Page 1

QL50 Luminescence Sensor

LISTED

US

!

Compact, self-contained luminescence sensor

Features

• Compact, self-contained design

• Senses luminescent marks, even on luminescent backgrounds and on reflective

surfaces, such as ceramic, metal, or mirrored glass

• Easy-to-set programming options for sensing precision and fine detection

• Low cost

• 2 indicator LEDs show operating and output status

• Fast 250 microsecond sensing response time

• NPN or PNP discrete output, depending on model

• Output OFF-delay option for longer ON condition

• 3-position swivel QD connector

Models

Model Cable/Connector* Supply Voltage Output type Sensing Range

QL50AP6XD20BQ

QL50AN6XD20BQ

* Mating cable required; see page 8 for cable options.

WARNING . . .

Never use these products as sensing devices for personnel protection. Doing so could lead to serious injury or death.

These sensors do NOT include the self-checking redundant circuitry necessary to allow their use in personnel safety applications. A

sensor failure or malfunction can cause either an energized or de-energized sensor output condition. Consult your current Banner Safety Products

catalog for safety products which meet OSHA, ANSI and IEC standards for personnel protection.

4-pin Euro-style (M12)

QD connector with

3-position swivel

Not To Be Used for Personnel Protection

10 to 30V dc

PNP

NPN

0 to 40 mm

(0 to 1.57")

