Page 1

BeoLab 3

Type 6881, 6882, 6883, 6884, 6885, 6886, 6887, 6888

from serial no. 19355490

Service Center repair guide

English

Page 2

CONTENTS

How to service, Warnings, PIN code protection .......................................... 1

English ................................................................................................ 1.1

German .............................................................................................. 1.3

French ................................................................................................ 1.5

Italian ................................................................................................. 1.7

Spanish ............................................................................................... 1.9

Danish .............................................................................................. 1.11

Nederlands ....................................................................................... 1.13

Japanese ........................................................................................... 1.15

Specication guidelines for service use ....................................................... 2

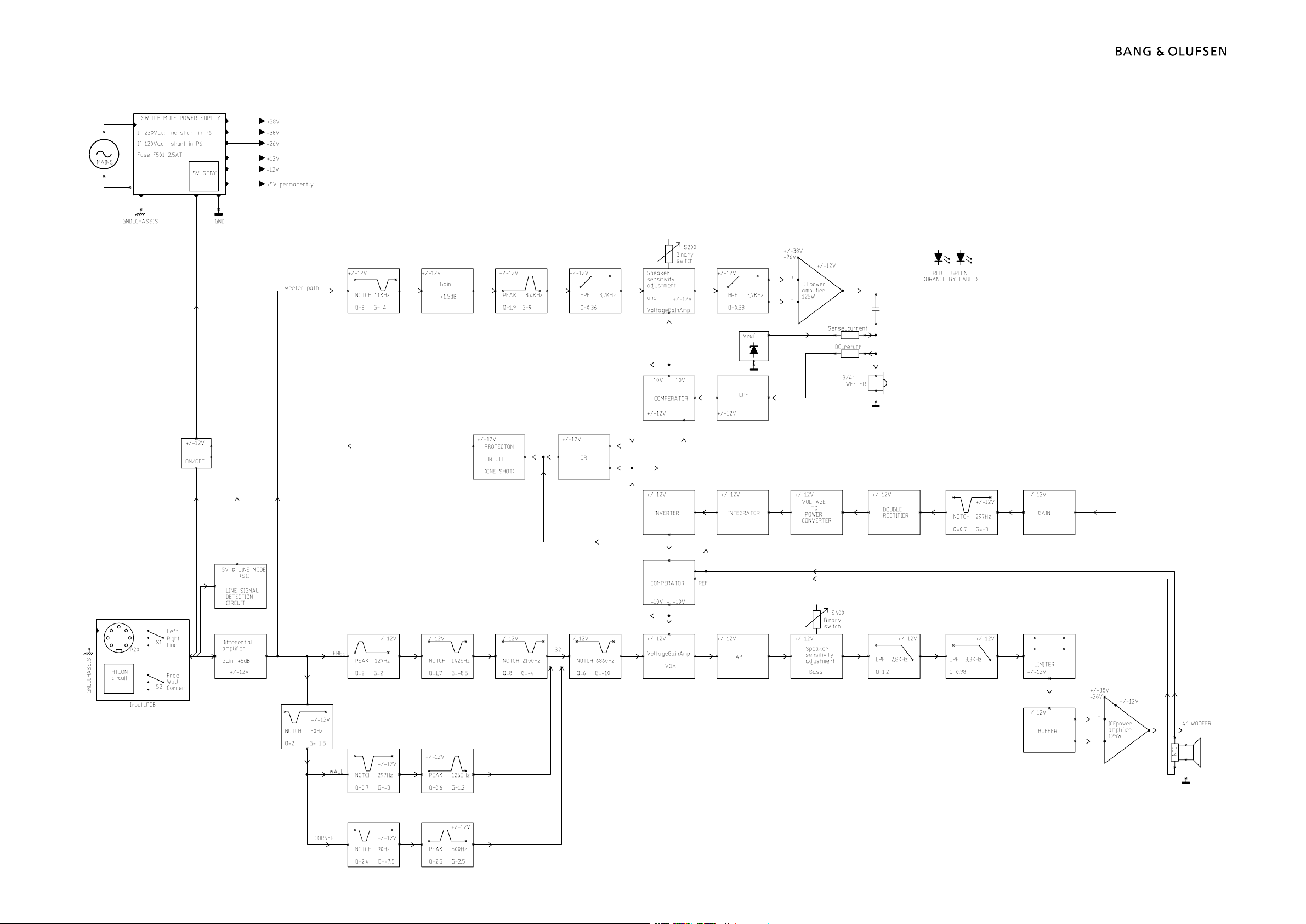

Diagrams ........................................................................................................ 3

Overall block diagram ......................................................................... 3.1

Wiring diagram ................................................................................... 3.2

Available parts ............................................................................................... 4

Service tips, Replacements, Cleaning ........................................................... 5

English ................................................................................................ 5.1

German .............................................................................................. 5.3

French ................................................................................................ 5.5

Italian ................................................................................................. 5.7

Spanish ............................................................................................... 5.9

Danish .............................................................................................. 5.11

Nederlands ....................................................................................... 5.13

Japanese ........................................................................................... 5.15

Disassembly .................................................................................................... 6

Insulation test ................................................................................................ 7

English ................................................................................................ 7.1

German .............................................................................................. 7.2

