Page 1

®

!

A-GAGE

MINI-ARRAY

®

Two-Piece Measuring Light Screen

Configured for Vehicle Separation

2 Discrete Outputs with EIA-485 Communication

Instruction Manual

Features

• Simple two-piece measuring light screen for inspection,

profiling, and object detection, tailored for vehicle

separation applications.

• Detects single-fault emitter, receiver and dirty lens

conditions; continues to function in single-fault

conditions.

• Diagnostic LEDs provide a simple means of monitoring

sensor performance.

• The sensor algorithm ignores objects up to 125 mm (5")

while detecting automobile trailer hitch profiles as small

as 25 mm (1").

• Models available with array lengths from 150 to 1220 mm

in 150 mm increments (6" to 4' in 6" increments) plus

1520 mm (5') and 1830 mm (6') models.

• Beam spacing 19.1 mm (3/4").

• Two discrete outputs plus EIA-485 serial communication.

• System is configurable via the EIA-485 serial interface.

• Alarm output signals dirty lens and system fault

conditions.

• EIA-485 serial communication enables a computer to

process scan data and system status.

WARNING . . .

Never use these products as sensing devices for personnel protection. Doing so could lead to serious injury or death.

These sensors do NOT include the self-checking redundant circuitry necessary to allow their use in personnel safety applications. A

sensor failure or malfunction can cause either an energized or de-energized sensor output condition. Consult your current Banner

Safety Products which meet OSHA, ANSI and IEC standards for personnel protection.

Printed in USA 04/10 P/N 117167 rev. A

Not To Be Used for Personnel Protection

Page 2

1.0 System Overview

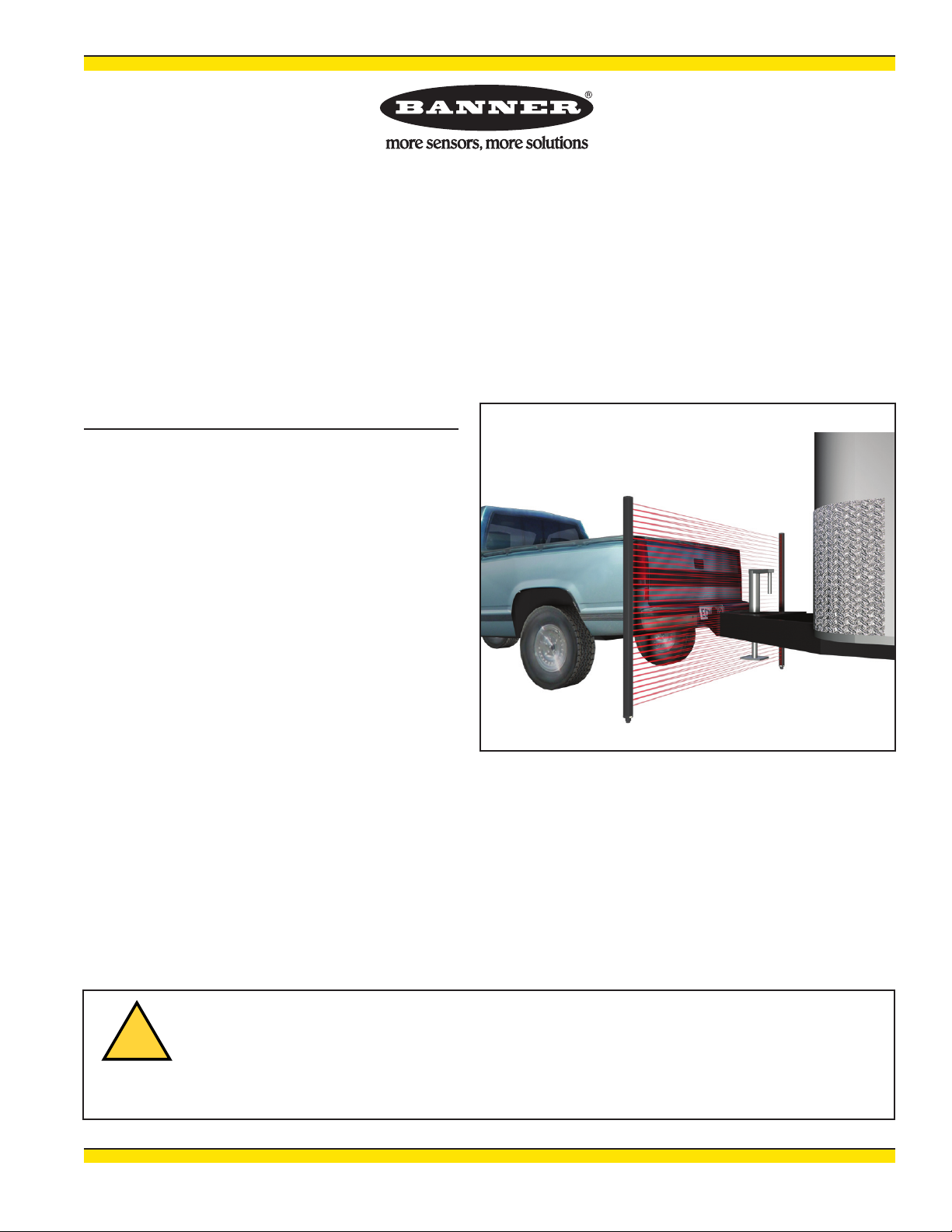

The Banner A-GAGE MINI-ARRAY Two-Piece Measuring Light Screen was

customized for vehicle separation applications. It incorporates the popular

MINI-ARRAY emitter and receiver design and ease of use, while simplifying

installation. This two-piece system does not require a separate controller.

A typical system consists of four components:

• Emitter

• Receiver

• Two interconnecting cables

Models are available in array lengths from 150 to 1220 mm in 150 mm increments

(6" to 4' in 6" increments), plus 1520 mm (5') and 1830 mm (6') lengths. Models

are listed in Section 2.1. Beam spacing is 19.1 mm (3/4"). Sensing range is 0.9 to

15 m (3' to 50').

