Page 1

BeoLab 9

Type 6217

Service Manual

English

German, French, Italian, Spanish, Danish, Dutch and Japanese versions

are available in the Retail System

This Service Manual must be returned

with the defective parts/back-up suitcase !

Page 2

CONTENTS

Survey of modules .................................................................... 1.1

How to service .......................................................................... 1.2

Fault flow chart ......................................................................... 2.1

Adjustments ............................................................................. 3.1

Repair tips ................................................................................. 3.2

Final check after repair .............................................................. 3.3

Replacement of modules ........................................................... 4.1

Specification guidelines for service use ...................................... 5.1

Block diagram ........................................................................... 6.1

Wiring diagram ......................................................................... 6.3

Available parts .......................................................................... 7.1

Page 3

4

999

7

3

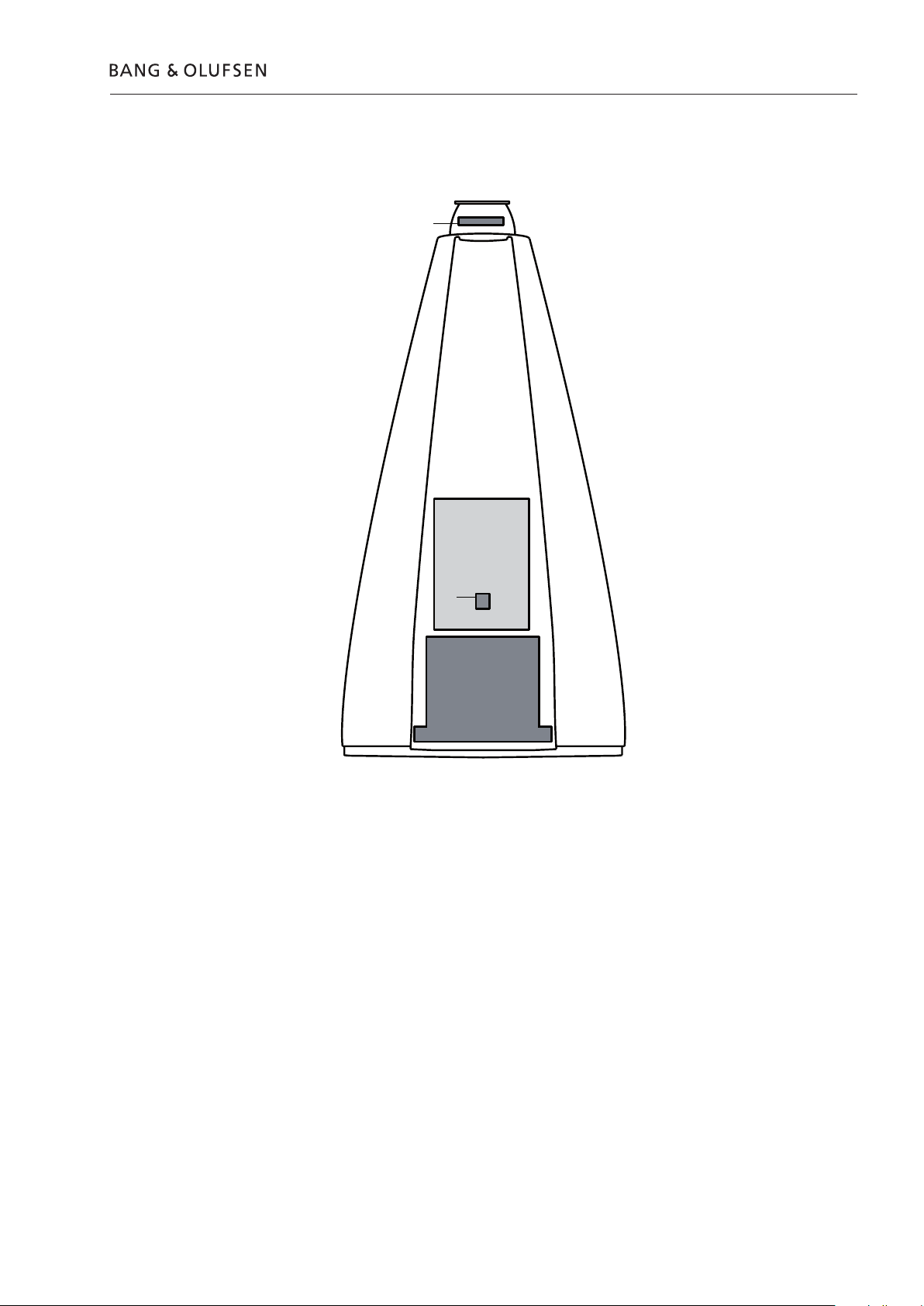

Survey of modules

Survey of modules 1.1

PCB1 Cross Over

PCB2 LC-Filter

PCB3 LED

PCB4 Power Supply

PCB5 ICEpower Amplifier

PCB7 NTC

999Module Chassis complete, incl. PCB1, PCB2, PCB5

Page 4

1.2 How to service

How to service

Strategy

BeoLab 9 has been split-up into as few service items as possible. Each servicefriendly item is packed individually, prepared for worldwide transport, and has a

separate seven digit spare part number to be found in the Bang & Olufsen Retail

System or the Service Manual. An exploded view drawing shows the service spare

parts.

The back-up suitcase holds all necessary electrical modules for front-line repair of

one loudspeaker in e.g. the customers home.

Cabinet parts must be brought with you separately, if to be replaced in the

customers home.

An adequate fault description must be returned with each replaced part. For this

purpose, use the Module Repair form or the form in the Retail Order System under

Exchange Module. To help the Bang & Olufsen Module Repair department it is

very important to answer the following questions:

1. Which products are in the setup?

2. Which software versions are used in these products?

3. How are the products linked together?

4. What happens in the actual situation?

Preparations before service

Fault explanation and demonstration

Recommended tools for service

All service repair will be on module level by means of the back-up suitcase.

Service Manuals in other languages can be found in the Retail System as PDF-files.