Printed in USA 03/05 P/N 112151 rev. C

Page 2

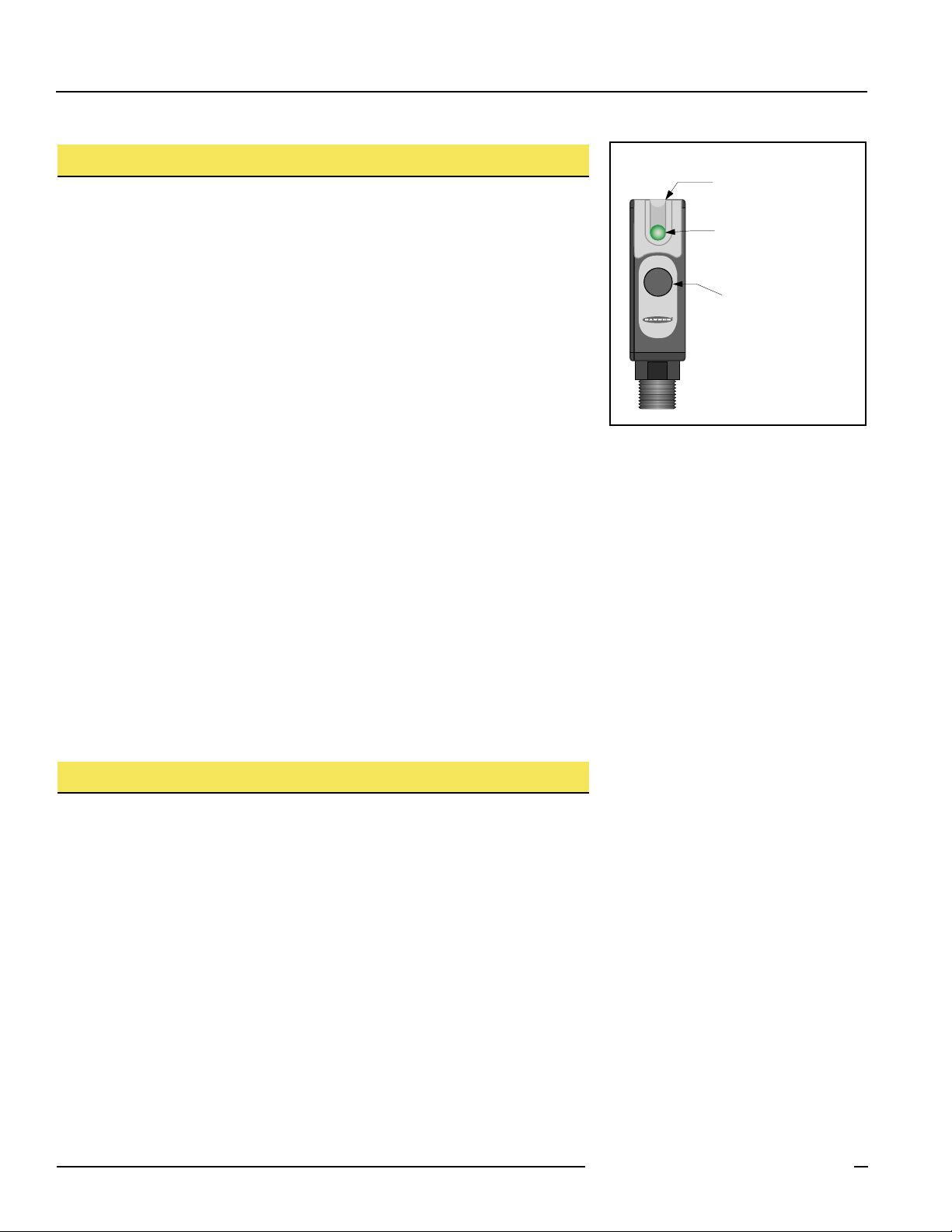

QL50 Luminescence Sensor

SET

Yellow Output LED

ON: Output conducting

Bicolor Power LED

ON Green: Power ON

Flashing green: Fine Mode

Flashing Red/Green: Error

Push Button

Overview

The QL50 Series Sensor is an easy-to-use, compact luminescence sensor that emits

ultraviolet light from an LED and scans for luminescence in materials. The QL50

senses luminescence that is inherent in a material, or it can sense luminophores that

have been added to a material in process to make it luminescent.

The sensor’s compact size allows it to be mounted almost anywhere. Configuration

options include teachable sensing precision and fine-detection programming for

accurate sensing of a wide range of luminescence intensities and background

conditions.

The QL50 is available with either NPN or PNP output. The sensor has one push button

for easy programming. Two LEDs provide power, error, and output information for easy

monitoring during operation. See Figure 1.

Luminescence Sensing

Luminescence sensing detects a form of electromagnetic radiation, caused by the

shining of UV light (“black” light, invisible to the human eye) on a luminescent

substrate material, such as an adhesive. When the UV light shines on the adhesive,

the light “excites” electrons in the material (effecting a change of state), causing it

to reflect visible light. Thus an invisible light source can produce a visible reflection.

Because it emits UV light but detects visible waves, the sensor can distinguish between

the fluorescent material and other highly reflective materials.

Cost Factors

When comparing luminescence sensors to make a selection, it is important to consider

whether luminophores must be added to the product sensed, in order for the sensor

to detect luminescence. Generally speaking, the more sensitive the sensor, the lower

the level of luminescence required for detection. Less sensitive (and usually less

expensive) sensors may require an additional step in the production process, and a

substantial cost over time, to add luminophores. For information on additional, more

sensitive luminescence sensor models, refer to data sheet p/n 112153, Model QL55

Luminescence Sensor, or contact a Banner applications engineer for more information.

Sensor Programming

The QL50 Sensor is pre-set to power up in RUN mode and sense a luminescent target.

Applications with varying degrees of luminescence or with background luminescence

may require additional programming:

Figure 1. QL50 Luminescence Sensor

features

• The Quick-Set procedure programs the sensor to detect a luminescence intensity

brighter than the background (see page 3).

• The Fine-Detect procedure increases sensing precision and programs the sensor

to detect a luminescence intensity that is either more or less luminescent than the

background (see page 4).

Programming Errors

If a programming error occurs, the bicolor Power LED flashes red and green. To

correct a programming error, reset the sensor to the factory settings as follows:

1. Remove all luminescent objects from the sensing range.

2. Press and hold the push button (approx. 2 sec.) until the green Power LED turns

2 P/N 112151 rev. C

OFF.

