Page 1

1

2

3

4

C-GAGE SLC1 Series Label Sensor

59369

Datasheet

• No user adjustments – Adaptive Digital Logic (ADL™)

revolutionary self-learning capability.

• Continuous automatic internal adjustment of sensing threshold and drift

compensation.

• Registration accuracy of ± 0.3 mm (0.012") typical at web speeds up to

1.5 m per second (5 ft per second)

• Reliably detects the presence of most types of labels on web backing

◦ Clear labels on an opaque backing

◦ Clear labels on a clear backing

◦ Opaque labels on an opaque backing

◦ Opaque labels on a clear backing

• Perfect for label-registering applications, and also for label-counting tasks

in slitting or rewinding applications.

• Heavy-duty metal housing, 1 mm (0.04") slot

Model Number

SLC1BB6

SLC1BB6Q 5-pin Euro-style (QD)

To order the 9 m (30 ft) cable models, add the suffix “W/30” to the model number of the cabled version (e.g., SLC1BB6

W/30). A model with a QD connector requires an accessory mating cable.

WARNING: Not To Be Used for Personnel Protection

Supply Voltage Cable Output Type User Adjustments

10 to 30 V dc

5-wire 2 m (6.5 ft)

Bipolar (NPN and PNP) None Required

1

provides

Never use this device as a sensing device for personnel protection. Doing so could lead to

serious injury or death. This device does not include the self-checking redundant circuitry necessary

to allow its use in personnel safety applications. A sensor failure or malfunction can cause either an

energized or de-energized sensor output condition.

