Page 1

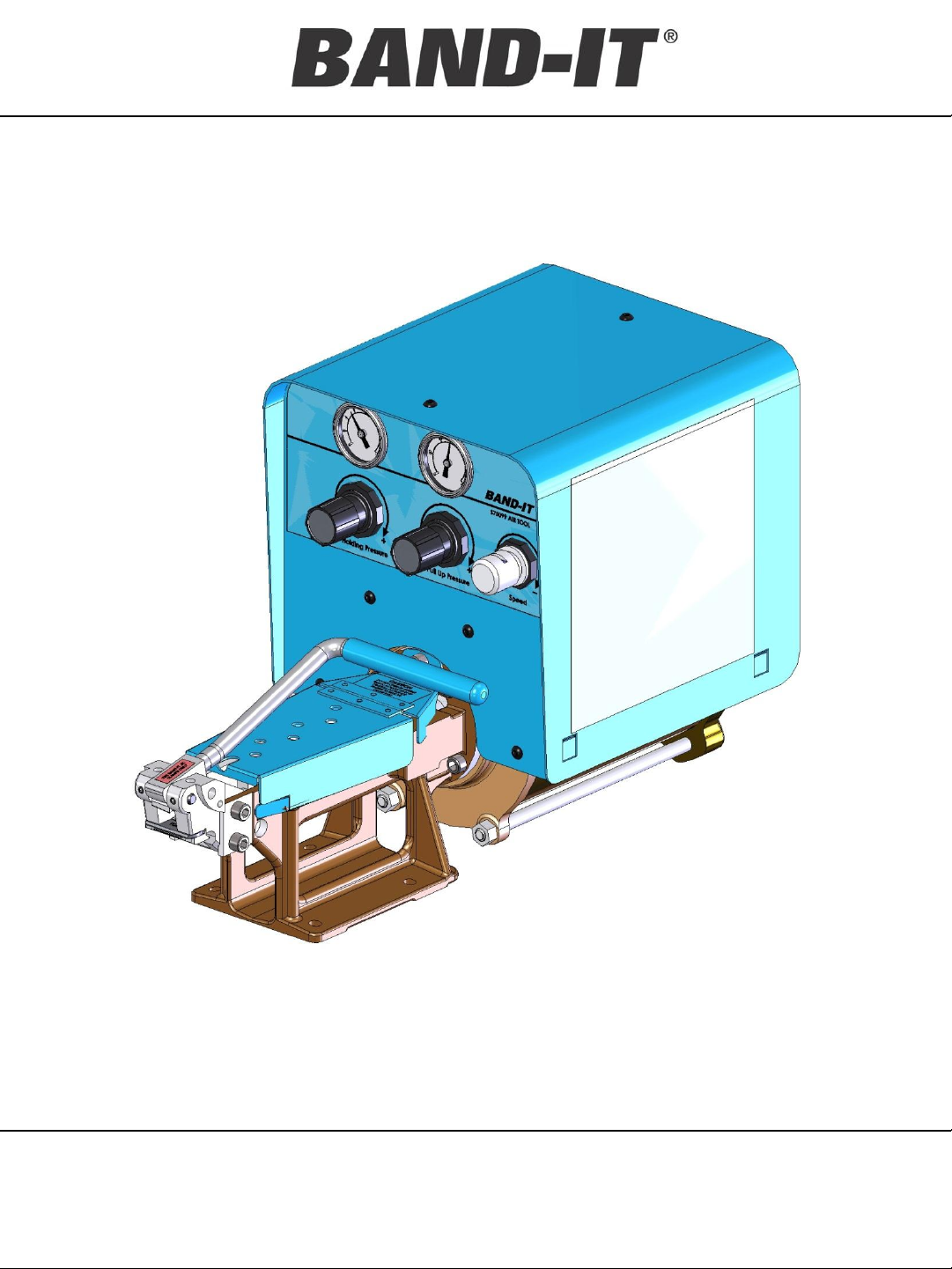

Owner’s Manual

S75099 Pneumatic

and Tool Operating

Instructions

Junior Clamp

Application Tool

BAND-IT-IDEX, Inc.

A Unit of IDEX Corporation

4799 Dahlia Street Denver,

CO 80216-3070 USA

P: 1-800-525-0758 F: 1-800-624-3925

www.BAND-IT-IDEX.com

1

Document# P36687 Rev. I

© Copyright

BAND-IT-IDEX, Inc. 2013

All rights reserved

Page 2

Table of

Contents

S75099 Pneumatic

Junior Clamp

Application Tool

Page Information

2 Table of Contents

3 Warranty and Safety Guidelines

4 Tool Performance and Overview

5 Air System Requirements

6 Tool Installation and Precautions

7-8 Setting Controls and Tool Operation

9 Trouble Shooting Guide

10 Preventative Maintenance

11-16 Replacement Service Parts Identification

17 Installing Clamps

18-19 Replacement Service Parts

20 Optional Reference Gauge

21 Factory Services

BAND-IT-IDEX, Inc.

A Unit of IDEX Corporation

4799 Dahlia Street Denver,

CO 80216-3070 USA

P: 1-800-525-0758 F: 1-800-624-3925

www.BAND-IT-IDEX.com

2

Document# P36687 Rev. I

© Copyright

BAND-IT-IDEX, Inc. 2013

All rights reserved

Page 3

S75099 Pneumatic

Warranty

and Safety

For Warranty information visit the following URL

www.BAND-IT-IDEX.com/Warranty.html

Use of the S75099 without proper filtration and lubrication will void the warranty.

See section on air system requirements for details.

Safety Guidelines:

• Read this manual and become familiar with the tool before installing any clamps.

• Protective eyewear should be worn when connecting and disconnecting the tool to

compressed air sources and during operation.

Junior Clamp

Application Tool

• Wear appropriate gloves for handling steel while operating this tool, applying steel

clamps and removing the scrap clamp tail.

• Tool should be firmly mounted to an adequate support surface.

• Clamp tensioning or clamp tail retrieval can be immediately stopped by releasing

pressure from the foot pedal.

• When applying clamps, care should be taken to insure fingers and loose clothing are

not in contact with the clamp being applied.