Banner Engineering Corp. • Minneapolis, MN U.S.A.

www.bannerengineering.com • Tel: 763.544.3164

Page 3

QL50 Luminescence Sensor

Output OFF Output ON

Background

Condition

Target

Object

Condition

Least

Luminescent

Most

Luminescent

T

TTT

T T

T T T

T T

T T

T

T T

T T

T

≈10 seconds

≈10 seconds

≈ 4 seconds

≈ 4 seconds

≈ 2 seconds

≈ 2 seconds

T

SET

SET

SET

SET

Remote Programming and Push-Button Lockout

The remote line allows programming with a remote switch. It can also be used to lock

out the push button, preventing unwanted tampering with the push button. Connect

the white remote wire to 0V if not used.

• To disable the push button and the remote program wire, connect the white remote

wire to high supply potential (+V dc), then power the sensor ON.

• To program the sensor using the remote line, connect a normally open (N.O.) switch

between the white remote wire and high supply potential (+V dc), then power the

sensor ON. This enables remote programming.

• To enable the push button, turn the sensor power OFF, remove the white wire from

high supply, and then turn sensor power ON.

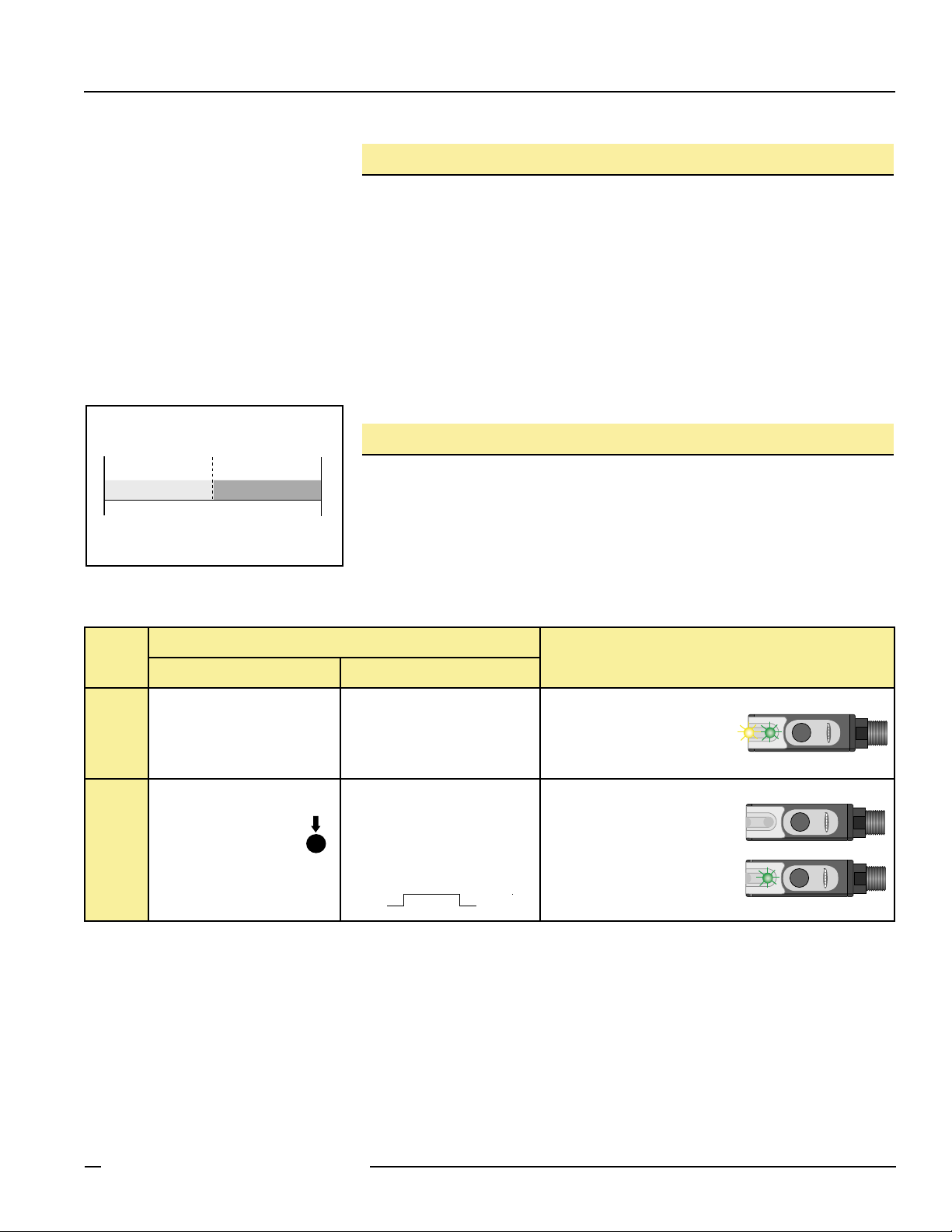

Quick-Set Programming

Quick-Set programming teaches the QL50 Sensor to respond to a specific

luminescence intensity and ignore less-intense luminescence conditions. The

programmed setting will be light operate; the sensor will respond to an equivalent or

more luminescent condition.

Sensing the luminescent target will close the normally-open output, turn the yellow

Figure 2. Quick-Set programming

Output LED ON, and cause the output to conduct current (see Figure 2).

Procedure

Push Button Remote Line

• Position luminescent target

for sensing.

Target

Position

• Press and hold push

button (approx. 2 sec.)

Program

LED turns OFF, then release.

until green Power

Sensor

*The Yellow LED may be ON or OFF, depending on target and range.

**The Green LED may go OFF if a target is presented at the sensor threshold.

• Position luminescent target for

sensing.

• Hold remote line (white wire)

high (approx. 2 sec.) until

green Power LED turns OFF,

then release.

Result

Yellow Output LED: ON (or OFF*)

Green Power LED: ON (or OFF**)

