Page 1

P

WORLD-BEAM QS18

63908

Datasheet

Miniature self-contained photoelectric sensors in universal housing

• Easily fits (or retrofits) almost any mounting situation

• Exceptional optical performance, comparable to larger “MINI-style” or barrel

sensors

• 10 to 30 V dc operation, with complementary (SPDT) NPN or PNP outputs,

depending on model

• Bright LED operating status indicators are visible from 360°

• Rugged sealed housing, protected circuitry

• Models available with or without 18 mm threaded “nose”

• Less than 1 millisecond output response for excellent sensing repeatability

• Choose 2 m (6.5 ft) or 9 m (30 ft) cable or 150 mm (6 inch) Pico-style pigtail QD

To order the 9 m (30 ft) cable model, add suffix "W/30" to the cabled model number.

QD Models. For 4-pin integral Euro-style QD, add suffix “Q8” (e.g., QS186EQ8). For 4-pin

integral Pico-style QD, add suffix “Q7” (e.g., QS186EQ7). For 4-pin 150 mm (6") Eurostyle pigtail, add suffix “Q5” (e.g., QS186EQ5). For 4-pin 150 mm (6") Pico-style pigtail,

add suffix “Q” (e.g., QS186EQ).

Opposed Mode Model Range Output

Effective beam: 13 mm (0.5 inch)

Effective beam: 13 mm (0.5 inch)

Polarized Retroreflective Mode Model Range Output

630 nm Visible Red

Retroreflective Mode Model Range Output

628 nm Visible Red QS18VN6LV

QS186EV (624 nm Visible Red)

QS186E (940 nm Infrared) N/A

QS18VN6R NPN

QS18VP6R PNP

QS186EB (940 nm Infrared)

QS18VN6RB NPN

QS18VP6RB PNP

QS18VN6LP

QS18VP6LP PNP

QS18VP6LV PNP

20 m (66 ft)

3 m (10 ft)

3.5 m (12 ft)

6.5 m (21 ft)

N/A

N/A

NPN

NPN

Original Document

63908 Rev. H

4 March 2014

Page 2

WORLD-BEAM QS18

Convergent Mode Model Range Output

630 nm Visible Red

QS18VN6CV15

QS18VP6CV15 PNP

QS18VN6CV45

QS18VP6CV45 PNP

16 mm (0.63 ft)

43 mm (1.7

inches)

NPN

NPN

Diffuse Mode Model Range Output

940 nm Infrared QS18VN6D

NPN

QS18VP6D PNP

450 mm (18

inches)

QS18VN6DB (Diffuse, wide) NPN

QS18VP6DB (Diffuse, wide) PNP

Divergent Mode Model Range Output

940 nm Infrared QS18VN6W

NPN

100 mm (4

QS18VP6W PNP

inches)

Fixed Field Mode Model Range Output

660 nm Visible Red

QS18VN6FF50

QS18VP6FF50 PNP

QS18VN6FF100

QS18VP6FF100 PNP

50 mm (2 inches)

100 mm (4

inches)

NPN

NPN

Plastic Fiber Optic Mode Model Range Output

660 nm Visible Red QS18VN6FP

NPN

Range varies by sensing

QS18VP6FP PNP

mode and fiber optics

used

Glass Fiber Optic Mode Model Range Output

940 nm Infrared QS18VN6F

NPN

Range varies by sensing

QS18VP6F PNP

mode and fiber optics

used

2 www.bannerengineering.com - tel: 763-544-3164 P/N 63908 Rev. H

Page 3

Model Suffix E, EV, R, and FF

15.0 mm

(0.59")

31.0 mm

(1.22")

3.0 mm

(0.12")

17.1 mm

(0.67")

24.1 mm

(0.95")

35.0 mm

(1.38")

Yellow

LED

Green

LED

Ø3.3 mm (0.13")

Max. torque 0.6 Nm (5 in-lbs)

Model Suffix EB, RB

3.0 mm

(0.12")

21.1 mm

(0.82")

Model Suffix DB, W

3.0 mm

(0.12")

21.1 mm

(0.82")