• Never attempt to clamp objects which have the potential to burst, shatter or

otherwise cause bodily harm.

• Disconnect air supply prior to maintenance and disassembly of tool components.

• Liquids such as soaps and solvents should never be put directly into the airlines or

allowed to circulate through the tool.

• Additional Safety messages are included as part of the tool operation and clamp

installation sections.

BAND-IT-IDEX, Inc.

A Unit of IDEX Corporation

4799 Dahlia Street Denver,

CO 80216-3070 USA

P: 1-800-525-0758 F: 1-800-624-3925

www.BAND-IT-IDEX.com

3

Document# P36687 Rev. I

© Copyright

BAND-IT-IDEX, Inc. 2013

All rights reserved

Page 4

Tool Performance

S75099 Pneumatic

and Overview

Junior Clamp

Application Tool

• The S75099 has been designed to tension, set the Junior style lock and cut-off the

remaining scrap clamp tail of Junior Smooth I.D. and standard Junior preformed

clamps. BAND-IT manufactures Junior style clamps using galvanized carbon steel,

Type 201 Stainless Steel and Type 316 Stainless Steel. Clamp widths are available

from ¼” to ¾” wide and available diameter clamps range from 13/16” to as large as 8”.

All clamps can be easily installed on hose assemblies or objects chosen by the operator

using the BAND-IT S75099 air tool.

• During the operator controlled cycle, the S75099 Air Tool will tension the clamp around

the object by pulling the band through the buckle until the desired tension is achieved. If

the cycle is allowed to continue, the tool will release an amount of tension pressure

automatically, switching to a lower holding pressure. This pressure drop is in

preparation for manually setting the lock and shearing the excess clamp tail by

operating the cut-off handle*. The completion of each clamp includes setting the lock

while simultaneously cutting off the excess, scrap clamp tail. The finished lock should

be even with the height of the buckle thickness, have a smooth edge with no sharp

burrs while maintaining the low profile of the Junior style buckle.

*Important operational note! The S75099 tool directs compressed air through a foot

pedal control to cycle the tool and complete the installation of BAND-IT Junior style

clamps. The foot pedal has a dual action, forward (toe) and reverse (heel). During

normal operation, the operator should fully depress the foot pedal forward (toe), not

removing this pedal pressure until the cycle has completed, including the assembly roll

up and clamp tail cut-off. Upon completion of the lock, the heel of the foot pedal should

then be depressed causing the clamp tail to be positioned in the band slot, ready for

removal from the tool by the operator.

• Operating tip: Operation can be stopped at any time by removing the operators foot

completely from the foot pedal control, however, this will affect the tension applied to

the clamp. If cycle is ended prematurely, prior to hose assembly roll-up, depress the

heel side of the foot pedal to remove the hose assembly from the tool or momentarily

allow the air system to stabilize and resume the clamping cycle by pressing the foot

pedal control forward. If the roll-up cycle has already been initiated, re-tensioning the

clamp will result in the tail being overstressed and breaking prematurely before the lock

can be formed.

BAND-IT-IDEX, Inc.