MINI-ARRAY

Two-Piece Measuring Light Screen

®

Figure 1-1. Typical vehicle separation application

2 P/N 117167 rev. A

Banner Engineering Corp. • Minneapolis, MN U.S.A.

www.bannerengineering.com • Tel: 763.544.3164

Page 3

MINI-ARRAY

Emitter

Receiver

Red

Operational

LED

Green Alignment LED

Red Blocked LED

Yellow Marginal

Alignment LED

Two-Piece Measuring Light Screen

®

System Overview

1.1 System Features

Built-in features simplify the operation of the MINI-ARRAY Two-Piece Light Screen

system, which is customized to specifically address the demanding requirements

needed to reliably detect vehicle separation. Large optical lenses provide strong

optical excess gain (needed for demanding outdoor environments).

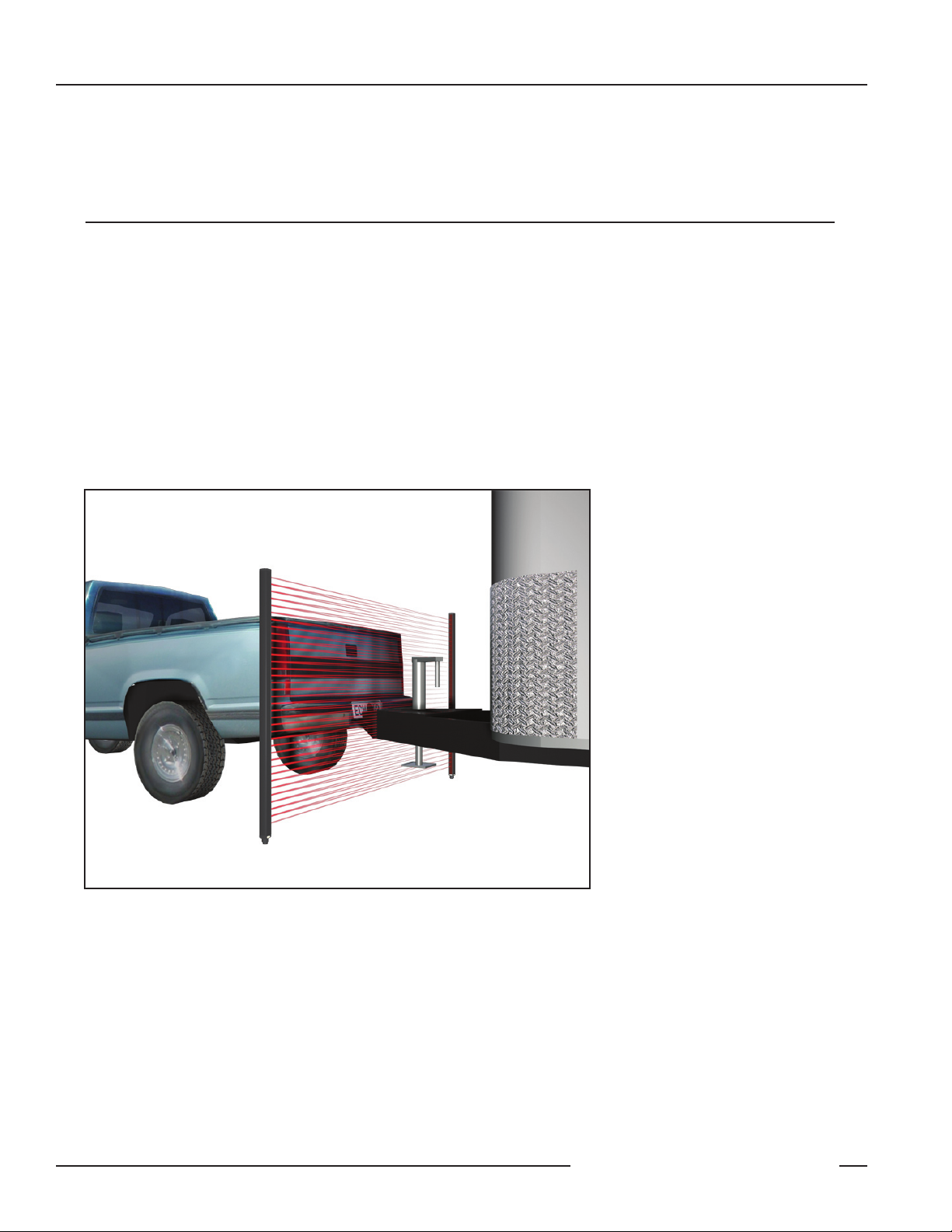

The system is pre-configured for an interlaced optical pattern, which provides

the minimum object detection necessary to detect a trailer hitch. A sensor scan

involves individually enabling each emitter channel twice. In effect, each emitter

channel fires at both its opposing receiver element, and at the one beneath it.

The result is an interlaced optical detection pattern, as shown in Figure 1-3. This

pattern can better detect objects within the middle third of the sensing area.

Along with using the interlaced pattern, the sensor processes the scan data in

a method that is tailored for Vehicle Separation applications: both for initial car

detection and trailer detection (see Sections 1.2 and 1.3). Several important

features have been built into the MINI-ARRAY Two-Piece system:

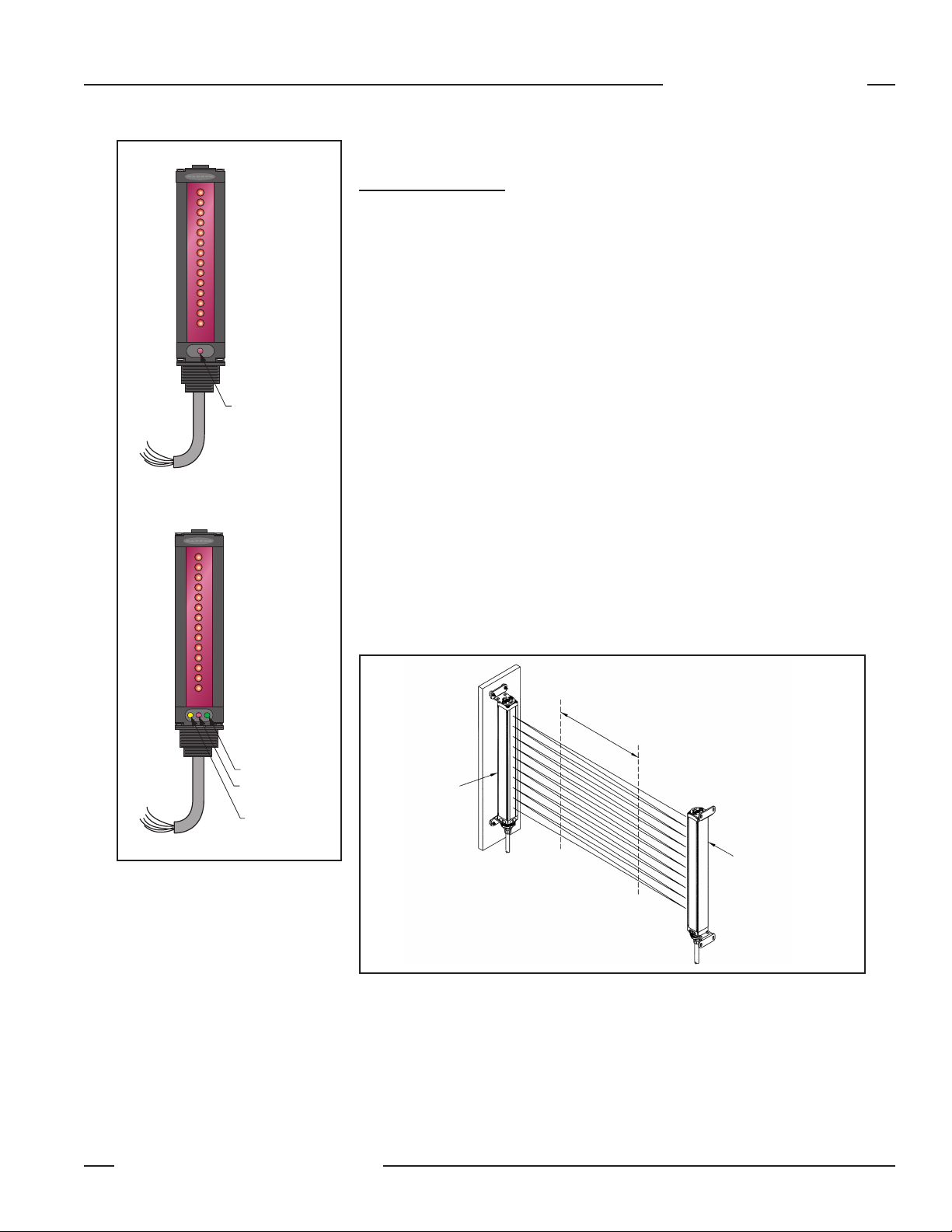

• Easy-to-understand diagnostic LEDs

Figure 1-2. System features

• 2 discrete outputs

• EIA-485 serial communication

• Self-diagnostics to detect dirty lens, faulty or degraded sensor operation

conditions

Interlaced Scan improves optical

resolution in the middle one-third

of the scanning range.

Emitter

Receiver

Figure 1-3. Interlaced scan

Banner Engineering Corp. • Minneapolis, MN U.S.A.

P/N 117167 rev. A 3

www.bannerengineering.com • Tel: 763.544.3164

Page 4

System Overview

Two-Piece Measuring Light Screen

1.1.2 Easy-to-Understand Diagnostic LEDs

The system provides simple, straightforward indications of sensor performance

(see Figure 1-2). See Section 3.3 for a more detailed guide to troubleshooting

system status using the diagnostic LEDs.

Emitter: 1 Red Diagnostic LED

LED Condition ON Solid OFF Flashing (5x per second) Flashing (1x per second)

MINI-ARRAY

®

Emitter Condition

Sensor is functioning

normally

No power to emitter

Receiver is removed from

the system

Receiver: 3 Diagnostic LEDs (Green, Red, and Yellow)

The combined status of the Green and Red LEDs provides a simple sensor

alignment process. The Yellow LED signals a dirty lens or degraded sensor

condition (see Section 1.4).

LED Condition ON Solid OFF Flashing (2 Hz)

Green

Red

Yellow

Light screen is

unobstructed

Light screen is

obstructed

Dirty lens (whether

light screen is blocked

or clear); will remain

ON until receiver

detects proper light

signal strength

Light screen is

obstructed

Light screen is

unobstructed

Non-functioning emitter

Non-functioning emitter

Light signal of one or more beam(s) is degraded

1.1.3 Two Solid-State Outputs

One or more emitter optical

channel(s) not working

properly

The receiver has two discrete outputs (Output #1 and Output #2). Each output is

independent and can be configured for either NPN or PNP operation. The sensor

is factory-configured for NPN outputs, with Output #1 designated for vehicle

separation detection and Output #2 for sensor “health” status output. These

outputs are rated to 150 mA and are short circuit protected.

1.1.4 EIA-485 Interface

To provide sensor profiling and system status information, the receiver has a serial

EIA-485 interface. Please see Appendix A for further information.

1.1.5 Sensing Scan Time

Sensing scan time is a function of the sensor length and number of beams

interrogated (i.e. steps) per scan of the array. The models table in Section 2.1

provides scan times for the Vehicle Separation scanning application (labeled as

interlaced scanning) for each light screen size. The worst-case response time is

twice the scan time.

4 P/N 117167 rev. A

Banner Engineering Corp. • Minneapolis, MN U.S.A.

www.bannerengineering.com • Tel: 763.544.3164

Page 5

MINI-ARRAY

Two-Piece Measuring Light Screen

®

System Overview

1.1.6 Supplied System Software

The system provides other scanning modes and operation features, which are not

optimized for vehicle separation but are useful for other applications.

These features are easily accessed via a simple-to-use Banner-supplied PC

software program and an appropriate EIA-485 interface (consult a Banner

Engineering representative for more information). The PC software can be run

on any computer running Windows® 98, NT, ME, XP or 2000. The menu-driven

program walks the user through the many scanning and output options. After the

desired options are selected, download the settings to the receiver; the receiver will

store the configuration settings in non-volatile memory.

This software also enables the user to check sensor alignment, obtain sensor

readings, and verify sensor status. The built-in system diagnostics can be used to

assess emitter and receiver hardware errors or dirty lens locations.

1.2 Vehicle Detection Applications (Output #1)

The MINI-ARRAY Two-Piece Light Screen features a superior interlaced (crosshatched) beam pattern. When the light screen is clear (no object is obstructing

the receiver’s view of the emitted beam pattern), the sensor will ignore small

objects while waiting to detect the beginning of a vehicle. Up to 125 mm (5”) of

consecutive light channels must be blocked before a valid object is detected; once

the sensor detects 125 mm or more of consecutive blocked light, Output # 1 will

become active (output ON).

