Page 1

BeoLab 4000 MKII

Type 6642, 6643, 6644, 6645, 6646, 6647, 6648

Service Manual

English

German, French, Italian, Spanish, Danish, Dutch and Japanese versions

are available in the Retail System

This Service Manual must be returned

with the defective parts/back-up suitcase !

Page 2

CONTENTS

Survey of modules .................................................................... 1.1

How to service .......................................................................... 1.2

Warnings – Insulation test ......................................................... 2.1

Adjustments ............................................................................. 3.1

Repaie tips ................................................................................ 4.1

Replacement of modules ........................................................... 5.1

Specification guidelines for service use ...................................... 6.1

Block diagram ........................................................................... 7.1

Wiring diagram ......................................................................... 7.1

Available parts .......................................................................... 8.1

Page 3

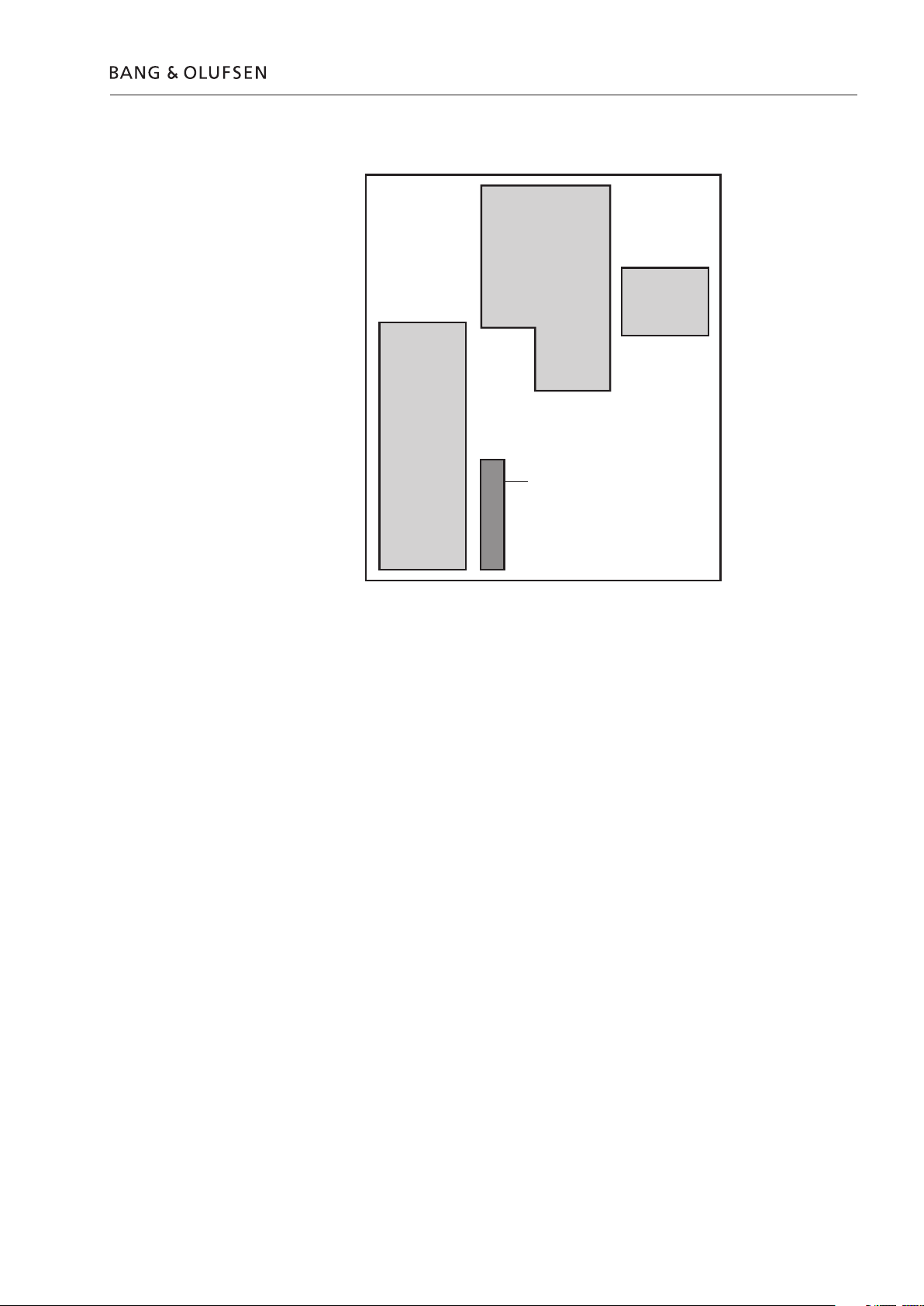

Survey of modules

1

2

3

4

Survey of modules 1.1

PCB01 Amplifier

PCB02 SMPS

PCB03 Main PCB

PCB04 LED

Page 4

1.2 How to service

How to service

Front line service

BeoLab 4000 MKII is to be serviced in the customer’s home when it comes to

electrical symptoms or exchange of mechanical parts. In this way you avoid having