French ................................................................................................ 7.3

Italian ................................................................................................. 7.4

Spanish ............................................................................................... 7.5

Danish ................................................................................................ 7.6

Nederlands ......................................................................................... 7.7

Japanese ............................................................................................. 7.8

There is no Brief operation guide in this Service Center repair guide.

Instead an english version of the user guide is enclosed the back-up suitcase.

Page 3

How to service

Front line service

BeoLab 3 must be serviced in the customers home when it comes to electrical

symptoms or exchange of mechanical parts. In this way you avoid having to make

more than one visit and using minimum of time on the case, all for the benet of

the customer.

The loudspeaker dimensions are H-215mm, W-135mm, L-162mm, 2,55 kg and

the carbon box for two loudspeakers are H-350mm, B-360mm, D-380mm, 6,5 kg.

In the customers house it is possible to replace :

The electrical parts :

The loudspeaker units

The passive radiators

The complete main chassis

The standby LED PCB

The mechanical parts :

The lens for the tweeter

The cabinet

The foot

A sound level adjustment procedure is necessary when replacing one or more

loudspeaker units, or replacing the main chassis. This is done easily be means of

click potentiometers.

Replacements of the cabinet can be done at the customers as it consist of a

complete cabinet with gaskets and other materials there are needed when

exchanging the complete cabinet. Only the lens, the loudspeaker units, the main

chassis and the foot must be put onto the new cabinet.

Back-up Suitcase

The service Back-up Suitcase will contain all needed electrical parts, that is needed

to service a failing speaker. All mechanical parts must be ordered separately from

B&O Struer DK. All the needed tools and a Service Center Repair Guide will be

found in the suitcase.

Converting mains voltage supply

If it is necessary to change voltage supply, e.g. when moving between two

countries, this can be done easily in the BeoLab 3 speakers (on module 01 – P504).

You will only need to mount/remove a jumper. The fuse will be a global type, so

here is no need for replacement. Remember to order new mains cables.

See illustration on page 6.11

Type survey

Variants Type Jumper P504 Mains cable

EU 6891 NOT mounted 6100273

GB 6892 NOT mounted 6200327

US/CDN 6893 Mounted 6100307

JAP 6894 Mounted 6100331

AUS 6895 NOT mounted 6100332

KOR 6896 NOT mounted 6100386

How to service, English 1.1

Page 4

1.2 Warnings – PIN code protection, English

STATIC ELECTRICITY

MAY DESTROY THE

PRODUCT

Warnings

ESD

When electrical replacements or disassembly is taking place use an ESD-mat. The

internal electronic are very sensitive to static electricity.