1.3 Trailer Hitch Detection Applications (Output #1)

Once an object is detected (see Section 1.1.1), Output #1 will remain active until

the receiver again detects the entire emitter beam pattern (sensor is clear). The

interlaced scan pattern will detect smaller objects after initially detecting a vehicle,

even if only one beam is obstructed. Once the receiver detects a fully unobstructed

light screen, Output #1 again will become inactive (output OFF).

1.4 System Self-Diagnostics (Output #2)

Advanced electronic and data processing allows the receiver to continually monitor

and evaluate light signal quality and alert the user to light signal degradation or

sensor faults. The sensor can detect marginal alignment, permanently blocked

channels, a faulty emitter element, or a non-functioning emitter.

This receiver was designed to detect system failures and remain operational.

Potential problems include a dirty lens that totally blocks (occludes) the optical

light signal or a light signal failure (caused by either the emitter or receiver).

Although sensor failures are rare, the Two-Piece MINI-ARRAY has been designed

to continue to function while warning the user of fault conditions, minimizing

system down time and providing advance notice that system maintenance or

repairs are required.

Whenever the receiver detects proper operation, Output #2 is active (ON). When

the sensor detects a system problem (either a sensor fault or a degraded signal),

Output #2 is disabled (goes OFF, an alarm condition).

A system problem is acknowledged in three ways:

1. The condition of the diagnostic LEDs,

2. Output #2 will be inactive (OFF), and

3. The condition can be transmitted to the monitoring system, via the EIA-485

interface (see Appendix A, System Status Information: command 0x66).

Banner Engineering Corp. • Minneapolis, MN U.S.A.

P/N 117167 rev. A 5

www.bannerengineering.com • Tel: 763.544.3164

Page 6

System Overview

Two-Piece Measuring Light Screen

1.4.1 Marginal Alignment/Dirty Lens Detection (Output #2)

When the received light signal drops below a predetermined threshold, the receiver

will recognize a “marginal alignment” or “dirty lens” condition. (The dirty lens

threshold is equivalent to three times the minimum light signal necessary for

detection.)

Once this condition is detected, the receiver will signal the user that the lens

surface should be cleaned or re-aligned. The Yellow diagnostic LED will turn ON

until the condition is no longer detected (whether the light screen is blocked or

clear). This advance recognition can be used to initiate a proper maintenance

process.

1.4.2 Fault Detection and Sensor Degradation Operation (Output #2)

The receiver detects an occluded light channel detected when one or two

consecutive light channels remain blocked after eight or more vehicles are

detected. Once a blocked channel is detected (the Yellow diagnostic LED will

flash at 2 hertz), the receiver will note the fault and begin to operate in sensor

degradation mode.

Once the receiver detects a permanently blocked optical channel, it will effectively

ignore the degraded optical channel while continuing to operate. This allows the

sensor to continue working and for many instances, provide reliable service.

MINI-ARRAY

®

Along with ignoring permanently blocked channels, the sensor continuously

monitors sensor performance. Should an optical channel become inoperable (due

to a faulty light channel), the sensor will detect the problem and begin to operate

in the sensor degradation mode. Sensor degradation mode provides the user with

advance notice of a fault while continuing to maintain a functional traffic lane.

Emitter faults: In addition to sensing a permanently blocked channel and a faulty

light channel, the receiver can detect a non-functioning emitter (possibly caused by

a disconnected cable). The receiver’s Green and Red diagnostic LEDs will flash at 2

hertz to signal this emitter condition.

6 P/N 117167 rev. A

Banner Engineering Corp. • Minneapolis, MN U.S.A.

www.bannerengineering.com • Tel: 763.544.3164

Page 7

MINI-ARRAY

75.1 mm

(2.95")

Y

L1

White

Blue

Pink

Gray

Yellow

Green

Brown

Red

M12 x 1

ø 15 mm

(0.6")

44 mm max.

(1.7")