Always remember to download the latest version of the Service Manual.

Fault description must be returned with the replaced parts.

Use the Module Repair form or the form in the Retail Order System, Exchange

Module.

Before troubleshooting is initiated, let the customer demonstrate the fault, if

possible.

White gloves.

Soft lint-free cloth.

Multimeter.

Page 5

Handling and cleaning

STATIC ELECTRICITY

MAY DESTROY THE

PRODUCT

ESD

Static electricity

How to service 1.3

Static electricity may damage the product.

Static-protective field service kit.

A static-protective field service kit must always be used when the product is

disassembled or modules are being handled.

Follow the instructions in this Service Manual and use the ESD-mat for both old

and new modules.

Please note:

When mains voltage on the product is required, remove the connection between

the product and the ESD-mat.

The chassis or modules must always be connected to the static-protective field

service kit or placed in an ESD-proof bag.

Symbol of safety components

Transport and handling

Cleaning

When replacing components with this symbol, the same type has to be used, also

the same values for ohm and watt.

The new component is to be mounted in the same way as the replaced one.

It is recommended to:

- use the product cover when transporting the product.

- do not move the product when it is operating.

Please refer to the chapter “Final check after repair” or the User’s guides.

Page 6

1.4

Page 7

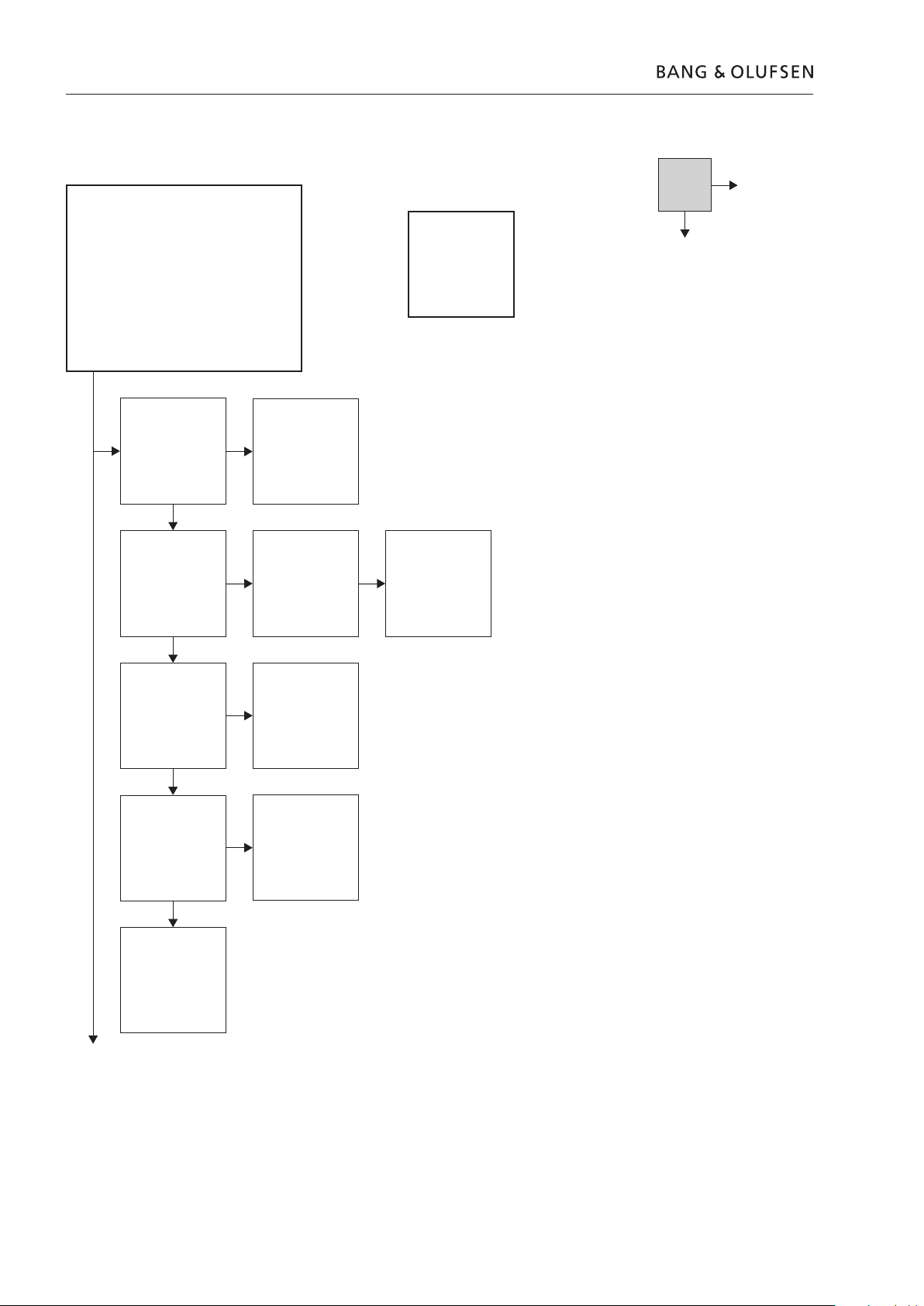

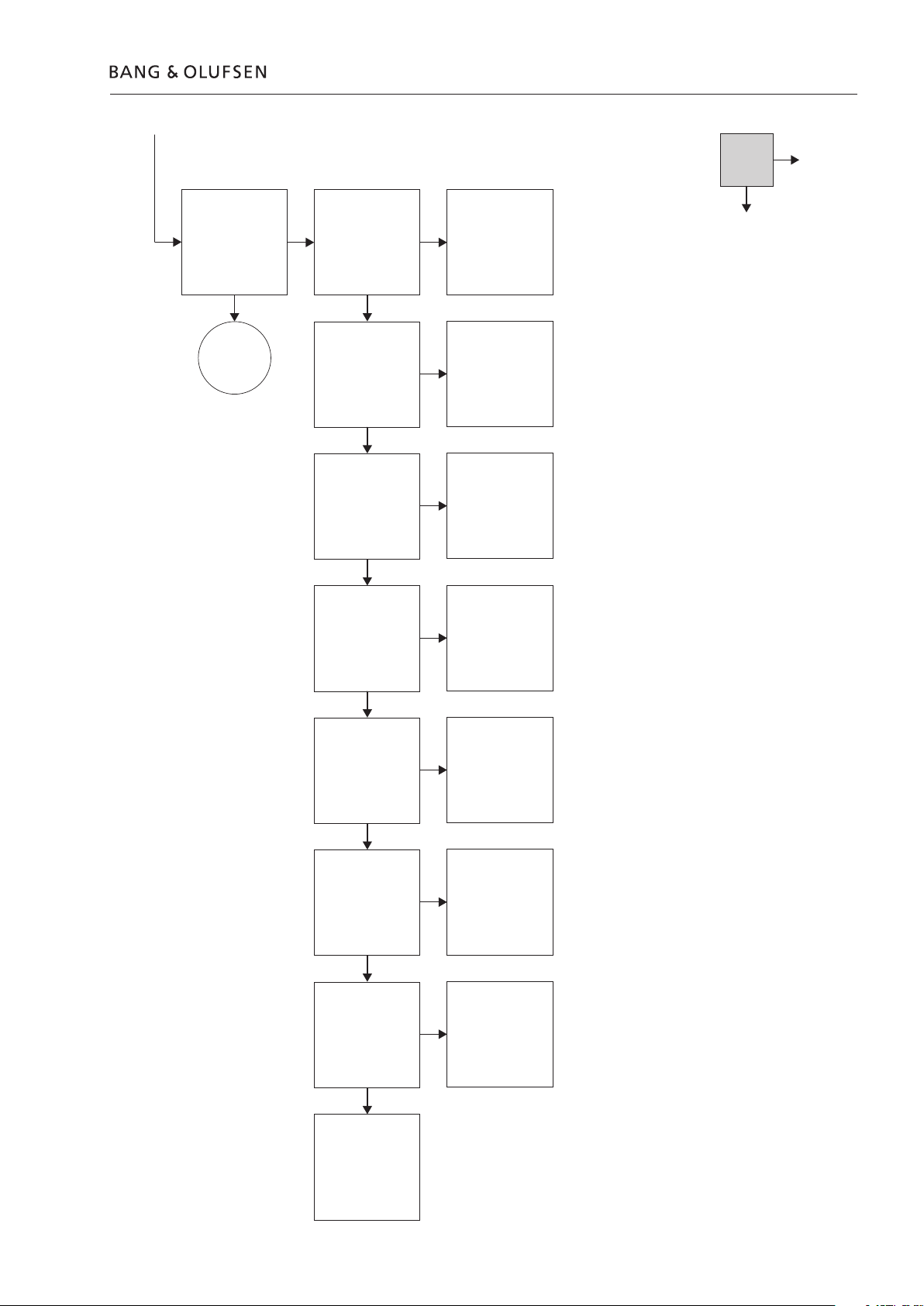

Fault flow chart

Fault flow chart 2.1

No red light in STANDBY ...................................................... 2.2

