Page 1

BAND-IT IDEX, Inc.

A Unit of IDEX Corporation

4799 Dahlia Street

Denver, CO 80216-0307 USA

P: 1-800-525-0758

F: 1-800-624-3925

Document # P07886 Rev. N

© Copyright

BAND-IT IDEX, Inc. 2013

All rights reserved

www.BAND-IT-IDEX.com

Page 1 of 14

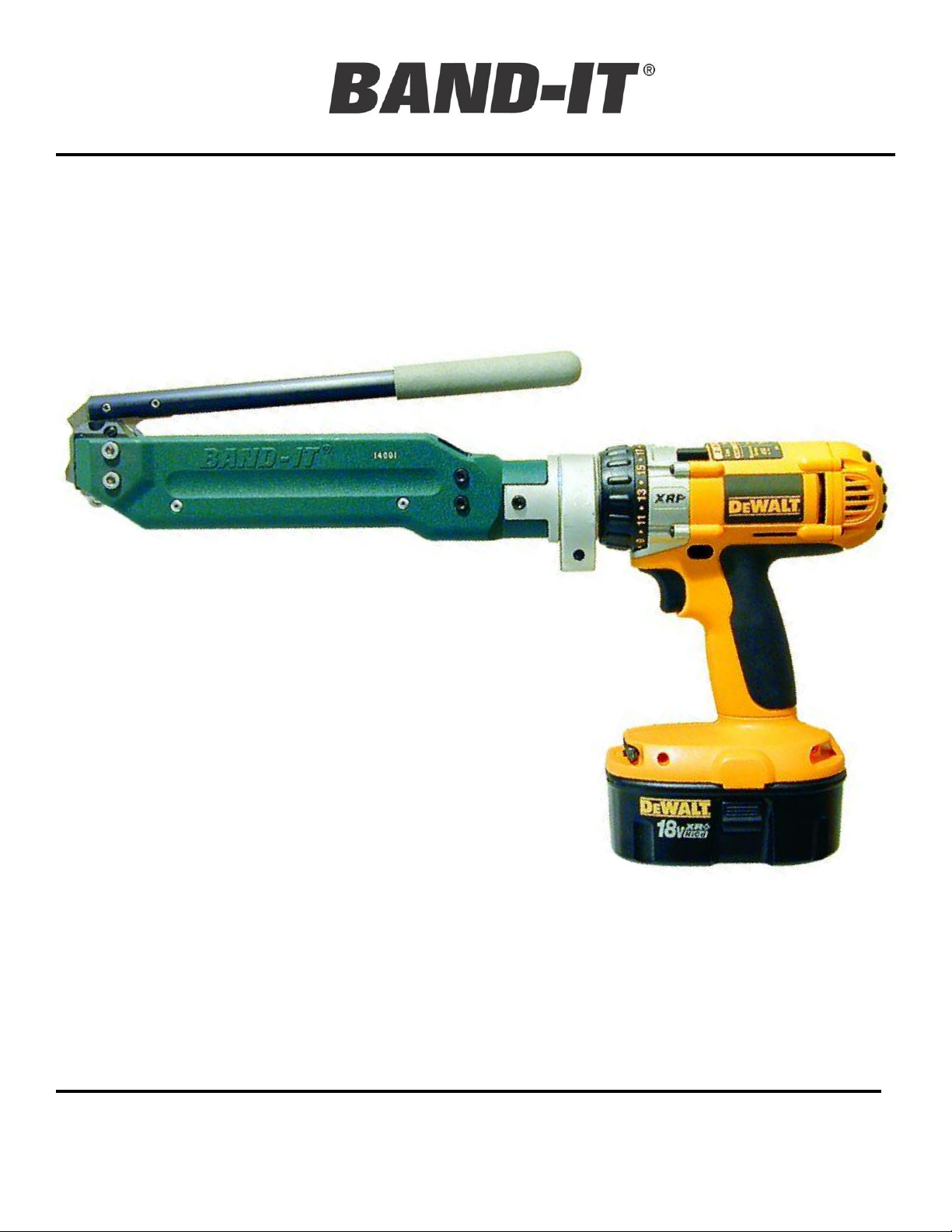

UL4000

Ultra-Lok Tool

Operating

Instructions

UL4000 Cordless Ultra-Lok Tool

Table of Contents

Warranty, Safety Guidelines, Contents

2

Setup Instructions

3-4

Settings

5

Parts List

6

Troubleshooting

7

Assembly Instructions

8

Clamp Application

Free-End

9-10

Preformed

11

Maintenance

12-13

Blade Change

14

Page 2

BAND-IT IDEX, Inc.