®

Two-Piece Measuring Light Screen

2.0 Specifications

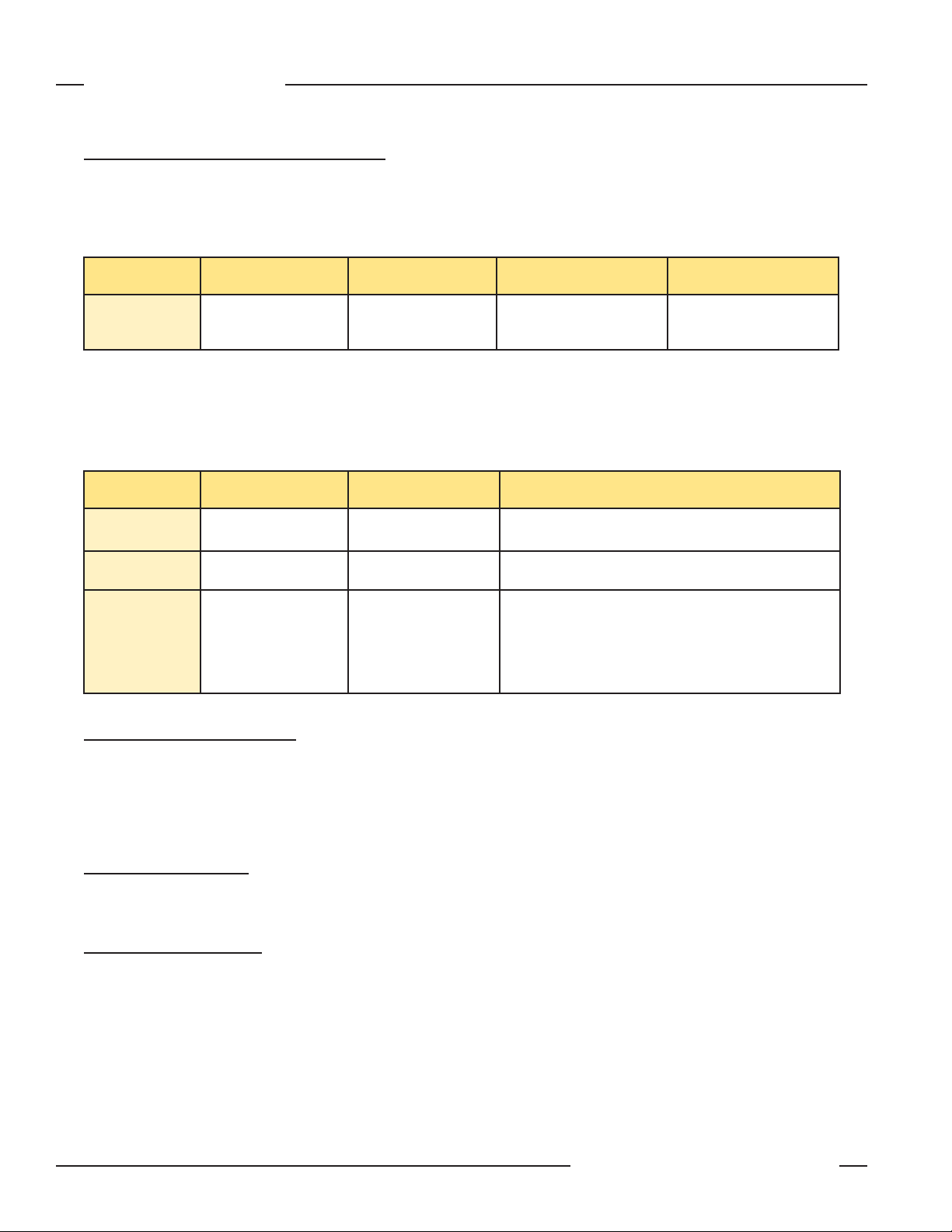

2.1 Emitter and Receiver Models

Specifications

Emitter/Receiver

Models*

MAE616 Emitter

MAR616NX485 Receiver

MAE1216 Emitter

MAR1216NX485 Receiver

MAE1816 Emitter

MAR1816NX485 Receiver

MAE2416Q Emitter

MAR2416NX485 Receiver

MAE3016 Emitter

MAR3016NX485 Receiver

MAE3616 Emitter

MAR3616NX485 Receiver

MAE4216 Emitter

MAR4216NX485 Receiver

MAE4816 Emitter

MAR4816NX485 Receiver

MAE6016 Emitter

MAR6016NX485 Receiver

MAE7216 Emitter

MAR7216NX485 Receiver

* Standard cabled models (2 m/6.5' long) only are listed. For 150 mm (6.5") Euro-style pigtail

QD model, add suffix “Q” to any model (e.g., MAE616Q).

** Worst-case response time is twice the scan time.

†

Scan time for Vehicle Separation scanning configuration.

Sensor Scan Time**

Interlaced

Scan

1.4 ms 0.91 ms

2.5 ms 1.5 ms

3.6 ms 2.0 ms

4.8 ms 2.6 ms

5.9 ms 3.2 ms

7.0 ms 3.7 ms

8.1 ms 4.3 ms

9.2 ms 4.8 ms

11.5 ms 6.0 ms

13.7 ms 7.1 ms

Straight

†

Scan

Array

Length

(Y)

143 mm

(5.62")

295 mm

(11.62")

448 mm

(17.62")

600 mm

(23.62")

752 mm

(29.62")

905 mm

(35.62")

1057 mm

(41.62")

1210 mm

(47.62")

1514 mm

(59.62")

1819 mm

(71.62")

Housing

Length

(L1)

231 mm

(9.1")

384 mm

(15.1")

536 mm

(21.1")

689 mm

(27.1")

841 mm

(33.1")

993 mm

(39.1")

1146 mm

(45.1")

1298 mm

(51.1")

1603 mm

(63.1")

1908 mm

(75.1")

Total

Beams

8

16

24

32

40

48

56

64

80

96

2.2 Euro-Style Quick-Disconnect Cables

Cable: PVC jacket, polyurethane connector body, chrome-plated brass coupling nut

Conductors: 24 AWG high-flex stranded, PVC insulation, gold-plated

Model Length Style Connector Pin Out (female view)

MAQDC-806

MAQDC-815

MAQDC-830

MAQDC-850

MAQDC-875

MAQDC-8100

MAQDC-8125

MAQDC-8150

Banner Engineering Corp. • Minneapolis, MN U.S.A.

P/N 117167 rev. A 7

www.bannerengineering.com • Tel: 763.544.3164

2 m (6.5')

5 m (15')

9 m (30')

15 m (50')

22 m (75')

30 m (100')

38 m (125')

46 m (150')

8-pin

Euro-style

straight

with shield

Page 8

Specifications

2.3 Specifications

MINI-ARRAY

Two-Piece Measuring Light Screen

®

Supply Voltage

and Power

Supply Protection

Circuitry

Discrete Output

Configuration

Serial Data Outputs

Controller

Programming

Emitter/Receiver

Range

Minimum Object

Sensitivity

Sensor Scan Time

Cable Connections

Status Indicators

(see Section 3.3 for

more information)

Environmental

Rating

Construction

Operating

Conditions

Application Notes

16 to 30V dc. Maximum power 12 watts.

Protected against transient voltages and reverse polarity

2 Discrete Outputs: Output 1 and Output 2. Outputs can be configured as either open collector NPN or PNP

transistors. For the vehicle separation application, the outputs are factory configured as NPN outputs.

Discrete Output (either NPN or PNP) ratings: Rated at 30V dc max, 150 mA max load, short circuit protected

OFF-State Leakage Current: <10 µA @ 30V dc

ON-State Saturation Voltage: <1V @ 10 mA, <1.5V @ 150 mA

EIA-485 interface

Baud rate 9600, 19.2 K, 38.4 K

8 data bits, 1 start bit, 1 stop bit, no parity

Via EIA-485 to PC-compatible computer running Windows® 98, NT, ME, XP, 2000 Operating System

Sensors < 1220 mm (4') long: 0.9 to 16.5 m (3' to 55')

Sensors ≥ 1220 mm (4') long: 0.9 to 13.5 m (3' to 45')

NOTE: Maximum range is specified at the point where 3x excess gain remains.

Interlaced Mode: 25.4 mm (1.0")*

Other scanning modes: 38.1 mm (1.5")

*NOTE: Assumes sensing is in middle one-third of scanning range.

See Section 2.1.

NOTE: Worst-case response time is twice the scan time.

Emitter and receiver connections: See Figure 3-6. For QD versions, use cable listed in Section 2.2.

Emitter and receiver cables may not exceed 80 m (250') each.