Yellow Output LED: OFF, then ON

Green Power LED: OFF, then ON

Sensor returns to RUN mode

Banner Engineering Corp. • Minneapolis, MN U.S.A.

www.bannerengineering.com • Tel: 763.544.3164

P/N 112151 rev. C 3

Page 4

QL50 Luminescence Sensor

Output OFF

Output OFF

Output ON

Output ON

Target Object

Condition

Ta

rget Object

Condition

Background

Condition

Background

Condition

Light Operate

Dark Operate

Least

Luminescent

Most

Luminescent

Least

Luminescent

Most

Luminescent

SET

SET

T T

T

≈10 seconds

≈ 4 seconds

T

≈10 seconds

≈ 4 seconds

SET

SET

Dark Operate

Light Operate

SET

SET

SET

SET

Fine-Detection Programming

Fine-Detection programming teaches the QL50 Sensor to respond to a more precise

specific luminescence intensity and ignore surfaces with either less intense or more

intense luminescence. Fine-Detection programming compares target luminescence to

background luminescence and automatically selects light operate or dark operate.

Light Operate: detects a target that is more luminescent than the background.

Sensing the more luminescent target will close the normally-open output, turn on the

yellow LED, and cause the output to conduct current (see Figure 3).

Dark Operate: detects a target that is less luminescent than the background.

Sensing the less luminescent target will close the normally-open output, turn on the

yellow LED, and cause the output to conduct current (see Figure 3).

Figure 3. Fine-Detection Programming

• Position luminescent target

Target

Position

Program

Condition

Target-Present

Target

Remove

Program

Condition

Target-Absent

Procedure

Push Button Remote Line

• Position luminescent target for

for sensing.

• Press and hold push button

(approx. 4 sec.) until Power

LED turns OFF and

begins to flash green.

• Perform next two steps

within 35 seconds.*

• Remove luminescent target. • Remove luminescent target.

• Press and hold push button

(approx. 4 sec.) until Power

LED turns ON.

sensing.

• Hold remote line (white wire)

high (approx. 4 sec.) until

Power LED turns OFF and then

begins to flash green.

• Perform next two steps within

35 seconds.*

• Hold remote line high

(approx. 4 sec.) until Power

LED turns ON green.