A Unit of IDEX Corporation

4799 Dahlia Street Denver,

CO 80216-3070 USA

P: 1-800-525-0758 F: 1-800-624-3925

www.BAND-IT-IDEX.com

4

Document# P36687 Rev. I

© Copyright

BAND-IT-IDEX, Inc. 2013

All rights reserved

Page 5

S75099 Pneumatic

Air System

Requirements

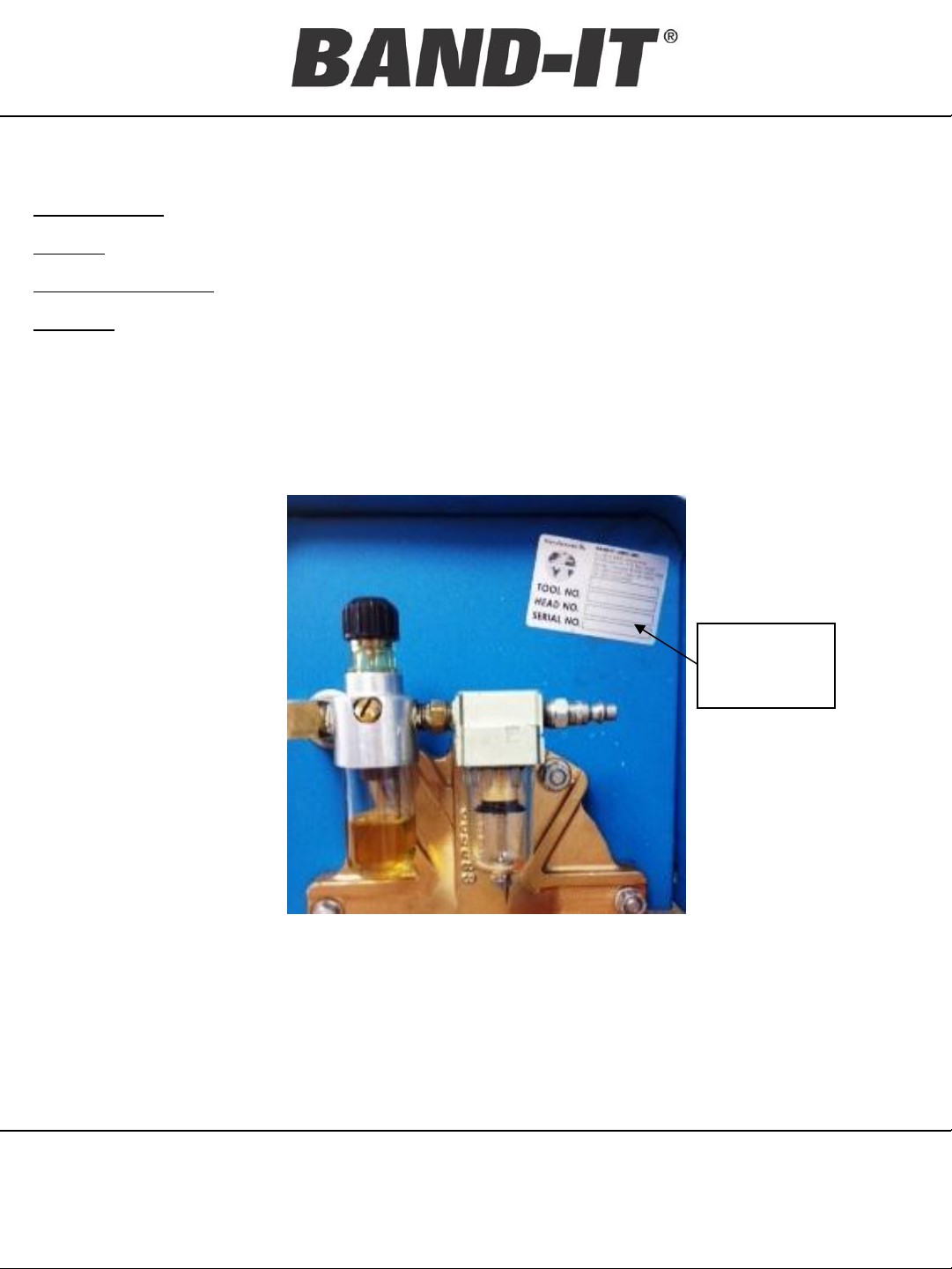

Important: For proper tool performance, air requirements for S75099 should be:

Line Pressure – 100 psi minimum,125 psi maximum (689 – 862 kPa)

Volume - should be 3-5 CFM

Air Delivery system - ¼” minimum diameter airline with a ¼” N.P.T. connection.

Filtration – Follow typical filtration requirements of air operated equipment. Standard filtering

systems should be located no further than 30’ from this tool in addition to the

supplemental system supplied at the back of the tool as shown below. This BAND-IT

supplied system includes a filter and lubricator. Lubricator should be refilled with DTE

24 hydraulic oil. The oil drip-rate can be verified by repeated full cycling the tool. One

drop should fall in the sight glass within 10-25 cycles. Excess oil will not benefit tool life

and may lead to blockage of air mufflers and a dirty environment.

Junior Clamp

Application Tool

Serial #

decal

location

View of the back side of the S75099 showing the

supplemental filtering and lubrication system as well as

the ¼” N.P.T. air connection with typical quick connect

coupling.

Warning: The lubricator should be refilled with DTE 24 hydraulic

oil only. The use of other oils may cause damage to the system.

BAND-IT-IDEX, Inc.

A Unit of IDEX Corporation

4799 Dahlia Street Denver,

CO 80216-3070 USA

P: 1-800-525-0758 F: 1-800-624-3925

www.BAND-IT-IDEX.com

5

Document# P36687 Rev. I

BAND-IT-IDEX, Inc. 2013

All rights reserved

© Copyright

Page 6

S75099 Pneumatic

Tool Installation

And Precautions

Tool Installation

1) Recommended work bench height is 34” – 40”. This height is suggested as the

optimum range for operator comfort and safety during typical clamp applications.

Locate and securely mount the tool on a solid surface making sure of ample

clearance on both left and right sides for handling hose assemblies of various

lengths.

2) The air tool should be firmly secured as close to the front edge of the work station

as possible using the angled mounting brackets supplied with the tool. This

position will reduce interference of hose assemblies during clamp application.

Mount the tool using 5/16” diameter fastening hardware (not supplied with tool).

Check hardware for tightness regularly.

3) Hardware may loosen during shipment. Loose fastening hardware will adversely

affect tool operation, specifically the cut off operation. All fasteners securing the

tool cover, pneumatics, head assembly, blade assembly, cut-off handle and

mounting hardware should be checked for tightness regularly and re-tensioned as

needed.

Junior Clamp

Application Tool

4) Use of the S75099 without properly maintained filtration and lubrication will cause

clamp tensioning problems and void the warranty.

Clamp Installation: Precautions

Operators should understand that a tighter clamp keeps the fitting more secure, but

excess tension could damage the hose assembly. The fitting stem must have prominent

barbs for proper retention inside the hose, but barbs must not be sharp to prevent cutting

into the hose. Hose, fitting and clamp must be compatible with each other and the

intended working environment. If in doubt, consult the hose or fitting manufacturer or call

BAND-IT.

Clamping objects other than hose require similar precautions.

CAUTION: Improperly tightened clamps may result in dangerous hose assemblies,

which could cause injuries or property damage.

CAUTION: Abuse or use of hose outside the manufacturers recommended conditions

may cause it to quickly deteriorate and become a safety hazard. This could result in

serious injury or property damage. Inspect and test hose assemblies frequently. Repair

or replace at the slightest sign of damage or deterioration.

BAND-IT-IDEX, Inc.

