Bang Olufsen DVD-2 Service Manual

DVD 2

Type 4629

Service Manual

English

German, French, Italian, Spanish, Danish, Dutch and Simplified Chinese

versions are available in the Retail System

This Service Manual must be returned

with the defective parts/back-up suitcase !

CONTENTS

Survey of modules .................................................................. 1.1

How to service ........................................................................ 1.2

Service Mode .......................................................................... 2.1

Fault flow chart ...................................................................... 3.1

Adjustments ............................................................................ 4.2

Software update .................................................................... 4.9

Repair tips .............................................................................. 4.13

Final check after repair ........................................................ 4.14

Replacement of modules ....................................................... 5.1

Specification guidelines for service use ................................ 6.1

Wiring diagram ...................................................................... 7.1

Block diagrams ....................................................................... 7.2

Available parts ........................................................................ 8.1

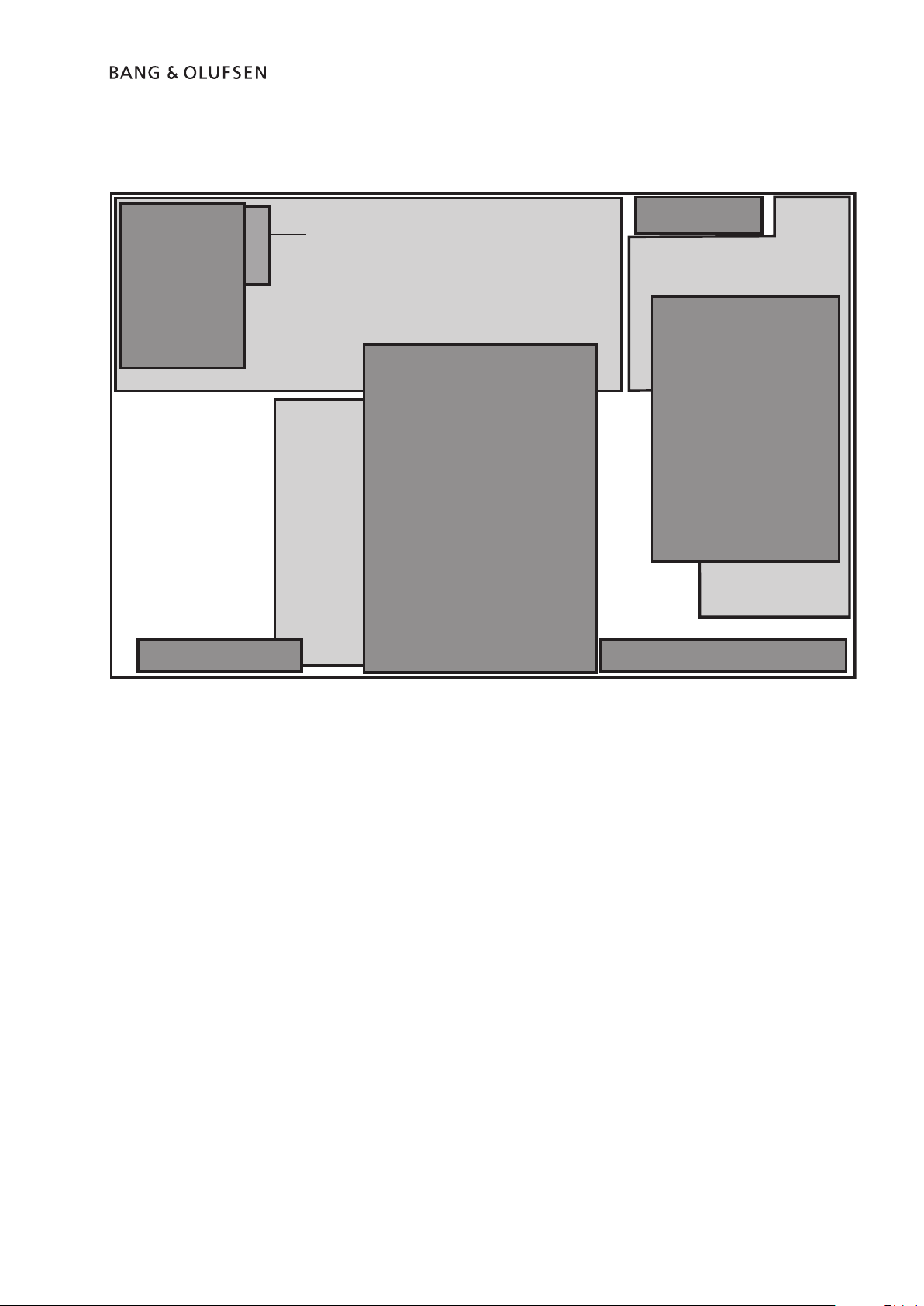

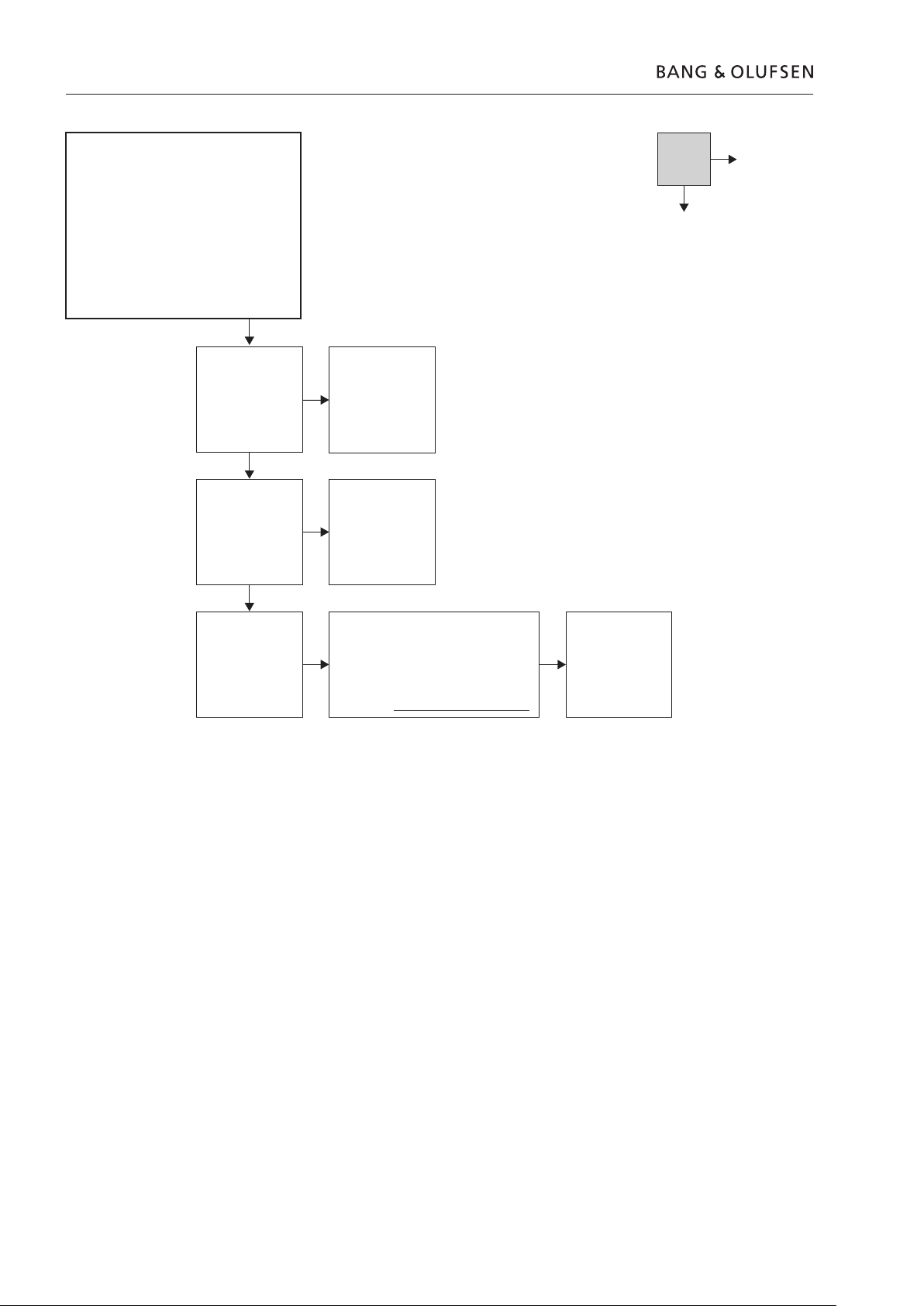

Survey of modules

05

10

03

04

01

02

14

95

94

FAN

Survey of modules 1.1

PCB01 Analog

PCB02 Digital

PCB03 Display

PCB04 Power Supply

PCB05 AV Input

PCB10 HDMI

PCB14 Keyboard (AVL)

94 Module Harddrive (HDD)

95 Module DVD Drive

Fan

1.2 How to service

How to service

Front line service

The static-protective field service kit must always be used when DVD 2 is

disassembled or modules are being handled.