Result**

Yellow Output LED:

ON (Light Operate), or

OFF (Dark Operate)

Green Power LED: ON

Yellow Output LED: OFF

Green Power LED: OFF,

then Flashing

Yellow Output LED: OFF

Green Power LED: Flashing

Yellow Output LED: OFF (no target)

Green Power LED: ON

Sensor returns to RUN mode.

*Sensor has a 35-second time-out. If a 35-second interval elapses between steps, the sensor returns to RUN mode without saving new values.

**Green LED brightness may diminish during poor signal conditions (near transition areas).

4 P/N 112151 rev. C

Banner Engineering Corp. • Minneapolis, MN U.S.A.

www.bannerengineering.com • Tel: 763.544.3164

Page 5

Sensor

Output

OFF-Delay (20 ms)

Output Ends

Output

Starts

Figure 4. OFF-delay: output continues for

SET

SET

SET

SET

SET

SET

SET

T

≈10 seconds

SET

SET

SET

SET

20 ms after sensing stops

QL50 Luminescence Sensor

Sensor Setup

Output OFF-Delay Option

This setup procedure toggles the delay status between active and inactive status.

Setting an output OFF-delay extends the duration of the sensor’s ON output by 20 ms.

See Figure 4.

The sensor will retain the most recent delay setting if a loss of power occurs.

NOTE: The QL50 Sensor is factory-set to power up without an output OFF-delay.

Push Button Remote Line

• Press and hold push

button (approx. 10 sec.)

until Power LED

turns OFF, then flashes

green, then stays OFF.*

Access

SETUP Mode

• Watch for Power

Delay

Change Delay

LED to flash green to

Status

indicate Delay status.

• To change delay, quickly

press (“click”)

push button and watch

for Power LED to flash green.

Setting

• Repeat step to activate or

deactivate delay, as desired.

Procedure

• Hold remote line (white

wire) high (approx. 10 sec.)

until Power LED turns OFF,

then flashes green, then stays

OFF. Open remote line.*

• Watch for Power LED to flash

green to indicate Delay status.

• To change delay, pulse remote

line again, and watch for

Power LED to flash green.

• Repeat step to activate or

deactivate delay, as desired.

Result

Yellow Output LED: OFF (no target)

Green Power LED:

ON 1 second, then

OFF 1 second, then

Flashing 8 seconds, then

OFF

Yellow Output LED: OFF

Green Power LED:

Flashes 2x - no delay

Flashes 4x - delay active (20 ms)

Yellow Output LED: OFF

Green Power LED:

Flashes 2x - no delay

Flashes 4x - delay active (20 ms)

Yellow Output LED: OFF

• Wait 10 seconds.* • Wait 10 seconds.*

Exit

SETUP Mode

Green Power LED: ON

Sensor returns to RUN mode with new setting.

* Sensor has a 10-second time-out. If a 10-second interval elapses without the button being pushed (or the remote line being pulsed), the

sensor returns to RUN mode with the current delay setting stored.

Banner Engineering Corp. • Minneapolis, MN U.S.A.

P/N 112151 rev. C 5

www.bannerengineering.com • Tel: 763.544.3164

Page 6

QL50 Luminescence Sensor

Relative Received Signal

Sensing Distance

0

0 10 mm

(0.4")

20 mm

(0.8")

30 mm

(1.2")

40 mm

(1.6")

20%

40%

60%

80%

100%

Installing the Luminescence Sensor

1. Position the swivel M12 connector as needed. Push and hold slide-release while

rotating connector.

2. Measure the appropriate operating distance from the front surface of the sensor

optics to the surface or object to be sensed. Do not exceed 40 mm (1.57").

3. Fasten the sensor to its intended location using two screws and washers. Any two of

three holes in the housing may be used for this purpose.