No sound, but green LED is OK ............................................ 2.4

No sound from woofer, but tweeter and midrange is OK ..... 2.4

No sound from midrange, but tweeter and woofer is OK ..... 2.5

No sound from tweeter, but midrange and woofer is OK ..... 2.5

No function of the PCB7, NTC ............................................. 2.6

No function of S1 and S2 ..................................................... 2.6

Page 8

2.2 Fault flow chart

Fault symptom:

- No red light in STANDBY

Possible causes:

- Fuse F1

- PCB4, Power Supply

- Module 999, Amplifier

Connect a Master Link cable from e.g. a

BeoSound 4, to BeoLab 9. Make sure that S101

is set to either L or R. Connect mains to BeoLab 9.

Is there red light in the LED on top of BeoLab 9?

Note:

Ground is

chassis

No

Yes

Confirm mains in the

mains wire

Confirm mains on

PCB4, Power Supply

P13 pin1 and 2

Confirm 5V on PCB4,

Power Supply P14

pin1

Confirm 4.2V on

PCB1, Cross Over P9

pin 2

Reconnect mains

If possible, check fuse

F1 on PCB1, Cross

Over

Replace PCB4, Power

Supply

Replace Module 999,

Amplifier

Replace fuse F1

Replace PCB3, LED

Page 9

Fault flow chart 2.3

No

Select e.g. Radio or

CD on the

Audiomaster, and

press GO on Beo4

Does BeoLab 9 turn

on (Green light in

LED)

Go to

next page

Confirm 5V on PCB4,

Power Supply P14 pin

7

Confirm -12V on

PCB4, Power Supply

P14 pin 3

Confirm 12V on

PCB4, Power Supply

P14 pin 5

Confirm 44V on PCB4,

Power Supply P15

pin 4

Check Power Link

cable and

Audiomaster.

Reconnect/replace if

nescessarry.

(This is not covered in

this fault flow chart)

