Page 1

QL55 Series Luminescence Sensor

!

Relative Received Signal

Sensing Distance

0

0

10 mm

(0.4")

20 mm

(0.8")

30 mm

(1.2")

40 mm

(1.6")

50 mm

(2.0")

20%

40%

60%

80%

100%

Relative Received Signal

Sensing Distance

0

0

10 mm

(0.4")

20 mm

(0.8")

30 mm

(1.2")

40 mm

(1.6")

50 mm

(2.0")

20%

40%

60%

80%

100%

Relative Received Signal

Sensing Distance

0

40 mm

(1.6")

30 mm

(1.2")

50mm

(2.0")

60 mm

(2.4")

70 mm

(2.8")

80 mm

(3.2")

20%

40%

60%

80%

100%

Self-contained, microprocessor-based luminescence sensor

Features

• Self-contained design in a robust, compact metal housing

• High sensitivity

• Microprocessor-controlled

• Senses luminescent marks, even on luminescent backgrounds

• Senses luminescence on reflective surfaces, such as ceramic, metal, or mirrored

glass

• Easy-to-set sensing threshold

• Fast 250-microsecond sensing response time; high 2 kHz switching frequency

• Switch-selectable NPN or PNP discrete output, plus 0 to 5.5V dc analog output

• Switch-selectable output OFF-delay

• 3-position swivel QD connector

Models

QL55M6XD15BQ

Sensing

Range

9 to 18 mm

(0.35" to 0.71")

Cable/

Connector*

4-pin Euro-style

(M12)

QD connector

with 3-position

swivel

QL55M6XD30BQ

20 to 40 mm

(0.79" to 1.57")

(locking

screw-secured)

QL55M6XD50BQ

40 to 75 mm

(1.57" to 2.95")

* Mating cable required; see back cover for cable options.

Models

Supply

Voltage

10 to

30V dc

Outputs Sensor Performance

One selectable

NPN or PNP

discrete plus

one

0 to 5.5V dc

analog

WARNING . . .

Not To Be Used for Personnel Protection

Never use these products as sensing devices for personnel protection. Doing so could lead to serious injury or death.

These sensors do NOT include the self-checking redundant circuitry necessary to allow their use in personnel safety

applications. A sensor failure or malfunction can cause either an energized or de-energized sensor output condition. Consult your current

Banner Safety Products catalog for safety products which meet OSHA, ANSI and IEC standards for personnel protection.