A Unit of IDEX Corporation

4799 Dahlia Street

Denver, CO 80216-0307 USA

P: 1-800-525-0758

F: 1-800-624-3925

Document # P07886 Rev. N

© Copyright

BAND-IT IDEX, Inc. 2013

All rights reserved

www.BAND-IT-IDEX.com

Page 2 of 14

UL4000

Ultra-Lok Tool

Warranty, Safety

Guidelines, Contents

Tension Body

Battery Charger

Additional Battery

Pack

Drill

Warranty:

Refer to website for warranty information: www.band-it-idex.com/warranty.html

NOTE: Any performance data published herein is based on laboratory tests, which cannot duplicate conditions that may

be encountered in field installations. Such conditions may vary results substantially from those shown (such as abuse in

handling and installation, failure to follow recommended handling and installation practices, abnormal environmental

conditions, disregard of operating instructions for BAND-IT tools or non-recommended combinations of BAND-IT

products). BAND-IT cannot be responsible for performance characteristics from such variables.

Safety Guidelines

When applying clamps, care should be taken to make certain that fingers are not in the way of the clamp being

applied. Tensioning the clamp can be stopped immediately by releasing the trigger. Detailed instructions are in

this manual and the operator is advised to read it and become familiar with operating the tool.

IMPORTANT: When clamping a hose end, remember that a tighter clamp keeps the fitting more secure, but

excess tension could damage the hose. Fitting stem must have prominent barbs for proper retention inside the

hose, but must not be sharp to prevent cutting into the hose. Hose, fitting and clamp must be compatible with

each other and the environment used in. If in doubt, consult the hose or fitting manufacturer or call BAND-IT.

Clamping objects other than hose requires similar precautions.

CAUTION: Improperly tightened clamps may result in dangerous hose assemblies, which could cause injuries or

property damage.

CAUTION: Abuse or use of a hose outside the manufacturers recommended conditions may cause it to quickly

deteriorate and become a safety hazard. This could result in serious injury or property damage. Inspect and test

hose assemblies frequently.

Contents

Page 3

BAND-IT IDEX, Inc.

A Unit of IDEX Corporation

4799 Dahlia Street

Denver, CO 80216-0307 USA

P: 1-800-525-0758

F: 1-800-624-3925

Document # P07886 Rev. N

© Copyright

BAND-IT IDEX, Inc. 2013

All rights reserved

www.BAND-IT-IDEX.com

Page 3 of 14

UL4000

Ultra-Lok Tool

Setup

Instructions

Warning:

Always wear safety glasses when operating this tool. Keep both hands away from clamp being tensioned. Use

common sense, squeezing force of ¾” clamp can reach as high as 2 tons. Never attempt to clamp objects which

can shatter, or otherwise cause bodily harm.