WORLD-BEAM QS18

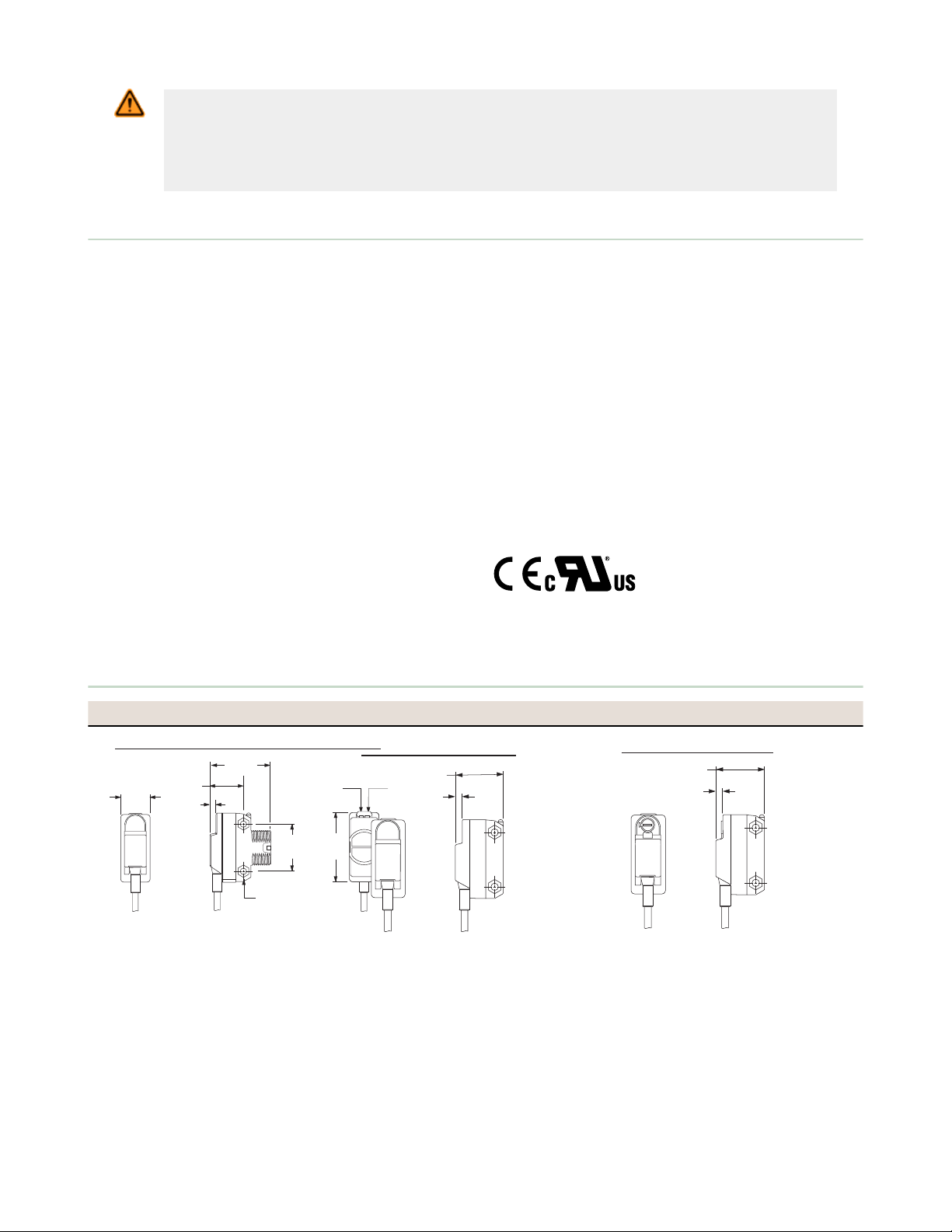

WARNING: Not To Be Used for Personnel Protection

Never use this device as a sensing device for personnel protection. Doing so could lead to

serious injury or death. This device does not include the self-checking redundant circuitry necessary

to allow its use in personnel safety applications. A sensor failure or malfunction can cause either an

energized or de-energized sensor output condition.

Specifications

Supply Voltage

10 to 30 V dc (10% maximum ripple) at less than 25 mA, exclusive of

load;

Protected against reverse polarity and transient voltages

Repeatability

Opposed Mode: 100 microseconds

FF Mode: 160 microseconds

All others: 150 microseconds

Adjustments

Glass Fiber Optic, Plastic Fiber Optic, Convergent, Diffuse, and

Retroreflective mode models (only): Single-turn sensitivity (Gain)

adjustment potentiometer

Indicators

2 LED indicators on sensor top:

Green solid: Power on

Amber solid: Light sensed

Green flashing: Output overloaded

Amber flashing: Marginal excess gain (1 to 1.5x excess gain)

Prior to date code 0223, the output indicator was red.