Printed in USA 02/05 P/N 112153 rev. C

Page 2

QL55 Series Luminescence Sensor

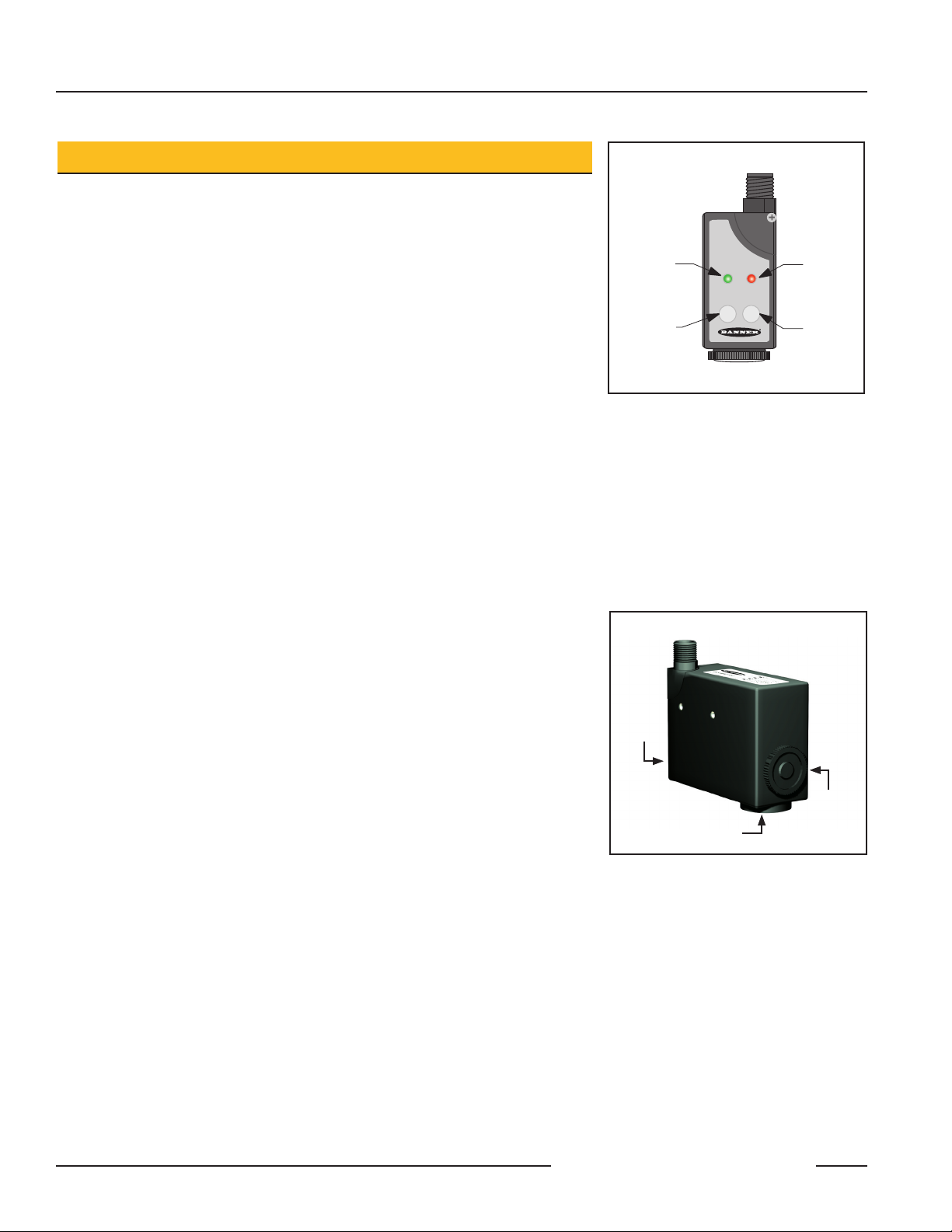

READY OUT

MARK

BKGD

Red

Output LED

Green Ready/

Overload LED

(Power ON

Indicator)

Mark

Push Button

Background

Push Button

Overview

The QL55 Series Sensor is an easy-to-use, extremely sensitive microprocessor-based

luminescence sensor that emits ultraviolet light from a high-power LED and scans for

luminescence in materials. The QL55 senses the luminescence inherent in a material,

or it can sense luminophores added to a material in process to make it luminescent.

The sensor can be set to accurately sense a wide range of luminescence intensities

and background conditions. The two-step QL55 Sensor programming procedure

sets the threshold for target luminescence and background. The Luminescent Target

condition is taught first, followed by the Luminescent Target Absent (background)

condition. During operation, the sensor outputs will be ON when the luminescent

target object is present, and OFF for the background condition. (The sensor may

instead be taught to respond to the Background condition; see page 3.)

Located within the QL55 Sensor, two selector switches may be used to enable an

output OFF-delay option and for setting the discrete output to NPN or PNP (see Figure

5). The QL55 is available with one of three operating ranges, to a maximum of 75 mm

(2.95"), depending on the model.

The sensor housing has two push buttons, Mark and Background, for easy

programming; it has two LEDs, Ready/Overload and Output, for easy monitoring

during operation. See Figure 1.

Figure 1. QL55 Luminescence Sensor

features (sensor back)

For easier understanding, the sensor faces are described in this data sheet as labeled

in Figure 2. The key pad is considered the sensor back, and the lens is on the bottom.

Luminescence Sensing

Luminescence sensing detects a form of electromagnetic radiation, caused by the

shining of UV light (“black” light, invisible to the human eye) on a luminescent

substrate material, such as a petroleum-based adhesive. When the UV light shines

on the adhesive, the light “excites” electrons in the material (effecting a change of

state), causing it to reflect visible light. Thus an invisible light source can produce a

visible reflection. Because it emits UV light but detects visible waves, the sensor can

distinguish between the fluorescent material and other highly reflective materials.