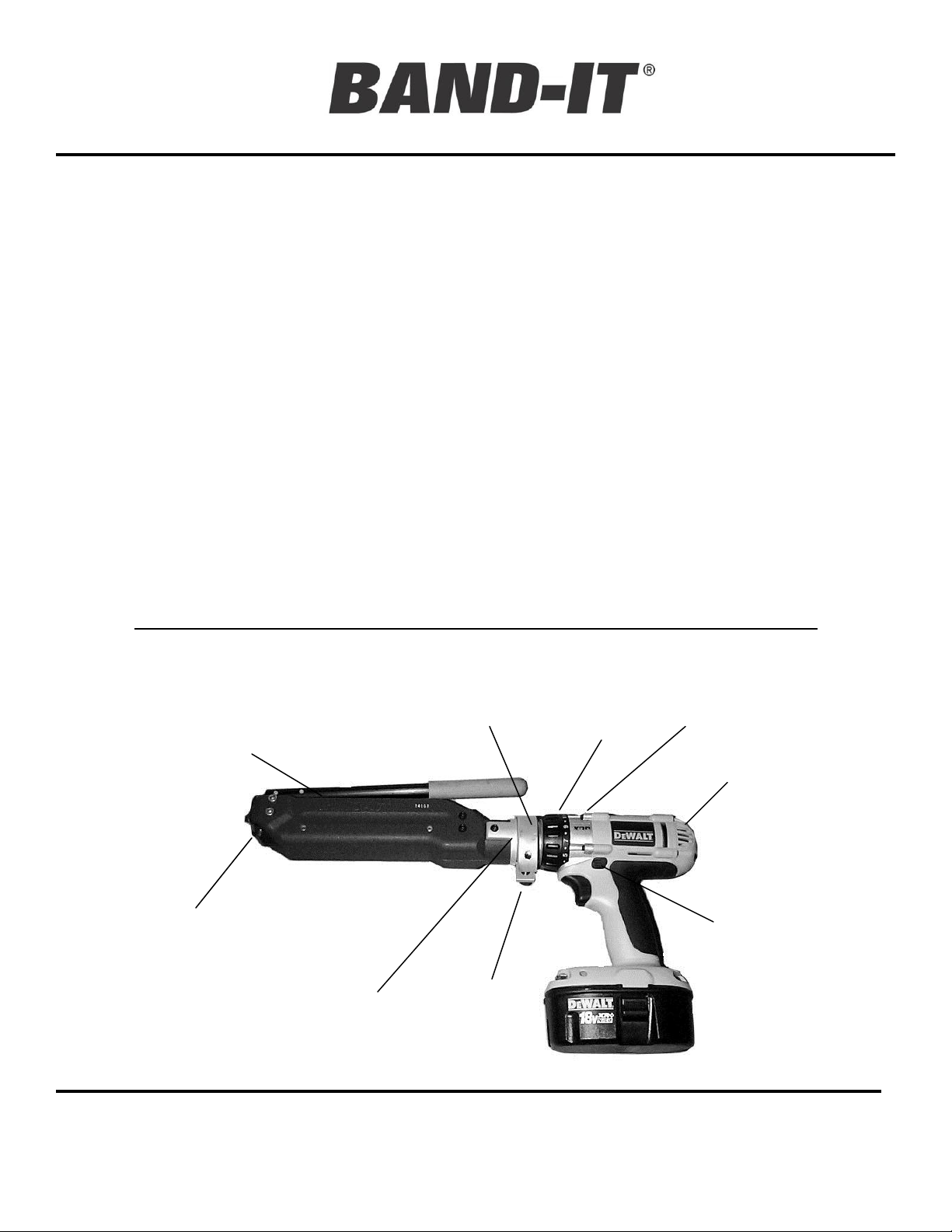

Gear Selector

Drill

Clutch

Tool Body

Adapter

M07687

Drill

M09485 ( DC987,

DC925, or equivalent)

or M07087 (DW987)

Tension Block Position

Viewing Slot

(also lubrication syringe access)

Forward

Reverse

Selector

Switch

Adapter Clamp

M08288

1. Read safety instructions and operator’s manual for the DeWalt DC987/DW987/DC925 cordless drill. Check to make

sure drill is properly set up for use with Band-It Ultra-Lok tool as follows:

-----Drill spindle has adapter clutch (Band-It #M21790) installed in place of standard drill chuck.

-----Speed gear selector must be on number 1, and drill clutch torque setting as shown on page 5.

2. Charge drill according to the operator’s manual for the DeWalt cordless drill.

3. To mount drill onto Band-It Ultra-Lok tool: First use the two #10-32 x 3/8” screws supplied with tool to tighten tool

adapter body to the tool. With adapter clamp on tool adapter body, insert drill into back of tool through the adapter

clamp. Turn drill manually to desired position in relation to tool. Press the drill firmly into tool. Actuate drill if necessary

to engage drill safety clutch (M21790) to tension screw. Tighten clamp screw while keeping the drill firmly pressed

against the tool. To remove drill from tool: loosen the clamp screw and pull drill away from the tool.

4. This tool was designed for, and can only be used with BAND-IT ¾” and ½” wide Ultra-Lok clamps. Do not attempt to

use on any other type of clamp as it may damage tool. Only use ½” wide clamps when the optional ½” shear plate

(BAND-IT #M09387) has been installed in the head in place of the ¾” shear plate.

Tool

Head

Band

Slot

Adapter

Clamp

Tension

Screw

Use only with BAND-IT ¾” and ½” Ultra-Lok Free-End and Preformed Clamps

Page 4

BAND-IT IDEX, Inc.