4. Attach the power cable to the sensor’s connector; see hookups on back cover.

Figure 5. Relative received signal vs. distance

6 P/N 112151 rev. C

Banner Engineering Corp. • Minneapolis, MN U.S.A.

www.bannerengineering.com • Tel: 763.544.3164

Page 7

Specifications

LISTED

US

QL50 Luminescence Sensor

Sensing Beam

Supply Voltage

Supply Protection Circuitry

Output Configuration

Output Rating

Output Protection

Output Response Time

Adjustments

Indicators Yellow Output LED: ON when output is conducting

Construction

Environmental Rating

Connections

Operating Conditions Temperature: -25° to +55°C (-13° to +131°F)

Data Retention

Sensing Range

Spot Diameter

Ambient Light Rejection

Shock Resistance

Vibration

Certifications

Ultraviolet LED (370 nm)

10 to 30V dc, 2Vpp max ripple

30 mA max exclusive of load

Protected against reverse polarity and transient voltages

PNP or NPN discrete output, depending on model

30V dc max

Leakage Current: <1 µA

100 mA maximum load

Protected against output overload and short circuit

250 microseconds

1 push button (set), and remote program wire:

• Fine-detect autoset for Light Operate or Dark Operate

• 20 ms output OFF-delay

• Remote wire to +V dc for remote programming and/or push-button lockout

Bicolor Ready/Error LED: Green ON = Default and Quick-Set programming RUN mode

Green OFF = Threshold

Green Flashing = Fine-Detection Program mode/Delay status

Green/Red bicolor flashing = programming error

ABS shock-resistant housing; glass lens and window (tilted, antireflective)

IEC IP62

4-pin Euro-style (M12) swivel QD connector. Cable required; see page 8 for available cable options.

Max. Relative Humidity: 90% at 50°C non-condensing

EEPROM nonvolatile memory

0 to 40 mm (0 to 1.57")

Maximum signal at 10 mm (0.39")

1.5 mm @ 10 mm (0.059" @ 0.39")

According to EN 60947-5-2

30 G; 3 shocks per axis; 11 ms duration

0.5 mm (0.02") amplitude; 10 to 60 Hz frequency; 30 minutes for each X, Y, Z axis

Banner Engineering Corp. • Minneapolis, MN U.S.A.

www.bannerengineering.com • Tel: 763.544.3164

P/N 112151 rev. C 7

Page 8

QL50 Luminescence Sensor

bn

bu

10 to 30V dc

wh

bk

Remote Line

Load

bn

bu

10 to 30V dc

wh

bk

Load

Remote Line

SET

50.0 mm

(1.97")

50.0 mm

(1.97")

16.0 mm

(0.63")

20.5 mm

(0.81")

7.5 mm

(0.30")

15.0 mm

(0.59")

2.0 mm (0.08")

2 x 4.5 mm (0.18")

42.0 mm (1.65")

6 mm (0.24")

17.5 mm (0.69")

4.0 mm

(0.16")

40.0 mm

(1.57")

4.0 mm

(0.16")

ø4.5 mm (ø0.18")

Connector swivels to 3 positions

Push and hold

slide-release while

rotating connector

M12 x 1

ø 15 mm

(0.6")

44 mm max.

(1.7")

White Wire

Blue Wire

Black Wire

Brown Wire

Dimensions

Hookups

NPN

QD Cables

Style Model Length Dimensions Pinout

4-Pin

Straight

Euro-style

(M12)

P/N 112151 rev. C

Banner Engineering Corp., 9714 Tenth Ave. No., Minneapolis, MN USA 55441 • Phone: 763.544.3164 • www.bannerengineering.com • Email: sensors@bannerengineering.com

MQDC-406

MQDC-415

MQDC-430

2 m (6.5')

5 m (15')

9 m (30')

WARRANTY: Banner Engineering Corp. warrants its products to be free from defects for

one year. Banner Engineering Corp. will repair or replace, free of charge, any product of its

manufacture found to be defective at the time it is returned to the factory during the warranty

period. This warranty does not cover damage or liability for the improper application of

Banner products. This warranty is in lieu of any other warranty either expressed or implied.

PNP

Loading...

Loading...