A Unit of IDEX Corporation

4799 Dahlia Street Denver,

CO 80216-3070 USA

P: 1-800-525-0758 F: 1-800-624-3925

www.BAND-IT-IDEX.com

6

Document# P36687 Rev. I

© Copyright

BAND-IT-IDEX, Inc. 2013

All rights reserved

Page 7

Setting Controls

S75099 Pneumatic

and Tool

Operation

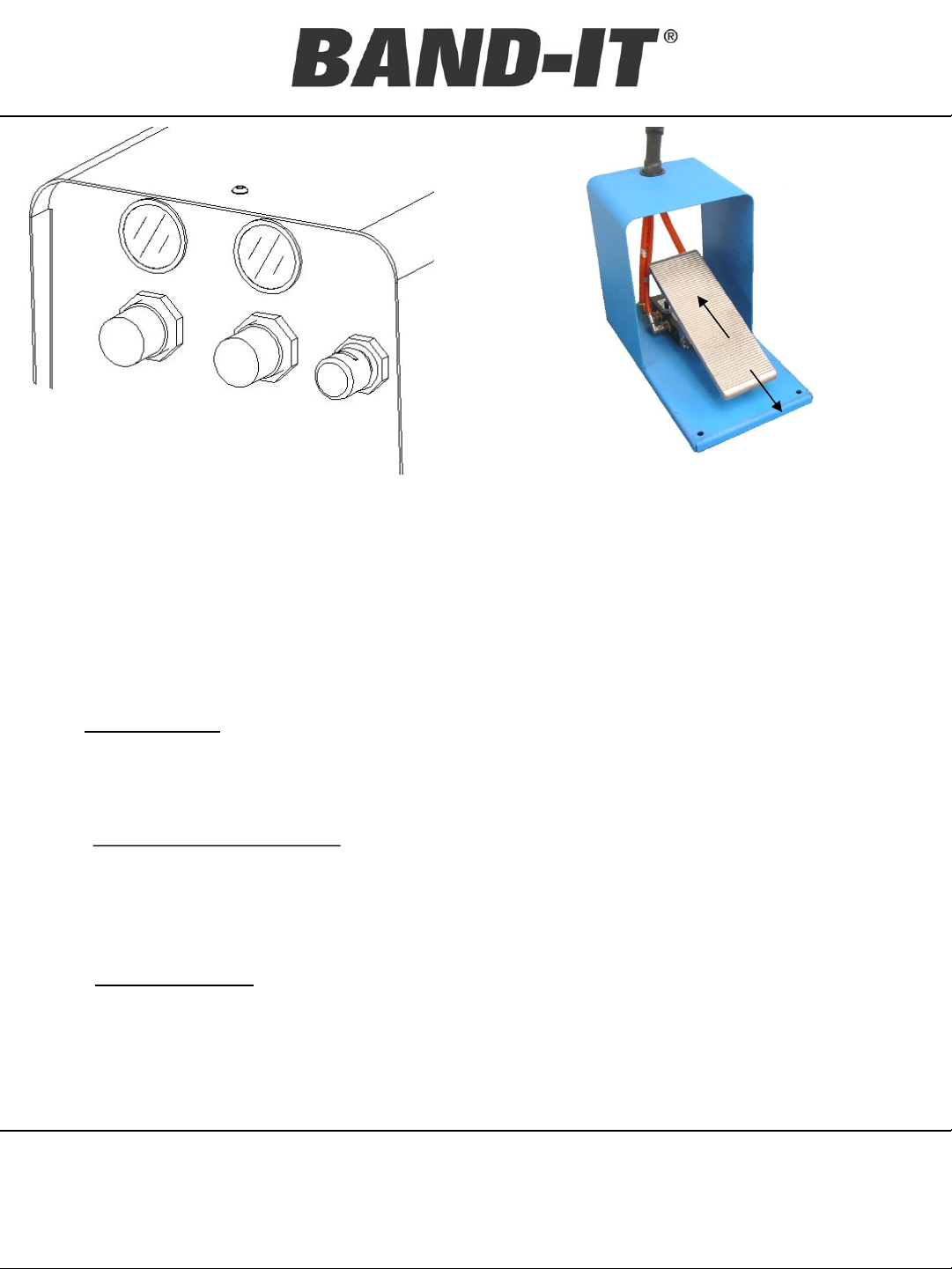

Air pressure setting can be made using the regulators

and gauges on face of the tool.

Junior Clamp

Application Tool

Dual function foot control valve. Pressing forward

activates clamp installation. Heel action activates tail

return and prepares for next clamp.

Rule: Always approach the pull-up pressure setting from below and the holding

pressure setting from above the recommended value.

Rule: Gauge readings are to be used as a guide. It may be necessary to adjust the

Pull-Up and Holding Pressure settings to match the requirements of the

particular hose assembly construction or application.

1. Speed Control adjusts the speed of piston travel during tensioning of the band clamp. A

slower setting will allow more time while a faster setting may cause increased friction

between the band and the buckle as the clamp tail is pulled through the buckle during

tensioning. Increased friction may cause the clamp to tension improperly.

2. Setting the Speed Control: The speed of the cycle should be set according to the width

of Junior Clamp being tensioned. Each width clamp has a color code setting on the

speed control regulator. See this manual page # 8 or the decal on the side of the tool.

Use the attached lock ring to secure the desired setting and prevent accidental

changes.

3. Pull-up Pressure reflects the tension applied to the clamp and is measured by force

applied to the clamp tail being pulled through the buckle. A pull-up pressure setting too

low may allow the fitting to be forced out of the hose assembly. A setting too high may

cause damage to the assembly or cause the clamp tail to tear. For most hose

applications, the ideal setting is as high as can be achieved without sacrificing the

strength of the lock, damaging the hose and fitting or breaking the clamp tail.

BAND-IT-IDEX, Inc.

A Unit of IDEX Corporation

4799 Dahlia Street Denver,

CO 80216-3070 USA

P: 1-800-525-0758 F: 1-800-624-3925

www.BAND-IT-IDEX.com

7

Document# P36687 Rev. I

© Copyright

BAND-IT-IDEX, Inc. 2013

All rights reserved

Page 8

Setting Controls

Clamp Width

Inch

Pull Up

Pressure

(PSI)

Holding

Pressure

(PSI)

Speed

Control

Setting

Pull Up

Pressure

(PSI)

Holding

Pressure

(PSI)

Speed

Control

Setting

Pull Up

Pressure

(PSI)

Holding

Pressure

(PSI)

Speed

Control

Setting

1/4" (6.4mm) 15 4 Blue 15 4 Blue NA NA NA

3/8" (7.5mm) 25 5 White 20 5 White 25 6 Blue

1/2" (12.7mm) 40 6 White 35 6 White 40 7 White

5/8" (15.9mm) 50 7 Red 40 7 Red 50 8 White

3/4" (19.1mm) 60 8 Red 50 8 Red 60 9 Red

Galvanized Carbon Steel

316 Stainless Steel

201 Stainless Steel

Guide for Operating Pressures for the S75099 Air tool

S75099 Pneumatic

and Tool

Operation

4. Setting Pull-up Pressure: Pull the identified regulator knob and turn clockwise to reach

Junior Clamp

Application Tool

pull-up pressure. Approach pressure setting from below by increasing pressure. Many

factors should be considered when choosing the correct operating setting for the tool.

The fitting design as well as the type, thickness and durometer of the hose material must

be considered when setting the correct pressures for your assembly.

5. Holding Pressure reflects a lower pressure designed to allow the hose assembly to be

rolled up in preparation for setting the lock with the shearing or cutting action on the clamp

tail. A setting too low will cause difficulty in shearing the clamp tail and leaving an

excessive burr on the buckle at the point of lock. A setting too high may cause the clamp

tail to “pop” free of the band gripper, cause the lock to slip back under the buckle or cause

a sudden jolt to the S75099 tool.