It is not allowed to solder in the customer’s home. Therefore, accessible modules

are mounted with plugs and connectors, and can be exchanged without the use

of a solder iron.

DVD 2 has been developed for simple module exchange to comply with the on-site

service strategy. Module exchange is possible on-site, at the dealershop or in the

service workshop, whatever is most convenient in each case. For on-site service a

Back-up suitcase must be used.

Module exchange is the recommended way to perform service, due to the fact

that most of the modules are multi-layer based, and most of the circuits are on a

single main PCB.

An electrical fault symptom can be removed during one visit to the customers

home, if you bring a DVD 2 Back-up suitcase with you.

Is it a mechanical symptom, the specific part must be brought with you separately.

Service documentation

Preparations before service

Recommended tools for service

Service documentation for DVD2 will be a Service Manual with part nos. for the

Back-up suitcase, electrical and mechanical parts, User’s guides, etc.

In the Back-up suitcase, an enclosed appendix with detailed description of

available nuclei will be located. This could be helpful when operating in

service mode.

Fault description and error codes must be returned with the replaced parts.

Use the Module Repair form or the form in the Retail Order System, Exchange

Module. To help the Bang & Olufsen Module Repair department it is very

important that you answer the following questions:

1 Which products are in the setup?

2 Which software versions are used in these products?

3 How are the products linked together?

4 What happens in the actual situation?

Note: In this case, the error code is generated by the Diagnostic Software and

contains 6 decimal numbers, it is not possible to clear the error code.

Service cable

Software disc

DVD/CD Player Test Pack

White cotton gloves

Soft lint-free cloth

Warnings

STATIC ELECTRICITY

MAY DESTROY THE

PRODUCT

ESD

CLASS 1

LASER PRODUCT

ESD

Static-protective field service kit

How to service 1.3

The internal electronics are very sensitive to static electricity, which may damage

the product.

When electrical replacement or disassembly is necessary, use ESD-mat and tools.

A static-protective field service kit must always be used when the product is

disassembled or modules are being handled.

Follow the instructions in the guide and use the ESD-mat for both old and new

modules.

Please note:

When mains voltage on the product is required, remove the connection between

the product and the ESD-mat.

The chassis or modules must always be connected to the static-protective field

service kit or placed in an ESD-proof bag.

Laser exposure

Symbol of safety components

General Warnings

Cleaning

The DVD 2 contains a laser system and is classified as a class 1 laser product.

The DVD 2 must be opened by qualified personal only.

When replacing components with this symbol, the same type has to be used, also

the same values for ohm and watt.

The new component is to be mounted in the same way as the replaced one.

Wear cotton gloves to avoid fingerprints on the product.

The aluminium and display surface on the product is very sensitive, so handling

should be done with great care to avoid damage.

When transporting the DVD 2, it is recommended to use the product cover.

Do not move the product or the HDD when it is operating. The HDD is very

sensitive to bumps which can cause great damage.

Clean the DVD 2 surfaces using a lint-free cloth which you have wrung firmly in

lukewarm water.

Never use alcohol or other solvents to clean any parts of the DVD 2.

1.4

Service Mode

Diagnostic Software(DS)

Service Mode 2.1

Service Mode in DVD 2 is a new software implemented in the PCB02, Digital and

is called ‘Diagnostic Software’. The Diagnostic Software consists of independent

‘atomic’ tests, called nuclei. Each nucleus forms a test to indicate possible

hardware failure.

Execution of each test is done by typing individual nucleus numbers in the

command promt line (a promt in the ‘Diagnostic Software’), which look like this:

DS:>

In this case use ‘HyperTerminal’ as user interface. HyperTerminal is a ‘Windows’

component, please see next page for setup.

Each nucleus has a unique number of four digits. This number is the input of the

command line interface.

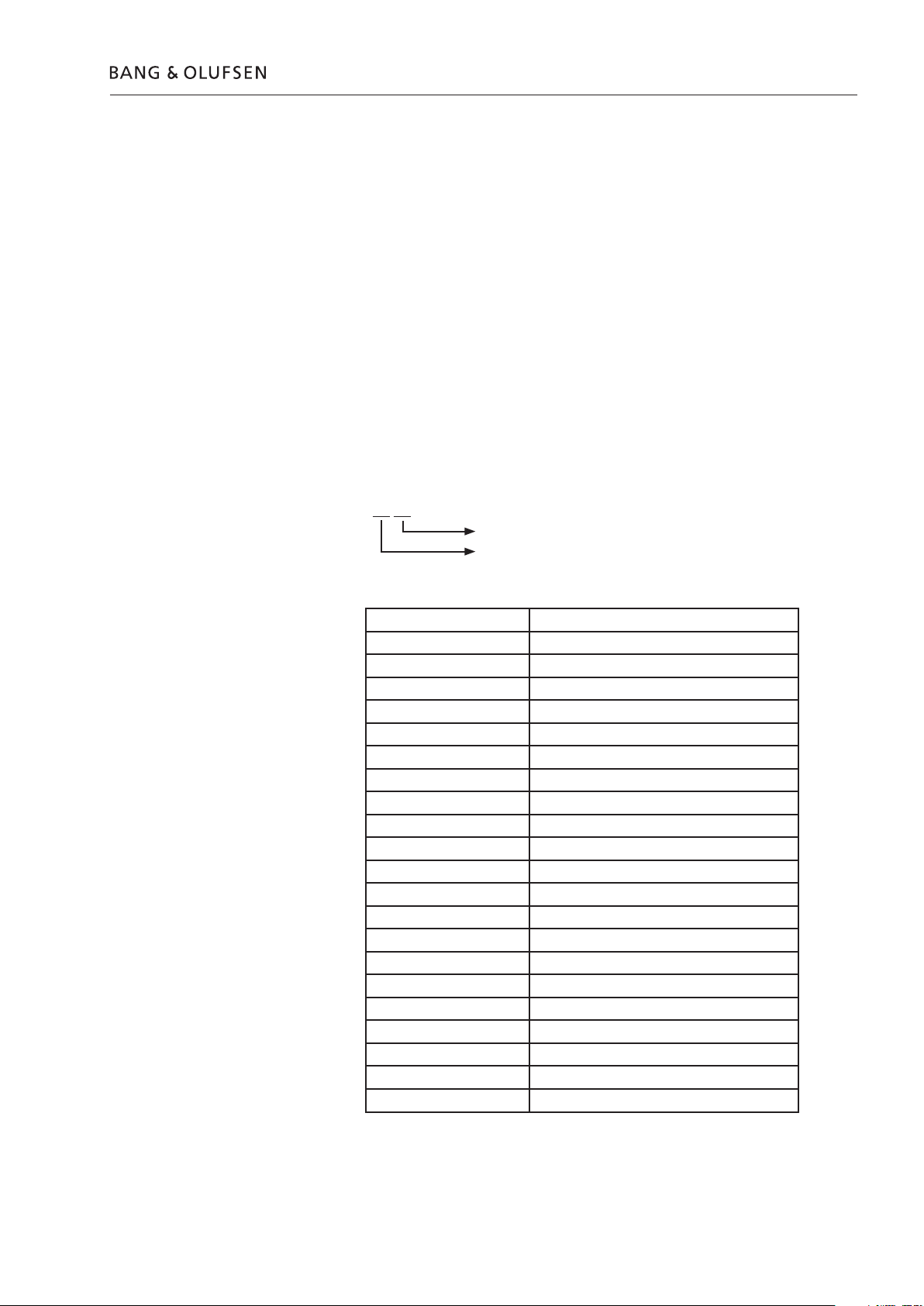

[ XX YY _ _ ]

Nucleus number

Nucleus group number

The Nucleus groups are defined as follows:

Nucleus Group Number Nucleus Group Name

0 Scripts

1 Codec (e.g. Chrysalis, Leco)

2 Boot EEPROM

3 NVRAM

4 SDRAM

5 FLASH

6 Video Input Processor

7 DVIO

8 Progressive Scan

9 Basic Engine

10 Display and Control Board

11 Analogue Board

12 System

13 Electronic Program Guide Board

15 HDMI

16 Analogue Slave Processor

17 Analogue Board EEPROM

18 Video Matrix

19 Audio Matrix

20 Front End

21 Hard Disk

2.2 Service Mode

Glossary

The Nucleus numbers are individual 2 digit numbers according to specific tests, and

are listed in a ‘detailed description of available nuclei’ which is an appendix to

the service manual.

In this description, there will be technical expressions like e.g. CHR and DVIO, which

are abbreviations for ‘Codec Host Repository’ and ‘Digital Video Input Output’ .