Replace PCB4, Power

Supply

Replace PCB4, Power

Supply

Replace PCB4, Power

Supply

Yes

Confirm -44V on

PCB4, Power Supply

P15 pin 5

Confirm 66V on

PCB4, Power Supply

P15 pin 6

Confirm approx 4.7V

on PCB4, Power

Supply P14 pin 9

Replace Module 999,

Amplifier

Replace PCB4, Power

Supply

Replace PCB4, Power

Supply

Replace PCB4, Power

Supply

Page 10

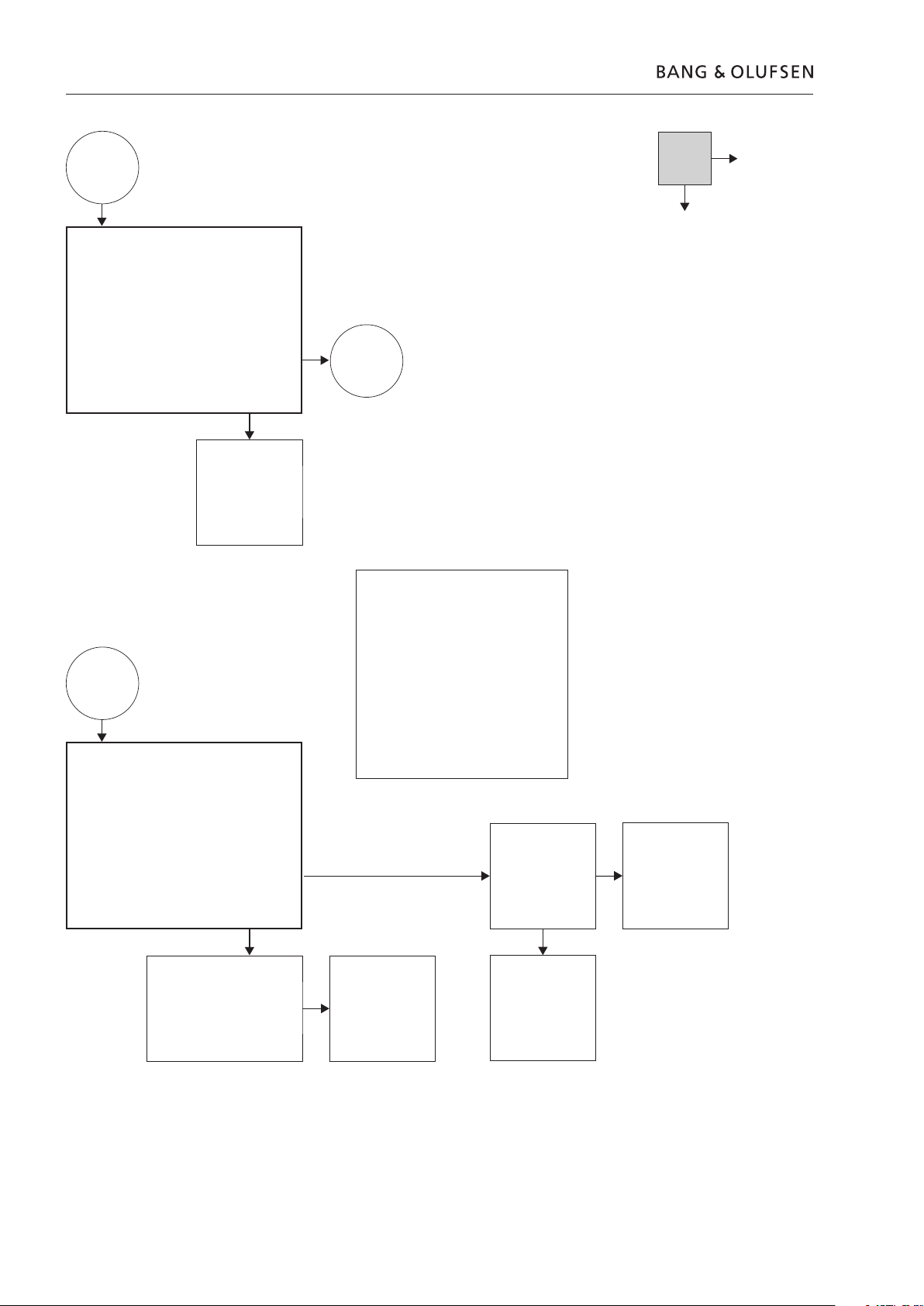

2.4 Fault flow chart

From previous

page

Fault symptom:

- No sound, but green LED is OK

Possible causes:

- Module 999, Amplifier

Is there no sound, but the green LED is OK?

Replace Module 999,

Amplifier

From above

Fault symptom:

- No sound from woofer, but tweeter and

midrange is OK

Possible cause:

- Woofer

- Module 999, Amplifier

Turn volume on the Audio Master up to 50.

Confirm an AC-Sound signal by means of the

Bar-graph on the multimeter or an oscilloscope,

when measuring across the woofer input

terminals.

Go to box

further down

on page

Note:

It wil give the best result if it is possible to

use an audio test CD with pure sine waves

and an oscilloscope, when measuring on

the woofer or midrange.

Warning:

Be very careful, when measuring on the

woofer, because there is approx 35Vdc on

both input terminals. Make sure to use a

differential probe, or make sure that the

oscilloscope and the product is not

connected to earth.

Visual confirm cable

connection between

woofer and Module

999, Amplifier

No

Yes

Reconnect/replace

cable

Remove mains from the

product. Remove the black wire

from the woofer. Measure the

resistance across the woofer

terminals:

Approx 2.9 ohm?

Replace woofer

Replace Module 999,

Amplifier

Page 11

Fault flow chart 2.5

No

Fault symtom:

- No sound from midrange, but tweeter and

woofer is OK

Possible cause:

- Midrange

- Module 999, Amplifier

Turn volume on the Audio Master up to 50.

Confirm an AC-Sound signal by means of the

Bar-graph on the multimeter or an oscilloscope,

when measuring across the midrange input

terminals.

Remove mains from the

product. Remove the black

wire from the midrange.

Measure the resistance across

the midrange terminals:

Approx 6.1 ohm?

Note:

It wil give the best result if it is possible to

use a audio test CD with pure sine waves

and an oscilloscope, when measuring on

the woofer or midrange

Visual confirm cable

connection between

midrange and Module

Replace midrange

Replace Module 999,

999, Amplifier

Amplifier

Yes

Reconnect/replace

cable

Fault symtom:

- No sound from tweeter, but midrange and

woofer is OK

Possible cause:

- Tweeter

- Module 999, Amplifier

Turn volume on the Audio Master up to 50.

Confirm an AC-Sound signal by means of the

Bar-graph on the multimeter or an oscilloscope,

when measuring between PCB1, Cross Over

P10 pin 1 and ground.