General warnings

Wear cotton gloves to avoid any ngerprints on the product.

The surfaces on the product is very sensitive, so handling should be done with

great care to avoid damage.

Cleaning of the speaker surfaces should only be done a lint-free cloth, which you

have dipped in lukewarm water and wrung rmly.

When doing disassembly small aluminum chips can occur when screws are

removed. Make sure all these small aluminum chips are removed from the speaker

cabinet before assembly is done. These aluminum chips can resolve in internal

shortcuts, and damage the Main chassis badly, if not removed.

If the speaker needs to be transported, a product cover can be ordered from B&O

(ordrenr. can be found in the back of this guide)

Page 5

Specication guidelines for service use BeoLab 3

Type no. 6891 Europe – 230V

Type no. 6892 England – 230V

Type no. 6893 USA, Canada – 120V

Type no. 6894 Japan – 100V

Type no. 6895 Australia – 240V

Type no. 6896 Korea – 220V

Dimensions for one speaker Height – 215mm (223mm on foot)

Width – 135mm

Length – 162mm

Weight – 2,55 Kg

Box for two loudspeakers Height – 350mm

Width – 360mm

Depth – 380mm

Weight – 6,5 Kg

Input sensitivity

Power Link 125mV – 88dB SPL

Line in (via Power Link socket, pin 3) 125mV – 88dB SPL (auto switch on)

Switch off time 3 min.

Maximum Sound Pressure Level 94 dB (Stereo, pair)

Power Ampliers 2 (Class D ICEpower)

Power amplier, bass 125 Watts, Class D, ICEpower

Power amplier, treble 125 Watts, Class D, ICEpower

Long Term Maximum, output per amplier Bass : 220 Watts (4 Ohm)

Treble : 120 Watts (8 Ohm)

Effective Frequency range 50 – 20.000 Hz

Crossover frequency 3300 Hz

Cabinet principle Double passive radiator system

Magnetically shielded Yes

Net volume, bass 1.5 litres

Woofer 4” (101,6 mm)

Passive radiators 2 x 4” (101,6 mm)

Treble ” (19mm)

Directivity control Treble *Acoustic Lens Technology

Bass equalization ABL (Adaptive Bass Linearization)

Protection Thermal protection

Connections

Power Link - input 1 (PL MKIII Semi-Balanced)

Mains – input 1

LINE in – input (via Power Link socket – pin3) 1 (auto switch on)

Indication 1 tri-color LED

Green On

Red Stand-by

Orange Protection (see “Service Hints”)

Operations

Switch for : Left – Right – LINE

Switch for : Wall – Corner – Free

Power consumption Typical : 7 Watts

IEC65 : 20 Watts

Stand-by : 0.2 Watts

*ALT (or Acoustic Lens Technology) is licensed from Sausalito Works LLC.