For an easy overview these are listed in the glossary below:

AC3 : Audio Compression format 3

ACK : Acknowledge

ADC : Analogue to Digital Conversion

AMIX : Audio Matrix (Audio switching)

ANAB : Analogue Board

AROM : Analogue Board EEPROM

ASP : Analogue Slave Processor

ATA : AT Attachment

ATAPI : AT Attachment Packet Interface

BE : Basic Engine

BROM : BOOT EEPROM

CHR : Codec Host Repository

CRC : Cyclic Redundancy Check

DAC : Digital to Analogue Conversion

DB : Digital Board

DCB : Display and Control Board

DENC : Digital (video) ENCoder

DMA : Direct Memory Access

DS : Diagnostic and Service Software

DSP : Digital Signal Processor

DTTM : Digital Terrestrial Tuner Module

DV : Digital Video

DVIO : Digital Video Input Output

EPGB : Electronic Program Guide Board

FRE : Front End (Tuner)

HDD : Hard Disk Drive

HDMI : High Definition Multimedia Interface

IC : Integrated Circuit

IDE : Integrated Drive Electronics

IH : Interface Handler

IIC : Inter IC Communication

INT : Interrupt

LED : Light Emitting Diode

NVRAM : Non Volatile Random Access Memory

OPC : Optimal Power Control

PIO : Peripheral IO pin

PSCAN : Progressive Scan

RC : Remote Control

S2B : Serial to Basic Engine

SYS : System

TOC : Table Of Contents

UART : Universal Asynchronous Receiver Transmitter

UDF : Universal Disc Format

VIP : Video Input Processor

VMIX : Video Matrix (Video switching)

Setup & Connection

Tools required

Setup

Service Mode 2.3

To enter Service Mode it is necessary to connect DVD 2 to a PC with a service

cable. The required tools are:

- PC with com port (if no com port is available, use USB/COM converter part. no.

3375151)

- Service Cable ( part.no. 6278222 )

- HyperTerminal ( Windows Component)

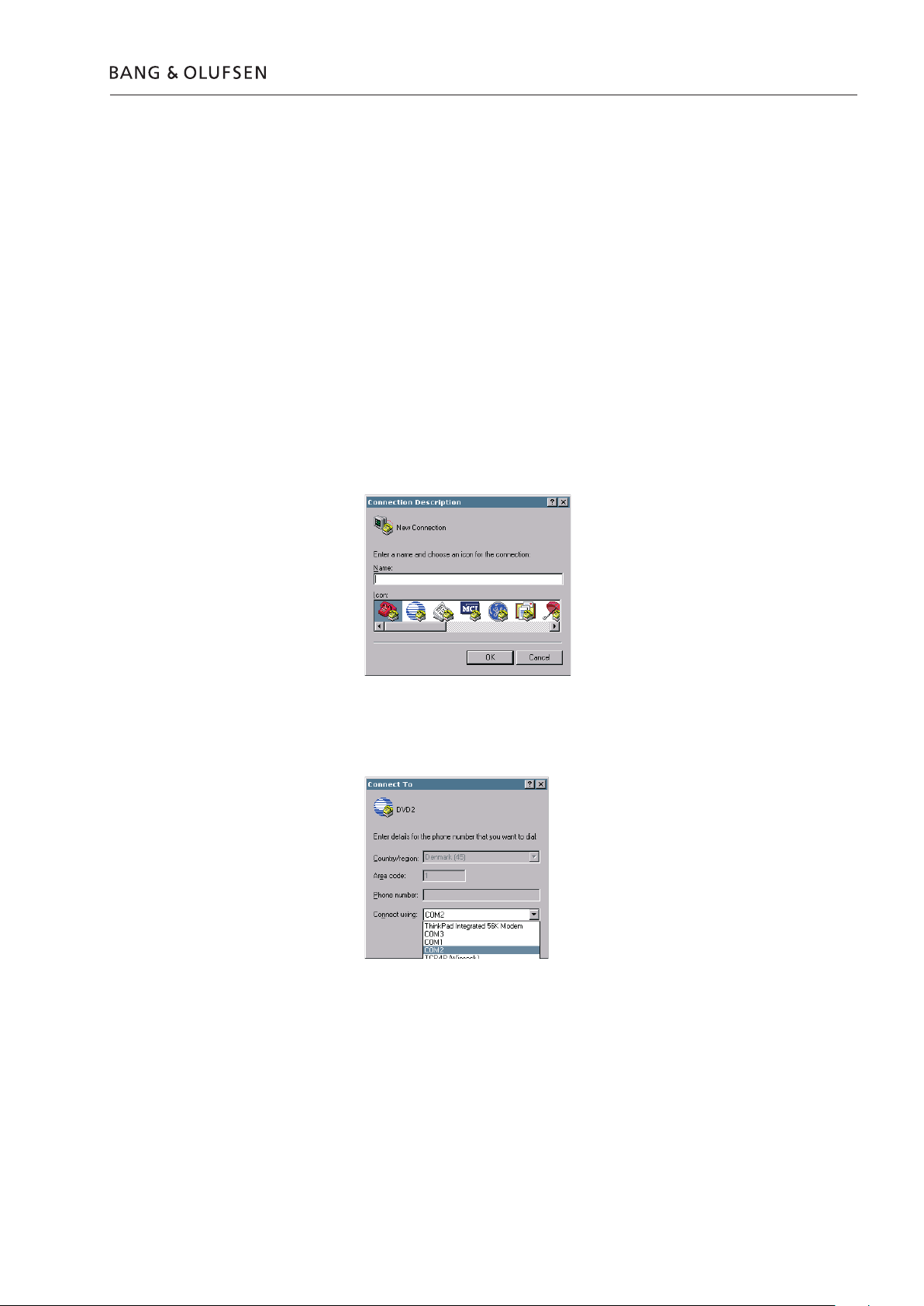

The first-time setup is described below. This is a one time only procedure.

1. Open PC or laptop (if no COM port is available, connect USB/COM Converter)

2. Run HyperTerminal (usually placed: Start/Programs/Accessories/Communications)

3. The ‘Connection description’ box appears on the screen

In the line ‘Name’ type ‘DVD2’ and choose an icon for the connection. Click OK.

The following appears on the screen:

In the line ‘Connect using’ choose the COM port (if USB/COM converter is used,

choose the ‘virtual COM port’ that represent the USB-converter) to be used.

Click OK.

2.4 Service Mode

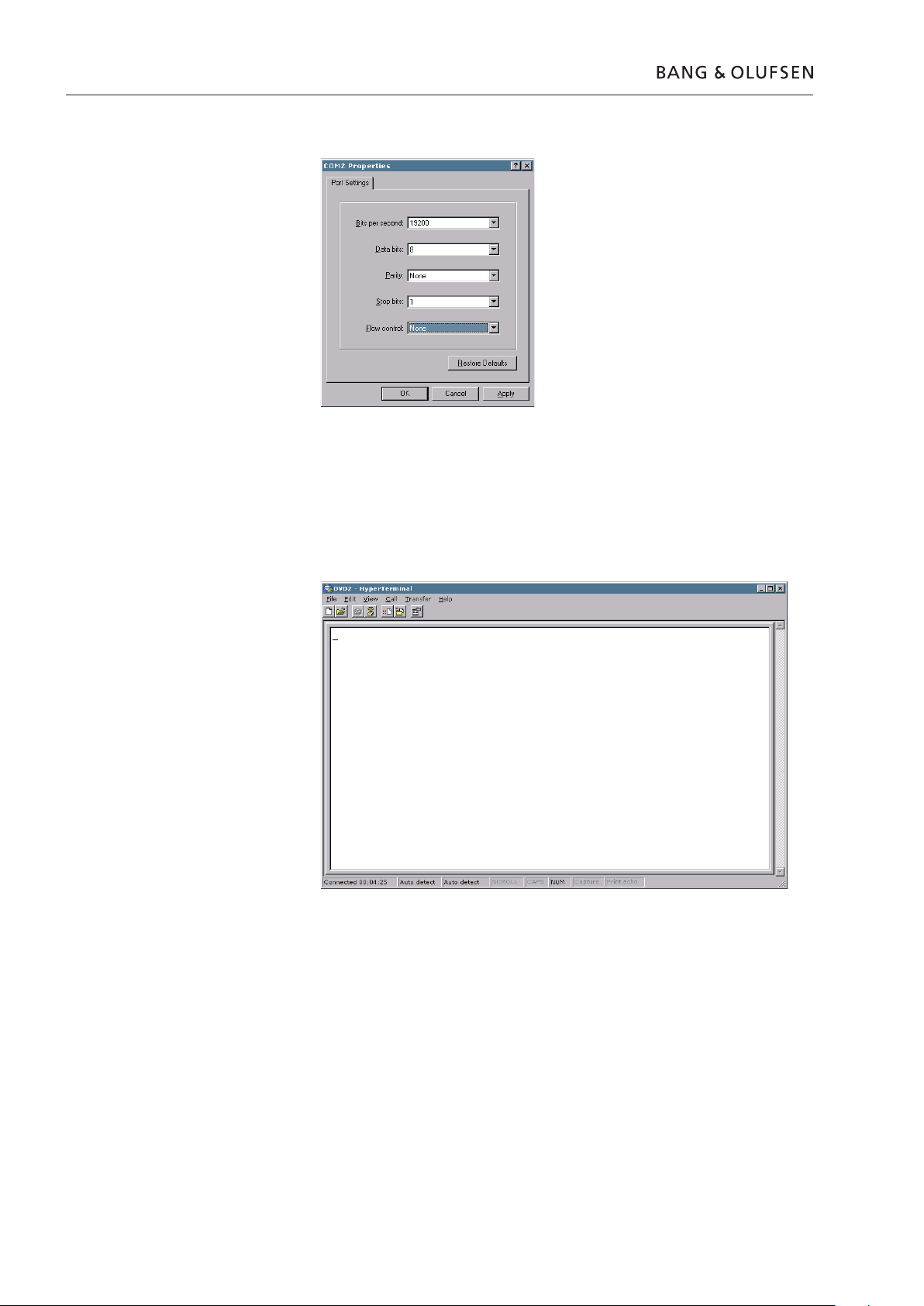

The following appears on the screen.

