, and

Pushed against the flanged cover.

•

When removing or closing the rotary switch

access cover, manually twist the cover

into position. Do not allow cross-threading

between the cover and the DX80 face.

Main Body Gasket

Rotary Access O-Ring

Once the cover is in place and manually

tightened, use a small screwdriver (no

longer than five inches total length) as a

lever to apply enough torque to bring the

rotary switch access cover even with the

DX80 cover surface.

Replacing O-Rings

Please refer to the list of replacement

parts on page 22 and contact Banner

Engineering with any questions.

Banner Engineering Corp. • Minneapolis, MN U.S.A.

www.bannerengineering.com • Tel: 763.544.3164

P/N 128185 Rev B 13

SureCross™ DX80 Quick Start Guide

DX80 Battery Replacement

Battery Replacement

To replace the lithum “D” cell battery in the

DX81 FlexPower battery kit,

Remove the four screws mounting the

1.

battery pack face plate to the body.

Remove the face plate.

2.

Remove the discharged battery and

3.

replace with a new battery. Verify

the battery’s positive and negative

terminals align to the positive and

negative terminals of the battery

holder mounted within the case.

After replacing the battery, allow up

4.

to 60 seconds for the device to power

up.

When removing the battery, press the

battery towards the negative terminal

to compress the spring. Pry up on the

battery’s positive end to remove from the

battery holder.

Properly dispose of your used battery by

taking it to a hazardous waste collection

site, an e-waste disposal center, or any

other facility qualified to accept lithium

batteries.

As with all batteries, these are a fire,

explosion, and severe burn hazard. Do not

burn or expose them to high temperatures.

Do not recharge, crush, disassemble, or

expose the contents to water.

14 P/N 128185 Rev B

Banner Engineering Corp. • Minneapolis, MN U.S.A.

www.bannerengineering.com • Tel: 763.544.3164

SureCross™ DX80 Quick Start Guide

Host Network - Gateway

Setting up the Network and Device IDs, powering up the devices, and conducting the Site Survey for a host-connected network is the

same as for the standard DX80 wireless system. All device I/O for the network is accessed using the host/master device.

To access the Modbus device, you may first need to configure system-level communication parameters on the DX80 Gateway, in

addition to the serial hookups shown below. The following procedure is necessary to change the Gateway Slave ID, Baud Rate, and

Parity.

Parameter Description

Slave ID (Default = 1)

Baud Rate (Default = 19200)

Parity (Default = None) Defines serial parity (none, even, or odd) between Gateway and Host.

Defines the slave number (01-99) for the serial Modbus RTU protocol. When operating more than one

network with a Modbus Master device, change the Slave IDs.

Defines communication data rate (19.2, 38.4 or 9.6 kbps) between the Gateway and the Host through the

serial interface.

Gateway (Host-Connected) Pinout Diagram

Brown 1 10-30V dc Input

White 2 RS485 / D1 / B /+

Blue 3 Ground Input

Black 4 RS485 / D0 / A / Gray 5 Comms Gnd

Wiring: 5-pin Euro pinouts for 485+, 485- and

Comms ground

Banner Engineering Corp. • Minneapolis, MN U.S.A.

www.bannerengineering.com • Tel: 763.544.3164

P/N 128185 Rev B 15

SureCross™ DX80 Quick Start Guide

Host Network - Gateway (con’t)

Setting the Slave ID, Baud Rate, and Parity

Similar to Network ID, the Slave ID, Baud Rate, and Parity parameters can be changed in the Device Configuration (*DVCFG) system

menu option.

Follow the top level system menu through *DVCFG to the Slave ID (SLID) parameter. The LCD displays an alternating current value and

new value for the parameter.

User Action Display/Status Notes

On the Gateway, single-click button one to move across the top level

menu options to the “Device Configuration” menu

Single-click Gateway push button 2

Single-click Gateway push button 1 to move to the Slave ID field. Default value is 1

Single-click Gateway push button 2

Using 0-9 on the left rotary switch and 1-9 on

SET SLAVE ID

the right switch, set the rotary switches to the

desired Slave ID

Single-click Gateway push button 2 to save the new Slave ID.

Single-click Gateway push button 1 to move to the next menu option,

the BAUD rate.

Single-click Gateway push button 2 to display the current setting.

Single-click Gateway push button 1 to cycle through the available

options. Stop on the desired setting.

SET BAUD RATE

Single-click Gateway push button 2 to save the new setting.

To navigate to the *DVCFG

(Device Configuration) menu,

see page 6.

The new Slave ID is defined

by the current position of the

rotary switches.