Cost Factors

When comparing luminescence sensors to make a selection, it is important to

consider whether luminophores must be added to the product sensed, in order for

the sensor to detect luminescence. Generally speaking, the more sensitive the sensor,

the lower the level of luminescence required for detection. Less sensitive (and usually

less expensive) sensors may require an additional step in the production process, and

a substantial cost over time, to add luminophores. For information on less expensive,

less sensitive luminescence sensor models, refer to data sheet p/n 112151, Model

QL50 Luminescence Sensor, or contact a Banner applications engineer for more

information (see back page for addresses).

Top

Back

Key

Pad

Bottom

Lens

Figure 2. QL55 orientation of features

Front

Blanking

Plug

2 P/N 112153 rev. C

Banner Engineering Corp. • Minneapolis, MN U.S.A.

www.bannerengineering.com • Tel: 763.544.3164

Page 3

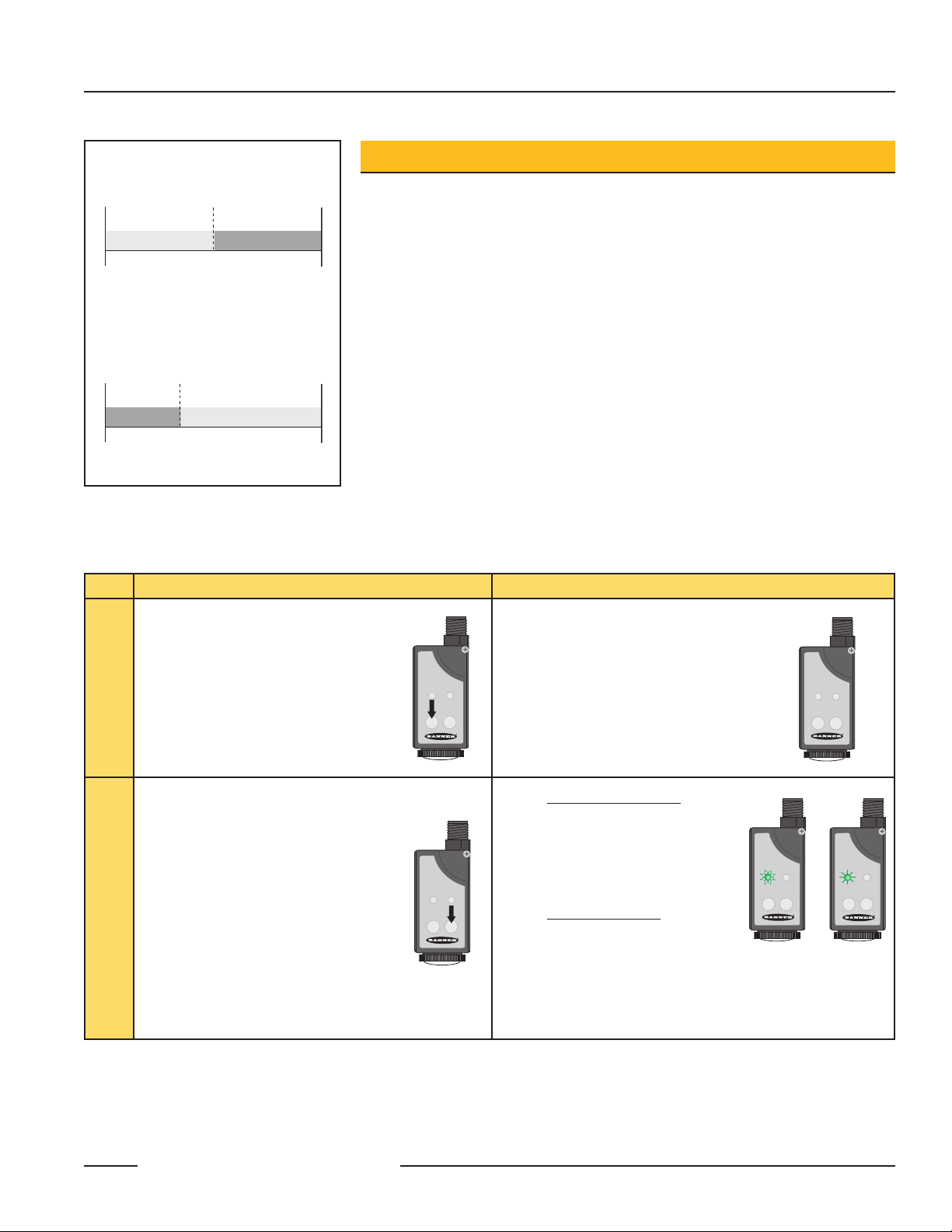

Output OFF Output ON

Less Luminescent

Condition

More Luminescent

Condition

Less Luminescent

Condition

More Luminescent

Condition

Least

Luminescent

Most

Luminescent

Output OFFOutput ON

Least

Luminescent

Most

Luminescent

Light Operate

Dark Operate

Figure 3. Sensor automatically selects light

READY OUT

MARK

BKGD

READY OUT

MARK

BKGD

READY OUT

MARK

BKGD

READY OUT

MARK

BKGD

OUTREADY

MARK

BKGD

then

operate or dark operate, when

configured as described below

QL55 Series Luminescence Sensor

Sensor Configuration

In this simple two-step procedure, the sensor samples the luminescence levels of

both the target (Mark) and the background (Background) conditions. The sensor

automatically selects light operate or dark operate (see Figure 3) based on the relative

luminescence of the two conditions. Using the procedure described below, sensing

the more luminescent condition (in this case the target to be sensed) will close the

normally open output, turn on the red Output LED, and cause the output to conduct

current (light operate).

If the application requires the output to conduct for a less luminescent condition,

reverse the procedure (dark operate):

• Present the less luminescent condition first (Mark push button) and then

• Present the more luminescent condition (Background push button).