Remove mains from the

product. Remove the connector

on PCB1, Cross Over P10.

Measure the resistance

between the orange and white

wire:

Approx 6.6 ohm?

Replace tweeter

Visual confirm cable

connection between

tweeter and Module

999, Amplifier

Replace Module 999,

Amplifier

Reconnect/replace

cable

Page 12

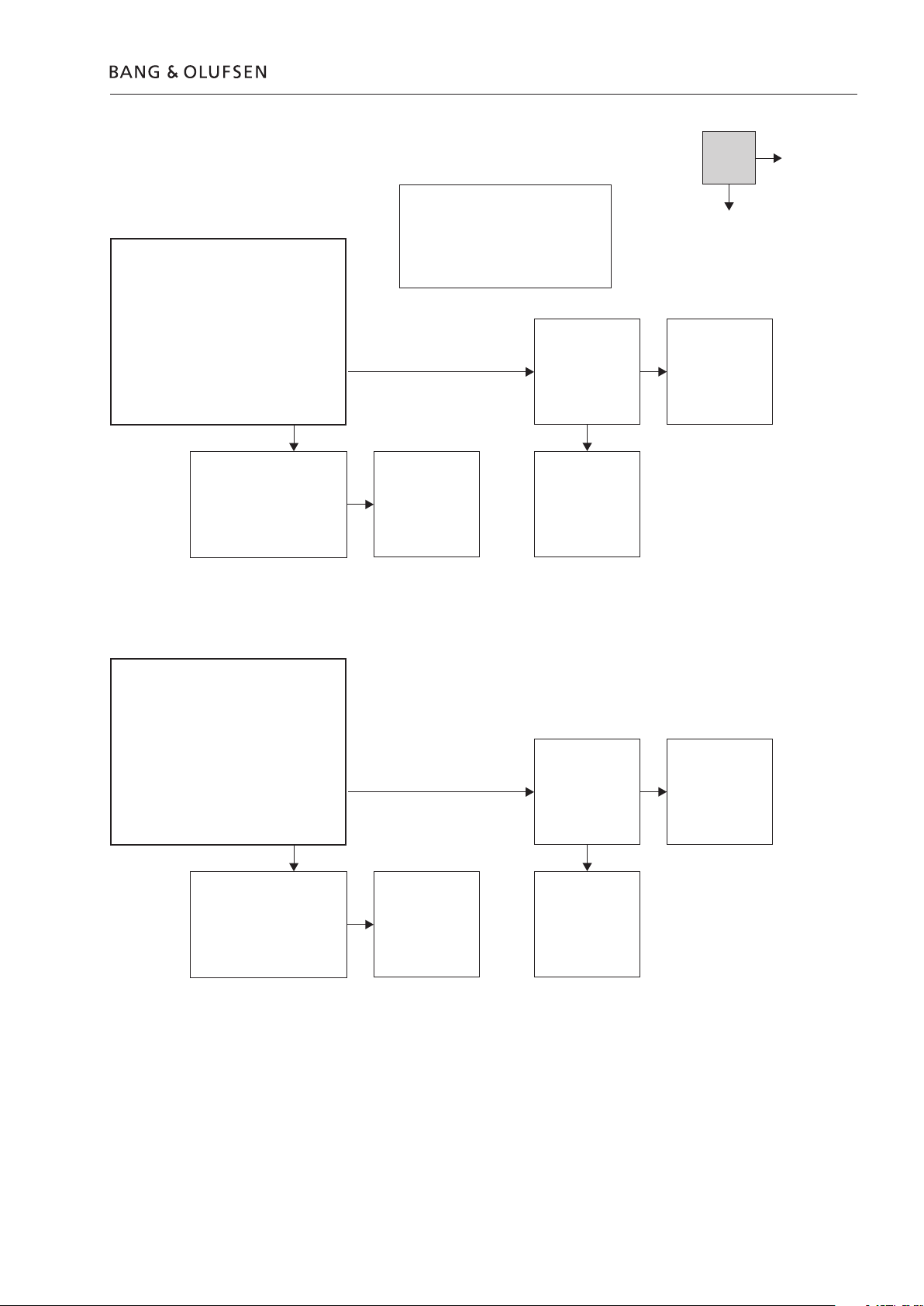

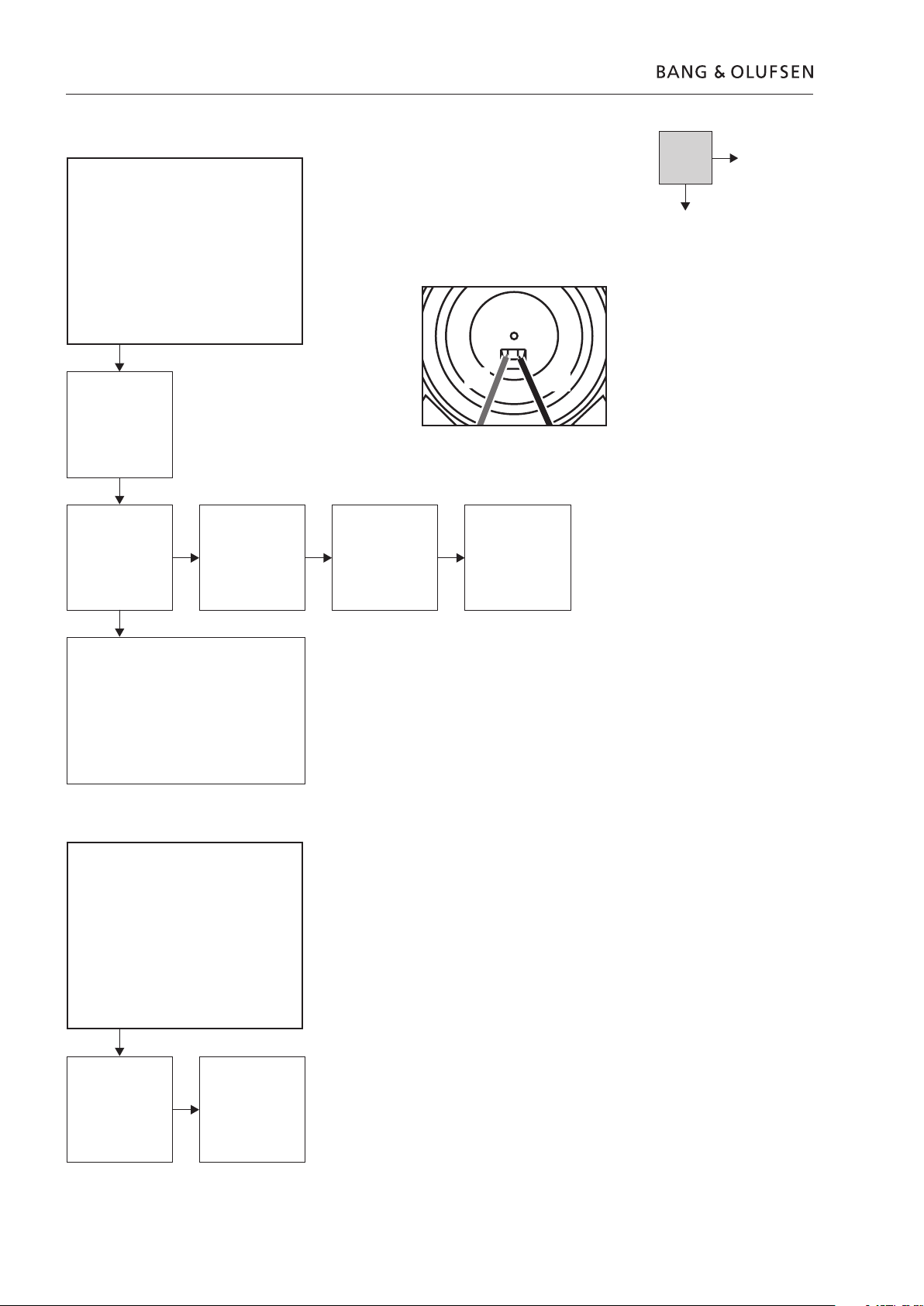

2.6 Fault flow chart

No

Fault symptom:

- No function of the PCB7, NTC

Possible cause:

- PCB7, NTC

- Cable W4

- Module 999, Amplifier

Is the loudspeaker in

protection mode?

Visual confirm cable

connection between

Module 999, Amplifier

and PCB7, NTC

To confirm correct operation of the NTC, measure

approx. 9.35V DC at normal room temperature, as

shown in fig 1

(When the temperature is rising, the DC voltage is

going towards 0)

When the loudspeaker goes into protection mode,

it is nescessarry to disconnect mains and wait one

minute before connecting it again.

Reconnect/replace

cable

Note:

Replace PCB7, NTC

Fig1

Red

Replace Module 999,

Black

Amplifier

Yes

Fault symptom:

- No function of S1 and S2

Possible cause:

- Module 999, Amplifier

Is there no function of

switch S1 and/or S2?

Replace Module 999,

Amplifier

Page 13

Adjustments

1

2

3

4

5

6

7

8

9

0

+

1

2

3

4

5

6

7

8

9

0

+

1

2

3

4

5

6

7

8

9

0

+

TW

MR

WO

TW: Tweeter

MR: Midrange

WO: Woofer

Adjustments described

Access to adjustment points

Speaker adjustment table

Adjustments 3.1

Speaker driver adjustment.

The speakers are individually measured and the speaker driver must be adjusted

accordingly.

Adjustment must be performed when either speaker or speaker driver is replaced.

The adjustment points are placed on the socket panel on the back of the product.

Speaker value from Switch position

label on speaker

1.8 – 2.3 0

1.3 – 1.7 1

0.8 – 1.2 2

0.3 – 0.7 3

-0.2 – 0.2 4

-0.3 – -0.7 5

-0.8 – -1.2 6

-1.3 – -1.7 7

-1.8 – -2.2 8

-2.3 – -2.5 9

Page 14

Power Link

MK III

3.2 Repair tips

Repair tips

Hum in speaker when no music is played