Construction

ABS housing

3 mm mounting hardware included

Connections

2 m (6.5 ft) 4-wire PVC cable, 9 m (30 ft) 4-wire PVC cable, 4-pin Picostyle or Euro-style QD, 4-pin Pico-style or Euro-style 150 mm (6 in)

pigtail QD, depending on model

Dimensions and Features

Models E, EV, R, and FF

Models EB and RB Models DB and W

Output Configuration

Solid-state complementary (SPDT): NPN or PNP (current sinking or

sourcing), depending on model;

Rating: 100 mA maximum each output at 25 °C

Off-state Leakage Current (FF Mode): less than 200 μA @ 30V dc

Off-state Leakage Current (All others): less than 50 μA @ 30V dc

ON-state Saturation Voltage: less than 1 V @ 10 mA; less than 1.5 V @

100 mA

Protected against false pulse on power-up and continuous overload or

short circuit of outputs

Output Response

Opposed Mode: 750 microseconds ON; 375 microseconds OFF

FF Mode: 850 microseconds ON/OFF

All others: 600 microseconds ON/OFF

NOTE: 100 millisecond delay on power-up; outputs do not conduct

during this time

Environmental

IEC IP67; NEMA 6

Operating Conditions

Temperature: –20 °C to 70 °C (–4 °F to 158 °F)

Relative Humidity: 90% @ 50 °C (non-condensing)

Certifications

P/N 63908 Rev. H www.bannerengineering.com - tel: 763-544-3164 3

Page 4

Model Suffix FP

15.0 mm

(0.59")

7.5 mm

(0.30")

13.4 mm

(0.53")

7.6 mm

(0.30")

17.1 mm

(0.67")

27.5 mm

(1.09")

5.2 mm

(0.21")

31.0 mm

†

(1.22")

3.0 mm

(0.12")

†

CV Models:

33.2 mm (1.31")

Model Suffix CV15, CV45, D, LV, LP

Single-turn

Sensitivity

Adjustment

M18x1 Thread

Max. torque 2.3 Nm (20 in-lbs)

Model Suffix F

17.1 mm

(0.67")

36.9 mm

(1.45")

19.8 mm

(0.78")

Slot for

Fiber Clip

Model Suffix Q7 Model Suffix Q8

Model Suffix Q

(e.g. QS186EQ)

Model Suffix Q5

(e.g. QS186EQ5)

(e.g. QS186EQ7) (e.g. QS186EQ8)

150 mm (6")

Pico-style

Pigtail

150 mm (6")

Euro-style

Pigtail

41.5 mm

(1.63")

49 mm

(1.93")

Integral

4-pin

Pico-Style QD

Integral

4-pin

Euro-Style QD

8.0 mm

(0.32")

24.2 mm

(0.95")

1

10

100

1 m

3.3 ft

10 m

33 ft

100 m

330 ft

0.1 m

0.3 ft

1000

E

X

C

E

S

S

G

A

I

N

DISTANCE

QS186E, EV and

QS18...R

Opposed Mode

20 m

66 ft

16 m

52 ft

12 m

40 ft

8 m

26 ft

4 m

12 ft

0

0

250 mm

500 mm

750 mm

250 mm

500 mm

750 mm

0

10 in

20 in

30 in

10 in

20 in

30 in

DISTANCE

QS186E, EV and QS18...R

Opposed Mode

1

10

100

0.1 m

0.33 ft

1 m

3.3 ft

10 m

33 ft

0.01 m

0.03 ft

1000

E

X

C

E

S

S

G

A

I

N

DISTANCE

QS186EB and

QS18...RB

Opposed Mode

3.75 m

12.5 ft

3.0 m

10 ft

2.25 m

7.5 ft

1.5 m

5 ft

.75 m

2.5 ft

0

0

150 mm

300 mm

450 mm

150 mm

300 mm

450 mm

0

6 in

12 in

18 in

6 in

12 in

18 in

DISTANCE

QS186EB and QS18...RB

Opposed Mode

WORLD-BEAM QS18

Models FP Models CV15, CV45, D, LV, and LP Models F

M18 x 1 Jam Nut Packing List

M3 hardware packet contents:

2 - M3 x 0.5 x 20 mm stainless steel screw

2 - M3 x 0.5 stainless steel hex nut

2 - M3 stainless steel washer

Sensor

M18 x 1 jam nut

M3 hardware packet

Installation sheet, p/n 63687

Performance Curves

Opposed Mode

Excess Gain Curve Beam Pattern Excess Gain Curve Beam Pattern

4 www.bannerengineering.com - tel: 763-544-3164 P/N 63908 Rev. H

Page 5

1

10

100

0.1 m

0.33 ft

1 m

3.3 ft

10 m

33 ft

0.01 m

0.03 ft

1000

E

X

C

E

S

S

G

A

I

N

DISTANCE

QS18...LP

Retroreflective Mode

with BRT-84 Reflector

3.75 m

12.5 ft

3.0 m

10 ft

2.25 m

7.5 ft

1.5 m

5 ft

.75 m

2.5 ft

0

0

10 mm

20 mm

30 mm

10 mm

20 mm

30 mm

0

0.4 in

0.8 in

1.2 in

0.4 in

0.8 in

1.2 in

DISTANCE

QS18...LP

Retroreflective Mode

with BRT-84 Reflector

1

10

100

0.1 m

0.33 ft

1 m

3.3 ft

10 m

33 ft

0.01 m

0.03 ft

1000

E

X

C

E

S

S

G

A

I

N

DISTANCE

QS18...LV

Retroreflective Mode

with BRT-84 Reflector

7.5 m

25 ft

6.0 m

20 ft

4.5 m

15 ft

3.0 m

10 ft

1.5 m

5 ft

0

0

50 mm

100 mm

150 mm

50 mm

100 mm

150 mm

0

2 in

4 in

6 in

2 in

4 in

6 in

DISTANCE

QS18...LV

Retroreflective Mode

with BRT-84 Reflector

1

10

100

10 mm

0.4 in

100 mm

4.0 in

1000 mm

40.0 in

1 mm

0.04 in

1000

E

X

C

E

S

S

G

A

I

N

DISTANCE

QS18...CV15

Convergent Mode

50 mm

2.0 in

40 mm

1.6 in

30 mm

1.2 in

20 mm

0.8 in

10 mm

0.4 in

0

0

2 mm

4 mm

6 mm

2 mm

4 mm

6 mm

0

.08 in

.16 in

.24 in

.08 in

.16 in

.24 in

DISTANCE

Convergent Mode

QS18...CV15

1

10

100

10 mm

0.4 in

100 mm

4.0 in

1000 mm

40.0 in

1 mm

0.04 in

1000

E

X

C

E

S

S

G

A

I

N

DISTANCE

QS18...CV45

Convergent Mode

75 mm

3.0 in

60 mm

2.4 in

45 mm

1.8 in

30 mm

1.2 in

15 mm

0.6 in

0

0

2 mm

4 mm

6 mm

2 mm

4 mm

6 mm

0

.08 in

.16 in

.24 in

.08 in

.16 in

.24 in

DISTANCE

Convergent Mode

QS18...CV45

1

10

100

10 mm

0.4 in

100 mm

4.0 in

1000 mm

40.0 in

1 mm

0.04 in

1000

E

X

C

E

S

S

G

A

I

N

DISTANCE

QS18...D

Diffuse Mode

500 mm

20.0 in

400mm

16.0 in

300 mm

12.0 in

200 mm

8.0 in

100 mm

4.0 in

0

0

2 mm

4 mm

6 mm

2 mm

4 mm

6 mm

0

.08 in

.16 in

.24 in

.08 in

.16 in

.24 in

DISTANCE

QS18...D

Diffuse Mode

1

10

100

10 mm

0.4 in

100 mm

4.0 in

1000 mm

40.0 in

1 mm

0.04 in

1000

E

X

C

E

S

S

G

A

I

N

DISTANCE

QS18...DB

Diffuse Mode

500 mm

20.0 in

400mm

16.0 in

300 mm

12.0 in

200 mm

8.0 in

100 mm

4.0 in

0

0

10 mm

20 mm

30 mm

10 mm

20 mm

30 mm

0

0.4 in

0.8 in

1.2 in

0.4 in

0.8 in

1.2 in

DISTANCE

QS18...DB

Diffuse Mode

1

10

100

10 mm

0.4 in

100 mm

4.0 in

1000 mm

40.0 in

1 mm

0.04 in

1000

E

X

C

E

S

S

G

A

I

N

DISTANCE

QS18...W

Divergent

Diffuse Mode

100 mm

4.0 in

80 mm

3.2 in

60 mm

2.4 in

40 mm

1.6 in

20 mm