Use the following Port Settings:

Bits per second 19200

Data bits 8

Parity None

Stop bits 1

Flow control None

Click OK to continue. The following window should appear on the screen.

Now the HyperTerminal is ready to use, but before going any further it would be

wise to save the connection setup, in this way it will be easy to connect next time.

This can be done in following way: Click ‘File’, Click ‘Save As.’

The ‘File Name’ is already suggested as ‘DVD2’, but the location in the line

‘Save in’ should be changed to a known location e.g. ‘Desktop’, for easy access.

Activation

Usage

Service Mode 2.5

1. Disconnect DVD 2 from the mains

2. Connect Service Cable from P1103 on PCB02 to COM port

3. Open HyperTerminal

4. Power on DVD 2 and confirm the following ‘read out’ in the HyperTerminal window:

Factory Diagnostics and Service Software

DVD Video Recorder (Sep 28 2006, 18:29:46)

Version :1388 Build :20060928_1821

Release :SG1_1 Buildtype :dev

Baseline :SGP29atl#SG1_1_20050609_base Variant :sxc

DS:>

The commands that can be given are the numbers of the nuclei. A command must

be terminated with an <ENTER> character from the control PC. When typing

commands, the backspace key can be used to make corrections. Apart from this,

the Up and Down arrows can be used to browse through previous commands.

When non-supported commands are entered, the interface returns to the

command prompt line DS:>

E.g.

DS:> 1888

DS:>

If the command (the nucleus number) is recognised, the nucleus is executed.

Result and output of an activated (and terminated) nucleus will be sent back to

the control service PC.

Example in case the command is correct:

DS:> 1200

120000: Hardware ID = 0x27

Test OK @

DS:>

Example in case there is an error in the communication:

DS:> 1100

110002: Communication with PCB01, Analog fails

Error @

DS:>

2.6 Service Mode

ERROR handling

Cancelling Service Mode

When a command is terminated by the user, and an error occurs in the communication,

the results are returned from a diagnostic nucleus to the control/service PC.

The result looks as follows

<number> : <string> [ Error] @

<number> is a 6-digit decimal number padded with leading zeros if its value is less

than 6 digits. The first four digits identify the generating nucleus (group and nucleus);

the last two digits indicate the error number.

[ XX YY ZZ ]

Error Code

Nucleus Number

Nucleus Group Number

For further specifications please refer to the enclosed appendix.

To cancel Service Mode, disconnect DVD 2 from mains and wait 10 sec. before

rebooting the system.

End User/Dealer script

The ‘End User/Dealer script interface’ gives a diagnosis on the DVD 2.

During this mode, a number of hardware tests (nuclei) are automatically executed

to check if the recorder is faulty. The diagnosis is simply a “FAIL” or “PASS”

message. If the message “FAIL” appears on the display, there is apparently a

failure in the recorder. If the message “PASS” appears, the nuclei in this mode

have been executed successfully. There can be still a failure in the recorder because

the nuclei in this mode do not cover the complete functionality of the recorder.

Before the product is returned to the customer this ‘End User/Dealer script’ test

must be executed to ensure correct functionality of the recorder. If the test fails,

continue to the fault flow chart to locate the error.

This test can be executed by:

1. Typing ‘script’ in the command promt line (see section fault flow chart for further

information)

or by

2. Pressing button ‘S6’ on back panel when connecting to the mains. The DVD

Recorder is tested stand-alone: no other equipment than the DVD Recorder is

needed.

Cancelling ‘End User/Dealer script’

To cancel ‘End User/Dealer’ script, disconnect DVD 2 from mains and wait 10 sec.

before rebooting the system.