Standby LED

The Power Link cable must be of type MK III or higher.

The ground connection in Power Link cable lower than MK III may be insufficient

for optimum sound performance.

The standby LED indicates the status of the BeoLab 9.

Standby LED STATUS

Red BeoLab 9 is in standby.

Green BeoLab 9 is operating.

Orange BeoLab 9 is shut down due to thermal overload.

If the LED Status is orange, turn off and disconnect the product from the mains.

Wait for minimum 5 minutes for the speaker to cool down.

Connect mains and turn on BeoLab 9.

If the LED status still is orange the fault may be due to:

1. Woofer protection – perform speaker check.

2. Tweeter protection – perform speaker check.

3. Midrange protection – perform speaker check.

4. NTC-board or connection on one of the woofers.

Access the NTC-board by dismantling the woofer.

4. Power supply failure.

Page 15

Final check after repair

Final check after repair

Insulation test

Final check after repair 3.3

The final check after repair describes the activities that are needed to ensure the

product will be returned in perfect condition to the customer.

The content is:

– Insulation test.

– Restore setup.

– Final cleaning of the product.

The product must be insulation tested after having been dismantled. Make the

test when the set has been reassembled and is ready to be returned to the

customer.

Flashover must not occur during the test.

Make the insulation test as follows:

Short-circuit the two pins of the mains plug and connect them to one of the

terminals of the insulation tester.

Connect the other terminal to ground on the Power Link socket.

Restore setup

Check sound

Clean the product

NOTE!

To avoid damaging the product it is essential that both terminals of the insulation

tester have good contact.

During the test the current must not exceed 5 mA.

Slowly increase the voltage on the insulation tester until a voltage of 2.5 kV (ac) is

obtained. Maintain the voltage level for one second, then slowly decrease the

voltage to 0 V (ac).

Ensure that,

– The F/W/C switch is in correct position.