Specication guidelines for service use 2.1 2.1 2.1

Page 6

3.1 Overall block diagramOverall block diagram 3.13.1

Overall block diagram

Page 7

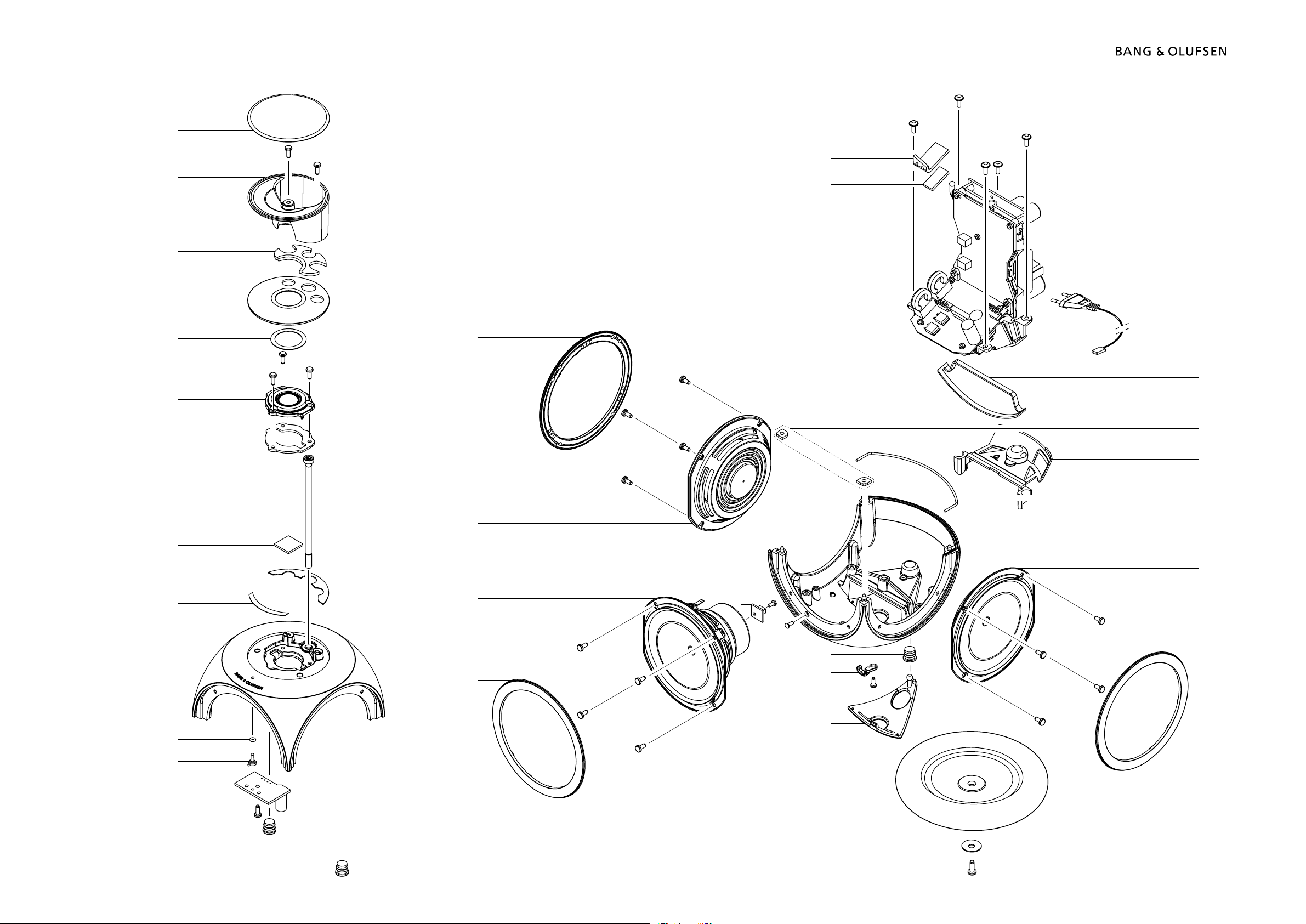

3.2 Wiring diagramWiring diagram 3.2 3.2

Wiring diagram

6

Page 8

4.1 Available partsAvailable parts 4.1

4.1

Available parts

BeoLab 3

9001

9002

9004

9005

9006

9007

9008

9009

9010

9011

9012*

9013

9014

9015

9015

Incl. pos. no. 9003

9003

Incl. pos. no. 9005

Incl. pos. no. 9007

9018

9018

9019

9020

9016

9017

9015

9026

9027

9028

9022

9024

9018

9019

9021

9025

9012*

5

999

6

1

1

1

1

1

1

2

2

2

2

2

3

3

3

3

3

3

3

3

3

3

3

3

4

5

6

7

8

9012*

Consist of pos. nos.

