Banjo 222PIH5, 222PI6PRO, 333PIH13, 444PIH24, 444PBI Instruction Manual

...

CAST IRON SELF-PRIMING CENTRIFUGAL PUMPS

INSTRUCTION MANUAL

2″ 222 SERIES

3″ 333 SERIES

4″ 444 SERIES

BANJO CORPORATION

150 Banjo Drive, Crawfordsville, IN 47933 U.S.A.

banjocorp.com | Telephone: (765) 362-7367

| A Unit of IDEX Corporation

BANJOCORP.COM

OVERVIEW

Read these instructions and the instructions covering operation of the pump drive unit.

The gas engine (if so equipped) is shipped with no oil. Consult your owners manual for specic oil recommendations, maintenance

procedures, schedules, and troubleshooting. The maximum angle of operation for gas engine drive units is 25° in all directions. For

engine warranty service contact your local engine dealer.

Make certain that all hose and pipe connections are airtight. An air leak in the suction line may prevent priming and will reduce the

performance of the pump.

Do not restrict the pump inlet. High volume pumps such as the Banjo 444 Series pumps should not have the inlet port or line

restricted. If the pump is equipped from the factory with a 4″ inlet ange, the pump should be plumbed with a 4″ inlet line. If the pump

is equipped from the factory with a 3″ inlet ange, the pump should be plumbed with a 3″ inlet line. If the pump is equipped from the

factory with a 2″ inlet ange, the pump should be plumbed with a 2″ inlet line. Failure to follow these instructions can result in pump

cavitation and pump failure.

Always place the pump as close to the liquid to be pumped as possible. Keep the suction line short and with few bends. Keep the

pump and engine on a level foundation. A poor foundation and a heavy suction hose (made heavier when ″primed″ full of liquid) could

result in a pump ″down the hole″. It is not necessary to drain the pump body after use, unless there is a danger of freezing.

There are no points on the pump that need lubrication. The pump seal is cooled and lubricated by the uid being pumped. When

pumping dirty water or liquids containing solids, always use a basket strainer on the end of the suction line.

Engine warranty service available at authorized Honda & Briggs and Stratton Dealers.

*Note: Do NOT operate pump without the supplied EPA approved fuel tank and lines.

WARNINGS

OPERATION WARNING

Do not operate the gas engine (if so equipped)

until you have put oil in the engine. Do not run the

pump dry. Serious damage to the mechanical seal

or complete failure of the mechanical seal can result

from running the pump dry. Always ll the pump with

water or the liquid being pumped before starting the

drive unit.

STORAGE WARNING

There are important instructions regarding the

preparation of the engine for long periods

without use (reference the engine owners manual).

Before long periods of storage, the pump should

be ushed with clean water and drained. Leave all

plugs (ll and drain) out of the pump. Always store

the pump in a heated and dry building.

WARNING! DO NOT USE WITH

FLAMMABLE LIQUIDS.

Do not use ammable liquids. This pump is not

designed or produced to pump ammable liquids of

any kind. Failure to follow this warning can result in

explosion, serious bodily injury or death.