Emitter

Red LED lights for proper operation

NEMA 4, 13 (IEC IP65)

Aluminum housing with black anodized finish; acrylic lens cover

Temperature: -40° to +70° C (-40° to +158° F)

Max. rel. humidity: 95% (non-condensing)

• The emitter and receiver sync lines (pink and white wires) will be damaged if connected to the power supply.

• The receiver EIA-485 interface (red and green wires) will be damaged if connected to the power supply.

Receiver

Green: sensors aligned (> 3x excess gain)

Yellow: marginal alignment (1x-3x excess gain)

Red: sensors misaligned or beam(s) blocked

8 P/N 117167 rev. A

Banner Engineering Corp. • Minneapolis, MN U.S.A.

www.bannerengineering.com • Tel: 763.544.3164

Page 9

MINI-ARRAY

Y

L1

L2

L3

75.1 mm

(2.95")

With Bracket Flanges “Out” With Bracket Flanges “In”

Two-Piece Measuring Light Screen

®

2.4 Emitter and Receiver Mounting Dimensions

Specifications

Emitter/Receiver

Models

MAE616 Emitter

MAR616NX485 Receiver

MAE1216 Emitter

MAR1216NX485 Receiver

MAE1816 Emitter

MAR1816NX485 Receiver

MAE2416 Emitter

MAR2416NX485 Receiver

MAE3016 Emitter

MAR3016NX485 Receiver

MAE3616 Emitter

MAR3616NX485 Receiver

MAE4216 Emitter

MAR4216NX485 Receiver

MAE4816 Emitter

MAR4816NX485 Receiver

MAE6016 Emitter

MAR6016NX485 Receiver

MAE7216 Emitter

MAR7216NX485 Receiver

Housing

Length

(L1)

231 mm (9.1") 262 mm (10.3") 205 mm (8.1")

384 mm (15.1") 414 mm (16.3") 357 mm (14.1")

536 mm (21.1") 567 mm (22.3") 510 mm (20.1")

689 mm (27.1") 719 mm (28.3") 662 mm (26.1")

841 mm (33.1") 871 mm (34.3") 815 mm (32.1")

993 mm (39.1") 1024 mm (40.3") 967 mm (38.1")

1146 mm (45.1") 1176 mm (46.3") 1119 mm (44.1")

1298 mm (51.1") 1329 mm (52.3") 1272 mm (50.1")

1603 mm (63.1") 1633 mm (64.3") 1577 mm (62.1")

1908 mm (75.1") 1938 mm (76.3") 1881 mm (74.1")

Distance Between Bracket Holes

L2 L3

Figure 2-1. Emitter and receiver mounting dimensions and defined area location

Banner Engineering Corp. • Minneapolis, MN U.S.A.

P/N 117167 rev. A 9

www.bannerengineering.com • Tel: 763.544.3164

Page 10

Emitter

or

Receiver

Mounting

Mounting

Bracket

Surface

M4

Nut (4)

Washer (2)

with Compression

Slotted Hex Head

M4 x 10 mm

Bracket

Mounting

Nut

Washer

M4 x 14 mm

Screw with Flat

Washer

Compression

Washer (4)

Torque to

12 in. lbs.

(1.3 N-m)

Installation and Alignment

MINI-ARRAY

Two-Piece Measuring Light Screen

®

3.0 Installation and Alignment

3.1 Emitter and Receiver Mounting

Banner MINI-ARRAY emitters and receivers are small, lightweight, and easy to mount; the mounting brackets (supplied) allow

±30 degrees rotation.

From a common point of reference, make measurements to position the emitter and receiver in the same plane with their

midpoints directly opposite each other. Mount the emitter and receiver brackets using the M4 x 0.7 x 14 mm bolts and

associated mounting hardware (all supplied). See Figure 3-1.

Although the internal circuitry of the emitter and receiver can withstand heavy impulse forces, vibration isolators can be used

instead of the M4 bolts to dampen impulse forces and prevent possible damage from resonant vibration of the emitter or

receiver assembly. Two different Anti-Vibration Mounting Kits are available from Banner as accessories.

P/N 48955 consists of 4 antivibration mounts (M4 x 0.7 x 9.5

mm) and 8 M4 Keps nuts. These

mounts are made from BUNA-N

rubber and are more resistant to

chemicals and oils.

P/N 12847 consists of 4 antivibration mounts (M4 x 0.7 x 9.5

mm) and 8 M4 Keps nuts. These

mounts are made from natural

rubber, which are less chemically

resistant than the 48955 mounts, but

have a greater sheer force spec at

higher temperature.

Figure 3-1. MINI-ARRAY emitter and receiver mounting hardware

10 P/N 117167 rev. A

Banner Engineering Corp. • Minneapolis, MN U.S.A.

www.bannerengineering.com • Tel: 763.544.3164

Page 11

MINI-ARRAY

Min. R.

34.8 mm

(1.37")

Slots have clearance

for M4 bolts (supplied)

and allow ± 30° rotation

11.9 mm

(0.47")

24.6 mm

(0.97")

57.2 mm

(2.25")

44.5 mm

(1.75")

R 6.4 mm

(0.97")

10.2 mm (2)

(0.40")

Full R (4)

38.1 mm

(1.5")

4.8 mm (2)

(0.19")

3.8 mm

(0.15")

6.4 mm

(0.25")

QD End Non-QD End

ø 30.5 mm

(ø 1.2")

ø 13.2 mm

(ø 0.52")

ø 6.8 mm (2)

(ø 0.27")

3.0 mm

(0.12")

53.8 mm

(2.12")

Tr im foil shield flush

with cable

Uninsulated

drain wire

13 mm (0.5") radius minimum bend

®

Two-Piece Measuring Light Screen

Installation and Alignment

Mount the emitter and receiver in their mounting brackets (see Figure 3-1), and

position the red lenses of the two units directly facing each other. The connector

ends of both sensors must point in the same direction. Measure from one or more

reference planes (i.e., the floor) to the same points on the emitter and receiver to

verify their mechanical alignment. If the sensors are positioned exactly vertical

or exactly horizontal, a carpenter’s level may be useful for checking alignment.

Extending a straight-edge or a string between the sensors may help with

positioning. Also check by eye for line-of-sight alignment. Make any necessary final

mechanical adjustments, and hand-tighten the bracket hardware.

Figure 3-2. Cable clearances

The “drain wire” is the uninsulated

stranded wire which runs between the

cable jacket and the foil shield. Remove

the foil shield at the point where the wires

exit the cable.