Condition

SET Output ON

Condition

SET Output OFF

Procedure Result

• Position luminescent target in front of

sensing lens.

• Press Mark push button (approx. 4 sec.)

until green Ready LED turns OFF.

• Remove luminescent target from

sensor’s field of view.

• Press and hold Background push button

(approx. 4 sec.) until green blinks.

Green Ready LED: turns OFF

Red Output LED: OFF

Green Ready LED stays OFF, and

sensor stores the Output ON condition.

Programming Accepted

Green Ready LED: Flashes 1x, then ON

Red Output LED: OFF

Green Ready LED stays ON, and

sensor stores the Output OFF

(background) condition.

Programming Error

(Due to insufficient contrast between

target and background luminescence)

Green Ready LED: flashes slowly (approx. 2 Hz)

Repeat programming procedure from the beginning.

If programming fails again, increase the target luminescence or

subdue the background.

P/N 112153 rev. C 3

Banner Engineering Corp. • Minneapolis, MN U.S.A.

www.bannerengineering.com • Tel: 763.544.3164

Page 4

QL55 Series Luminescence Sensor

Sensor

Output

OFF-Delay (20 ms)

Output Ends

Output

Starts

ON

1 2

OFF-delay

Active

OFF-delay

Inactive

(default)

NPN (default)

PNP

NPN/PNP Selector

(recessed

below top board)

ON

1 2

DIP Switch 2:

Output OFF-Delay Selector

DIP Switch 1:

For factory use only;

leave in OFF position

Sensor Setup

Output OFF-Delay

Setting an output OFF-delay extends the duration of the QL55 sensor’s ON output by

20 ms. See Figure 4. The sensor default is for no OFF-delay.

NOTE: Take precautions against potential static discharge.

To activate the output OFF-delay option:

1. Remove power from sensor.

2. Remove the four cover screws and the sensor side cover.

3. Slide DIP switch 2 (shown in Figure 5) to the ON position.

NOTE: Leave DIP switch 1 in its factory-set position.

4. Change NPN/PNP output selection, if applicable.

5. Replace the sensor side cover and screws.

Setting NPN / PNP Output

The QL55 has a selector switch for setting the output to NPN (current sinking) or PNP

(current sourcing). The sensor is pre-set with the output set to NPN. If the sensor will

be operating with an NPN output (and no output OFF-delay), the sensor housing does

not need to be opened.