– The plug is inserted over the standby LED.

– The Power Link cable is a MK III or higher.

Ensure that all speakers are OK.

Clean dusty surfaces using a dry soft cloth. If necessary, remove grease stains or

persistent dirt with a lint-free, firmly wrung cloth, dipped in a solution of water

containing only a few drops of mild detergent such as washing-up liquid.

The loudspeaker front grill may be cleaned with a vacuum cleaner with a soft

brush nozzle, and set to the lowest level.

Page 16

3.4

Page 17

Replacement of modules

ESD

ESD-Mat

Modules that can be replaced

Warning – Static electricity

4.1Replacement of modules

BeoLab 9 in service position ....................................... 4.2

Replace PCB3, LED ..................................................... 4.4

Replace PCB4, Power Supply ...................................... 4.6

Replace 999Module, Amplifier ................................... 4.7

Replace tweeter ......................................................... 4.9

Replace midrange .................................................... 4.11

Replace woofer ........................................................ 4.12

Replace rubber foot ................................................. 4.13

Static electricity may damage the product.

A static-protective field service kit must always be used when the product is

disassembled or modules are being handled.

Notice!

Purpose of replacement of modules

- The correct sequence for replacing modules.

- Text and illustrations.

- Reference to adjustment.

After replacement of drivers

All modules must be placed on the ESD-mat or in an ESD-proof bag.

Short instructions for replacement of the available modules, with reference to

additional illustrations:

Modules that do not require any special procedure may be shown as only

illustrations.

After replacing a driver, see Adjustments and Repair tips.

Page 18

BeoLab 9 in service position

4.2

- Remove cover

- Remove cables connected to BeoLab 9

- Remove cover, top

- Use Special tool

- Remove screws for lens

2x

3mm

3x

2.5mm

Page 19

- Gently lift off lens

- Pull off fabric frame

BeoLab 9 in service position

4.3

Page 20

4.4 Replace PCB3, LED

- Remove cover

- Remove cables connected to BeoLab 9

- Remove cover, top

- Use Special tool

- Remove screws for lens

2x

3mm

3x

2.5mm

Page 21

- Gently lift off lens

1

3

2

- Remove screws and pull of lens top

Remove cable

Replace PCB3, LED

4.5

3P25

- Remove screws and pull off PCB3, LED with chassis

- Remove screws for PCB3, LED

3x

TX20

4x

TX10

3x

TX10

Page 22

4.6 Replace PCB4, Power Supply

+ 4.2 BeoLab 9 in service position

- Remove screws

- Flip down heat sink as shown

12x

TX20

- Remove cables

- Remove screws

4P15

4P14

4P13

9x

TX10

Page 23

+ 4.2 BeoLab 9 in service position

- Remove screws

- Flip down heat sink as shown

4.7Replace 999Module, Amplifier

12x

TX20

- Remove cables from woofer

- Remove cables as shown

1P10

1P9

4P15

4P14

Page 24

4.8 Replace 999Module, Amplifier

- Remove screws as shown

- Remove screws as shown

3x

TX20

3x

TX10

- Remove cable on backside of 999Module, Amplifier

1P2

Page 25

- Remove cover

- Remove cables connected to BeoLab 9

4.9Replace tweeter

- Remove cover, top

- Use Special tool

- Remove screws for lens

2x

3mm

3x

2.5mm

Page 26

4.10 Replace tweeter

1

3

2

- Gently lift off lens

- Remove screws and pull of lens top

Remove cable

3P25

- Remove tweeter cover

- Remove screws for tweeter

3x

TX20

3x

TX10

Page 27

+ 4.2 BeoLab 9 in service position

- Remove screws

- Remove cables

4x

TX20

Replace midrange

4.11

Page 28

4.12 Replace woofer

+ 4.2 BeoLab 9 in service position

- Remove screws

- Remove cables (remember NTC)

4x

TX20

Page 29

- Remove screw

- Pull off bracket

4.13Replace rubber foot

1x

TX10

- Pull off rubber foot

Page 30

4.14

Page 31

Specification guidelines for service use 5.1

Specification guidelines for service use BeoLab 9

Type number 6217

Dimensions W x H x D 775mm x 400mm x 300mm

Dimensions W x H x D, incl. packaging two pcs. in one carton box 1004mm x 800mm x 600mm

Weight 16.6 kg

Weight, incl. packaging 44.9 kg

Cabinet finish Black cloth, aluminium

Blue cloth, aluminium

Dark grey cloth, aluminium

Red cloth, aluminium

Mains 90-240Vac

Power consumption 65W (IEC60065)

25W typical

< 0,5W in standby

Power amplifier, bass 400W, 4 ohm, class D ICEpower

Power amplifier, midrange 100W, 6 ohm, class AB

Power amplifier, treble 100W, 8 ohm, class AB

Effective Frequency range 30 - 20,000 Hz

Crossover frequency 180/2000 Hz

Cabinet principle Closed box

Net volume, bass 18 litres

Net volume, midrange 4 litres

Woofer 10” / 250mm cone

Midrange 5” / 125mm cone

Tweeter 3/4” / 19mm dome in acoustic lens

Bass equalization ABL (Adaptive Bass Linearization)

Input sensitivity (Power Link) and (line) 125mV @ 91dB SPL

Switch off time (line) Automatic on /off (up to 3min)

Indication On/Off LED placed in the acoustic lens

Operation Switch for Free standing - Against wall - In corner

Switch for Left - Right - Line (via PL plug)

Protection Thermal protection of all drivers

ABL system protects the bass unit against mechanical damage

Connections

Power Link Two (use semi-balanced PL cable type MKIII, or fully mounted PL cable)

POWER LINK Pin 1 PL ON => 2.5V, OFF = < 0.5V

Pin 2 Signal GND

Pin 3 Audio L out 0V - 6.5V RMS

Pin 4 PL speaker ON => 2.5V, OFF = < 0.5V

Pin 5 Audio R out 0V - 6.5V RMS

Pin 6 Data: High > 3.5V, Low < 0.8V

Pin 7 Data GND

Pin 8 Not used

Line-in Via PL using Line-to-PL adaptor cable

Mains One (two pin male shaver plug type)