Dealer test

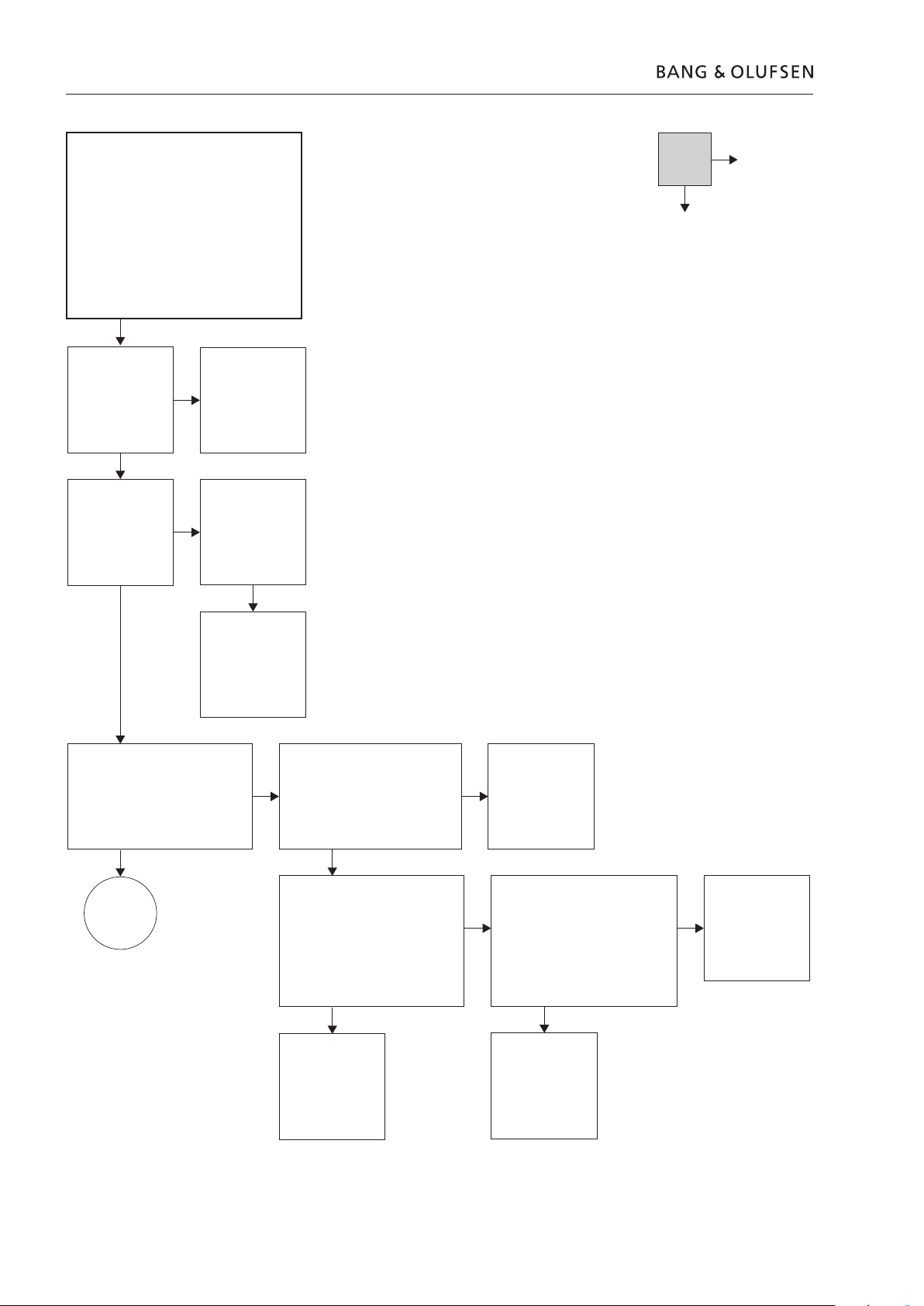

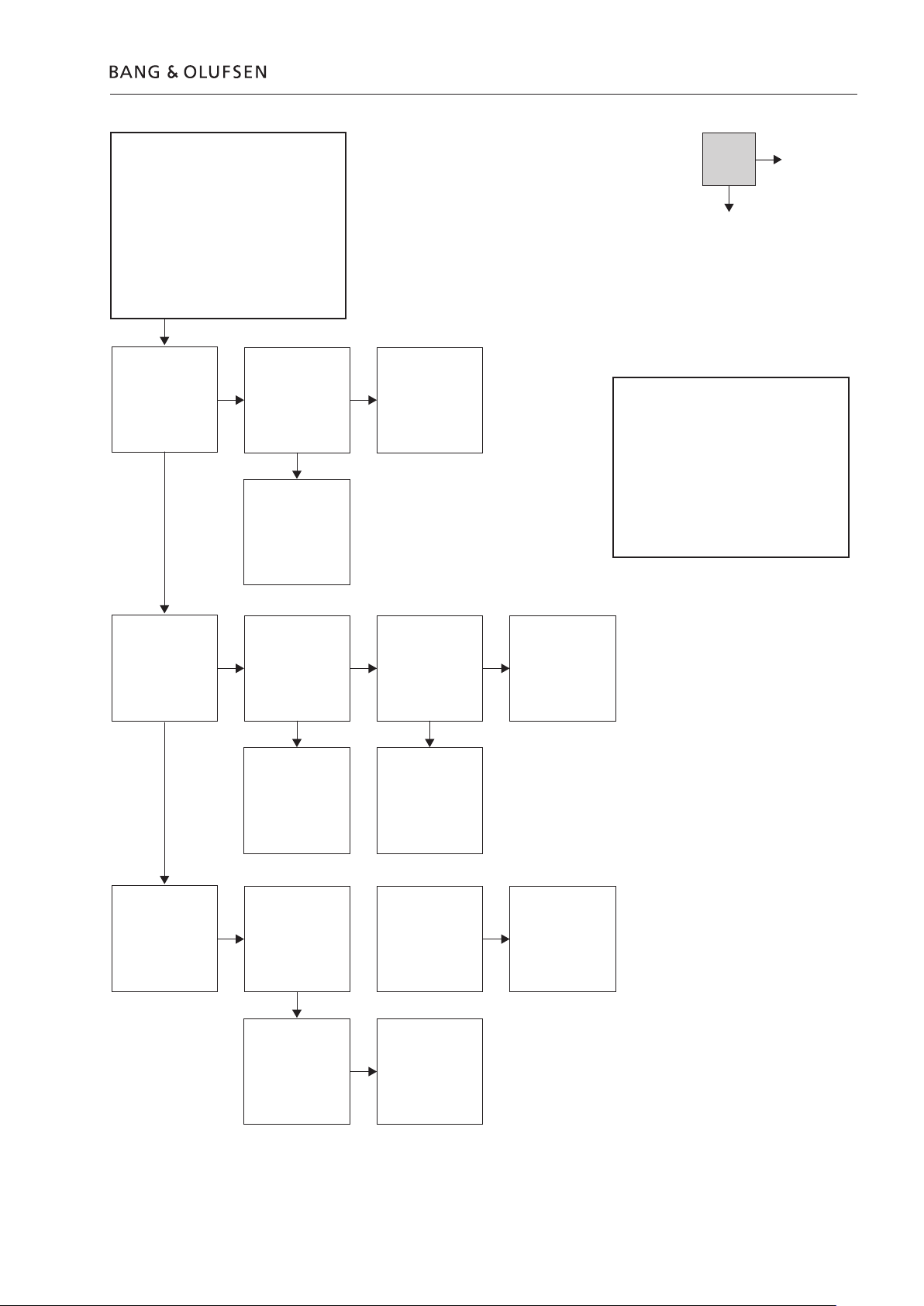

Fault flow chart

Fault flow chart 3.1

Perform built-in dealer test:

- Unplug power cord

- Press and hold ‘play’ buton (S6)

- Connect to mains and release button after 2 sec.

PASS in display = No errors found

FAIL xxxxxx = Error found in DVD 2

If the Dealer test fails in the test sequence, it will display an error code.

Locate the error code and refer to the error list in enclosed appendix.

If it is not possible to locate the error code, and the DVD 2 is still faulty, continue

with the fault flow chart.

No start up .......................................................................... 3.2

DVD 2 does not complete startup sequence ......................... 3.6

DVD 2 starts up but goes to standby .................................... 3.8

Fan error .............................................................................. 3.9

HDD playback check .......................................................... 3.10

DVD playback check .......................................................... 3.10

Manual recording with TSB (Time Shift Buffer) ................... 3.11

Manual HDD recording ...................................................... 3.12

No audio ........................................................................... 3.13

No picture ......................................................................... 3.15

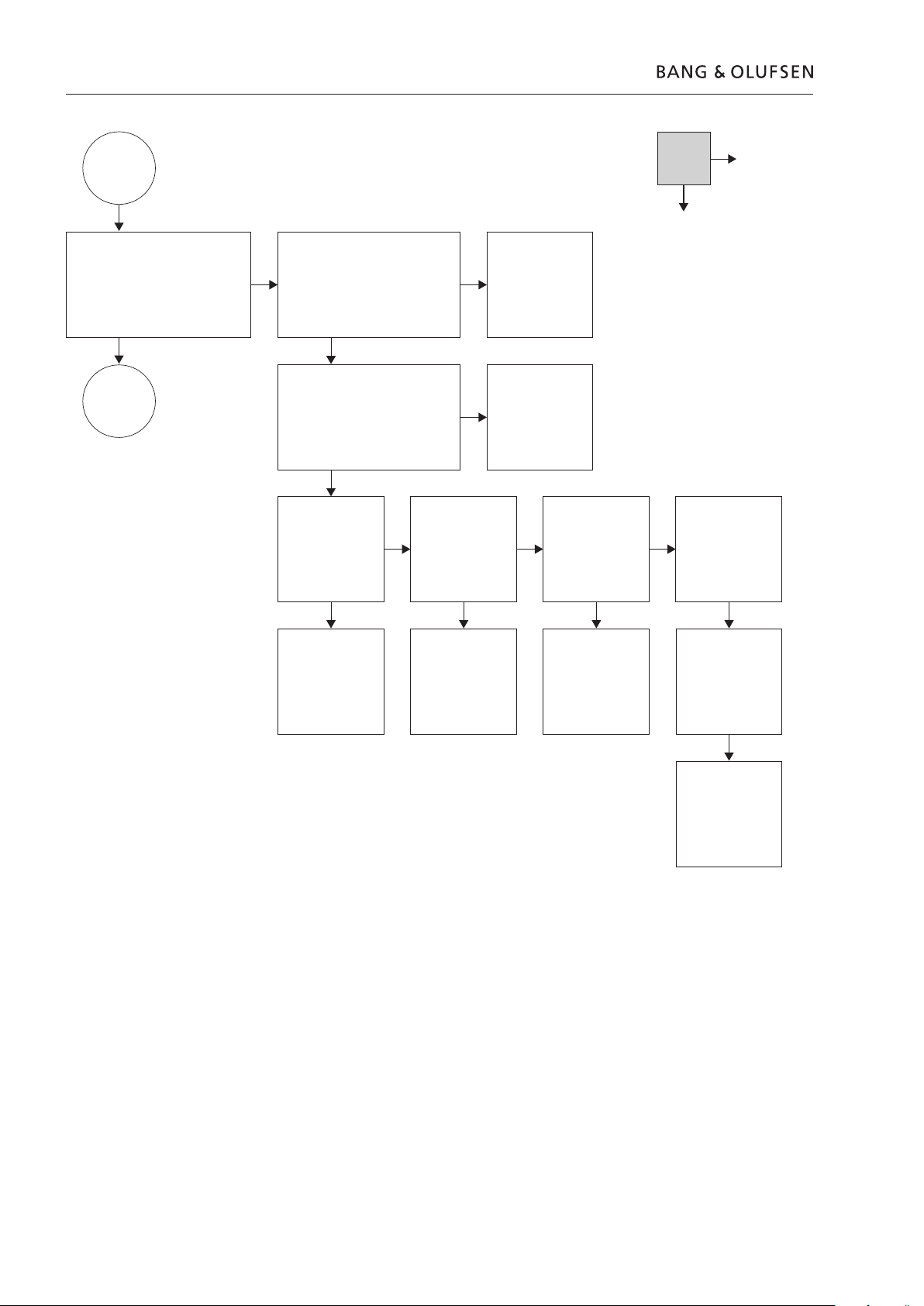

3.2 Fault flow chart

Fault symptom:

No start up

No STBY. LED (normally red)

No Display

Possible causes:

Mains not supplied

Blown fuse F1 on PCB04, Power Supply

Missing voltages

Defective PCBs

Defective cables

Confirm the mains

supply is connected

and applied

OK?

Fuse F1 on PCB04,

Power Supply

OK?

Replace/reconnect

mains cable

Replace fuse F1 on

PCB04 and connect

to mains

Does fuse F1 on

PCB04, Power Supply

blow again?