Overview

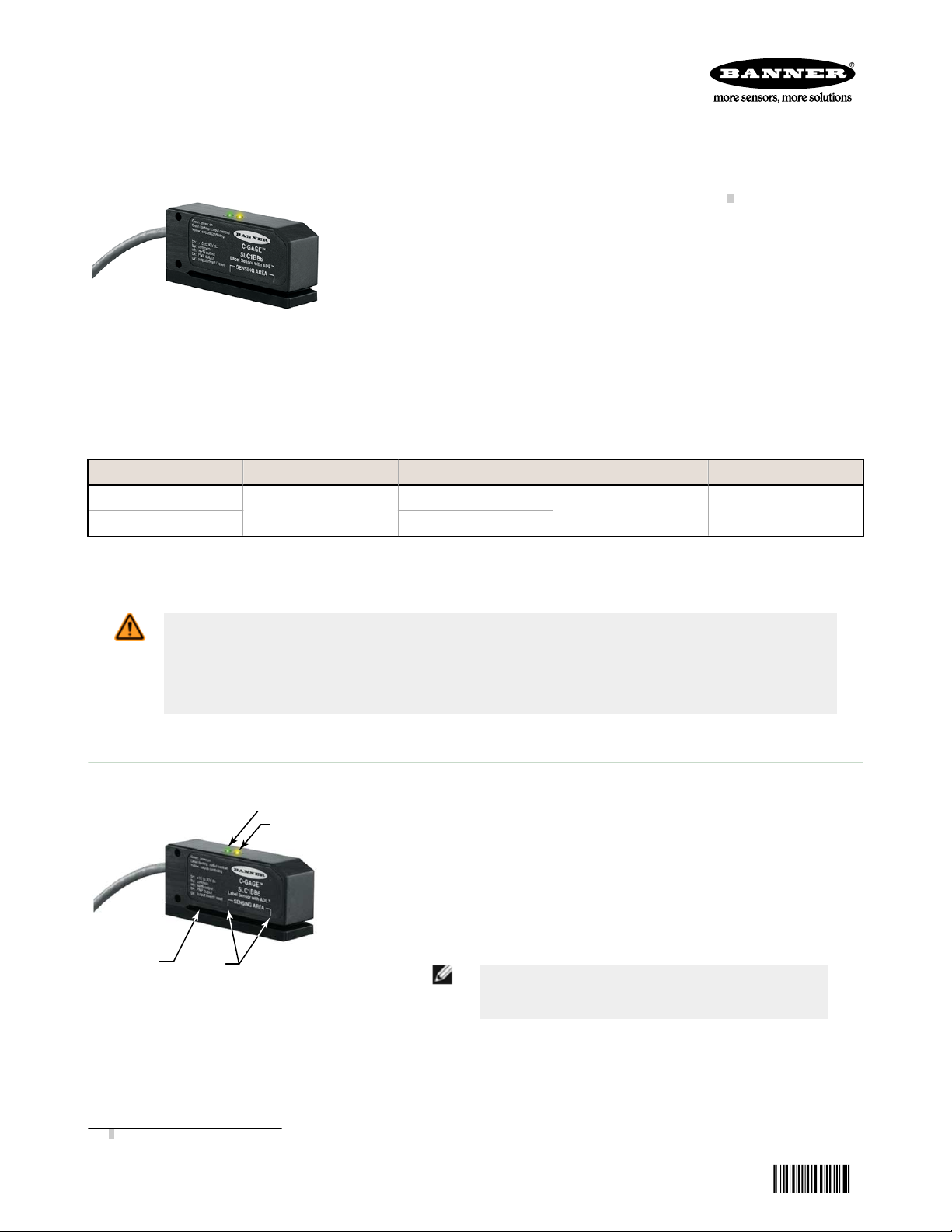

Figure 1. SLC1 Label Sensor Features

1. Green power LED

2. Amber output LED

3. 1 mm (0.04 inch) slot

4. Web alignment guides

The SLC1 Series Label Sensor was developed to provide trouble-free

detection of labels on web backing material. It reliably senses the

difference between materials of extremely low visual contrast, including

clear labels on clear or opaque backing. The SLC1 uses Banner’s

exclusive Adaptive Digital Logic (ADL™) to automatically make all sensor

settings; no user adjustments are necessary.

NOTE: Labels with metallic inks, foil embossing or

metal substrates are not recommended for use with

SLC1 Series sensors.