Subject to change without notice

Page 32

5.2

Page 33

Block diagram

Module 999

PCB4

PCB5

6.1 Block diagramBlock diagram 6.1 6.1

Page 34

6.26.26.2

Page 35

6.3 Wiring diagramWiring diagram 6.3 6.3

>

>

>

<

>

>

>

>

>

<

>

>

<

<

<

<

>

>

>

>

>

>

>

>

>

>

>>>>>>>

>

>

>

>

>

>

>

>

>

>

>

>

>

>

>

>

>

>

>

>

<

>

>

<

<

>

>

<

<

>

>

>

>

>

>

>

<

<

>

>

>

>

>

>

>

>

<

<

>

>

<

<

>

>

<

>

>

>

>

Molex MLX

JST VH

Micro-Match

4

Power Supply

W1

JST SDN

Soldered into PCB

JST VH

Micro-Match

Soldered into PCB

1

Cross Over

Micro-Match

Soldered into PCB

JST 2mm

JST 2mmJST XA

W2

W3

W5

8 ohm

Tweeter + Lens

W4

JST VH

2

LC-Filter

Micro-Match

JST SAN

Soldered into PCB

JST SDN

Soldered into PCB

7

ICE-Power Amplifier

JST PHMolex Micro-Fit

5

W7

8 ohm

Midrange

4 ohm

Woofer

W9

3

W8

LED

W6

Module 999

Amplifier

NTC

Page 36

9002

9001

9003

9004

9005

9006

9007

9008

9009

9010

9011

9004

9012

9013

9014

9016

9015

9017

9017

9017

9017

9017

9017

9023

9018

9018

9020

9021

9019*

9022

*

*

*

9024

9025

4

999

7

3

1

1

2

2

2

3

3

3

3

3

3

3

4

4

4

5

5

5

8

7

6

6

6

6

6

6

6

6

6

6

6

6

10

11

11

11

11

11

11

11

11

11

3

3

3

12

12

12

10

9

9

9

10

10

10

10

10

10

10

10

10

10

10

3

6

6

6

6

6

6

6

6

6

6

6

6

4

4

9

9

9

9

13

13

11

11

9026

Incl. pos. no. 1

Incl. pos. nos.

9010, 9011

Incl. pos. nos. 9016, 9017,

9020, 9021, 9, 10

Incl. pos. nos. 9018, 9019,

9022, 9024, 3, 4, 11, 9, 13

3

Incl. pos. no. 9022

Incl. pos.

no. 9008

9027

*

Available parts

BeoLab 9

7.1 Available partsAvailable parts 7.17.1

Page 37

Available parts 7.2

BeoLab 9

9001 3458152 Cover, top

9002 3321047 Fabric frame, black

3321048 Fabric frame, dark grey

3321049 Fabric frame, blue

3321050 Fabric frame, red

9003 3131109 Lens, top incl. pos. no. 1

9004 3332007 Damping material

9005 3152321 Chassis w/light guide

9006 3912009 Acoustic felt

9007 3459508 Cover, tweeter

9008 3947303 Gasket

9009 8480084 Tweeter

9010 3947306 Gasket

9011 3947318 Gasket

9012 3131108 Lens, bottom incl pos. nos. 9010, 9011

9013 8480080 Midrange

9014 8480082 Woofer 10”

9015 3400061 Cabinet incl. pos. nos. 9016, 9017, 9020, 9021, 9, 10

3947350 Tape/foam 3 x 7mm – 10m

9016 3332010 Damping material

9017 3151911 Guide

9018 3152235 Clips f/wire

9019 3947305 Gasket, set

9020 3152154 Bracket f/foot

9021 2954004 Rubber foot

9022 3947304 Gasket

9023 3358277 Heat sink incl. pos. nos. 9018, 9019, 9022, 9024, 3, 4, 11, 9, 13

9024 3151552 Wire holder

9025 3160408 Cover

9026 6100273 Mains wire, EU

6100329 Mains wire, UK

6100307 Mains wire, US

6100332 Mains wire, AUS

6100386 Mains wire, KOR

6100331 Mains wire, JPN

6100047 Mains wire, CHN

9027 6270688 Powerlink cable, black, 5m

Survey of screws etc.

3Module 8003276 PCB3, LED

4Module 8003325 PCB4, Power Supply

7Module 8100090 PCB7, NTC

999Module 8052273 999Module, Amplifier consists of: PCB1 - PCB2 - PCB5, incl. pos. no. 9022

F1 6600177 Fuse T 5A 250V

1 2930112 Gasket

2 2052040 Screw 3 x8 mm

3 2054060 Screw 3 x 10mm

4 2058092 Screw 4 x 10mm

5 2019025 Screw 4 x 12mm

6 2019021 Screw 4 x 12mm

7 2058026 Screw 3 x 8mm

8 2625002 Lock washer

9 2930178 Bushing

10 2052011 Screw 3 x 10mm

11 2054043 Screw 3 x 10mm

12 2015005 Screw 4 x 55mm

13 7530118 Solder pin

Page 38

7.3 Available parts

Wire bundles

Parts not shown

Accessories

Packing

Available documentation

W2 6277985 Wire from PCB1, P2 – PCB4, P13

3395313 Back-up suitcase

3376000 Product cover

3040017 Special tool

6270856 Cable, RCA-phono to PL Line-in, black, 5m

6270433 Adapter, mini-jack/male – RCA female x 2

3393016 Outer carton, top-bottom

3396425 Packing, complete

3392768 Pallet

See Retail Ordering System

Page 39

Page 40

Bang & Olufsen

DK-7600 Struer

Denmark

Phone +45 96 84 11 22*

Fax +45 97 85 39 11

3538063 02-07

Loading...

Loading...