No

Yes

Replace PCB04,

Power Supply

Confirm:

+3.3V Stby. on PCB04, J2 pin 5

+5V Stby. on PCB04, J2 pin 3

+12V Stby. on PCB04, J2 pin 1

OK?

Go to next

page

Disconnect J2 on PCB04, Power Supply

Confirm:

+3.3V Stby. on PCB04, J2 pin 5

+5V Stby. on PCB04, J2 pin 3

+12V Stby. on PCB04, J2 pin 1

OK?

Reconnect J2 on PCB04, Power Supply

Disconnect cable P1101 on PCB14,

Keyboard

Confirm:

+3.3V Stby. on PCB04, J2 pin 5

+5V Stby. on PCB04, J2 pin 3

+12V Stby. on PCB04, J2 pin 1

OK?

Replace PCB03,

Display

Replace PCB04,

Power Supply

Reconnect P1101 on PCB14

Disconnect P1100 on PCB14, Keyboard

Confirm:

+3.3V Stby. on PCB04, J2 pin 5

+5V Stby. on PCB04, J2 pin 3

+12V Stby. on PCB04, J2 pin 1

OK?

Replace PCB14,

Keyboard

Replace PCB01,

Analog

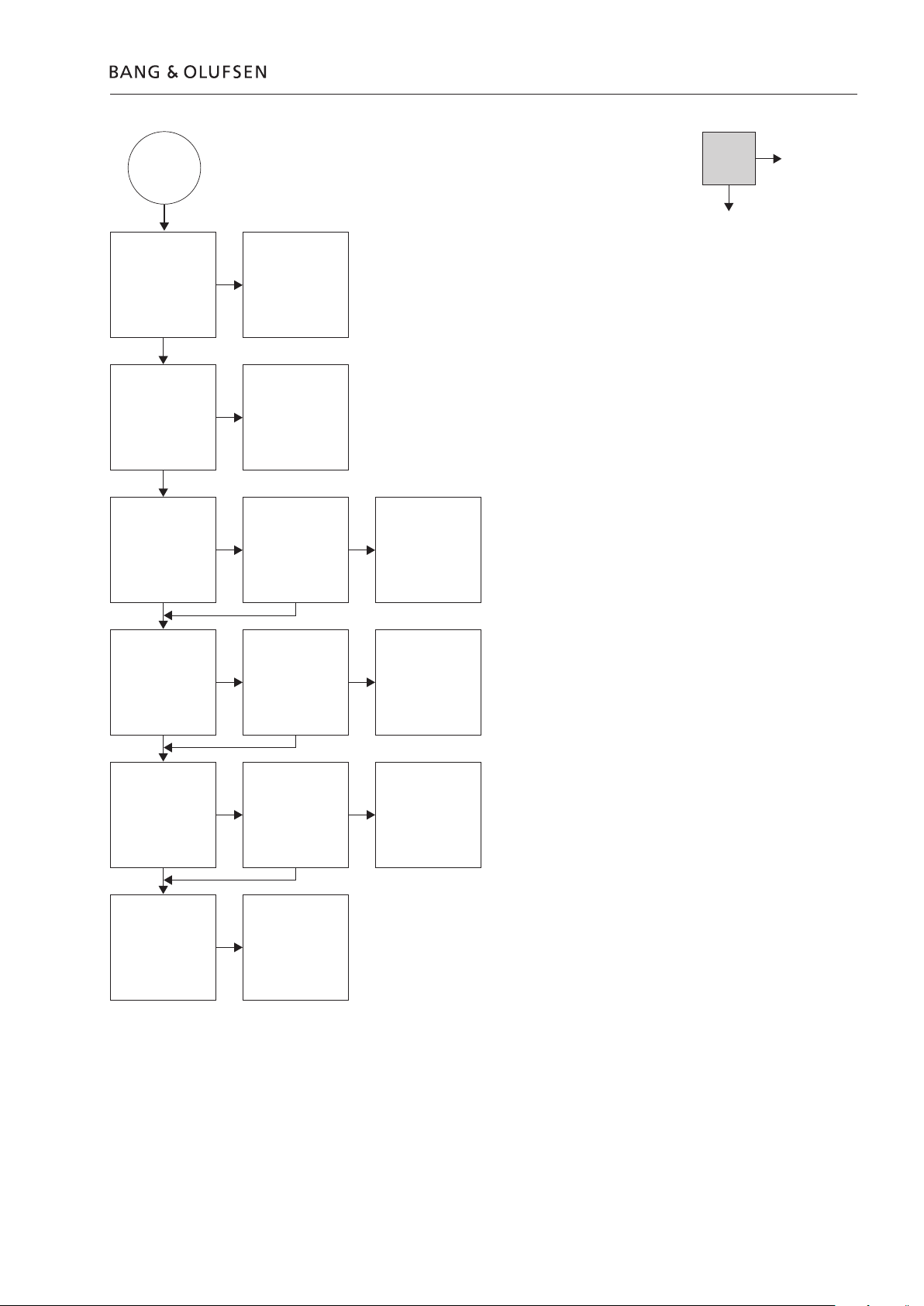

Fault flow chart 3.3

From previous

page

Confirm:

3.3V on PCB04, J1 pin 1, 2, 3, 4

5V on PCB04, J2 pin 9

-5V on PCB04, J1 pin 12

OK?

Go to next

page

Disconnect J1 on PCB04, Power Supply

Confirm:

3.3V on PCB04, J1 pin 1, 2, 3, 4

5V on PCB04, J2 pin 9

-5V on PCB04, J1 pin 12

OK?

Reconnect J1 on PCB04, Power Supply

Disconnect P1004 on PCB02, Digital

Confirm:

3.3V on PCB04, J1 pin 1, 2, 3, 4

5V on PCB04, J2 pin 9

-5V on PCB04, J1 pin 12

OK?

Replace PCB10,

HDMI

No

Yes

Replace PCB04,

Power Supply

Replace PCB02,

Digital

Refer to ‘Adjustments’

when replacing

3.4 Fault flow chart

From previous

page

Start HyperTerminal

(Refer to Service Mode for use)

Is HyperTerm promt OK?

Go to next

page

3.3V Stby. on PCB01, P1932 pin 5

5V Stby. on PCB01, P1932 pin 3

12V Stby. on PCB01, P1932 pin 1

3.3V on PCB03, P1500 pin 1, 2, 3, 4

-5V on PCB02, P1500 pin 12

Replace PCB02,

HyperTerm OK?

Confirm:

OK?

Confirm:

5V on PCB02, P1500 pin 9

OK?

Digital

Replace PCB01,

HyperTerm OK?

Analog

Reconnect/Replace

cable W16

Reconnect/Replace

cable W10

Replace PCB14,

HyperTerm OK?

Keyboard

No

Yes

Disconnect PCB10,

HDMI

HyperTerm OK?

Is DVD 2 OK?

Otherwise start at the

beginning with the

new PCB

Is DVD 2 OK?

Otherwise start at the

beginning with the

new PCB

Is DVD 2 OK?

Otherwise start at the

beginning with the

new PCB

Replace PCB10,

HDMI

Is DVD 2 OK?