CONNECT WITH CONFIDENCE

™

2

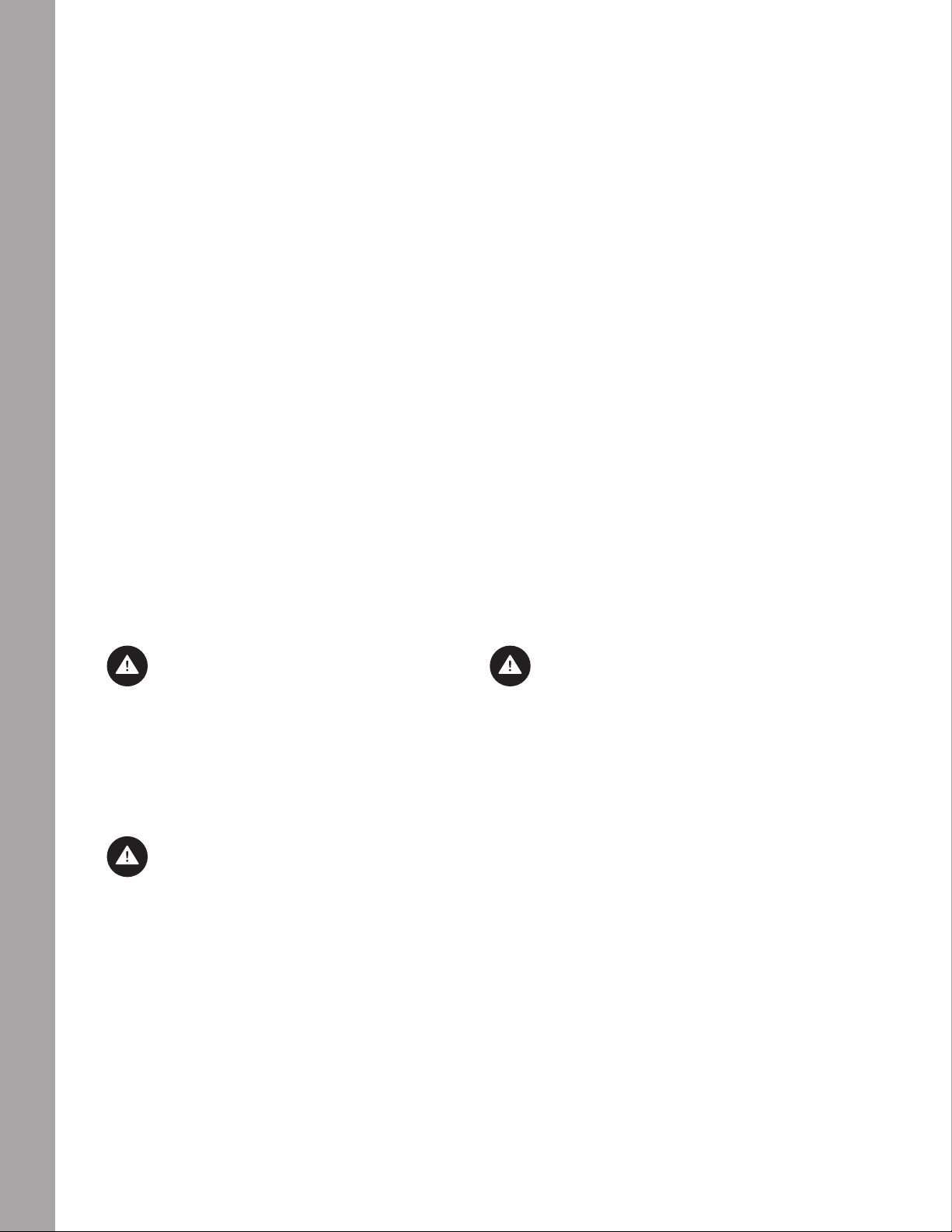

PERFORMANCE

Pressure (PSI)

Head (FT)

2″ CAST IRON PUMPS

Port Size

Suction ....................................... 2″ NPT

Discharge .................................. 2″ NPT

3″ CAST IRON PUMPS

Port Size

Suction ....................................... 3″ NPT

Discharge .................................. 3″ NPT

50

45

40

35

30

25

20

15

10

5

0

205 175 134 97 69 29 0

FLOW CHART

FLOW (GPM)

FLOW CHART FOR 222PIH5, 222PI6PRO & 222PBI

120

100

80

60

40

20

0

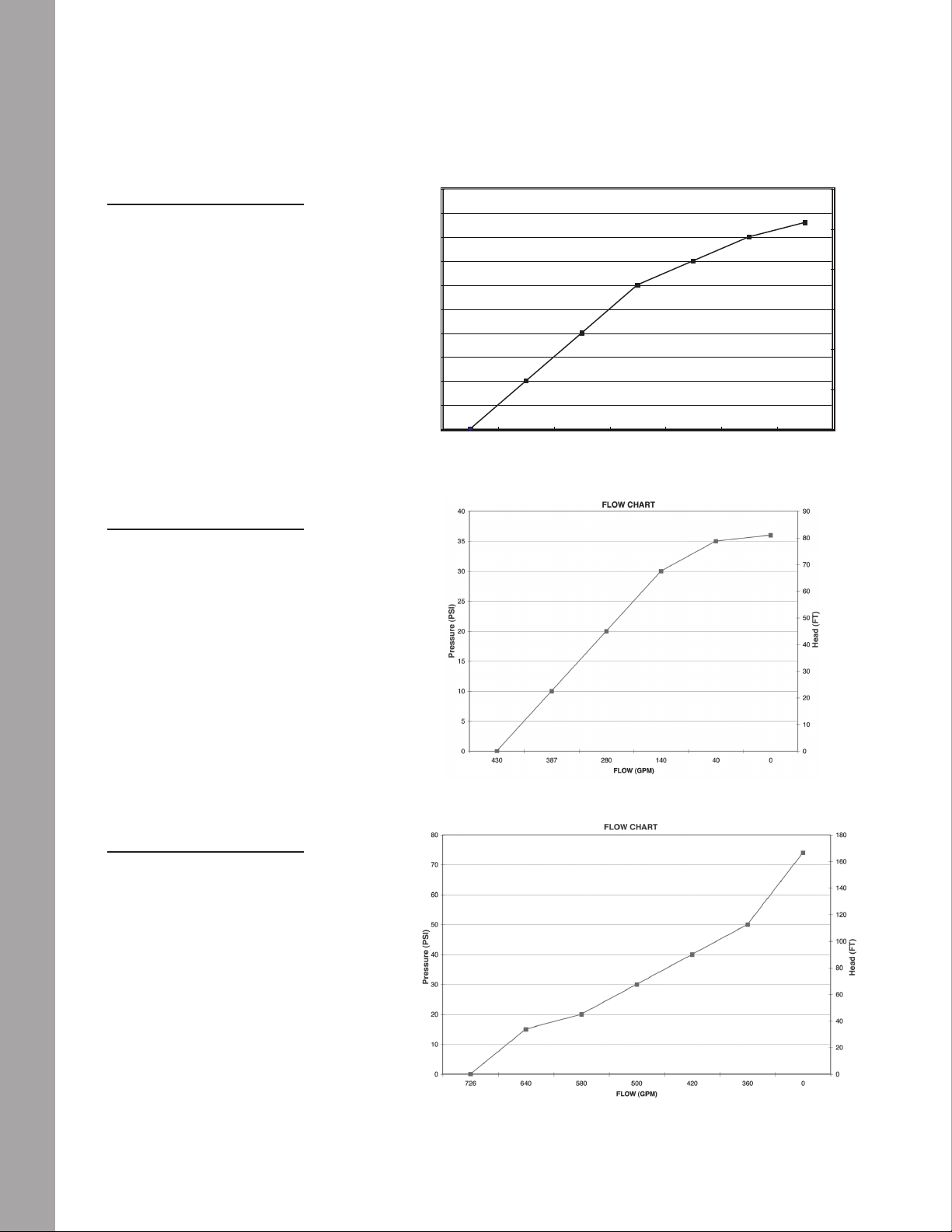

4″ CAST IRON PUMPS

Port Size

Suction ....................................... 4″ NPT

Discharge .................................. 4″ NPT

CONNECT WITH CONFIDENCE

FLOW CHART FOR 333PIH13 & 333PBI

FLOW CHART FOR 444PIH24 & 444PBI

™

3

Loading...

Loading...