Select between 01 to 99.

The factory default is set

to 1. Change the Slave ID

when running more than one

network into the Modbus

Master device.

The options are 9600, 19200,

38400. The factory default is

19200.

Single-click Gateway push button 1 to move to the next field, the

PARITY field.

Single-click Gateway push button 2 to display the current setting.

Single-click Gateway push button 1 to cycle through the available

SET PARITY

options. Stop on the desired setting.

Single-click Gateway push button 2 to save the new setting.

Adjust the left rotary switch back to NID value.*

Adjust the right rotary switch back to zero.

Double-click Gateway push button 2 to return to the Device

Configuration (*DVCFG) menu.

Click Gateway push button 1 until reaching the *RUN menu option.

* To avoid losing the network connection between the Gateway and Nodes, reset the rotary switches back to their appropriate values before leaving the

*DVCFG sub-menus. If the Gateway and Nodes lose their connection, the network may take up to 20 seconds to re-synchronize.

Banner Engineering Corp. • Minneapolis, MN U.S.A.

16 P/N 128185 Rev B

www.bannerengineering.com • Tel: 763.544.3164

The options are NONE,

EVEN, ODD. The factory

default is NONE.

SureCross™ DX80 Quick Start Guide

65.0 mm

(2.56")

65.0 mm

(2.56")

80.3 mm

(3.16")

80.8 mm

(3.18")

60 mm

(2.36")

120 mm

(4.72")

127 mm

(5")

19 mm

(0.75")

30.65 mm

(1.21")

22.2 mm

(.875")

7.9 mm

(0.31")

7.65 mm

(0.30")

14.67 mm

(0.578")

DX80 Gateway and Node Dimensions

Banner Engineering Corp. • Minneapolis, MN U.S.A.

www.bannerengineering.com • Tel: 763.544.3164

P/N 128185 Rev B 17

SureCross™ DX80 Quick Start Guide

Troubleshooting

RF Link Time-Out and Recovery

The SureCross™ DX80 wireless devices employ a deterministic link time-out method to address RF link interruption or failure. As

soon as a specific Node/Gateway RF link fails, all pertinent wired outputs are de-energized until the link is recovered (see component

data sheet for more information.) Through this process, users of Banner wireless networks can be assured that disruptions in the

communications link will result in predictable system behavior.

The link time-out feature uses a fully-acknowledged polling method to determine the RF link status of each Node on the network. If after

a specified number of sequential polling cycles the Node does not acknowledge a message, the Gateway considers the link with the

Node timed out. LCD displays on both the Node and Gateway show *ERROR. Following a time-out, the Node de-energizes outputs and

the Gateway sets all outputs linked to the Node in question to a de-energized state. Inputs from the Nodes are mapped to outputs on

the Gateway and are suspended during a link timeout.

Once a link has failed, the Gateway must receive a specified number of good RF communications packets from the Node in question

before the link is reinstated. Outputs are restored to current values when the link is recovered.

For information regarding Host-connected systems and link time-out and recover, please refer to Banner’s DX80 and Modbus Guide.

Link between Gateway and Node 1 timed out.

Link between Gateway and Node 1 recovered.

18 P/N 128185 Rev B

Banner Engineering Corp. • Minneapolis, MN U.S.A.

www.bannerengineering.com • Tel: 763.544.3164

SureCross™ DX80 Quick Start Guide

Troubleshooting (con’t)

A wireless network can be hindered by radio interference and by obstructions in the path of the receiver and transmitter. To achieve the best radio

performance possible, carefully consider the installation locations for Gateways and Nodes. The need for a clear path increases as the transmission

distance increases. Use Site Survey (RSSI) to confirm signal quality before fixing devices for permanent installation.

Problem Description

No LEDs, No LCD

display

Node flashes the red

LED (no sync)

Marginal Site Survey

(RSSI) results

No communications

with the DX80 Gateway

using RS485

DX80 Display shows

*ERROR

Possible Solutions

Basic power–up issues

DX80 devices should immediately display ‘POWER’ on the LCD for the first 5-10 seconds after power is applied.

•

For the Gateway, LED 1 will always be green when power is connected. The Node devices will flash a red LED 2

every three seconds or a green LED 1 every second depending upon the RF Link status.

Battery powered devices can be put into a power-down mode using button 1 on the front panel. To put a battery

•

device into power-down mode, hold button 1 for three to five seconds. To make a battery device come out of

power-down mode, hold button 1 for three to five seconds.

Recheck the power connections and power requirements. Line powered devices require 10 to 30V dc. The DX81

•

Battery Module provides 3.6V dc.