NOTE: Take precautions against potential static discharge.

To set NPN or PNP output:

1. Remove power from sensor.

Figure 4. Output OFF-delay: Output

continues for 20 ms after sensing

stops

2. Access the red sliding NPN/PNP selector switch by removing the four cover screws

and the sensor side cover. The switch is located deep within the sensor housing;

do not confuse it with the bank of two DIP switches. The NPN/PNP selector switch

is visible below the circuit board, next to the exposed mounting screw location (see

Figure 5).

Figure 5. Selector switches: Output OFF-

Delay and NPN/PNP output select

3. Carefully use a small screwdriver (preferably non-metallic) to select the NPN or

PNP switch position.

4. Replace the sensor side cover and screws before installing the sensor.

NOTE: If a cover screw is lost, contact the Banner applications group for a free

replacement (see back page for addresses).

4 P/N 112153 rev. C

Banner Engineering Corp. • Minneapolis, MN U.S.A.

www.bannerengineering.com • Tel: 763.544.3164

Page 5

QL55 Series Luminescence Sensor

Sensor Installation

Do not attempt to change the lens position on the sensor housing. The sensor will

work only with the lens in the bottom port (see Figure 2). No optical components

exist behind the blanking plug on the sensor front; do not remove the blanking plug.

1. Loosen the connector locking screw (several turns), and position the QD connector

as needed (back, side, or bottom of the sensor). Tighten the locking screw after the

connector is properly positioned.

2. Measure the appropriate operating distance from the front surface of the sensor

optics to the surface or object to be sensed. Do not exceed the sensing range for

your model (see page 1 for sensor model and range).

3. Fasten the sensor to its intended location using two to four M5 mounting screws

and washers. There are four mounting holes on the bottom (lens side) of the

sensor and two on each side (see page 7).

NOTE: Proper mounting screw length depends on mounting bracket thickness.

Additional washers may be necessary to make sure the screws do not

exceed the thread depth.

4. Attach the QD cable to the sensor’s connector; see hookups on page 7.

Sensor Operation

Power up the QL55 Sensor after programming, setup, and installation. The green

Ready LED turns ON to indicate that the sensor is in RUN mode and ready to sense

the luminescent target as programmed. When configured as described on page 3,

sensing the target object will cause the normally-open output to close and the red

Output LED to turn ON.

If the sensor experiences an output overload condition during operation, the green

Ready LED will flash fast (approx. 4 Hz). Verify that output current is less than

200 mA.

Banner Engineering Corp. • Minneapolis, MN U.S.A.

P/N 112153 rev. C 5

www.bannerengineering.com • Tel: 763.544.3164

Page 6

QL55 Series Luminescence Sensor

Specifications

Sensing Beam

Supply Voltage

Supply Protection Circuitry

Output Configuration

Output Rating

Output Protection

Output Response Time

Adjustments

Indicators

Construction

Environmental Rating

Connections

Operating Conditions

Data Retention

Scanning Range

Spot Diameter

Ambient Light Rejection

Shock Resistance

Vibration

Ultraviolet high-power LED (370 nm)

10 to 30V dc, 2 V pp max ripple

80 mA max, exclusive of load

Protected against reverse polarity

Discrete NPN or PNP

Analog 0 to 5.5V dc ± 10%, ripple 40 mV pp max.

Saturation Voltage: 1V max. NPN / 2V max PNP

Leakage Current: <100 µA

200 mA maximum load

NPN/PNP: Protected against reverse polarity, overload, and short circuit

(pull down/up resistance 10 k

Analog: Protected against short circuit (output resistance 2.2 kΩ)

250 microseconds

2 push buttons (MARK and BKGD) determine switching threshold and Light/Dark operate (see page 3)

2 selector switches (see Figure 5)

• 20 ms Output OFF-delay

• NPN/PNP output

Red Output LED

ON: output is conducting

Green Ready/Overload LED

ON: normal operating condition, RUN mode

Flashing 2 Hz: setup failure due to insufficient contrast

Flashing 4 Hz: output overload condition (verify output current ≤ 200 mA)

Housing: zinc, aluminum, and magnesium alloy

Lens: glass

IEC IP62

4-pin Euro-style (M12) QD connector. See back cover for required accessory cable options.