Original Document

59369 Rev. B

1

Patent pending

20 March 2014

Page 2

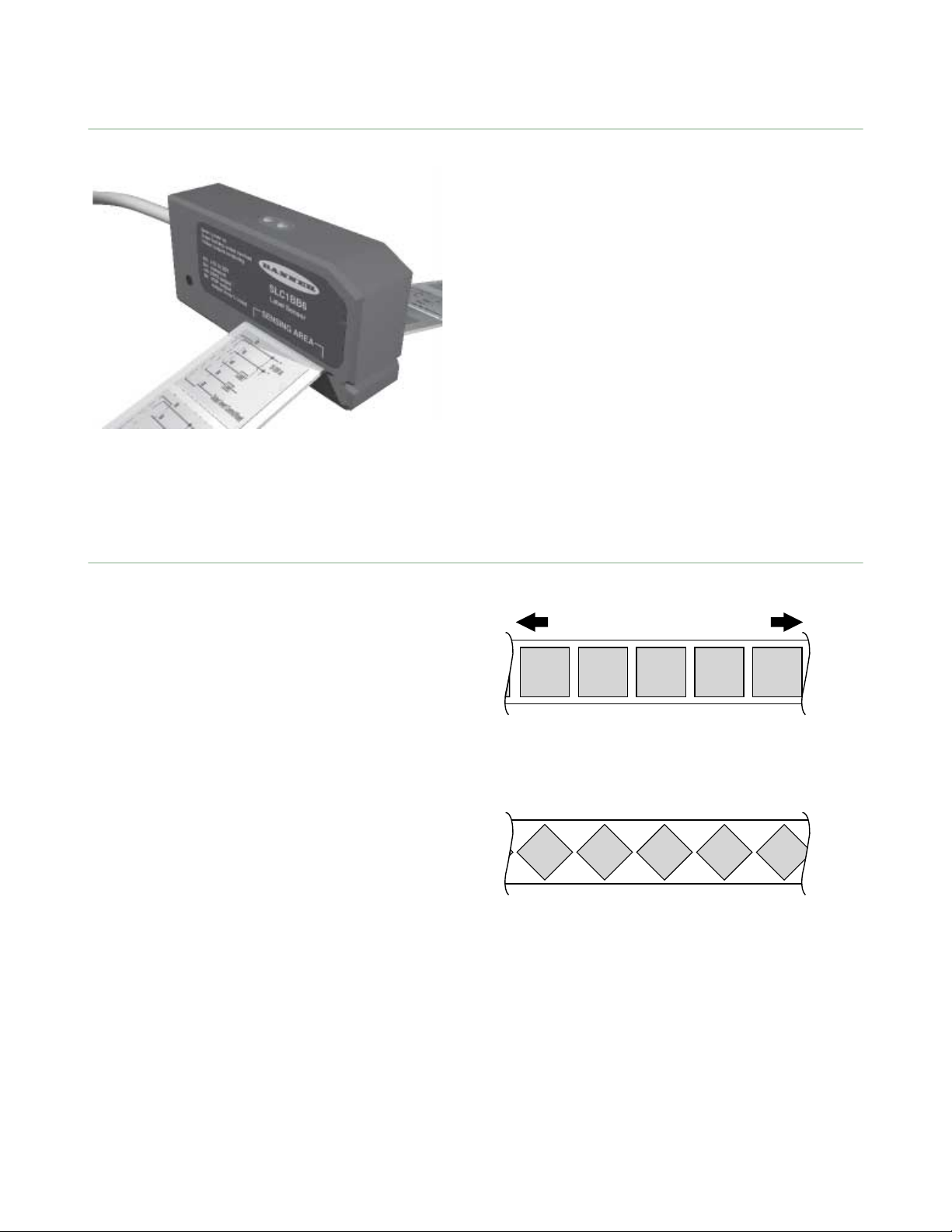

Best Repeatability

Web movement

Less Repeatability

C-GAGE SLC1 Series Label Sensor

Installing the SLC1 Series Label Sensor

Mount directly and securely to a firm surface using M4 (#8)

hardware (bolts not included). See dimensions for mounting

hole locations. To lessen the effects of web flutter, position

the bottom fork of the sensor slightly above the web’s path

so that the web can glide over the bottom fork with slight

tension.

For the most reliable operation, take steps to eliminate

static electricity near the SLC1 Label Sensor.

Figure 2. Allowing the web to glide over the bottom fork with slight

tension lessens the effects of web flutter.

Operating the SLC1 Series Label Sensor

The SLC1 Series is self-teaching and needs no programming;

there are no adjustments to set. Simply align the label web

in the slot, between the guides, and allow the labels to run

through the sensor. After the passing of four successive

labels or 250 milliseconds (whichever is greater), the SLC1

learns the characteristics of the labels and adjusts for the

proper sensing threshold and drift compensation.

For best self-programming results, turn power to the sensor

ON or perform a reset after the web has been positioned in

the slot. Align the labels within the web alignment guides on

the side of the sensor slot as completely as possible.

For best repeatability, position the label to cover the entire

sensing area (between the sensor’s web alignment guides,

see Figure 2 on page 2). Some label configurations are

sensed with greater repeatability than others; the sensor

performs best when there is an abrupt change between

labels. For example, labels with sharply defined edges that

are perpendicular to the web direction and have larger gaps

between labels are sensed most easily. Tiny gaps between

labels and labels whose shape tapers at the leading and

trailing edges are more difficult to sense.

Figure 3. SLC1 Label Sensor preferred sensing configurations

If sensing a label with a shape like that shown in Figure 4 on page 3, the best repeatability results if the most

perpendicular edge of the label is aligned fully within the sensing area.

2 www.bannerengineering.com - tel: 763-544-3164 P/N 59369 Rev. B

Page 3

C-GAGE SLC1 Series Label Sensor

Reset Procedure

Resets are performed at startup, when changing label

types, or in response to an internal error indication.

To reset, turn the SLC1's power ON or cycle the power OFF

for 1 second or longer and then ON again.

The SLC1 may also be reset using the sensor’s gray wire.

To do so, toggle the gray wire to the opposite polarity for

>100 ms. Again, the sensor automatically adjusts to the

current sensing conditions after the passing of four labels or

250 ms, whichever is greater.