After replacing the battery, allow up to 60 seconds for the device to power up.

•

DX80 devices will not synchronize

There are two things that MUST be set on every Node device to make it synchronize with the Gateway device:

•

1) The Network ID on the Node must match the Gateway Network ID. (0-15)

2) Each node within that network must have the Device ID rotary switch set to a unique number (1-15). Refer to

“Getting Started – Multiple Networks, Setting Network ID”

If the Gateway and Node are less than two meters apart, the devices may not communicate properly (radios may

•

saturate).

The Gateway and Node may be too far apart to achieve sync – consult factory for options.

•

A qualified antenna should be mounted on both the Gateway and Node devices.

•

After any system parameter changes, cycle power to cause the devices to resync with the network.

•

If a Node device loses synchronization with the network, it is programmed to try to acquire sync for five seconds,

•

then sleep for 15 seconds. Synchronizing may require up to 20 seconds.

Recycle power on the Gateway and Node devices.

•

Site survey (RSSI) returns > 30 MISSED packets

If the distance between devices is greater than about 5,000 meters (3 miles) line-of-sight *OR* objects, such as

trees or man-made obstructions, interfere with the path, and the MISSED packet count exceeds 30 per 100 packets,

consider the following steps:

Raise the DX80 units to a higher elevation – either by physically moving the devices or installing the antenna(s)

•

remotely at a higher position.

Use high-gain antenna(s) such as Yagi and/or Omni (see Accessories).

•

Decrease the distance between devices.

•

DX80 Gateway will not talk with the host system

Default communications parameters for the RS485 are: 1 start bit, 8 data bits, no parity, 1 stop bit and 19.2k baud.

•

The DX80 Gateway uses Modbus RTU protocol for all communications. The supported Modbus function codes are

3, 6, and 16.

Make sure the DX80 model supports RS485 serial communications.

•

Make sure the Slave ID is set properly for the bus environment. Factory default Slave ID = 1.

•

Factory default for the Modbus timeout is set to four seconds.

•

RS485 termination or biasing is not supplied on the DX80 Gateway and should be provided externally to the DX80.

•

(Termination is not required by the DX80 Gateway, proper biasing of the serial lines is required.)

RF link time-out and recovery

The Gateway utilizes fully-acknowledged polling to ensure each Node RF link is robust. Consequently, if after

•

a prescribed number of sequential polling cycles are not acknowledged by a Node, the Gateway considers the

particular link with that Node to be timed out. All outputs on the Node in question will be set to “OFF” (discrete) or

“0” (analog, regardless of type).

If the Node’s RF link is recovered and the Gateway can determine that enough acknowledged polling messages

•

have been accumulated, then the link is reinstated and outputs are restored to the current values.

Banner Engineering Corp. • Minneapolis, MN U.S.A.

www.bannerengineering.com • Tel: 763.544.3164

P/N 128185 Rev B 19

SureCross™ DX80 Quick Start Guide

Troubleshooting (con’t)

Problem Description

Particular inputs and/or

outputs are not working

Possible Solutions

I/O functionality

Use manual scrolling mode within *RUN to freeze the I/O status on the LCD display for the device in question.

•

Verify that when the input device changes state or changes value, the LCD mirrors the behavior.

Also verify that the LCD on the output side mirrors the linked input’s behavior. If the input device state, LCD

•

on origination DX80, and LCD on destination DX80 all behave exactly the same, there may be a wiring issue

or an interfacing problem. Consult factory.

Accessories and Replacement Parts - 900 MHz and 2.4 GHz

Model Number Description

Antennas Banner offers a range of omni-directional and directional (Yagi) antennas for use with the SureCross™ DX80

wireless network. For more information on antenna specifications and the options available for your system, please

contact the applications engineers at Banner Engineering Corp.