6. Setting Holding Pressure: Cycle the tool, holding the foot pedal in the toe forward position.

The tool will reach pull-up tension and kick down to a holding pressure. Read the gauge

and repeat the cycle turning the holding regulator clockwise to raise pressure or counter

clockwise to lower pressure. Allow the tool to settle after each cycle before reading the

value on the gauge.

7. Check pressure setting by cycling tool until hold pressure gauge stops.

8. Reset tool by depressing heel end of foot pedal. Remove foot.

9. Repeat steps 2, 4, 6, and 7. At pressure kick down, verify all settings and adjust if

necessary. Lock settings in place.

Rule: Allow air to completely exhaust between each stage of the tools cycle. Failure

to let air completely exhaust may result in clamps not pulling up tight.

BAND-IT-IDEX, Inc.

A Unit of IDEX Corporation

4799 Dahlia Street Denver,

CO 80216-3070 USA

P: 1-800-525-0758 F: 1-800-624-3925

www.BAND-IT-IDEX.com

8

Document# P36687 Rev. I

© Copyright

BAND-IT-IDEX, Inc. 2013

All rights reserved

Page 9

Problem Probable Cause Correction

Sharp or scarred edges on clamp. Metal

deposits on underside of tail at buckle

edge.

Loose or broken cutter blade /

backing plate. Sharp edge on cutter

blade due to wear

Remove and examine the cutterblade kit for

chips, cracks, excessive wear or material

build-up. Lightly hone with a medium grit India

stone to polish the leading surfaces. Alw ays

replace components as a kit, not individually.

Fully tighten included hardware.

Tail is broken at approximately 45°. Clamp

material stretched or thinned at break.

Pull-up pressure exceeds the

strength of the band clamp.

Reduce pull-up pressure to the suggested

range. Adjust lower if necessary.

Clamp not inserted properly. Insert clamp straight and level.

Pull-up cylinder needs lubrication Check filter / lubricator, fill to proper level.

Loose or worn cutter blade kit on

head

Check and tighten all hardware.

Teeth on band gripper lever are

chipped, filled with metal build up or

have excessive w ear

Remove and examine band gripper lever. Clean

or replace as necessary.

Pressure settings too high

Settings are a guide, it may be necessary to

lower pressure settings.

Gripper spring stretched out

Replace spring. Always replace gripper lever

and spring as a set.

Tripper plate stuck or broken Examine, clean and lube the tripper plate.

Clamp tail catches as heel of foot pedal is

depressed and cylinder is returned for

next clamp cycle.

Clamp tension or pull up pressure is

set low and has not yielded the band.

This may be necessary depending

upon the type of hose construction.

1) Re-cycle tool 2) Cycle tool keeping foot

control toe end depressed. 3) To remove

clamp tail, reach under piston rod and locate

band gripper lever. 4) Pull lever forward,

reaching under with pliers to grasp tail and

carefully remove tail. (Never position fingers

anywhere but on gripper lever, keep foot

control valve depressed forw ard while

working in this area).

Loose or broken cutter blade Tighten or replace cutter blade.

Low pressure on incoming air supply

Check and adjust incoming air supply. Note:

Minimum supply pressure is 75 PSI.

Air leaks from loose connection or

worn parts

Remove tool cover. Examine all air

connections, tighten loose connections and /

or replace worn parts.

Speed Control regulator set tool low

Adjust setting per instructions in this manual or

side panels decal.

Previous clamp tail has not been

Remove clamp tail from tool

Tripper plate may be broken or

binding.

Remove, inspect, clean and lubricate or

replace tripper plate.

Clamp pulls in a jerky manner.

Tool doesn't cut-off clamp.

Tool takes excessive time for clamp pullup.

Clamp tail cannot be inserted into tool.

Clamp tail slips in band gripper lever.

Trouble Shooting

Guide

S75099 Pneumatic

Junior Clamp

Application Tool

BAND-IT-IDEX, Inc.

A Unit of IDEX Corporation

4799 Dahlia Street Denver,

CO 80216-3070 USA

P: 1-800-525-0758 F: 1-800-624-3925

www.BAND-IT-IDEX.com

9

Document# P36687 Rev. I

© Copyright

BAND-IT-IDEX, Inc. 2013

All rights reserved

Page 10

S75099 Pneumatic

Component Check Action Frequency

Clamp Head

Check for loose mounting

screws

Tighten all screws and fasteners Daily

Shear hook

Check working edge for

wear or damage

replace if necessary (J00587). Daily

Cutter Blade and

Backing Plate

Check to see if blade is

loose or has any broken or

chipped edges

Tighten all screws and fasteners.

Replace if necessary (J93099).

Daily

Filter / Lubricator

Check for build-up of dirt,

etc. Check for low,

contaminated or discolored

lubricant

Drain and clean with soap and water.

Refill with hydraulic oil DTE 24. Set drip

rate to 1 drop each 10-25 cycles. Order

more lubricant if necessary (S31589).

Every 2,000

clamps

Gripper Lever

Check for build-up of dirt,

etc., in teeth and check

spring for tension.

Remove and clean with small pointed

object - knife blade, etc. Replace as

necessary with new gripper and new

spring as a kit (S45799).

Every 2,000

clamps

Cylinder

Check for build-up of dirt,

contaminants externally on

piston rod seals

Clean with soap and warm water 6 Months

Tripper Plate

Check for cracks, build-up

of dirt, contaminants

Clean and apply a light coating of moly

grease or equivalent

6 Months

Check for build-up of dirt,

contaminants, etc.

Remove and clean with non-flammable

degreaser

6 Months

Check for tight connection Tension as necessary 6 Months

Air Exhaust Mufflers

Maintenance Checklist

Preventative

Maintenance

Junior Clamp

Application Tool

1. For proper functioning of the S75099 air tool, a filter / lubricator must be used on the

air supply within 30 feet of the air tool. The warranty is voided if a filter / lubricator is

not used.