A Unit of IDEX Corporation

4799 Dahlia Street

Denver, CO 80216-0307 USA

P: 1-800-525-0758

F: 1-800-624-3925

Document # P07886 Rev. N

© Copyright

BAND-IT IDEX, Inc. 2013

All rights reserved

www.BAND-IT-IDEX.com

Page 4 of 14

UL4000

Ultra-Lok Tool

Setup

Instructions

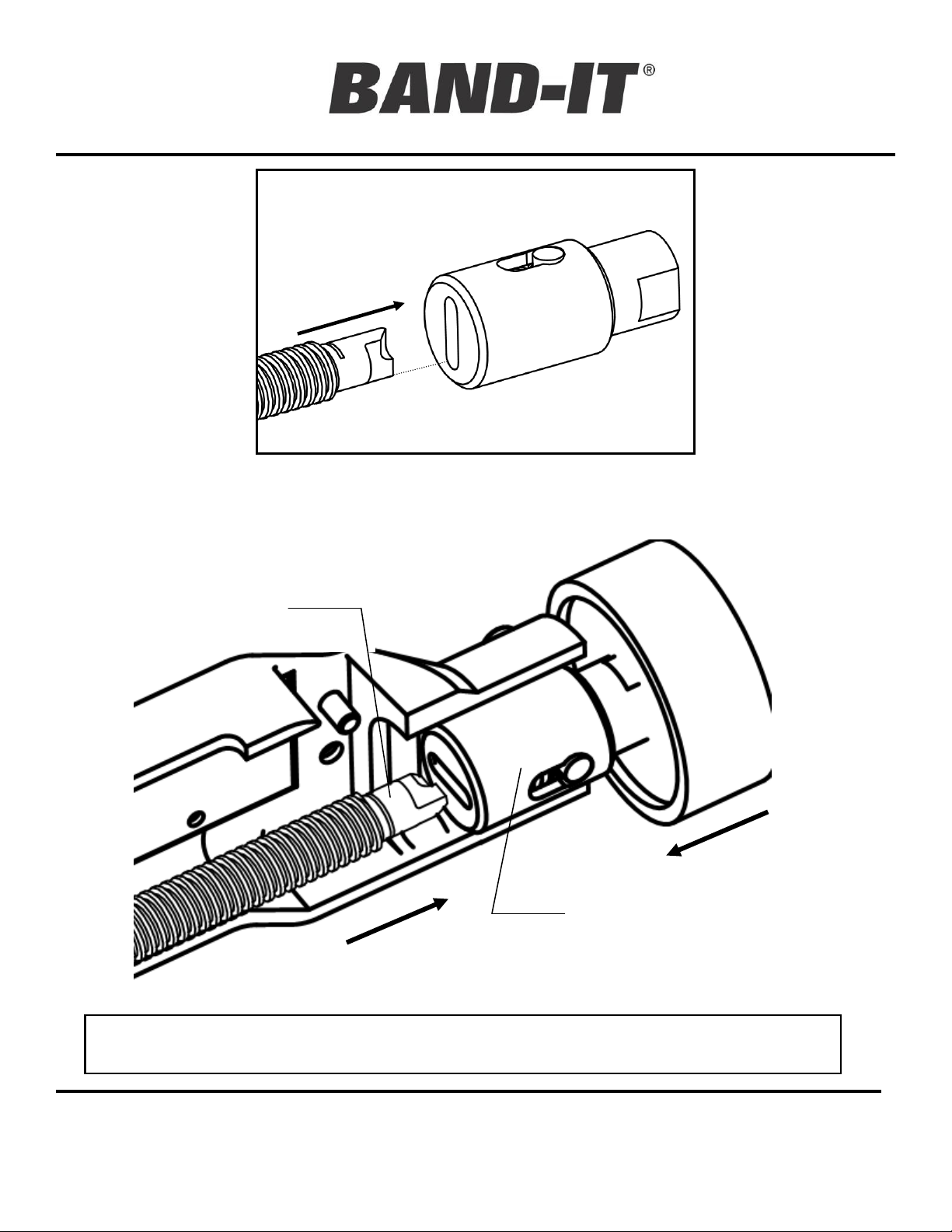

Tension Screw

NOTE: Alignment is critical for proper tool function.

Safety Clutch

When installing the tool on the drill, be careful to align the end of the Tension Screw with

the slot in the end of the safety clutch, as shown above.

Note: Some components are not visible in this illustration.

Page 5

BAND-IT IDEX, Inc.

A Unit of IDEX Corporation

4799 Dahlia Street

Denver, CO 80216-0307 USA

P: 1-800-525-0758

F: 1-800-624-3925

Document # P07886 Rev. N

© Copyright

BAND-IT IDEX, Inc. 2013

All rights reserved

www.BAND-IT-IDEX.com

Page 5 of 14

UL4000

Ultra-Lok Tool

Settings

NOTE: When tightening the adapter clamping screw, safety clutch (M21790) must be engaged

with tension screw inside of BAND-IT tool.

Important: Changing speed setting will alter tension output. Speed setting must remain at 1 when

applying tension to the clamp tail. Drill switch must be depressed fully by the operator to attain

correct tension when installing clamps. Tension output may be somewhat different from tool to

tool on the same setting, depending on condition and wear of internal components.

CAUTION !

The UL4000 tool is designed to work mounted to the DeWalt DC987/DW987/DC925 cordless drill. Use of any other

drills in place of the DeWalt may result in unsatisfactory performance, hazards to the operator and/or the tool, or

unsafe clamps. Use of alternate drills must be approved in writing by the Director of Engineering at BAND-IT-IDEX,

Inc. Disregard of this caution voids the warranty of the tool and releases BAND-IT of any and all liabilities arising

from such misuses.