Figure 3-3. Emitter/receiver cable

preparation

Figure 3-4. MINI-ARRAY emitter and receiver mounting bracket dimensions

Connect the shielded cables to the emitter and receiver, and route them to the

terminal location. Follow the local wiring code for low-voltage dc control cables.

The same cable type is used for both emitter and receiver (two cables required per

system). Cut the cables to length after making sure they are routed properly.

P/N 117167 rev. A 11

Banner Engineering Corp. • Minneapolis, MN U.S.A.

www.bannerengineering.com • Tel: 763.544.3164

Page 12

L

LÕ

«

Ü

}Þ

Þi

À`

À`

}

}

L>Ài

L

LÕ

«

Ü

}Þ

Þi

³

q

£ÈÎä6Ê`V

*°-°Ê6ʳ

*°-°Ê6Êq

-9 ʳ

-9 Êq

"1/£

"1/ÓÉ,

Ê{nxʳ

Ê{nxÊq

- -

*°-°Ê6³

*°-°Ê6q

-9 ʳ

-9 Êq

,iViÛiÀ ÌÌiÀ

>`Ê£

>`ÊÓ

Ê*ÜiÀ

-Õ««Þ

ÌÊiÝÌiÀ>

{nx

`iÛViÊÌiÀ>

ViVÌ

Installation and Alignment

3.2 Emitter and Receiver Hookups

Connect the emitter and receiver cables as

shown in Figure 3-6.

Receiver Output 1: (OUT1) is an opencollector NPN transistor switch rated at

30V dc max., 150 mA max. It is protected

against overload and short circuits.

Receiver Alarm: (ALARM) is an opencollector NPN transistor switch rated at

30V dc max., 150 mA max. It is protected

against overload and short circuits.

Both outputs are current sinking.

3.3 Diagnostic LED Indicators

The emitter has a single Red status LED.

The receiver’s three LEDs (Green, Yellow,

and Red) are used in combination to

diagnose system status.

Figure 3-5. A-GAGE MINI-ARRAY Two-Piece Measuring Light Screen hookup diagram

MINI-ARRAY

Two-Piece Measuring Light Screen

®

Receiver LED Condition

System Status Possible Action

Green Yellow Red

ON OFF OFF Emitter/receiver pair aligned • None

ON ON OFF Emitter/receiver pair aligned with dirty lens

• Clean lenses

• Align emitter and receiver

OFF OFF ON Emitter/receiver pair blocked • None

OFF ON ON Emitter/receiver pair blocked with dirty lens

• Clean lenses

• Align emitter and receiver

ON ON ON Receiver error • Replace receiver

ON

OFF

Flashing

@ 2 Hz

Flashing

@ 2 Hz

Flashing

@ 2 Hz

OFF

OFF Degraded mode; emitter/receiver pair aligned

ON Degraded mode; emitter/receiver pair blocked

Flashing

@ 2 Hz

Emitter is not functioning • Connect emitter

• Clean lenses

• Align emitter and receiver*

• Clean lenses

• Align emitter and receiver*

Emitter LED Condition Emitter Status Possible Action

Red ON Emitter operating properly • None

Red Flashing @ 1 Hz Emitter is degraded • Replace emitter

Red Flashing @ 5 Hz Emitter has power, but receiver is not hooked up • Connect or replace receiver

* If after cleaning the emitter and receiver lenses, the emitter diagnostic is solid Red, consider replacing the receiver.

3.4 Optical Alignment

After connecting the cables per Figure 3-5, apply 16-30V dc power to the sensor.

Rotate the emitter and/or receiver as necessary to align them. When aligned, the

receiver Green LED is ON. Align the emitter and receiver until the receiver’s Green

LED is ON and the Yellow and Red LED are OFF.

12 P/N 117167 rev. A

Banner Engineering Corp. • Minneapolis, MN U.S.A.

www.bannerengineering.com • Tel: 763.544.3164

Page 13

MINI-ARRAY

Two-Piece Measuring Light Screen

Command

Value

(Hexadecimal)

0x53

0x64

0x66

0x67

Table A-1.

®

Command

Description

Request Sensor to

Scan

Request Sensor

to Transmit Each

Optical Channel

State

(0-clear, 1-blocked)

Request Sensor to

Transmit System

Status Information

Request Sensor to

Transmit One or Two

Measurement Values

Appendix A

Appendix A. Serial Communication

Appendix A describes the serial communication data format and commands

that are available to serially communicate over the EIA-485 interface. The

serial commands can be used to initiate scanning, request sensor light channel

information, request system status, and request one or two sensor measurements.

The serial communication data format utilized by the sensor is described and

related to the sensor commands; examples follow.

Serial Communication Data Format

The serial communication utilizes a standard universal asynchronous receiver/

transmitter architecture. The sensor baud rate can be 9600, 19200, or 38400.

The data will have one start bit, one stop bit, no parity, eight data bits and is

transmitted least significant bit first. The serial communication string format will

consist of a start-of-header byte, a sensor-identification byte, a command byte, a

count of the data bytes, the data bytes, and a two-byte check sum.

All serial communication will follow this data format. The start-of-header byte

will always have hexadecimal value 0xF4 (244 decimal). The sensor identification

byte can have hexadecimal values ranging from 0x41 through 0x5A (65 through 90

decimal). The command bytes used for the sensor are listed in Table A-1.

The count of the data bytes defines the number of data bytes that will be

transmitted for the particular command. For instance, if four data bytes are

transmitted, then the value for the number of data bytes will equal four. The actual

data bytes follow the byte representing the number of data bytes. The check sum

is a two-byte value that is calculated by summing the previous bytes in the string.

Once the sum is known, then a ones complement of the sum is calculated and

used as the string check sum value. Examples will be given in the description of

each command.

Request Sensor to Scan Command (Command 0x53)

This command will be used when the sensor is configured for host scanning. This

command is useful for instances where multiple sensors are present and sensor

cross talk is an issue. Assuming the sensor ID is 0x41, the command string would

be as follows:

Transmit string to sensor: 0xF4, 0x41, 0x53, 0x00, 0x77, 0xFE

Receive string from sensor: 0xF4, 0x41, 0x53, 0x01, 0x06, 0x70, 0xFE

This receive string would be interpreted as follows:

0xF4 is the start-of-header byte

0x41 is the sensor-identification byte

0x53 is the command requesting the sensor scan initiation

0x01 is the number of data bytes

0x06 is the valid response stating that the sensor initiated a scan

The last two bytes are the check sum in low-byte, high-byte order and calculated

as follows:

0xF4 + 0x41 + 0x53 + 0x01 + 0x06 = 0x18F.