2. Before using air tool, check to see that the blade and backing plate are fully tensioned.

3. Clean gripper occasionally. Metal particles and dirt on the gripper lever can cause it to

slip off the clamp tail. To remove gripper lever, loosen set screw in the head assembly

from underneath the block and tap out pin.

BAND-IT-IDEX, Inc.

A Unit of IDEX Corporation

4799 Dahlia Street Denver,

CO 80216-3070 USA

P: 1-800-525-0758 F: 1-800-624-3925

www.BAND-IT-IDEX.com

10

Document# P36687 Rev. I

BAND-IT-IDEX, Inc. 2013

All rights reserved

© Copyright

Page 11

Replacement

S75099 Pneumatic

Service Parts

Identification

Junior Clamp

Application Tool

regular cleaning, lubrication and checking all fasteners for tension will reduce the replacement

frequency of these parts.

including new bolts.

Tension Air

Holding Air

Pressure

Gage

Pressure

Gage

Tension

Pressure

Regulator

Holding

Pressure

Regulator

Shear Hook

Cutter Blade,

Backing Plate, and

Gripper Assembly

BAND-IT-IDEX, Inc.

A Unit of IDEX Corporation

4799 Dahlia Street Denver,

CO 80216-3070 USA

P: 1-800-525-0758 F: 1-800-624-3925

www.BAND-IT-IDEX.com

11

Clamp

Tension

Speed

Control

Tension Cylinder

Cut-off

Handle

Document# P36687 Rev. I

© Copyright

BAND-IT-IDEX, Inc. 2013

All rights reserved

Page 12

Replacement

ITEM

PART

QTY

ITEM

PART

QTY

C00387

0.15 LOCKING COMPOUND, HIGH STRENGTH (CC)

S42387

PLUG, CAP, 1/4 NPT

G00689

SWIVEL UNION, M X F

S44687

PISTON, CYLINDER

G92188

NUT, HEX, 5/16

S44887

SPACER, .205 X .504

J60767

TUBE, CYLINDER

S44987

BOLT, HEX, 1/2

J61967

PLATE, ROD GUIDE

S45087

PLATE, BAND GRIPPER

J62187

CYLINDER BOLT

S45186

GRIPPER, BAND, FINISHED, REX

J63187

O

S45389

PISTON ROD ASSEMBLY

J63287

O

S45587

O

J64887

SCREW, SET, #10

S45687

WASHER, 17/32 X 1

J66587

LOCK WASHER, 5/16 ID

S45799

KIT, GRIPPER/SPRING

J66687

GASKET, CYLINDER

S45888

SLIDE COVER ASSEMBLY

J67687

NUT, HEX, 3/8

S46088

PANEL, FRONT, S750

J68587

SCREW, CAP, #8

S46188

PANEL, REAR

J90887

PIN, SHEAR HOOK PIVOT

S46288

PANEL, TOP COVER

J90987

SCREW, CAP, 5/16

S46587

HEX, #10

J93099

KIT, CUTTER BLADE

S46687

HEX, #10

P00187

LABEL, BLANK 1

S46787

ADAPTER, BULKHEAD

P06386

LABEL, FRONT, S750

S46888

GUARD, FOOT VALVE

P06486

DECAL, BAND

S46987

BASE, INCLINED

P06586

DECAL, PRESSURE, S750

S47087

VALVE, FLOW CONTROL

P36687

MANUAL,OPERATION S750 AIR TOOL

S47287

VALVE, 4

P70287

BAG, PLASTIC 4"X6"X.004

S47387

VALVE, FOOT

P70587

BAG, PLASTIC 10"X18"X.004

S47487

REGULATOR, PULL UP

R00608

TUBING, NYLON 1/4 OD X .180 ID (FT)

S47587

REGULATOR, HOLDING

R00631

BUMPER, SELF ADHESIVE

S47687

GAUGE, PRESS, 0

S10086

LINER, SHIPPING CARTON

S47787

GAUGE, HOLDING

S10087

PLYWOOD, BASE, AIR TOOL

S47988

COVER, CYLINDER, REAR

S10088

SHIPPING CARTON, AIR TOOL

S48187

NUT, HEX, 3/4

S11589

HANDLE ASSY, JR. HEAD

S48387

ELBOW, 90 DEG, STREET

S11787

MUFFLER, AIR EXHAUST, 1/4 NPT

S48487

BUSHING, REDUCER

S15587

PLUG, NYLON, 1/4

S48687

FITTING, Q

S18059

HEAD, JUNIOR CLAMP, ASSEMBLY

S48787

ELBOW, MALE, 90 DEG

S21587

PIN, GRIPPER PIVOT

S48887

CONNECTOR, 1/8 NPTF X 1/4 OD TUBE

S21789

TOOL BASE

S48987

ELBOW, MALE, 90 DEG

S21877

HEAD, FRONT, CYLINDER

S49287

RUN TEE, MALE

S25487

ELBOW, R.A STREET, 1/4 NPT

S49387

CLAMP, HOSE

S25587

COMPOUND, TEFLON, SEALANT (CC)

S49987

VALVE, QUICK EXHAUST

S25687

LOCKING COMPOUND MEDIUM STRGTH

S50287

RING, PANEL MOUNT

S25787

0.01 LUBRICANT, MOLY PASTE (OZ)

S50687

LUBRICATOR

S26387

WASHER, LOCK, 1/4

S50987

BOLT, CARRIAGE, 1/4

S30587

LETTER,ADHESIVE IDENTIFICATION

S51287

HEAD, JR AIR TOOL

S31487

0.05 OIL, DTE 24 HYDRAULIC (QT)

S51787

GROMMET, HOSE

S31589

OIL, LUBRICATION, & BOTTLE

S51987

HOSE ASSY, FOOT CONTROL S750

S31788

DECAL,

S52587

FILTER

S32687

SCREW, CAP, 1/4

S52987

PIN, CAM PIVOT

S32787

NUT, HEX, 1/4

S52687

SPRING, GRIPPER CLOSING

S34187

WASHER, FLAT, .19 X .44 X .05

S67587

TEE, UNION, 1/4

S34287

LOCK WASHER, 3/8 ID

S69587

SCREW, BUTTON HD, #10

S36887

ELBOW, MALE R.A, 1/4 NPT X 3/8 TUBE

S75091

INSERT, PACKAGING, S750 #1

S37387

COUPLER, MALE, 1/4 NPT

S75092

INSERT, PACKAGING, S750 #2

S37487

TEE, STREET

S75093

INSERT, PACKAGING, S750 #3

S39387

DECAL, DTE 24 REQUIREMENT

S76287

DECAL, CAUTION

S39787

0.25 COMPOUND,GASKET&JOINT SEALANT (OZ)

S75099 Pneumatic

Service Parts

Identification

NO.