Use of Alternate Drills

NOTE: These torque settings are suggested settings only, individual tools should be

adjusted for the clamping application.

The tool accompanying this manual was function tested at a clutch setting of __________

and produced a pull-up force of _____________ lbf.

Serial #__________________Tested by:________________ Test date:_______________

*IMPORTANT: Larger sizes of preformed clamps (5" and up) may require a lower setting

to avoid over-stressing the lock and creating potentially unsafe assemblies. Inspect lock per

instructions on page 9-11.

Recommended Drill Clutch Torque Settings:

Drill Model

DC987

DW987

DC925

Clamp Size

¾”

½”

¾”

½”

¾”

½”

Single Wrap

11-13

5-9

5-7

4-6

11-15

3-7

Double Wrap

17-22

11-13

15-19

5-7

19-20

11-15

*Preformed

17-22

11-13

15-19

5-7

19-20

11-15

Always Set Speed Selector to “1”

Page 6

BAND-IT IDEX, Inc.

A Unit of IDEX Corporation

4799 Dahlia Street

Denver, CO 80216-0307 USA

P: 1-800-525-0758

F: 1-800-624-3925

Document # P07886 Rev. N

© Copyright

BAND-IT IDEX, Inc. 2013

All rights reserved

www.BAND-IT-IDEX.com

Page 6 of 14

UL4000

Ultra-Lok Tool

Parts List

Notes:

Apply Item 31 (Grease) to:

Item 4 (Cut off Cam)

Item 3 (Cutter Knife) at contact point with item 1 (Tool Head)

Item 26 (Spring) before installation

Apply Item 32 (Grease) to:

Item 7 (Tension Screw) threads and grooved end

Item 2 (Cutter Blade) counter-bore only, after item 14 (Bearing Tip) has been installed.

Tighten the following:

Item 23 (#10-32 Screws)

to 60 – 70 in-lbs.

Item 22 (1/4-28 Screws)

to 90 – 110 in-lbs.

Adjust Item 24 (Plunger) for

positive detent action when

item 6 (Handle) is actuated.

Item

Part Number

Quantity

Description

1

M00587

1

Tool Head, Fin. UL

2

M09787

1

Cutter Blade, UL

3

M08687

1

Cutter Knife, UL

4

M08987

1

Cam, Cut-off, UL

5

M09087

1

Tension Block, Mach., UL

6

UL1219

1

Handle Assembly:

Includes Handle, Handle Grip, and Pins

7

M00987

1

Tension Screw, Fin.

8

M08887

1

Gripper, UL

9

M01787

1

Plate, Back, Cast/Fin.

10

M09187

1

Gripper Guide, UL

11

M02387

1

Plate, Release, cast/fin.

12

M00287

1

Roller, Cut-off, Fin.

13

M01388

2

Pin, .187 Dia X 1.50 Long, Fin.

14

M05387

1

Bearing Tip, Fin.

15

M06587

1

Ball, ¼” Diameter

16

M02287

1

Tip, Load Bearing, Fin.

17

M04387

1

Tripper Bracket, Cast/Fin.

18

M07387

1

Body, Left, Finished, UL

19

M07487

1

Body, Right, Finished, UL

20

M07587

2

Wear Plate, Fin.

21

M05787

2

Screw, Socket Head Cap, ¼ X 1”

22

J67287

4

Screw, Socket Head Cap, ¼ X ½”

23

M06187

4

Screw, Socket Head Cap, #10-32 X 3/8”

24

M02487

2

Screw, Spring Plunger, ¼-20

25

A33887

1

Spring, Compression, .180 X .813 Long

26

A53587

2

Spring, Compression, .300 X 1.00 Long

27

M01487

1

Pin, Dowel, ¼ Dia X 1.50 Long

28

M08187

4

Washer, .128 ID X .238 OD

29

M08087

4

Rivet, Blind, .125 X .328 Long

30

M07987

2

Threaded Insert, #10-32

31

I16387

-

Lubricant, Super Lube w/ Teflon

32

C23199

-

Lubricant, Moly, Syringe

33

M09887

1

Shear Plate, ¾”, UL

34

M09387

1

Shear Plate, UL, ½” (Optional)

35

M07687

1

Tool adapter # 1, UL

36

M08288

1

Adapter clamp, UL

Page 7

BAND-IT IDEX, Inc.