Temperature: -10° to +55°C (+14° to +131°F)

Max. Relative Humidity: 85% at 50°C (non-condensing)

EEPROM nonvolatile memory

QL55M6XD15BQ: 9 to 18 mm (0.35" to 0.71")

QL55M6XD30BQ: 20 to 40 mm (0.79" to 1.57")

QL55M6XD50BQ: 40 to 75 mm (1.57" to 2.95")

QL55M6XD15BQ: 2 mm (0.08")

QL55M6XD30BQ: 3 mm (0.12")

QL55M6XD50BQ: 4 mm (0.16")

According to EN 60947-5-2

30 G; 3 shocks per axis; 11 ms duration

0.5 mm (0.02") amplitude; 10 to 60 Hz frequency, 30 minutes for each X, Y, Z axis

Ω)

Certifications

Banner Engineering Corp. • Minneapolis, MN U.S.A.

6 P/N 112153 rev. C

www.bannerengineering.com • Tel: 763.544.3164

Page 7

QL55 Series Luminescence Sensor

4.3 mm

(0.17")

25 mm

(0.98")

28 mm

(1.10")

28.6 mm

(1.13")

Model QL55M6XD50BQ

21.6 mm

(0.85")

33 mm

(1.30")

Model QL55M6XD30BQ

READY OUT

MARK BKGD

READY OUT

MARK BKGD

READY OUT

READY OUT

MARK

BKGD

31.0 mm

(1.22")

M12

Connector

77.0 mm

(3.03")

81.2 mm

(3.20")

16.0 mm

(0.63")

58.0 mm

(2.28")

36.6 mm

(1.44")

28.0 mm

(1.10")

39.8 mm

(1.57")

28.2 mm

(1.10")

14.1 mm

(0.56")

27.5 mm

(1.08")

21.0 mm

(0.83")

Connector swivels to 3 positions

Blanking Plug Only

No optical axis

in this location

Do Not Remove

Model QL55M6XD15BQ

Loosen locking

screw to rotate

connector

bn

bu

10 to 30V dc

wh

bk

Load

Analog Out

0 to 5.5V dc

bn

bu

10 to 30V dc

wh

bk

Load

Analog Out

0 to 5.5V dc

Dimensions

Hookups

NPN PNP

Banner Engineering Corp. • Minneapolis, MN U.S.A.

www.bannerengineering.com • Tel: 763.544.3164

P/N 112153 rev. C 7

Page 8

QL55 Series Luminescence Sensor

White Wire

Blue Wire

Black Wire

Brown Wire

M12 x 1

ø 15 mm

(0.6")

44 mm max.

(1.7")

Quick-Disconnect Cables

Style Model Length Dimensions Pinout

4-Pin

Straight

Euro-style

MQDC-406

MQDC-415

MQDC-430

2 m (6.5')

5 m (15')

9 m (30')

Accessory Mounting Brackets

See the current Banner Photoelectric Catalog or website, www.bannerengineering.com, for bracket dimensions.

SMB55A

• 15° offset bracket

• 12-gauge stainless steel

SMB55RA

• Right-angle bracket

• 12-gauge stainless steel

SMB55F

• Flat-mount bracket

• 12-gauge stainless steel

SMB55S

• 15° offset bracket

• 12-gauge stainless steel

WARRANTY: Banner Engineering Corp. warrants its products to be free from defects for one year. Banner Engineering Corp. will repair

or replace, free of charge, any product of its manufacture found to be defective at the time it is returned to the factory during the warranty

period. This warranty does not cover damage or liability for the improper application of Banner products. This warranty is in lieu of any

other warranty either expressed or implied.

P/N 112153 rev. C

Banner Engineering Corp., 9714 Tenth Ave. No., Minneapolis, MN USA 55441 • Phone: 763.544.3164 • www.bannerengineering.com • Email: sensors@bannerengineering.com

Loading...

Loading...