O-Rings BWA-ORING-001 O-Ring, Rotary Access Cover, PG21

BWA-GASKET-001 O-Ring, Body Gasket

BWA-CLRCOVER-001 Rotary Access Cover, Clear Plastic

Hardware BWA-HW-001 Mounting Hardware, DX80

BWA-HW-002 Access Hardware (Plugs, Glands), DX80

SMBDX80DIN Bracket Assembly, DIN Rail, for DX80

BWA-HW-003 Tape, PFTE Sealant

BWA-HW-004 Screws, Cover Mount, #8-32 x 3/4, 18-8 SS

Power DX81 Battery Pack Kit, DX81, with mounting hardware

DX121 Battery Pack Kit, DX121, 6 cells

BWA-BATT-001 Replacement Battery, 3.6V, “D” Lithium Cell

SPS101Q DC Power Supply, 120mA, 12-30V dc, 5-pin Euro

SPS101QP DC Power Supply, 120mA, 12-30V dc, 5-pin Euro, pigtail

PS24W DC Power Supply, 500mA, 24V dc

EZAC-E-QE5 DC Power Supply, 700mA, 24V dc, 5-pin Euro QD

EZAC-E-QE5-QS5 DC Power Supply, 700mA, 24V dc, 5-pin M12 Euro QD

Cabling MQDC1-506 2M Cord Set, 2 Meter, 5-pin, 5-conductor, MQDC1-506 2M

MQDC1-506.5 Cord Set, 0.5 Meter, 5-pin, 5-conductor, MQDC1-506.5

BWA-RIBBON-001 Ribbon Cable, 20 pin DBL socket

BWC-LFNMN Lightning Suppressor, 900 MHz, 2.4 GHz

There is a wide range of antenna cabling available. Please contact Banner Engineering Corp for more information

or for specific cable lengths and connectors.

20 P/N 128185 Rev B

Banner Engineering Corp. • Minneapolis, MN U.S.A.

www.bannerengineering.com • Tel: 763.544.3164

SureCross™ DX80 Quick Start Guide

Agency Certifications

Industry Canada

This Class A digital apparatus meets all requirements of the Canadian Interference Causing Equipment Regulations. Operation

is subject to the following two conditions: (1) this device may not cause harmful interference, and (2) this device must accept any

interference received, including interference that may cause undesired operation.

Cet appareil numérique de la classe A respecte toutes les exigences du Règlement sur le matériel brouiller du Canada. Le present

appareil numérique n’emet pas de bruits radioélectriques dépassant les limites applicables aux appareils numeriques de le Classe A

préscrites dans le Reglement sur le brouillage radioélectrique édits par le ministere des Communications du Canada.

Banner Engineering Corp. • Minneapolis, MN U.S.A.

www.bannerengineering.com • Tel: 763.544.3164

P/N 128185 Rev B 21

SureCross™ DX80 Quick Start Guide

FCC Certification - 900 MHz

FCC Certification

The DX80 Module complies with Part 15 of the FCC rules and regulations.

FCC ID: TGUDX80 This device complies with Part 15 of the FCC Rules. Operation is subject to the following two conditions: (1) this

device may not cause harmful interference, and (2) this device must accept any interference received, including interference that may

cause undesired operation.

FCC Notices

IMPORTANT: The DX80 Modules have been certified by the FCC for use with other products without any further certification (as per

FCC section 2.1091). Changes or modifications not expressly approved by the manufacturer could void the user’s authority to operate

the equipment.

IMPORTANT: The DX80 Modules have been certified for fixed base station and mobile applications. If modules will be used for portable

applications, the device must undergo SAR testing.

IMPORTANT: If integrated into another product, the FCC ID label must be visible through a window on the final device or it must be

visible when an access panel, door, or cover is easily removed. If not, a second label must be placed on the outside of the final device

that contains the following text: Contains FCC ID: TGUDX80.

Note

This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to Part 15 of the FCC Rules.

These limits are designed to provide reasonable protection against harmful interference in a residential installation. This equipment

generates, uses, and can radiate radio frequency energy and, if not installed and used in accordance with the instructions, may cause

harmful interference to radio communications. However, there is no guarantee that interference will not occur in a particular installation.

If this equipment does cause harmful interference to radio or television reception, which can be determined by turning the equipment off

and on, the user is encouraged to try to correct the interference by one or more of the following measures:

Reorient or relocate the receiving antenna,

•

Increase the separation between the equipment and receiving module,

•

Connect the equipment into an outlet on a circuit different from that to which the receiving module is connected, and/or

•

Consult the dealer or an experienced radio/TV technician for help.

•

Antenna Warning WARNING: This device has been tested with Reverse Polarity SMA connectors with the antennas listed in Table 1

Appendix A. When integrated into OEM products, fixed antennas require installation preventing end-users from replacing them with nonapproved antennas. Antennas not listed in the tables must be tested to comply with FCC Section 15.203 (unique antenna connectors)

and Section 15.247 (emissions).

FCC-Approved Antennas

WARNING: This equipment is approved only for mobile and base station transmitting devices. Antenna(s) used for this transmitter must

be installed to provide a separation distance of at least 20 cm from all persons and must not be co-located or operating in conjunction

with any other antenna or transmitter.

DX80 Module may be used only with Approved Antennas that have been tested with this module.