to make more than one visit and using minimum of time on the case, all for the

benefit of the customer.

BeoLab 4000 MKII has been split-up into as few service items as possible. Each

service friendly item is packed individually, prepared for worldwide transport, and

has a separate seven digit spare part number to be found in the Service Manual or

on the Bang & Olufsen Retail System. The exploded view drawing will show the

service spare parts.

All necessary electrical modules and the two loudspeaker units can be ordered to

prepare front-line service. Cabinet parts must also be brought with you separately,

if to be replaced in the customer’s home.

To improve the quality and secure a better service please send the defective part

for quality analyse purposes to:

Att:

Bang & Olufsen Operation a/s

Att.: JEB 7210-3

Peter Bangsvej 15

DK-7600 Struer

Delivery

Installation and setting-up

Fault Finding

Please remember to fill-in a fault description (part no.: 3542206).

There is several type numbers for BeoLab 4000 MKII, however, this is only due to

market approvals. All types can be used on all markets with 100 to 240 V (ac)

mains voltage. When you order BeoLab 4000 MKII (set of two) two mains cables

and two Power Link cables are included.

Only the switch for Left, Right or Line must be set into correct position as

described in the User Guide, before Power Link or a Line signal and AC power

wires are connected. If Power Link is used, the switch is for Left or Right setting. If

a Line signal (0 to 1V) is connected (via phono-male to PL Line-in) part no. see

Parts not shown) the switch must be set to Line position. See more details in the

User Guide. The LED will indicate on (green) or off (red).

Before troubleshooting is initiated, let the customer demonstrate the fault, if

possible. There are four electrical modules in the product. Therefore a faulty

module is easy to point out in most cases. The PCB’s has been divided into:

PCB01, Amplifier - PCB02, SMPS - PCB03, Main PCB and PCB04, LED.

No special service programs are available in this product or via the ServiceTool.

If there is a fault in the PCB02, SMPS or PCB01, Amplifier the LED is typically off.

Replacement

Each loudspeaker is individually adjusted from production to ensure optimal stereo

perspective. When replacing a speaker unit bass/treble level have to be adjusted.

On the back of the new unit will be printed a rated value for the sensitivity of the

particular unit. The rated value is rated in dB.

Page 5

Warnings

ESD

ESD-Mat

ESD

Handling

Cleaning

Warnings – Insulation test 2.1

When electrical replacement or disassembly is taking place, use an ESD-mat. The

internal electronics are very sensitive to static electricity.

Wear cotton gloves to avoid any fingerprints on the product.

The surfaces on the product are very sensitive, so handling should be done with

great care to avoid damage.

Clean the surfaces of the BeoLab 4000 MKII using a soft, lintfree cloth which you

have wrung firmly in a solution of lukewarm water containing a few drops of mild

household cleaner, for example a dish washing detergent. The cooling fins on the

rear may be cleaned using a soft brush or a vacuum cleaner. The front cloth may

be cleaned with a vacuum cleaner set to the lowest level.

Insulation test

Note: Never use alcohol or other solvents to clean any part of the BeoLab 4000 MKII !

The product must be insulation tested after having been dismantled. Make the test

when the set has been reassembled and is ready to be returned to the customer.

Flashover must not occur during the test.

Make the insulation test as follows:

Short-circuit the two pins of the mains plug and connect them to one of the

terminals of the insulation tester.

Connect the other terminal to ground on the Power Link socket.

NOTE!

To avoid damaging the product it is essential that both terminals of the insulation

tester have good contact.

During the test the current must not exceed 10 mA.

Slowly increase the voltage on the insulation tester until a voltage of 2.5 kV (ac) is

obtained. Maintain the voltage level for one second, then slowly decrease the

voltage to 0 V (ac).