The ones complement of 0x18F = 0xFE70.

Hence the low-byte, high-byte order would be 0x70, 0xFE.

Banner Engineering Corp. • Minneapolis, MN U.S.A.

P/N 117167 rev. A 13

www.bannerengineering.com • Tel: 763.544.3164

Page 14

Appendix A

Request Sensor to Transmit all Receiver Channel State (Command 0x64)

This command requests the sensor to provide the state of each optical channel.

The two states for each optical channel are clear (value =0) and blocked (value

=1). Eight optical channels of information are transmitted in each data byte. The

first data byte contains the information for the eight optical channels located

closest to the sensor cable end cap. The following data bytes will contain

information for eight successive optical channel sections. For a data byte, each bit

of the data byte is directly related to the status of an individual optical channel. For

example, if the first eight optical channels have the following states:

MINI-ARRAY

Two-Piece Measuring Light Screen

®

Optical

Channel

Position

1 blocked 1 5 clear 0

2 clear 0 6 blocked 1

3 blocked 1 7 clear 0

4 blocked 1 8 clear 0

Status

Binary

Value

Optical

Channel

Position

Status Binary Value

Then the data byte would be 0x2D. If the array has 32 optical channels, then there

would be four data bytes representing the status of all 32 optical channels. Assume

that the sensor ID is 0x41 and the following serial transmission occurs:

Transmit string to sensor: 0xF4, 0x41, 0x64, 0x00, 0x66, 0xFE

Receive string from sensor: 0xF4, 0x41, 0x64, 0x04, 0x2D, 0x03, 0xC0, 0x81,

0xF1, 0xFC

This receive string would be interpreted as follows:

0xF4 is the start-of-header byte

0x41 is the sensor-identification byte

0x64 is the command requesting the sensor optical channel information

0x04 is the number of data bytes

0x2D optical channels 1, 3, 4, 6 are blocked; optical channels 2, 5, 7, 8 are

clear

0x03 optical channels 9 and 10 are blocked; optical channels 11-16 are clear

0xC0 optical channels 17-22 are clear; optical channels 23 and 24 are blocked

0x81 optical channels 25 and 32 are blocked; optical channels 26-31 are clear

The last two bytes are the check sum in low-byte, high-byte order

Request Sensor to Transmit System Status Information (Command 0x66)

This command will be used to extract information about the sensor. The

information that can be received includes the following six data bytes:

Number of Emitter Channels

First Emitter Failed Channel

Number of Receiver Channels

First Bad Receiver Channel

State

0 – System is working properly

1 – System detects weak alignment

2 – System detects dirty lens

3 – System detects degraded emitter (faulty emitter element)

4 – System detects emitter is not functioning

Degraded Channel

14 P/N 117167 rev. A

Banner Engineering Corp. • Minneapolis, MN U.S.A.

www.bannerengineering.com • Tel: 763.544.3164

Page 15

MINI-ARRAY

Two-Piece Measuring Light Screen

®

Appendix A

Assume that the system has 48 channels and the system detects weak alignment.

The transmit and receiver strings would be as follows:

Transmit string to sensor: 0xF4, 0x41, 0x66, 0x00, 0x64, 0xFE

Receive string from sensor: 0xF4, 0x41, 0x66, 0x06, 0x30, 0x00, 0x30, 0x00,

0x01, 0x00, 0xFD, 0xFD

This receive string would be interpreted as follows:

0xF4 is the start-of-header byte

0x41 is the sensor-identification byte

0x66 is the command requesting the sensor status information

0x06 is the number of data bytes

0x30 there are 48 emitter channels

0x00 all emitter channels are OK

0x30 there are 48 receiver channels (that’s good, because the emitter has 48

channels also!)

0x00 all receiver channels are OK

0x01 the system detects weak alignment

0x00 there are no degraded channels

The last two bytes are the check sum in low-byte, high-byte order.

Request Sensor to Transmit One or Two Measurement Values (Command 0x67)

This command requests the sensor to transmit the previous scan’s measurement

values (one or two measurement values). The command will transmit either two or

four bytes (as specified by the sensor configuration). Assume that the sensor ID

is 0x41 and the sensor is configured to transmit the First Beam Blocked and Total

Beams Blocked information. Also assume that the twentieth light channel happens

to be the first beam blocked and a total of 15 light channels are blocked.

Transmit string to sensor: 0xF4, 0x41, 0x67, 0x00, 0x63, 0xFE

Receive string from sensor: 0xF4, 0x41, 0x67, 0x04, 0x14, 0x00, 0x0F, 0x00,

0x3C, 0xFE

This receive string would be interpreted as follows:

0xF4 is the start-of-header byte

0x41 is the sensor-identification byte

0x67 is the command requesting the sensor measurement information

0x04 is the number of data bytes

0x14, 0x00 is the low-byte, high-byte integer value for the first beam

blocked = 20

0x0f, 0x00 is the low-byte, high-byte integer value for the total beams

blocked=15

The last two bytes are the check sum in low-byte, high-byte order. The check sum

is calculated as follows:

0xF4 + 0x41 + 0x67 + 0x04 + 0x14 + 0x00 + 0x0F + 0x00 = 0x1C3.

The ones complement of 0x1C3 = 0xFE3C.

Hence the low-byte, high-byte order would be 0x3C, 0xFE.

Banner Engineering Corp. • Minneapolis, MN U.S.A.

P/N 117167 rev. A 15

www.bannerengineering.com • Tel: 763.544.3164

Page 16

WARRANTY: Banner Engineering Corp. warrants its products to be free from defects for one year. Banner Engineering Corp. will

repair or replace, free of charge, any product of its manufacture found to be defective at the time it is returned to the factory

during the warranty period. This warranty does not cover damage or liability for the improper application of Banner products. This

warranty is in lieu of any other warranty either expressed or implied.

P/N 117167 rev. A

Banner Engineering Corp., 9714 Tenth Ave. No., Minneapolis, MN USA 55441 • Phone: 763.544.3164 • www.bannerengineering.com • Email: sensors@bannerengineering.com

Loading...

Loading...