NO.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

8.5

0.5

1

4

1

1

6

1

1

1

4

2

8

4

1

14

1

1

1

1

1

1

1

1

4

1

1

1

1

3

1

1

1

1

1

1

2

6

2

1

1

2

6

4

6

3

3

2

1

DESCRIPTION

-18

-RING, .734 ID X .139

-RING, 5.437 ID X .295

-32 X .188 L

-24

-32 X .38 L

-18 X .88 L

-7/8" X 3-1/2"

-IT, LARGE

NAME PLATE

-20 X 1.75 L

-20

Junior Clamp

Application Tool

NO.

(CC) 91

100

101

102

103

104

105

NO.

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

81

82

83

84

85

86

87

88

89

90

92

93

94

95

96

97

98

99

1

1

1

1

1

1

1

1

-RING, .487 ID X .103

1

1

1

1

1

1

3

1

1

1

2

1

1

1

1

1

1

1

1

1

1

1

3

7

2

2

1

1

1

1

1

4

1

1

1

1

1

1

1

8

1

1

1

1

DESCRIPTION

-13 X 2.5L

-1/16

-32 X 3/8-24 X 3/4" L

-32 X 3/8-24 X 5/8" L

-WAY, ASSY

-100, 1/8 NPT

-16

-R, STRAIGHT, 1/4 X 1/4NPT

-20 X 1L

-32 X 3/8

BAND-IT-IDEX, Inc.

A Unit of IDEX Corporation

4799 Dahlia Street Denver,

CO 80216-3070 USA

www.BAND-IT-IDEX.com

P: 1-800-525-0758 F: 1-800-624-3925

12

Document# P36687 Rev. I

© Copyright

BAND-IT-IDEX, Inc. 2013

All rights reserved

Page 13

Replacement

S75099 Pneumatic

Service Parts

Identification

Junior Clamp

Application Tool

**

*

*See sheet 16 for additional part

numbers

**Insert S51987 hose assembly

through here using R00608 nylon

tubing.

BAND-IT-IDEX, Inc.

A Unit of IDEX Corporation

4799 Dahlia Street Denver,

CO 80216-3070 USA

P: 1-800-525-0758 F: 1-800-624-3925

www.BAND-IT-IDEX.com

13

Document# P36687 Rev. I

© Copyright

BAND-IT-IDEX, Inc. 2013

All rights reserved

Page 14

Replacement

S75099 Pneumatic

Service Parts

Identification

Junior Clamp

Application Tool

BAND-IT-IDEX, Inc.

A Unit of IDEX Corporation

4799 Dahlia Street Denver,

CO 80216-3070 USA

P: 1-800-525-0758 F: 1-800-624-3925

www.BAND-IT-IDEX.com

14

Document# P36687 Rev. I

© Copyright

BAND-IT-IDEX, Inc. 2013

All rights reserved

Page 15

Replacement

S75099 Pneumatic

Service Parts

Identification

Junior Clamp

Application Tool

BAND-IT-IDEX, Inc.

A Unit of IDEX Corporation

4799 Dahlia Street Denver,

CO 80216-3070 USA

P: 1-800-525-0758 F: 1-800-624-3925

www.BAND-IT-IDEX.com

15

Document# P36687 Rev. I

© Copyright

BAND-IT-IDEX, Inc. 2013

All rights reserved

Page 16

Replacement

S75099 Pneumatic

Service Parts

Identification

Junior Clamp

Application Tool

BAND-IT-IDEX, Inc.

A Unit of IDEX Corporation

4799 Dahlia Street Denver,

CO 80216-3070 USA

P: 1-800-525-0758 F: 1-800-624-3925

www.BAND-IT-IDEX.com

16

Document# P36687 Rev. I

© Copyright

BAND-IT-IDEX, Inc. 2013

All rights reserved

Page 17

S75099 Pneumatic

Installing

Clamps

Installing BAND-IT Junior and Junior Smooth I.D. Clamps:

1) Choose correct material type, band width and diameter clamp to best satisfy the

needs of the application. Adjust air pressure settings per S75099 tool

specifications per page 8.

2) Installation of two BAND-IT Junior style clamps per hose end is suggested.

Place clamps over hose, then install fitting. Note the location of the fitting’s hose

barbs in order to locate clamps between barbs for maximum fitting retention.

The buckle locations of each clamp should be applied opposite of each other to

increase resistance to leak paths.

3) Insert the clamp tail fully into the nose of the tool with the buckle on top.

Position the hose assembly inside the clamp in the desired location.

4) Depress the toe end of the foot pedal control to tension clamp, keeping the toe

end down until the clamp has been fully tensioned, locked and cut-off is

complete. Caution: If an oversized clamp is used on the assembly, the piston

may travel it’s full length and bottom out against the cylinder wall. The tool will

sense full pressure and switch to the lower Holding Pressure setting but clamp

will not be as tight as required! The clamp should be removed from the tool by

pressing the heel of the foot pedal and the operator will need to cut off excess

clamp tail, leaving 4” attached for inserting back into the tool head and taking

another grip of clamp tail. Cycle tool as explained above.

Junior Clamp

Application Tool

5) The clamp has now been fully tensioned and is ready to be completed. Allow

the tool to cycle into the cut-off mode and fully bleed off until holding pressure is

attained. Roll up the hose assembly to position the buckle under the Shear

Hook in the head assembly. Using a strong quick pulling action, pull the cut-off

handle which will cause the shear hook to generate a strong downward

pressure on the buckle. For a moment, just prior to the cut-off, the buckle will be

wedged between the shear hook and the backing plate at the mouth of the band

slot.