Page 6

LI NE

L

R

1 2

POW ER

LIN K

W T

12

3

1

2

11

10

9

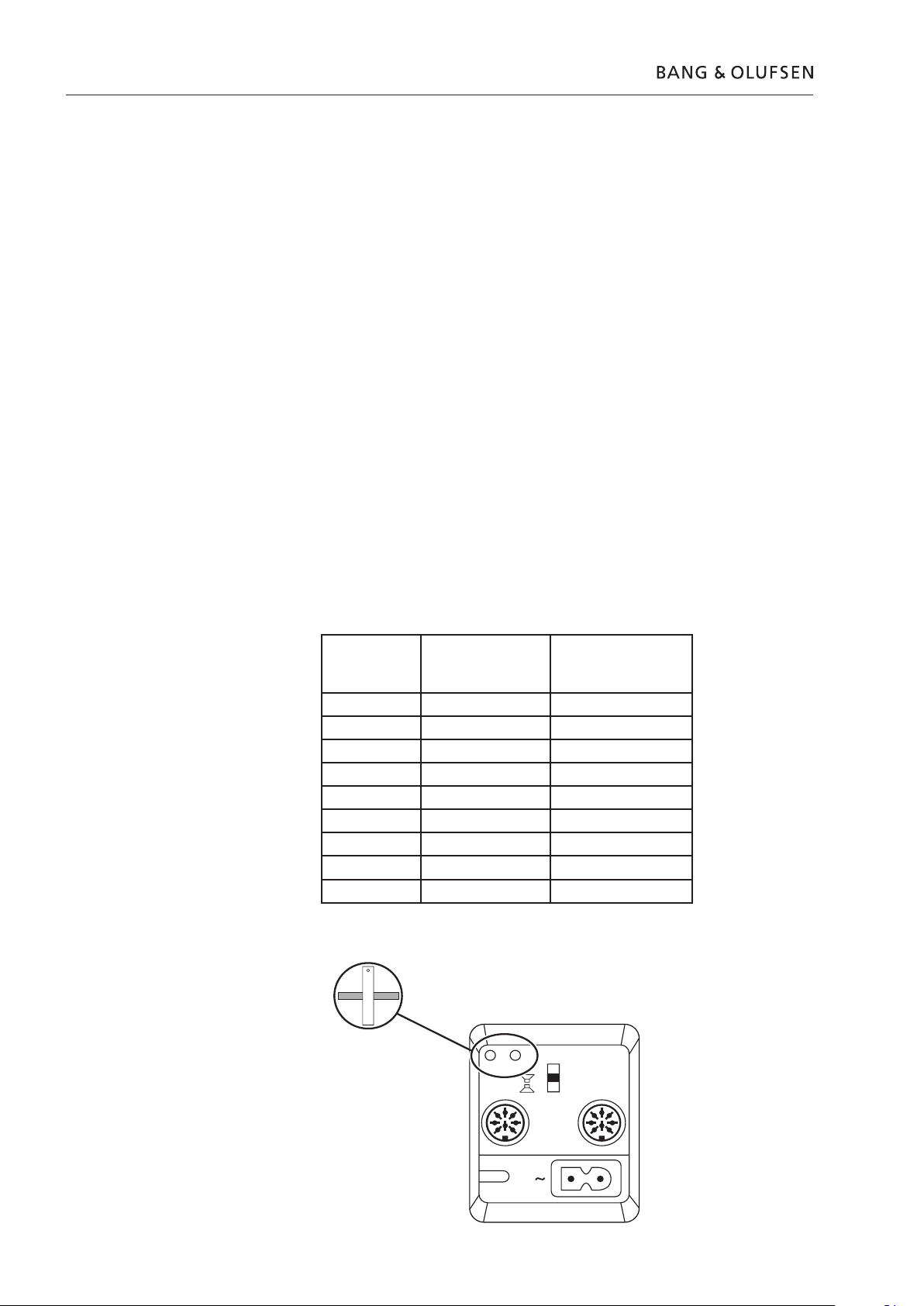

3.1 Adjustments

Adjustments

Adjustments after replacing PCB03, Main PCB

Adjustments of bass/treble levels

After replacing a speaker unit

- Adjust treble level by means of (R301) and the bass level by means of (R312).

- Adjusts according to the drawing and table 1. Only the potentiometer of the

Read out the adjustment position of the old potentiometers, R301 & R312, and

set the new potentiometers to the same position.