9009, 9011, 9013, 9014, 9015,

9022, 9023, 9024, 9025

9023

Page 9

Available parts 4.2

Top plate

Acoustic lens w/ lt

Tweeter cover w/gasket

Tweeter 19mm w/gasket

Thermal conductive rubber

Thermal conductive rubber

Woofer

Wire holder

8052223

Washer

Page 10

Wire bundles

Wire bundle, PCB2 - PCB5

Wire bundle, PCB3 - PCB5

Wire bundle, PCB3 - PCB6

3395305

Accessories

Available documentation

Page 11

Available parts 4.4

Tube

9501

Incl. pos. no. 9006

9502

9503

9504

9505

9506

Page 12

Table stand 2166

Tube

9512

9513

9511

9510

Page 13

Wall bracket 2167

9521

9520

9522

9520

Page 14

Page 15

Service hints and adjustment

Service Hints

Doing fault searching, the BeoLab 3`s LED can give you a hint.

If the LED turns orange in colour it can be a result of a thermal shutdown, remove

the mains and let the speaker cool down. If the LED still light orange when the

mains is connected again, then it is a indication of an internal error.

A internal error indication can be caused by many things, but the most likely is

listed below.

1. The NTC module on the bass driver unit is not connected to the Main chassis, the

plug is disconnected.

2. Tweeter unit is failing (How to measure the driver units is described later on this

page)

3. Bass unit is failing (How to measure the driver units is described later on this page)

4. Error in Switch Mode Power Supply

How to measure the Driver units (treble/bass), using a Ohm-meter :

Dismantle the speaker to get access to the driver unit you want to measure.

Disconnect the unit completely

Measure with an Ohm-meter

The bass unit should be 4,0 Ohm +/- 10% (between 3,6 - 4,4 Ohm)

The treble unit should be 6,4 Ohm +/- 10% (between 5,7 - 6,9 Ohm)

If the measurements are below the – 10% value, it indicates that the driver unit

coil is shortcut.

If the measurements is over the + 10% value, it indicates that the driver unit coil is

disconnected.

Adjustment after driver unit or Main chassis replacement

When a driver or a Main chassis is replaced, the driver unit levels needs to be

adjusted, so the speaker once again is in accordance with specications.

The adjustment is done with two click-potentiometers, one for treble level

adjustment and one for bass level adjustment. Each potentiometer haves 10 step

(10 * 0,5 dB) and is located on module 03, on the Main chassis.

Service hints and adjustment, English 5.1

Tweeter

Woofer

Page 16

Remove the left slave unit, to gain access to the potentiometers.

When the Main chassis is replaced, the potentiometers on the new chassis are set

to the same value (click) as the old chassis. No further adjustment is used, as long

as the driver units not have been replaced.

When a driver unit is replaced, either treble or bass, you will need to perform an

adjustment on the two potentiometers. On the new service driver unit there will

be a dB value stated on the back. This value is used along with the table below to

adjust the correct potentiometer.

Bass adjustment (the lower potentiometer)

Stated value on the

service driver unit

Position of the click-

potentiometer

3,5 - 3,8 0

2,6 - 3,4 1

1,8 - 2,5 2

1,1 - 1,7 3

0,4 - 1,0 4

-0,3 - 0,3 5 (0 dB level)

-0,4 - -0,9 6

-1,0 - -1,7 7

-1,8 - -2,4 8

-2,5 - -2,8 9

Treble adjustment (the upper potentiometer)

Stated value on the

service driver unit

Position of the click-

potentiometer

3,1 - 3,7 0

2,4 - 3,0 1

1,7 - 2,3 2

1,0 - 1,6 3

0,4 - 0,9 4

-0,3 - 0,3 5 (0 dB level)