0.8 in

0

0

10 mm

20 mm

30 mm

10 mm

20 mm

30 mm

0

0.4 in

0.8 in

1.2 in

0.4 in

0.8 in

1.2 in

DISTANCE

Divergent

Diffuse Mode

QS18...W

WORLD-BEAM QS18

Polarized Retroreflective Retroreflective

Excess Gain Curve Beam Pattern Excess Gain Curve Beam Pattern

Convergent (Performance is based on a 90% reflectance white test card.)

Excess Gain Curve Beam Pattern Excess Gain Curve Beam Pattern

Diffuse (Performance is based on a 90% reflectance white test card.)

Excess Gain Curve Beam Pattern Excess Gain Curve Beam Pattern

Divergent (Performance is based on a 90% reflectance white test card.)

Excess Gain Curve Beam Pattern

P/N 63908 Rev. H www.bannerengineering.com - tel: 763-544-3164 5

Page 6

1

10

100

1.0 mm

0.04 in

10.0 mm

0.4 in

100 mm

4.0 in

0.1 mm

0.004 in

1000

E

X

C

E

S

S

G

A

I

N

DISTANCE

QS18...FF50

Fixed-Field

1

10

100

1.0 mm

0.04 in

10.0 mm

0.4 in

100 mm

4.0 in

0.1 mm

0.004 in

1000

E

X

C

E

S

S

G

A

I

N

DISTANCE

QS18...FF100

Fixed-Field

1

10

100

10 mm

.40 in

100 mm

4.0 in

1000 mm

40 in

1 mm

.04 in

1000

E

X

C

E

S

S

G

A

I

N

DISTANCE

QS18..FP

QS18..FP

Opposed Mode

Plastic Fibers

PIT66U Fiber

PIT46U Fiber

250 mm

10 in

200 mm

8 in

150 mm

6 in

100 mm

4 in

50 mm

2 in

0

0

20 mm

40 mm

60 mm

20 mm

40 mm

60 mm

0

0.8 in

1.6 in

2.4 in

0.8 in

1.6 in

2.4 in

DISTANCE

QS18..FP

QS18..FP

PIT46U

PIT66U

Opposed Mode

Plastic Fibers

1

10

100

1 mm

.04 in

10 mm

.4 in

100 mm

4 in

.1 mm

.004 in

1000

E

X

C

E

S

S

G

A

I

N

DISTANCE

Diffuse Mode

Plastic Fibers

PBT66U Fiber

PBT46U Fiber

QS18..FP

QS18..FP

100 mm

4.8 in

80 mm

3.2 in

60 mm

2.4 in

40 mm

1.6 in

20 mm

0.8 in

0

0

10 mm

20 mm

30 mm

10 mm

20 mm

30 mm

0

0.4 in

0.8 in

1.2 in

0.4 in

0.8 in

1.2 in

DISTANCE

QS18..FP

QS18..FP

PBT46U

PBT66U

Diffuse Mode

Plastic Fibers

1

10

100

.1 m

.33 ft

1 m

3.3 ft

10 m

33 ft

.01 m

.033 ft

1000

E

X

C

E

S

S

G

A

I

N

DISTANCE

QS18F

Opposed Mode

Glass Fibers

IT23S Fibers

w/L9 lenses

IT23S

Fibers

IT13S

Fibers

500 mm

20 in

400 mm

16 in

300 mm

12 in

200 mm

8 in

100 mm

4 in

0

0

25 mm

50 mm

75 mm

25 mm

50 mm

75 mm

0

1 in

2 in

3 in

1 in

2 in

3 in

DISTANCE

QS18F

Opposed Mode

IT13S IT23S

1

10

100

10 mm

.4 in

100 mm

4 in

1000 mm

40 in

1 mm

.04 in

1000

E

X

C

E

S

S

G

A

I

N

DISTANCE

QS18F

Diffuse Mode

Glass Fibers

BT23S Fiber

BT13S Fiber

37.5 mm

1.5 in

30 mm

1.2 in

22.5 mm

0.9 in

15 mm

0.6 in

7.5 mm

0.3 in

0

0

0.65 mm

1.3 mm

1.9 mm

0.65 mm

1.3 mm

1.9 mm

0

0.025 in

0.050 in

0.075 in

0.025 in

0.050 in

0.075 in

DISTANCE

QS18F

Diffuse Mode

BT23SBT13S

3

1

4

2

10-30V dc

–

+

Load

Load

3

1

4

2

10-30V dc

–

+

Load

Load

bn (1)

bu (3)