A Unit of IDEX Corporation

4799 Dahlia Street

Denver, CO 80216-0307 USA

P: 1-800-525-0758

F: 1-800-624-3925

Document # P07886 Rev. N

© Copyright

BAND-IT IDEX, Inc. 2013

All rights reserved

www.BAND-IT-IDEX.com

Page 7 of 14

UL4000

Ultra-Lok Tool

Troubleshooting

19

23

22 6 18

29

30

4 Places

4 Places

28 6 20

See page 6 for parts list

Trouble-Shooting

1. Lock slips down in buckle: Tighten blade mounting screws. If lock on clamp is still not adequate,

reduce tension on tool by setting torque setting on the drill clutch to a lower number.

2. Safety clutch between drill and tool releases prematurely: Make sure tool is fully seated on drill.

(see page 4) If problem still remains, contact BAND-IT technical support.

Note: To prevent over-travel safety clutch wear, do not over-use safety clutch. When tensioning clamp,

let drill switch go as tension block nears its end of travel. Reverse drill and send tension block all the way

forward for a second pull on the band.

3. If tool does not cut off on initial setting:

Step 1: Pull trigger of tool after engaging cutter blade.

Step 2: Increase torque setting slightly, and repeat tensioning band and engaging of cutter blade.

Step 3: Repeat steps 1 and 2 until band cuts.

4

Tension Block

ASSY

Head Unit

Page 8

BAND-IT IDEX, Inc.

A Unit of IDEX Corporation

4799 Dahlia Street

Denver, CO 80216-0307 USA

P: 1-800-525-0758

F: 1-800-624-3925

Document # P07886 Rev. N

© Copyright

BAND-IT IDEX, Inc. 2013

All rights reserved

www.BAND-IT-IDEX.com

Page 8 of 14

UL4000

Ultra-Lok Tool

Assembly

Instructions

17 9 5

Component

under spring

load when

assembled

10 7 32

Brush lubricant evenly

on threads

2 Places

26

31 8 16

32

31

All around inside

profile both sides

Tension Gripper Assembly

Tool Head Assembly

See page 6 for parts list

* M09387 (Optional)

½” Shear Plate Insert

can be substituted for

M09887

13

31

2 Places

2 Places

24

4

Lubricate

both sides

31

2 Places

21

32

15

14 2 33 * 3

12

31 1 25

31

Component

under spring

load when

assembled

11

27

31

31

Inside knife cavity

Page 9

BAND-IT IDEX, Inc.

A Unit of IDEX Corporation

4799 Dahlia Street

Denver, CO 80216-0307 USA

P: 1-800-525-0758

F: 1-800-624-3925

Document # P07886 Rev. N

© Copyright

BAND-IT IDEX, Inc. 2013

All rights reserved

www.BAND-IT-IDEX.com

Page 9 of 14

UL4000

Ultra-Lok Tool

Clamp Application

Free-End Clamps

Push all

the way

forward

to a solid

stop

1. Break off an Ultra-Lok Free-End

tie from the roll. Slide the buckle

onto band with indented arrows

pointing in same direction and

same side up. Slide buckle all

the way onto band until it comes

to a stop between the two buckle

dimples at opposite end of tie.

2. Wrap tie around object to be clamped.

Insert the tie through buckle once for

single-wrap or twice for double-wrap.

Double-wrapped clamps have more

than 3 times the loop-tensile strength.

3. If desired, you may preform a clamp in the same

fashion as step 2, or use a

preformed clamp in place

of a Free-End

4. Position the tie on the

object you are clamping.

Pull the wrapped tie

hand-tight. Slightly bend

the tail up to keep the

clamp in place

5. Actuate drill until tension block is all the

way forward against the tool body. Set

drill to clock-wise rotation. With cut-off

handle down as shown, insert clamp tail

into tool head slot. Actuate drill until drill’s

built-in clutch disengages. If tension

block comes near its end of travel,

release actuator switch and reverse drill

to pull more on clamp tail. Excessive use

of disengaging clutch indicated by a loud

ratcheting sound leads to premature

wear of tension screw.

6. Do not force tool against clamp; it may

result in a folded clamp tail.

7. Pull the cut-off handle forward to cut

tail off and form a lock, then return

handle to the down position. Reverse

drill and feed clamp tail out of tool.

8. Tap down buckle shroud to complete

clamp. Tool is ready for next clamp.

Correct position of tool

while tensioning

Incorrect position of tool

while tensioning

DO NOT

FEATHER

the drill’s

TRIGGER

when

tensioning

a clamp.

USE FULL

SPEED OF

TOOL

Warning: Always wear safety glasses when operating tool.

Page 10

BAND-IT IDEX, Inc.