Figure 4. For best repeatability, align the labels' flat sides between

the sensor's web alignment guides

LED Behavior

The SLC1 Series sensor has one green LED and one amber LED:

Green LED

Solid Power to sensor is ON

Flashing at 4 Hz Output is overloaded

Flashing alternatively at 1 Hz

Amber LED Description

Solid NPN and PNP outputs are ON

Internal error; reset sensor. Internal errors are caused by several factors:

• Moisture in the sensing slot

• Extreme and prolonged web flutter

• Label jams (labels touching both the top and the bottom sensor

forks)

If an internal error occurs, correct its cause and perform a reset (cycle the

sensor power OFF for at least 1 second and ON again or toggle the gray

wire to the opposite polarity for >100 milliseconds).

Maintenance

The SLC1 Series sensor may be disassembled for periodic cleaning, as needed. Use a 7/64" hex key to remove the four

screws at the bottom and remove the bottom fork for cleaning. Clean the fork surfaces with a mild solvent, such as

isopropyl alcohol, taking care to avoid the clear indicator light window.

Repairs

Contact Banner Engineering for troubleshooting of this device. Do not attempt any repairs to this Banner device; it

contains no field-replaceable components. If the device or a device component is determined to be defective by a

Banner Applications Engineer, they will advise you of Banner's RMA (Return Merchandise Authorization) procedure.

Important: If instructed to return the device, pack it with care. Damage that occurs in return shipping

is not covered by warranty.

P/N 59369 Rev. B www.bannerengineering.com - tel: 763-544-3164 3

Page 4

bn

wh

bu

+

–

bk

gy*

Load

Load

10-30 V dc

bn

wh

bu

+

–

bk

gy*

Load

Load

10-30 V dc

C-GAGE SLC1 Series Label Sensor

Wiring Diagrams

Outputs ON during gap (Turn OFF at leading edge of

Outputs ON during label (Turn ON at leading edge of

label)

*Toggle to opposite polarity for > 100 milliseconds to reset microprocessor.

Specifications

Supply Voltage and Current

10 to 30 V dc (10% max. ripple) @ less than 60 mA (exclusive of load )

Supply Protection Circuitry

Protected against reverse polarity and transient voltages

Power-Up or Reset Delay

1 second typical (outputs are non-conducting during this time)

Output Configuration

Bipolar: one current-sourcing (PNP) and one current-sinking (NPN)

open-collector transistor

Output Rating

150 mA max. (each output)

OFF-state leakage current: < 5 microamps at 30 V dc

Output saturation voltage: < 1 V at 10 milliamps dc; < 1.6 V at 150

milliamps dc

Output Protection

Protected against continuous overload and short-circuit of outputs

Overload trip point: > 200 milliamps, typical, at 20 °C

Output Invert Control/Reset

Gray wire has dual functionality, and may be controlled by a PLC

Input impedance: 10 KΩ

Outputs ON during gap (turn OFF at leading edge of label): leave open,

or connect to 0 to +1 V dc

Outputs ON during label (turn ON at leading edge of label): connect to

+5 to 30 V dc

Microprocessor reset: toggle gray wire to opposite polarity for > 100

milliseconds

Environmental Rating

IP67, NEMA 6

Operating Conditions

Temperature: 5 °C to 50 °C (41 °F to 122 °F)

Maximum relative humidity: 90% at 50 °C, non-condensing

Registration Accuracy

±0.3 mm (0.012 inch) typical, at web speeds up to 1.5 m per second

(5 ft per second)

Maximum Counting Speed

Web speed of 10 m per second (33 ft per second)

Minimum Sensing Speed

Web speed of 100 mm per minute (4 inches per minute)

Response Time

Maximum Switching Speed

Minimum Gap or Label Size

Adjustments

Indicators

Construction

Connections

Certifications

2

100 μs

2

1 kHz

2 mm (0.08 inch)

No user adjustments; automatic continuous adjustment of sensing

threshold and drift compensation under internal microprocessor control

Adjustment interval: every 250 milliseconds or 4 labels, whichever is

greater

Two LEDs, green and amber

Green ON: power to sensor is ON

Green flashing at 4 Hz: output is overloaded

Amber ON: NPN and PNP outputs are ON

Green and amber flashing alternately at 1 Hz: internal error; reset

sensor

Housings are machined aluminum with black anodized finish

2 m (6.5 ft) or 9 m (30 inches) 5-wire attached cable, or 5-pin Eurostyle quick-disconnect fitting

Cables for QD models are purchased separately

label)

2

2

2

Approval expected: UL

2

Based on 3.2 mm (0.125 inch) gap between labels. Instantaneous web speed, not average web speed, must be used to determine actual operating speeds

in stepped-advance label systems.