-0,4 - -0,8 6

-0,9 - -1,5 7

-1,6 - -2,2 8

-2,3 - -2,7 9

5.2 Service hints and adjustment, English

Page 17

6.1

BeoLab 3 in serviceposition

BeoLab 3 in serviceposition

1

2

3

4

1

2

1x

TX10

Page 18

6.2

Replace Top plate

Replace Top plate

1

Page 19

6.3

Replace Acoustic lens

2

1

Replace Acoustic lens

See page 6.1, BeoLab 3 in serviceposition

See page 6.2, Remove Top plate

2x

TX15

Page 20

6.4

Replace tweeter cover

Replace tweeter cover

See page 6.1, BeoLab 3 in service position

See page 6.2, Remove Top plate

See page 6.3, Remove acoustic lens

1

Page 21

6.5

Replace Tweeter

Replace Tweeter

See page 6.1, BeoLab 3 in service position

See page 6.2, Remove Top plate

See page 6.3, Remove acoustic lens

See page 6.4, Remove tweeter cover

2

1

3x

TX15

2x

ESD

ESD-Mat

Page 22

6.6

Replace Bezel

Replace Bezel

See page 6.1, BeoLab 3 in service position

1

2

Page 23

6.7

Replace woofer

2

1

Replace woofer

See page 6.1, BeoLab 3 in serviceposition

See page 6.6, Remove Bezel

4x

TX10

3x

ESD

ESD-Mat

Page 24

Replace passive radiator

Replace passive radiator6.8

2

1

See page 6.1, BeoLab 3 in serviceposition

See page 6.6, Remove Bezel

4x

TX10

3x

ESD

ESD-Mat

Page 25

Replace PCB 5

2

1

See page 6.1, BeoLab 3 in serviceposition

See page 6.2, Remove Top plate

1x

TX30

2x

See page 6.3, Remove Acoustic lens

See page 6.4, Remove Tweeter cover

Replace PCB 5 6.9

See page 6.6, Remove Bezels

See page 6.7, Remove Woofer

See page 6.8, Remove Passive radiators

5P15

5P17

PCB 5

ESD

ESD-Mat

Page 26

Replace main chassis

2

1

6.10

Replace Main chassis

See page 6.1, BeoLab 3 in serviceposition

See page 6.2, Remove Top plate

See page 6.3, Remove Acoustic lens

See page 6.4, Remove Tweeter cover

See page 6.5, Remove Tweeter

See page 6.6, Remove Bezels

See page 6.7, Remove Woofer

See page 6.8, Remove Passive radiators

2x

5P15

5P17

5x

TX15

ESD

ESD-Mat

1x

Page 27

6.11

Converting mains voltage supply

Converting mains voltage supply

See page 6.10, Remove main chassis

Page 28

Insulation test

BeoLab 3 must be insulation tested if it has been dismantled.

Make the test when the BeoLab 3 is reassembled and is ready to be returned to

the customer.

Insulation test at the Service center

Short-circuit the two pins of the mains plug and connect them to one of the

terminals of the Insulation tester. Connect the other terminal of the insulation

tester to ground on the Power Link socket.

To avoid damaging the BeoLab 3, it is essential to ensure that both terminals of

the insulation tester have good contact.

Slowly turn up the voltage control of the insulation tester until a voltage of 2.5kV(ac) is

obtained.

Maintain that voltage level for one second, then slowly turn it down again.

During the testing the current must not exceed 5mA.

Insulation test at the customer

Remove the mains cable from the wall outlet.

Place a jumper across the two AC plug prongs.

Use a multi-meter, set for measurements in the Ohm-area.

Place one lead from the multi-meter on the AC plug and place the other lead on

ground at the Power Link plug.

The resistance during this measurement must be of 1 Mega Ohm or more.

Resistance measured below 1 Mega Ohm indicates an abnormal situation and

corrective action must be taken.

Please note:

Avoid all skin contact with the AC plug and all other metal parts while performing

the test, as this contact may inuence the measurement.

Insulation test, English 7.1

Page 29

Page 30

Bang & Olufsen

DK-7600 Struer

Denmark

Phone +45 96 84 11 22*

Fax +45 97 85 39 11

3538052 06-06

Loading...

Loading...