Each loudspeaker is individually adjusted from production to ensure optimal stereo

perspective. When replacing a speaker unit or PCB03, Main PCB, bass/treble levels

have to be adjusted. On the back of the new speaker unit will be printed a rated

value for the sensitivity of the particular unit. The rated value is stated in dB and

have to be converted to a mechanical position of the two potentiometers by using

table 1 and fig.1.

These two potentiometer are accessible via the two holes in the socket well, see

fig. 1.

replaced unit have to be adjusted.

Table 1

Fig.1

WARNING: Do under no circumstances adjust the level of a unit that has not been

replaced!

‘‘Clock position’’

(The new position

of the

potentiometer)

Bass deviation ±dB Treble deviation ±dB

0830 +3.1 +3.9

0900 +2.7 +3.3

1000 +1.8 +2.2

1100 +0.9 +1.1

1200 0.0 0.0

0100 -0.9 -1.1

0200 -1.8 -2.2

0300 -2.7 -3.3

0330 -3.1 -3.9

Page 7

Repair tips

Power Link

MK III

Hum in loudspeaker when no music is played

Check loudspeaker units

Repair tips 4.1

The Power Link cable must be of type MK III or higher.

The ground connection in Power Link cable lower than MK III may be insufficient

for optimum sound performance.

The loudspeaker units can be checked by an ohm-meter.

OK values for tweeter and woofer are approx. 6 W.

How to check the Switch Mode Power Supply

- Take off the baffle.

- Connect an audio signal (set the input switch corresponding to the applied signal).

- Connect mains, 100 - 240V.

- Confirm 12V standby on PCB02, SMPS P2 pin 6, GND pin 3 (if not OK, replace

PCB02, SMPS).

- Confirm 12V HT_ON, on PCB02, SMPS P2 pin 8 (if not OK replace PCB03, Main

PCB).

- Confirm ±12V on PCB02, SMPS P2 +12V pin 1, 2 and -12V pin 4, 5 (GND pin 3).

If not OK replace PCB02, SMPS.

Page 8

4.2

Page 9

Replacement of modules

ESD

ESD-Mat

Modules that can be replaced

Warning – Static electricity

5.1Replacement of modules

BeoLab 4000 MKII in service position ......................... 5.2

Replace PCB01, Amplifier .......................................... 5.4

Replace PCB02, SMPS ................................................ 5.5

Replace PCB03, Main PCB ......................................... 5.6

Replace PCB04, LED ................................................... 5.7

Static electricity may damage the product.

A static-protective field service kit must always be used when the product is

disassembled or modules are being handled.

Notice!

All modules must be placed on the ESD-mat or in an ESD-proof bag.

Purpose of replacement of modules

- The correct sequence for replacing modules.

- Text and illustrations.

- Reference to adjustment.

Adjustments

Short instructions for replacement of the available modules, with reference to

additional illustrations:

After replacing PCB03, Main or a loudspeaker an adjustment is required, see

adjustments.

Page 10

BeoLab 4000 MKII in service position

LINE

L

R

1 2

POWER

LINK

5.2

- Remove cables connected to BeoLab 4000 MKII

- Remove front frame

- Remove profile

- Remove screws for baffle

2x

TX10

10x

TX10

Page 11

- Remove cables for speaker units

BeoLab 4000 MKII in service position

5.3

Page 12

5.4 Replace PCB01, Amplifier

+ 5.2 BeoLab 4000 MKII in service position

- Remove screws

- Remove cables on backside of PCB

4x

TX10

4P300

4P301

Page 13

5.5Replace PCB02, SMPS

+ 5.2 BeoLab 4000 MKII in service position

- Remove cables

- Remove screws and pull out PCB02, SMPS

2P1

2P2

6x

TX10

Page 14

5.6 Replace PCB03, Main PCB

+ 5.2 BeoLab 4000 MKII in service position

- Remove screws and pull out PCB03, Main PCB

- Remove ground cable!

- Remove cables

5x

TX10

Ground

3P300

3P103

3P100

Page 15

+ 5.2 BeoLab 4000 MKII in service position

- Remove screw and pull out LED

- Remove screws and pull PCB04, LED out

5.7Replace PCB04, LED

1x

TX10

2x

TX10

- Remove screw and pull off light guide

1x

TX10

Page 16

5.8

Page 17

Specification guidelines for service use

Specification guidelines for service use BeoLab 4000 MKII

Type 6642 (EU), 6643 (GB), 6644 (US), 6645 (J), 6646 (AUS), 6647 (KOR)

6648 (CN)

Power supply:

Voltage 100-240 Volt

Power consumption Typical: 6 W, Standby: 0.5 W

Cabinet finish Grey, black, dark grey, yellow, red/black, blue/black

Front cloth Grey, black, dark grey, yellow, red, blue

Dimensions W x H x D 28 x 32 x 16 cm (with wall bracket)

Weight 4.5 kg

Indicator LED for On (green) or Off (red)

Operation Left, Right or LINE, switch

Protection Thermal protection of SMPS

Tweeter protection

System data:

Effective Frequency range 55–20,000 Hz

Sound Pressure Level (SPL) 97 dB/IEC noise 3 m/stereo/room

Input impedance 47kW

Harmonic distortion <6% 90 dB SPL/1 m/250-1000 Hz

<2% 90 dB SPL/1 m/1000-5000 Hz

Electronics:

Active crossover network Linkwitz/Riley

High pass filter 30 dB/octave, 51 Hz

Low frequency equalization 51 Hz/+10 dB

Bass equalization ABL (Adaptive Bass Linearization)

6.1

Acoustics and cabinet:

Cabinet principle Bass reflex

Woofer 114 mm (4½”), 8W

Tweeter 18 mm (¾”), 8W

Magnetically shielded Yes

Crossover frequency 3.3 kHz

Net volume, bass 4 litres

Power amplifier:

Signal to noise ratio >= 84 dBA (1W in Woofer)

Input sensitivity/impedance:

Input sensitivity Power Link & Line 125 mV (88 dB SPL) Auto switch on

Power link sockets 1V/47 kW

Power link channel separation >55 dB/10,000 Hz

Standby function Automatic On-Standby

Switch off time (line) 3 min.

Power amplifier, bass 30 W, Class D, ICE power®

Power amplifier, treble 30 W, Class D, ICE power®

Long-term maximum output power 56 W

Connections:

Power Link 2 x 8-pin socket

Pin 1 Power up/down not used

(interconnected between the two Power Link plugs )

Pin 2 Signal GND

Pin 3 Left in (also used for line in. Note: pin2&7 in the plug

must be connected when used for line in)

Pin 4 Loudspeaker on/sense => 2.5V, OFF =< 0.5V

Pin 5 Right in

Pin 6 Data (Not used)

(interconnected between the two Power Link plugs )

Pin 7 Data GND

Pin 8 (Not used)

(Jacket: No connect)

Subject to change without notice

Page 18

6.2

Page 19

P301

4/5pinsPlug

>

>

>

>

P300

Plug

>

>

>

>

<

>

>

8/8pins

AMPLIFIER

01

Plug

P300

>

>

<

>

>

>

>

8/8pins

W03

P103

Plug

>

>

3/3pins

Plug

P104

>

>

3/3pins

W04

04

LED

MAIN PCB

03

SMPS

02

P100

Plug

>

>

>

>

>

<

8/8pins

P2

Plug

>

>

>

>

>

<

8/8pins

W02

2/3pinsP1Plug

>

>

W01

W05

Tweeter level Woofer level

Power Link 1

Power Link 2

Line R/L

AC Inlet

Neutral

Live

Tweeter

Black

Red

Woofer

White

Purple

G

R

GND

R302

R312

PCB04, LED

PCB03, Main

PCB02,

SMPS

PCB01,

Amplifier

Autostart

HT On

1

2

Tweeter gain adjust

EQ

notch

4 kHz

EQ

notch

7 kHz

H. P. F

fc

3200 Hz

Tweeter

Protection

Limiter

H. P. F

fc

3200 Hz

Differential

Output

Tweeter

Tweeter

amp.

gain

20dB

ICE power

Woofer

amp.

gain

20dB

Woofer

MUTUAL EQ

750Hz

notch

1.35kHz

notch

2.4kHz

peak

ABL

L. P. F

fc

3560Hz

Filter PWB

L. P. F

fc

3560Hz

Differential

Output

Gain 12dB

Woofer

Gain adjust

1

2

Input amp.

DIN input

Input

select

AC in

+12V stby.

+/-12V

HT on

Block diagram

7.1Block diagram – Wiring diagram 7.1 7.1 Block diagram – Wiring diagram

Wiring diagram

Page 20

Baffle

Baffle – left

Baffle – right

!

!

9001

9002

9104

9101

9102

9102

9103

9001

9005

9004

9003

9003

9014

9006

9007

9008

9009

9013

9012

9010

9011

9015

9016

9017

9018

9019

9020

9020

9021

1

3

2

4

1

1

1

1

2

3

3

1

1

1

1

2

4

4

4

4

4

4

5

8

8

7

6

6

6

6

6

6

6

6

6

6

6

6

6

4

4

4

4

4

4

9

9

9

9

2

10

10

10

11

11

12

10

10

10

10

11

10

10

10

10

10

10

10

10

10

Incl. pos. nos.