Part Number Antenna Type Maximum Gain

— Integral antenna Unity gain

BWA-9O1-x Omni, 1/4 wave dipole ≤2 dBi

BWA-9O2-C Omni, 1/2 wave dipole, Swivel ≤2 dBi

BWA-9O6-A Omni Wideband, Fiberglass

Radome

BWA-9O5-B Omni Base Whip ≤7.2 dBi

BWA-9Y10-A Yagi ≤10 dBi

≤8.2 dBi

22 P/N 128185 Rev B

Table 1. Type certified Antenna

Banner Engineering Corp. • Minneapolis, MN U.S.A.

www.bannerengineering.com • Tel: 763.544.3164

FCC Certification - 2.4 GHz

FCC Certification

The DX80 Module complies with Part 15 of the FCC rules and regulations.

SureCross™ DX80 Quick Start Guide

FCC ID: UE300DX80-2400

this device may not cause harmful interference, and (2) this device must accept any interference received, including interference that

may cause undesired operation.

This device complies with Part 15 of the FCC Rules. Operation is subject to the following two conditions: (1)

FCC Notices

IMPORTANT: The DX80 Modules have been certified by the FCC for use with other products without any further certification (as per

FCC section 2.1091). Changes or modifications not expressly approved by the manufacturer could void the user’s authority to operate

the equipment.

IMPORTANT: The DX80 Modules have been certified for fixed base station and mobile applications. If modules will be used for portable

applications, the device must undergo SAR testing.

IMPORTANT: If integrated into another product, the FCC ID label must be visible through a window on the final device or it must be

visible when an access panel, door, or cover is easily removed. If not, a second label must be placed on the outside of the final device

that contains the following text: Contains FCC ID: UE300DX80-2400.

Note

This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to Part 15 of the FCC Rules.

These limits are designed to provide reasonable protection against harmful interference in a residential installation. This equipment

generates, uses, and can radiate radio frequency energy and, if not installed and used in accordance with the instructions, may cause

harmful interference to radio communications. However, there is no guarantee that interference will not occur in a particular installation.

If this equipment does cause harmful interference to radio or television reception, which can be determined by turning the equipment off

and on, the user is encouraged to try to correct the interference by one or more of the following measures:

Reorient or relocate the receiving antenna,

•

Increase the separation between the equipment and receiving module,

•

Connect the equipment into an outlet on a circuit different from that to which the receiving module is connected, and/or

•

Consult the dealer or an experienced radio/TV technician for help.

•

Antenna Warning WARNING: This device has been tested with Reverse Polarity SMA connectors with the antennas listed in Table 1

Appendix A. When integrated into OEM products, fixed antennas require installation preventing end-users from replacing them with nonapproved antennas. Antennas not listed in the tables must be tested to comply with FCC Section 15.203 (unique antenna connectors)

and Section 15.247 (emissions).

FCC-Approved Antennas

WARNING: This equipment is approved only for mobile and base station transmitting devices. Antenna(s) used for this transmitter must

be installed to provide a separation distance of at least 20 cm from all persons and must not be co-located or operating in conjunction

with any other antenna or transmitter.

DX80 Module may be used only with Approved Antennas that have been tested with this module.

Part Number Antenna Type Maximum Gain

— Integral antenna Unity gain

BWA-2O2-C Omni, 1/2 wave dipole, Swivel ≤2 dBi

BWA-2O5-C Omni, Collinear, Swivel ≤5 dBi

BWA-2O7-C Omni, Coaxial Sleeve, Swivel ≤7 dBi

Table 1. Type certified Antenna

Banner Engineering Corp. • Minneapolis, MN U.S.A.

www.bannerengineering.com • Tel: 763.544.3164

P/N 128185 Rev B 23

CAUTION . . .

Make no modifications

All specifications published in this document are subject to change. Banner reserves the right

to modify the specifications of products, prior to their order, without notice.

to this product.

Any modifications to this product not

expressly approved by Banner Engineering

could void the user’s authority to operate

the product. Contact the Factory for more

information.

P/N 128185 Rev B

Banner Engineering Corp., 9714 Tenth Ave. No., Minneapolis, MN USA 55441 • Phone: 763.544.3164 • www.bannerengineering.com • Email: sensors@bannerengineering.com

WARRANTY: Banner Engineering Corp. warrants its products to be free from defects for

one year. Banner Engineering Corp. will repair or replace, free of charge, any product of its

manufacture found to be defective at the time it is returned to the factory during the warranty

period. This warranty does not cover damage or liability for the improper application of

Banner products. This warranty is in lieu of any other warranty either expressed or implied.

Loading...

Loading...