A Unit of IDEX Corporation

4799 Dahlia Street

Denver, CO 80216-0307 USA

P: 1-800-525-0758

F: 1-800-624-3925

Document # P07886 Rev. N

© Copyright

BAND-IT IDEX, Inc. 2013

All rights reserved

www.BAND-IT-IDEX.com

Page 10 of 14

UL4000

Ultra-Lok Tool

Clamp Application

Free-End Clamps

FRONT VIEW

Completed Free-End Clamp

(Visually inspect lock)

Buckle Shroud

Lock sheared in center

and formed inside

shroud

SIDE VIEW

Completed Free-End

Clamp

Tap down buckle shroud to

complete clamp

Completed clamp

should appear as

shown.

Important: Visually inspect lock formed in band as shown. If lock has slipped under the sheared surface of the

buckle, remove clamp and install a new one at reduced tension by lowering the drill clutch torque setting.

Shear Surface

Section View

Good Clamp

Bad Clamp

Lock has slipped back

under sheared buckle

surface

Inspect buckle on completed clamp and tap down buckle shroud.

Page 11

BAND-IT IDEX, Inc.

A Unit of IDEX Corporation

4799 Dahlia Street

Denver, CO 80216-0307 USA

P: 1-800-525-0758

F: 1-800-624-3925

Document # P07886 Rev. N

© Copyright

BAND-IT IDEX, Inc. 2013

All rights reserved

www.BAND-IT-IDEX.com

Page 11 of 14

UL4000

Ultra-Lok Tool

Clamp Application

Preformed Clamps

When applying clamps on soft, thick-walled hose, tension clamp then wait a full 30

seconds. Clamps may be retensioned by squeezing the actuator switch on the power

unit a second time prior to forming the lock and cutting the excess clamp tail. This allows

hose to “settle” under the band of the clamp. This hose material attribute is called Cold

Flow. Finally, complete clamp by tapping down the buckle shroud as described above.

Important: Visually inspect lock formed in band as shown. If lock has slipped under the sheared surface of the

buckle, remove clamp and install a new one at reduced tension by lowering the drill clutch torque setting.

Front View

Completed Clamp

(Visually inspect lock)

Buckle Shroud

Lock sheared in center and

formed inside shroud

Side View

Completed Clamp

Tap down buckle

shroud to complete

clamp

Shear Surface

Section View

Good Clamp

Bad Clamp

Lock has slipped back

under sheared buckle

surface

Place clamp in desired position on object to be clamped.

Follow steps 5 and 6 on page 9.

Inspect buckle on completed clamp and tap down buckle shroud as shown below.

Page 12

BAND-IT IDEX, Inc.

A Unit of IDEX Corporation

4799 Dahlia Street

Denver, CO 80216-0307 USA

P: 1-800-525-0758

F: 1-800-624-3925

Document # P07886 Rev. N

© Copyright

BAND-IT IDEX, Inc. 2013

All rights reserved

www.BAND-IT-IDEX.com

Page 12 of 14

UL4000

Ultra-Lok Tool

Maintenance

1. Approximately every 500 clamps, lubricate tension screw with

molybdenum disulfide lubricant, or equivalent.

Make sure tension block is all the way forward against the tool head. Remove

cap from syringe and insert tip of syringe into slot on top of tool body. Press

the tip against the tension screw just behind the tension block and squeeze

out approximately ½” long bead of lubricant. Remove syringe, and actuate

tool without a clamp a couple of times to spread lubricant evenly on tension

screw.

To order more lubricant, specify BAND-IT #C23199

3. To gain access to bearing components: remove blade mounting

screws (2 places) and slide blade free. Paper clip may be used to push

bearing components out of blade. Wipe lubricant from components. If ball or

bearing tips appears heavily worn, replace with new one. Note: ¼” ball is

made from hard tungsten carbide material, do not replace with regular ball

bearing. (Smooth indention from ball in the bearing tips is normal).

To re-assemble bearing components: wipe blade cavity clean. Push small

bearing tip into blade cavity. Apply lubricant to ball and push into blade cavity

and fill remaining space with lubricant. Push load bearing tip firmly into blade

cavity, some lubricant will be squeezed out. Re-attach blade to tool head,

making sure that load bearing tip extends into tension screw. While turning

blade mounting screws into blade, push on blade rearwards. Tighten screws

to approximately 120 in-lbs.

4. When replacing worn blade follow instructions above to properly

re-assemble bearing components.

2. Every 500-1000 clamps, depending on tension setting, inspect

and repack front bearing with same lubricant. Turn load bearing tip and

small bearing tip over for a new bearing surface.

Small Bearing Tip

Item 14

¼” Ball

Item 15

Load Bearing Tip

Item 16

Access Hole to push

out components (use

paper clip)

Blade

Item 2

Blade Cavity,

must be packed

with lubricant

Tension

Screw

Item 7

Bearing Detail

Blade Mounting

Screws

Item 21

Tool

Body

Tool

Head

Item 1

Lubricating

Syringe. Reorder

#C23199

Page 13

BAND-IT IDEX, Inc.