+

−

10–30V dc

WORLD-BEAM QS18

Fixed Field - 50 mm Fixed Field - 100 mm

Excess Gain Curve Spot Sizes Excess Gain Curve Spot Sizes

At 25 mm: 7.5 × 5.7

mm

At 50 mm: 6.1 × 4.6 mm

At 100 mm: 2.9 × 2.9 mm

At 50 mm: 6.3 × 4.9

mm

Opposed - Plastic Fiber Bifurcated - Plastic Fiber (Performance is based on a

90% reflectance white test card.)

Excess Gain Curve Beam Pattern Excess Gain Curve Beam Pattern

Opposed - Glass Fiber (Performance is based on a

90% reflectance white test card.)

Bifurcated - Glass Fiber (Performance is based on a

90% reflectance white test card.)

Excess Gain Curve Beam Pattern Excess Gain Curve Beam Pattern

Wiring Diagrams

QS18 with NPN (Sinking) Outputs

6 www.bannerengineering.com - tel: 763-544-3164 P/N 63908 Rev. H

QS18 with PNP (Sourcing) Outputs QS18 Emitters

Page 7

Cutting Ports

Lift to Open Ports

A

B

C

Fiber end

Adapter

Adapter Installation

WORLD-BEAM QS18

Installing Fibers

Cutting Unterminated Plastic Fibers QS18V..6FP

Unterminated plastic fibers are designed to be cut by the user to the length required for the application.

To facilitate cutting, a Banner model PFC-1 cutting device is supplied with the fiber. Cut the fiber as follows:

Use small ports for fiber sizes:

• 0.25 mm (0.01 inches)

• 0.5 mm (0.02 inches)

Use large ports for fiber sizes:

• 0.75 mm (0.03 inches)

• 1.0 mm (0.04 inches)

• 1.5 mm (0.06 inches)

Figure 1. PFC-1 Cutting Device

1. Locate the control end of the fiber (the unfinished end).

2. Determine the length of fiber required for the application. If using a bifurcated fiber, separate the two halves of the

fiber at least 51 mm (2 inches) beyond the fiber cutting location.

3. Lift the top (blade) of the cutter to open the cutting ports.

4. Insert one of the control ends through one of the cutting ports on the cutter so that the excess fiber protrudes from the

back of the cutter.

5. Double-check the fiber length, and close the cutter until the fiber is cut.

6. Using a different cutting port, cut the second control end to the required length.

NOTE: To ensure a clean cut each time, do not use a cutting port more than once.

7. Gently wipe the cut ends of the fiber with a clean, dry cloth to remove any contamination. Do not use solvents or

abrasives on any exposed optical fiber.

Installing Plastic Fibers QS18V..6FP

Follow these steps to install the plastic fibers.

Figure 2. Installing Plastic Fibers

1. Slide the fiber gripper up to unlock it (A).

2. If using 0.25 mm or 0.5 mm core fibers, slide the plastic fiber adapters onto the fibers, flush with the fiber ends.

3. Carefully insert the prepared plastic fiber ends into the ports (B) as far as possible without applying extra force.

4. Slide the fiber gripper down to lock the fibers in place (C).

P/N 63908 Rev. H www.bannerengineering.com - tel: 763-544-3164 7

Page 8

O-rings

Retaining Clip

44 Typ.

ø 14.5

M12 x 1

2

3

4

1

32 Typ.

[1.26"]

30 Typ.

[1.18"]

ø 14.5 [0.57"]

M12 x 1

ø 9.0

32 Typ.

4

3

1

2

WORLD-BEAM QS18

Installing Glass Fibers QS18V..6F

Follow these steps to install the glass fibers.