Otherwise start at the

beginning with the

new PCB

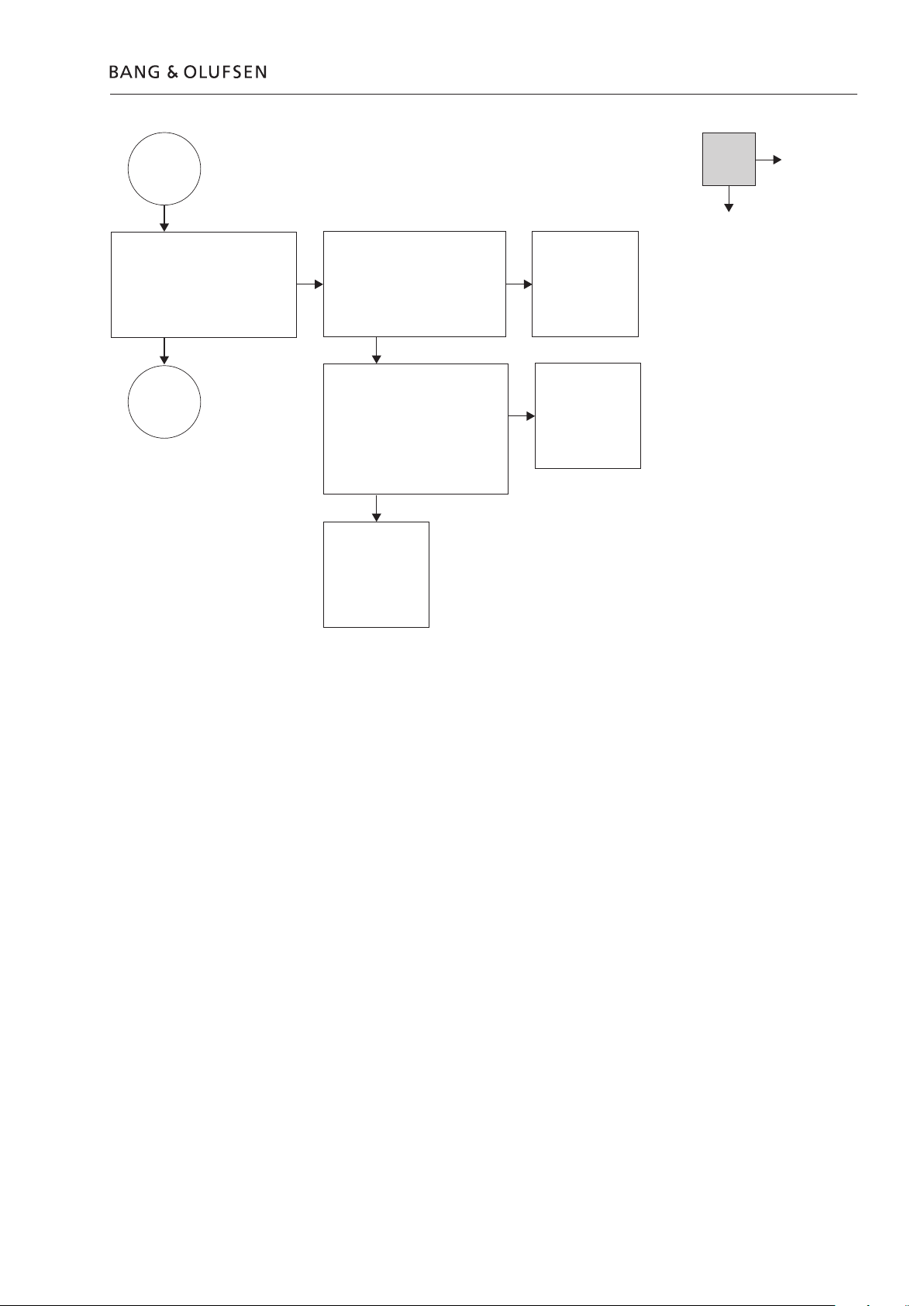

Fault flow chart 3.5

From previous

page

Confirm

communication with

PCB02, Digital by

typing:

DS:>1228 at prompt

OK?

Confirm

communication with

ASP on PCB01,

Analog by typing:

DS:>1600 at prompt

OK?

Confirm ‘slash

version’ by typing:

DS:>1218 at prompt.

Slash version must be

‘11221’

OK?

Replace PCB02,

Digital

Refer to ‘Adjustments’

when replacing

Replace PCB01,

Analog

Set slash by typing

‘DS:1217 11221’ at

prompt

Confirm result by

typing DS:>1218

OK?

No

Yes

Replace PCB02,

Digital

Refer to ‘Adjustments’

when replacing

Confirm IEEE unique

number by typing:

DS:>1208 at prompt

Result must be a ‘10-

digit-hexadecimal-

number’

OK?

Confirm ‘diversity

string’ by typing:

DS:>1229 at prompt.

Result must be a ‘128-

digit-decimal-number’

OK?

Confirm

‘SettingsDisplay’ by

typing:

DS:>1228 at prompt

OK?

Set IEEE unique

number by typing

DS:>1207 xxxxxxxxxx

at prompt. Confirm

result by typing

DS:>1208

OK?

To set ‘diversity string’

please refer to

‘Adjustments’

Confirm result by

typing DS:>1208

OK?

Replace PCB02,

Digital

Refter to

‘Adjustments’ when

replacing

Replace PCB02,

Digital

Refer to ‘Adjustments’

when replacing

Replace PCB02,

Digital

Refer to ‘Adjustments’

when replacing

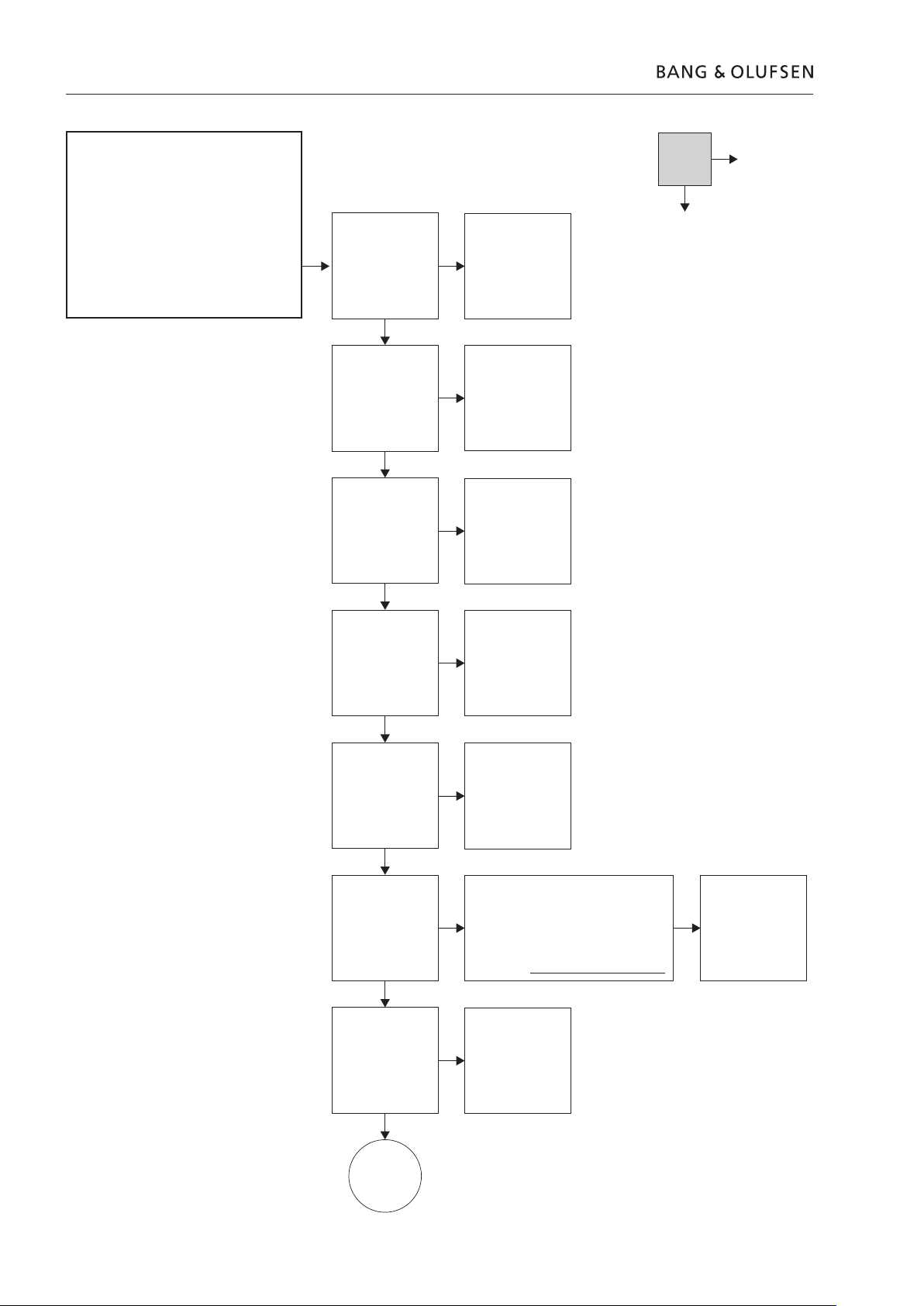

3.6 Fault flow chart

Fault symptom:

DVD 2 does not complete startup sequence

STBY. LED (red -> green)

Display shows ➀ or ➁

➀ ‘BUSY’ for about 45 sec., then ‘STARTING’

for about 15 sec., then ‘CLOCK’

➁ ‘STARTING’ and HDD reboots for every 45 sec.

Possible causes:

Defective DVD ‘DVD Drive’

Defective HDD

Defective PCB

Confirm:

+5V on

PCB04 J5 pin 4

+12V on PCB04 J5

pin 1

OK?

Start HyperTerminal

(Refer to

Service Mode for use)

Confirm

communication with

DVD Drive by typing:

DS:>900 at prompt

Test OK?

Confirm ‘open/close’

function by typing:

DS:>904 at prompt

(open)

DS:>905 at prompt

(close)

Test OK?

No

Yes

Replace PCB04,

Power Supply

Replace DVD Drive

Replace DVD Drive

Check HDD

Confirm:

+5V on PCB04 J4

pin 4

+12V on PCB04 J4

pin 1

OK?

Confirm

communication with

HDD by typing:

DS:>2100 at prompt

Test OK?

Confirm HDD

diagnostic test by

typing:

DS:>2105 at prompt

Test OK?

Confirm

communication with

PCB10, by typing:

DS:>1501 at prompt

Test OK?