4 www.bannerengineering.com - tel: 763-544-3164 P/N 59369 Rev. B

Page 5

Remove 4 screws for cleaning.

Use 7/64" hex key

Clearance for

M4 (#8) screws

(2 holes)

10.2 mm

(0.40")

25.4 mm

(1.00")

3.8 mm

(0.15")

32.8 mm

(1.30")

1 mm

(0.04")

8.9 mm

(0.35")

23.1 mm

(0.91")

40.8 mm

(1.61")

88.9 mm

(3.49")

30.5 mm

(1.20")

68.8 mm

(2.71")

SLC1BB6

Label Sensor

SENSING AREA

Green: power on

Green flashing: output overload

Yellow: outputs conducting

bn: +10 to 30 V dc

bu: common

wh: NPN output

bk: PNP output

gy: output invert / reset

44 Typ.

ø 14.5

M12 x 1

2

3

4

1

5

32 Typ.

[1.26"]

30 Typ.

[1.18"]

ø 14.5 [0.57"]

M12 x 1

C-GAGE SLC1 Series Label Sensor

Dimensions

Accessories

All measurements are listed in millimeters (inches).

5-Pin Threaded M12/Euro-Style Cordsets (Single Ended)

Model Length Style Dimensions Pinout (Female)

MQDC1-501.5 0.50 m (1.5 ft)

MQDC1-506 1.83 m (6 ft)

MQDC1-515 4.57 m (15 ft)

MQDC1-530 9.14 m (30 ft)

MQDC1-506RA 1.83 m (6 ft)

MQDC1-515RA 4.57 m (15 ft)

MQDC1-530RA 9.14 m (30 ft)

Banner Engineering Corp Limited Warranty

Banner Engineering Corp. warrants its products to be free from defects in material and workmanship for one year following

the date of shipment. Banner Engineering Corp. will repair or replace, free of charge, any product of its manufacture

which, at the time it is returned to the factory, is found to have been defective during the warranty period. This warranty

does not cover damage or liability for misuse, abuse, or the improper application or installation of the Banner product.

P/N 59369 Rev. B www.bannerengineering.com - tel: 763-544-3164 5

Straight

Right-Angle

1 = Brown

2 = White

3 = Blue

4 = Black

5 = Gray

Page 6

C-GAGE SLC1 Series Label Sensor

THIS LIMITED WARRANTY IS EXCLUSIVE AND IN LIEU OF ALL OTHER WARRANTIES WHETHER EXPRESS OR

IMPLIED (INCLUDING, WITHOUT LIMITATION, ANY WARRANTY OF MERCHANTABILITY OR FITNESS FOR A

PARTICULAR PURPOSE), AND WHETHER ARISING UNDER COURSE OF PERFORMANCE, COURSE OF DEALING OR

TRADE USAGE.

This Warranty is exclusive and limited to repair or, at the discretion of Banner Engineering Corp., replacement. IN NO

EVENT SHALL BANNER ENGINEERING CORP. BE LIABLE TO BUYER OR ANY OTHER PERSON OR ENTITY FOR

ANY EXTRA COSTS, EXPENSES, LOSSES, LOSS OF PROFITS, OR ANY INCIDENTAL, CONSEQUENTIAL OR

SPECIAL DAMAGES RESULTING FROM ANY PRODUCT DEFECT OR FROM THE USE OR INABILITY TO USE THE

PRODUCT, WHETHER ARISING IN CONTRACT OR WARRANTY, STATUTE, TORT, STRICT LIABILITY,

NEGLIGENCE, OR OTHERWISE.

Banner Engineering Corp. reserves the right to change, modify or improve the design of the product without assuming any

obligations or liabilities relating to any product previously manufactured by Banner Engineering Corp.

www.bannerengineering.com - tel: 763-544-3164

Loading...

Loading...