Figure 3. Installing Glass Fibers

1. Slide the supplied o-ring on the sensor end of the fibers, as shown.

2. Press the fiber ends firmly into the ports located on the front of the sensor.

3. Slide the supplied u-shaped retaining clip into the slot in the sensor’s barrel until the clip snaps into place.

Accessories

Cordsets

4-Pin Threaded M12/Euro-Style Cordsets

Model Length Style Dimensions Pinout

MQDC-406 1.83 m (6 ft)

MQDC-415 4.57 m (15 ft)

MQDC-430 9.14 m (30 ft)

MQDC-450 15.2 m (50 ft)

MQDC-406RA 1.83 m (6 ft)

MQDC-415RA 4.57 m (15 ft)

MQDC-430RA 9.14 m (30 ft)

MQDC-450RA 15.2 m (50 ft)

4-Pin Snap-on M8/Pico-Style Cordsets

Model Length Style Dimensions Pinout

PKG4-2 2.00 m (6.56 ft) Straight

Straight

Right-Angle

1 = Brown

2 = White

3 = Blue

4 = Black

1 = Brown

2 = White

3 = Blue

4 = Black

8 www.bannerengineering.com - tel: 763-544-3164 P/N 63908 Rev. H

Page 9

ø 10.9

29 Typ.

15 Typ.

30

41

46

A

B

C

46

B

C

A

32

20

WORLD-BEAM QS18

4-Pin Snap-on M8/Pico-Style Cordsets

Model Length Style Dimensions Pinout

PKW4Z-2 2.00 m (6.56 ft) Right-Angle

WORLD-BEAM QS18 Brackets

All measurements are in millimeters.

SMB18A

• Right-angle

mounting bracket

with a curved slot

for versatile

SMB312S

• Stainless steel 2axis, side-mount

bracket

orientation

• 12-ga. stainless

steel

• 18 mm sensor

mounting hole

• Clearance for M4

(#8) hardware

A = 4.3 x 7.5, B = diam. 3,

C = 3 x 15.3

Hole center spacing: A to B = 24.2

Hole size: A = ø 4.6, B = 17.0 × 4.6, C = ø 18.5

Retroreflective Targets

See the Accessories section of your current Banner Engineering Corp catalog for complete information. NOTE: Polarized

sensors require corner cube type retroreflective targets only.

Plastic and Glass Fiber Optics

See the Accessories section of your current Banner Engineering Corp catalog for a list of plastic and glass fiber optic

cables.

Banner Engineering Corp Limited Warranty

Banner Engineering Corp. warrants its products to be free from defects in material and workmanship for one year following

the date of shipment. Banner Engineering Corp. will repair or replace, free of charge, any product of its manufacture

which, at the time it is returned to the factory, is found to have been defective during the warranty period. This warranty

does not cover damage or liability for misuse, abuse, or the improper application or installation of the Banner product.

THIS LIMITED WARRANTY IS EXCLUSIVE AND IN LIEU OF ALL OTHER WARRANTIES WHETHER EXPRESS OR

IMPLIED (INCLUDING, WITHOUT LIMITATION, ANY WARRANTY OF MERCHANTABILITY OR FITNESS FOR A

PARTICULAR PURPOSE), AND WHETHER ARISING UNDER COURSE OF PERFORMANCE, COURSE OF DEALING OR

TRADE USAGE.

This Warranty is exclusive and limited to repair or, at the discretion of Banner Engineering Corp., replacement. IN NO

EVENT SHALL BANNER ENGINEERING CORP. BE LIABLE TO BUYER OR ANY OTHER PERSON OR ENTITY FOR

ANY EXTRA COSTS, EXPENSES, LOSSES, LOSS OF PROFITS, OR ANY INCIDENTAL, CONSEQUENTIAL OR

SPECIAL DAMAGES RESULTING FROM ANY PRODUCT DEFECT OR FROM THE USE OR INABILITY TO USE THE

PRODUCT, WHETHER ARISING IN CONTRACT OR WARRANTY, STATUTE, TORT, STRICT LIABILITY,

NEGLIGENCE, OR OTHERWISE.

P/N 63908 Rev. H www.bannerengineering.com - tel: 763-544-3164 9

Page 10

WORLD-BEAM QS18

Banner Engineering Corp. reserves the right to change, modify or improve the design of the product without assuming any

obligations or liabilities relating to any product previously manufactured by Banner Engineering Corp.

www.bannerengineering.com - tel: 763-544-3164

Loading...

Loading...