Replace PCB04,

Power Supply

Replace HDD

(Check cables W11 &

W13 before replacing)

Refer to ‘Adjustments’

when replacing

Perform an ‘image download’ from DVD

format disc, by typing:

DS:>2107 at prompt

Refer to ‘Adjustments’ for further

information

(Formatting a new HDD)

WARNING!: All recording data will be lost

Replace PCB10, HDMI

Replace HDD

(Check cables W11 &

W13 before replacing)

Refer to ‘Adjustments’

when replacing

See next page

Fault flow chart 3.7

From previous

page

Confirm

communication with

FrontEnd (Tuner) on

PCB01, by typing:

DS:>2000 at prompt

Test OK?

Confirm

communication with

ASP on PCB01 by

typing:

DS:>1600 at prompt

Test OK?

Confirm

communication with

PCB02 by typing:

DS:>100 at prompt

Test OK?

No

Yes

Replace PCB01,

Analog

Replace PCB01,

Analog

Replace PCB02,

Digital

Refer to

‘Adjustments’ when

replacing

Confirm ‘slash version’

by typing:

DS:>1218 at prompt

Slash version must be

‘11221’

Test OK?

Confirm IEEE unique

number by typing:

DS:>1208 at prompt

Result must be a ‘10-

digit-hexadecimal-

number’

Test OK?

Confirm ‘diversity

string’ by typing:

DS:>1229 at prompt

Result must be a ‘128-

digit-decimal-number’

Test OK?

Confirm

‘SettingsDisplay’ by

typing:

DS:>1228 at prompt

Test OK?

Set slash by typing:

DS:>1217 11221 at

prompt

Confirm result by

typing:

DS:>1218

Test OK?

Set IEEE unique

number by typing:

DS:>1207 xxxxxxxxxx

at prompt. Confirm

result by typing:

DS:>1208

OK?

To set ‘diversity string’,

please refer to

‘Adjustments’

Confirm result by

typing:

DS:>1208

Test OK?

Replace PCB02,

Digital

Refer to

‘Adjustments’ when

replacing

Replace PCB02,

Digital

Refer to ‘Adjustments’

when replacing

Replace PCB02,

Digital

Refer to ‘Adjustments’

when replacing

Replace PCB02,

Digital

Refer to ‘Adjustments’

when replacing

3.8 Fault flow chart

Fault symptom:

DVD 2 starts up but goes to standby

Stby. LED = Red

Display shows ‘STARTING’ and the DVD 2 is

locked!

After a few minutes DVD 2 reboots and the

sequence is repeated

Possible causes:

Defective HDD

Defective Power Supply

Confirm on PCB04,

Power Supply:

+5V on J4 pin 4

+12V on J4 pin 1

Start HyperTerminal

(Refer to Service Mode

for use)

Confirm

communication with

HDD by typing:

DS:>2100 at prompt

No

Yes

Replace PCB04,

Power Supply

Replace HDD

(Check cables W11 &

W13 before replacing)

Refer to ‘Adjustments’

when replacing

Confirm HDD

diagnostic test by

typing:

DS:>2105 at prompt

OK?

Perform an ‘image download’ from DVD

format disc, by typing:

DS:>2107 at prompt

Refer to ‘Adjustments’ for further

information

(Formatting a new HDD)

WARNING!: All recording Data will be lost

Replace HDD

(Check cables W11 &

W13 before replacing)

Refer to ‘Adjustments’

when replacing

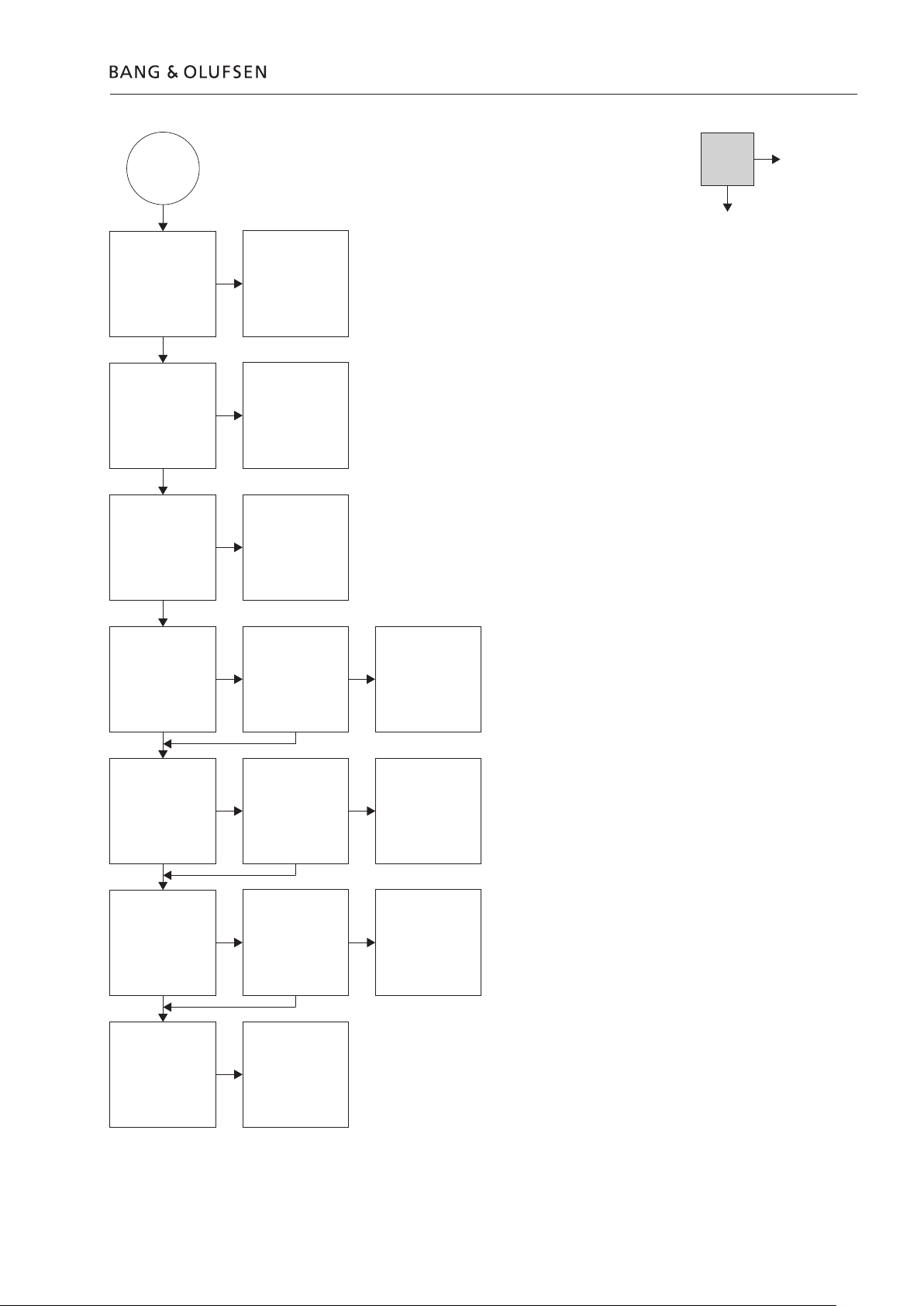

Fault flow chart 3.9

Fault symptom:

Fan error

Fan continues running in standby

Fan not running

Fan always runs at high speed

Possible causes:

Defective Fan

Defective NTC on PCB03, Display

Defective software

Confirm 5~12V on

Is the Fan running

when DVD 2 is on?

between pin 1 and

PCB01 P1913

pin 2

OK?

Replace Fan

Replace PCB01,

Analog

No

Yes

* Measuring made at 22 deg. celsius

Fan speed low (normal/switched on):

-5V PCB01 P1913 between pin 1 and pin 2

-1.6V or higher at PCB03 P1910 pin 8

Fan speed high (switched on):

-10~12V PCB01 P1913 between pin 1 and pin 2

- 1.6V or lower at PCB03 P1910 pin 8

Fan off (stby. only):

-1.9V or higher at PCB03 P1910 pin 8

Is the Fan speed

normal?*

Confirm that Fan stops

running approx. 15

sec. after DVD 2 is

switched off

Is DC level lower than

1.6V at PCB03 P1910

pin 8?

Replace PCB03,

Display

Is DC level higher than

1.9V at PCB03 P1910

pin 8?

Verify that the

software version is the

latest available.

Refer to ‘Adjustments’

for readout

OK?

Verify that the

software version is the

latest available.

Refer to ‘Adjustments’

for readout

OK?

Replace PCB01,

Analog

Wait 1-2 minutes and

measure again

(DC level should

increase)

Update to latest

version. Software can

be downloaded at

Bang & Olufsen Retail

system under the

BeoWise section

Update to latest

version. Software can

be downloaded at

Bang & Olufsen Retail

system under the

BeoWise section

Replace PCB03,

Display

Loading...

Loading...