6) Depress the heel end of the foot pedal and retrieve the clamp tail from between

the cutter blade and shear plate.

Important advice and warning to user, read notes on page 6 before

applying clamps.

BAND-IT-IDEX, Inc.

A Unit of IDEX Corporation

4799 Dahlia Street Denver,

CO 80216-3070 USA

P: 1-800-525-0758 F: 1-800-624-3925

www.BAND-IT-IDEX.com

17

Document# P36687 Rev. I

BAND-IT-IDEX, Inc. 2013

© Copyright

All rights reserved

Page 18

Replacement

Service Parts

Installation Instructions for the J93099 Cutter Blade Kit

S75099 Pneumatic

Junior Clamp

Application Tool

*Components of this kit are a

dimensionally matched set. You may

have parts that look similar, but they

are different dimensionally. Parts

should be discarded and only new

matched sets should be used.

1. Remove old Cutter Blade Screws,

Cutter Blade and Backing Plate and

discard.

2. See illustrations to determine the

correct positions for correct component

assembly.

3. Hold Cutter Blade and Backing Plate

together, insert screws and tighten.

Installation Tip: This kit contains multiple sets

of screws with varying lengths. Choose the

correct length screw for your application.

Threads should protrude through the Cutter

Blade by less than ¼” .

Operating Tip: Keep the bolts tight. A loose

bolt may cause cracking or premature wear of

the Cutter Blade or Backing Plate. This could

result in improper clamp tensioning, locking

and cutting of excess clamp tail.

Operating Tip: Keep the leading edges of the

Cutter Blade and Backing Plate free of metal

shavings. Metal shavings will result in clamp

material gauging during tensioning. By hand,

DO NOT USE POWER TOOLS, clean and

hone the leading edges. Honing should polish

surfaces, not remove material.

BAND-IT-IDEX, Inc.

A Unit of IDEX Corporation

4799 Dahlia Street Denver,

CO 80216-3070 USA

P: 1-800-525-0758 F: 1-800-624-3925

www.BAND-IT-IDEX.com

18

Document# P36687 Rev. I

© Copyright

BAND-IT-IDEX, Inc. 2013

All rights reserved

Page 19

Replacement

Service Parts

S45799 Gripper and Spring Kit Installation Instructions

1. Extend the tool piston fully

forward. The gripper pin should

be visible through the access

hole.

S75099 Pneumatic

Junior Clamp

Application Tool

2. Disconnect air from the tool.

3. Loosen set screw and

disconnect gripper spring.

4. Tap out gripper pin, remove old

gripper and replace with new.

5. Connect new spring between

gripper and spring pin.

Shear Hook and Handle Assembly

To remove handle, loosen the

2 set screws and tap out pin.

Handle

Pin

S52987

Set

Screw

Gripper Pin

and Access

Hole

Gripper

Spring

Gripper

Cut-Off

Handle

S11589

Shear

Hook

J00587

BAND-IT-IDEX, Inc.

A Unit of IDEX Corporation

4799 Dahlia Street Denver,

CO 80216-3070 USA

P: 1-800-525-0758 F: 1-800-624-3925

www.BAND-IT-IDEX.com

Set

Screws

J64887

19

Shear

Hook Pin

J90887

Document# P36687 Rev. I

© Copyright

BAND-IT-IDEX, Inc. 2013

All rights reserved

Page 20

Optional

S75099 Pneumatic

Reference

Gauge

Remote Reference Gauge Kit

BAND-IT Part Number S67199

Union Tee

Remove Plug and

Insert Tube From

Air Gauge

Wood

Screws (3x)

Front Cylinder

Port

Remote Air

Gauge, 0-160 PSI

Tube From Union

Tee on Line “K”

Junior Clamp

Application Tool

Female

Connector

The Remote Reference Air Gauge will read air pressure in the front of the cylinder for both pull-up and holding

pressures. To read gauge: When tensioning a clamp, the maximum pressure the gauge reads during the cycle is

the pull-up pressure. After the tool switches over to the lower pressure holding cycle and before the clamp is

rolled up in preparation for lock, the pressure shown is the holding pressure.

For Tool with a Union Tee Installed at Line “K”:

1. Shut off air supply to tool. Completely bleed air tool system.

2. Remove plug from union tee. Connect the tube from the remote air gauge to the port the plug was

removed from.

3. Add sealant to the threads of the female connector and attach to the remote air gauge. Mount gauge in

desired location either using the 3 wood screws supplied or fasting hardware appropriate for the material

the gauge is to be mounted to.

For Tool without a Union Tee Installed at Line “K”:

1. Shut off air supply to tool. Completely bleed air tool system.

2. Cut tube line “K” 2 inches from front cylinder port. Insert supplied union tee between cut ends. Connect

the tube from the remote air gauge to the union tee.

3. Add sealant to the threads of the female connector and attach to the remote air gauge. Mount gauge in

desired location either using the 3 wood screws supplied or fasting hardware appropriate for the material

the gauge is to be mounted to.

BAND-IT-IDEX, Inc.

A Unit of IDEX Corporation

4799 Dahlia Street Denver,

CO 80216-3070 USA

P: 1-800-525-0758 F: 1-800-624-3925

www.BAND-IT-IDEX.com

20

Document# P36687 Rev. I

© Copyright

BAND-IT-IDEX, Inc. 2013

All rights reserved

Page 21

S75099 Pneumatic

Factory Services

Junior Clamp

Application Tool

Additional Factory Support and Tool Service:

repairs can be greatly reduced by following a simple, regular, preventative maintenance such

as maintaining tension on fasteners and proper lubrication as outlined in this manual. If this

tool needs repair or complete overhaul, it should be returned to BAND-IT in Denver.

charges in addition to parts replacement charges will be invoiced if tool is not covered by our

warranty. Please visit our website for our warranty information.

BAND-IT-IDEX, Inc.

A Unit of IDEX Corporation

4799 Dahlia Street Denver,

CO 80216-3070 USA

P: 1-800-525-0758 F: 1-800-624-3925

www.BAND-IT-IDEX.com

21

Document# P36687 Rev. I

© Copyright

BAND-IT-IDEX, Inc. 2013

All rights reserved

Loading...

Loading...