A Unit of IDEX Corporation

4799 Dahlia Street

Denver, CO 80216-0307 USA

P: 1-800-525-0758

F: 1-800-624-3925

Document # P07886 Rev. N

© Copyright

BAND-IT IDEX, Inc. 2013

All rights reserved

www.BAND-IT-IDEX.com

Page 13 of 14

UL4000

Ultra-Lok Tool

Maintenance

5. To replace gripper: Make sure tension block is all the way forward against the tool head.

Remove drill. Remove tool adapter body. Remove one side of the tool body or the other, not both.

Slide gripper out sideways and replace with a new one. Re-attach tool body side. Caution: Do

not push or move tension block while gripper is out of tool.

6. To replace tension screw: Move tension block all the way back (away from tool head) using drill

in tensioning mode (clock-wise). Remove Ultra-Lok tool from drill. Remove the tool adapter body from

the Ultra-Lok tool. Remove blade and load bearing tip from tensioning screw (see bearing detail).

Remove one side of the tool body or the other, not both. Grasp the smooth barrel on tension screw and

pull all the way forward until tension block is against the tool head. If tension screw is stuck, use a

punch and tap the center of the screw from the back end of the tool. Turn tension screw out of tension

block. Lubricate new tension screw with Molybdenum Disulfide lubricant, or equivalent. Install new

tension screw in reverse order, making sure that back end of tension screw extends well beyond the

back end of the tension block. Push the assembly all the way back and extend the round portion of the

tension screw through holes on the tripper bracket and back guide plate. Reinstall tool body side.

Reinstall blade and tighten the blade mounting screws approximately 120 in-lbs. Reattach tool adapter

body to Ultra-Lok tool. Reattach tool to drill and drive tension block all the way forward.

Note: Drills needing repair must be forwarded to an authorized ‘DeWalt’ repair center in your area. Be

sure to remove BAND-IT safety clutch (M21790) from drill.

Tension

Screw

Item 7

Move tension

block all the way

forward against

the tool head.

Tool Head

Item 1

Gripper

Item 8

This tip must align with

the safety clutch

(M21790) on the DeWalt

drill. See page 4.

DeWalt Drill is covered solely by the DeWalt warranty as described in the DeWalt literature. BAND-IT

does not extend any warranty of any kind to the drill.

Tool body

adapter,

Item 35

Collar, Adapter,

Item 36

Page 14

BAND-IT IDEX, Inc.

A Unit of IDEX Corporation

4799 Dahlia Street

Denver, CO 80216-0307 USA

P: 1-800-525-0758

F: 1-800-624-3925

Document # P07886 Rev. N

© Copyright

BAND-IT IDEX, Inc. 2013

All rights reserved

www.BAND-IT-IDEX.com

Page 14 of 14

UL4000

Ultra-Lok Tool

Optional ½” Tool

Blade Change

Figure 1

Figure 2

Optional ½” Insert

(M09387)

Orient as shown

Blade (M09787)

Blade Cap Screw

(M05787) Qty. 2

¼” Ball (M06587)

Bearing Tip (M05387)

Blade (M09787)

To change out the UL4000 tool to the 1/2” version, the following steps should be followed.

*NOTE: Do not attempt to use 1/2” clamps with 3/4” head. (Adapter change-out: 3-5 minutes)

1. Prior to separation from power drill, back off tension block assembly ½” from head unit. See page 7.

2. Detach tension body from the battery-powered drill by loosening the single tensioning bolt on the aluminum collar and

separating the two sections.

3. Remove the blade from head by removing two cap screws (M05787) from the top of the head. It is not necessary to

remove entire head from tool in order to remove blade. (Figure 1) Remove the ¾” adapter plate from the blade.

4. Align the ½” adapter plate (M09387) with the blade (M09787) so that the guide is facing up. Incorrect placement will

not allow bands to be inserted into the tool. (Figure 1)

Note: To convert tool back to ¾”, replace ½” insert with ¾” insert (M09887) and follow same instructions.

Be sure to retain unused shear plate for later use.

5. Attach the blade and ½” adapter plate onto head using the two previously removed cap screws. These cap screws

must be tight to assure proper cut-off of clamp tails.

6. Re-attach drill to tension body making sure the drill and tension body are properly aligned, and tighten the single

adapter cap screw located on the aluminum collar.

7. This tool is not designed to work with traditional band and buckle designs. BAND-IT Ultra-Lok clamps must be

used.

Loading...

Loading...