9004, 9005

Incl. pos. nos. 9004, 9005

Available parts

Available parts 8.1 8.1 Available parts8.1

Page 21

Available parts 8.2

BeoLab 4000 MKII

9001 3451181 Top/bottom, red

3451227 Top/bottom, blue

3451242 Top/bottom, dark grey

3456201 Top/bottom, aluminium

3456202 Top/bottom, black

3456205 Top/bottom, yellow

9002 3358346 Heat sink incl. pos. nos. 9004, 9005

9003 3947350 Foam tape, 10m

9004 3340136 Gasket

9005 3340090 Gasket

9006 3169054 Bracket incl. pos. nos. 9004, 9005

9007 3170226 Shield

9008 3152399 Holder f/PCB2

9009 3151432 Holder f/PCB1

9010 2576128 Adapter

9011 6150039 Light guide

9012 3340134 Gasket f/light guide

9013 2938320 Bush f/light guide

9014 3440162 Baffle, left

9015 3440163 Baffle, right

9016 8480321 Tweeter

9017 8480384 Woofer

9018 3320300 Front frame, black

3320742 Front frame, grey

3320750 Front frame, yellow

3320885 Front frame, dark grey

9019 2568090 Set of profiles, black

2568111 Set of profiles, yellow

2568148 Set of profiles, red

2568150 Set of profiles, blue

2568158 Set of profiles, dark grey

9020 2816315 Spring

9021 3332015 Set of gaskets

Screws etc.

Wires

01Module 8003563 PCB01, Amplifier

02Module 8003556 PCB02, SMPS

03Module 8003562 PCB03, Main PCB

04Module 8003555 PCB04, LED

9101 3031601 Bracket f/wall

9102 3031620 Bracket f/speaker

9103 2816297 Clips

9104 3031651 Wall bracket, complete

1 2013177 Screw 3 x 13mm

2 2816298 Spring

3 2042053 Screw 4 x 16mm

4 2013229 Screw 3 x 6mm

5 7530087 Solder tab

6 2013137 Screw 3 x 10mm

7 7530119 Solder tab

8 2015182 Screw 3 x 13mm

9 2015132 Screw 3.5 x 10mm

10 2015139 Screw 3.5 x 16mm

11 2054046 Screw 3.5 x 12mm

12 3340137 Gasket

The W number refers to the Wiring diagram page 7.1

W01 6278171 Wire, Inlet

W02 6278172 Wire, SMPS

W03 6278173 Wire, Amplifier

W04 6278174 Wire, LED

W05 6278175 Wire, speaker

Page 22

8.3 Available parts

Mains cables

Packing

Parts not shown

Accessories

Available documentation

6100273 Mains cable, EU, 3m

6100329 Mains cable, UK, 3m

6100307 Mains cable, US, 3m

6100331 Mains cable, JP, 3m

6100332 Mains cable, AUS, 3m

6100386 Mains cable, KOR, 3m

6100047 Mains cable, China, 3m

3397996 Set of foam

3392504 Outer carton

3658262 Product cover

3103325 Rubber foot

3040030 Allen key

6270041 Power Link cable MKIII, 5m, black

1203726 Base

6270856 Phono male to PL line-in, black, 5 m

6270433 Stereo mini-jack (male) to 2 x phono-female, black, 3m

See Retail Ordering System

Page 23

Incl. pos. no. 9210

9210

9211

9201

9202

9203

9204

9205

Available parts 8.4

Floor Speaker Stand – type 2069

9201 3031707 Fitting

9202 2072119 Fixing screw

9203 2950216 Aluminium tube

9204 3459257 Cover plate

9205 2752081 Foot incl. pos. no. 9210

9210 3103392 Foot “soft”

9211 3103390 Foot “spike”

3390616 Bag w/parts (2 screws 4x12mm, 6 pcs. of pos. no. 9211 and 1 torx key

3504637 Setting-up guide

3392710 Outer carton

3396136 Foam packing top/bottom

Page 24

8.5

Page 25

Page 26

Bang & Olufsen

DK-7600 Struer

Denmark

Phone +45 96 84 11 22*

Fax +45 97 85 39 11

3538061 03-07

Loading...

Loading...