Page 1

Operators

S35099

Manual

Automatic Air Tool

BAND-IT-IDEX, Inc.

A Unit of IDEX Corporation

4799 Dahlia Street

Denver, CO 80216-0307 USA

P: 1-800-525-0758

F: 1-800-624-3925

www.BAND-IT-IDEX.com

Page 1 of 34

Document # S41067 rev. H

© Copyright

BAND-IT-IDEX, Inc. 2010

All rights reserved

Page 2

Table of Contents

Warranty and Safety Information 3

Front Tool Controls 4

Specifications 5

Installation 6-7

Operating Instructions 8-14

S35099

Automatic Air Tool

Maintenance Instructions 15-16

Maintenance Summary 17

Troubleshooting 18-21

Repair Parts 22-34

BAND-IT-IDEX, Inc.

A Unit of IDEX Corporation

4799 Dahlia Street

Denver, CO 80216-0307 USA

P: 1-800-525-0758

F: 1-800-624-3925

www.BAND-IT-IDEX.com

Page 2 of 34

Document # S41067 rev. H

© Copyright

BAND-IT-IDEX, Inc. 2010

All rights reserved

Page 3

Warranty and

S35099

Safety Information

Refer to website for warranty information: http://www.band-it-idex.com/warranty.html

SAFETY RULES:

When applying clamps, care should be taken to make certain that fingers are not in the way of the

clamp being applied. Tensioning the clamp can be stopped immediately by releasing the foot pedal.

Detailed instructions are in this manual and the operator is advised to read it and become familiar

with operating the tool.

IMPORTANT: When clamping a hose end, remember that a tighter clamp keeps the fitting more

secure, but excess tension could damage the hose. Fitting stem must have prominent barbs for

proper retention inside the hose, but must not be sharp to prevent cutting into the hose. Hose, fitting

and clamp must be compatible with each other and the environment used in. If in doubt, consult the

hose or fitting manufacturer or call BAND-IT.

Clamping objects other than hose requires similar precautions.

CAUTION: Improperly tightened clamps may result in dangerous hose assemblies, which could

cause injuries or property damage.

CAUTION: Abuse or use of a hose outside the manufacturers recommended conditions may cause it

to quickly deteriorate and become a safety hazard. This could result in serious injury or property

damage. Inspect and test hose assemblies frequently.

Automatic Air Tool

BAND-IT-IDEX, Inc.

A Unit of IDEX Corporation

4799 Dahlia Street

Denver, CO 80216-0307 USA

P: 1-800-525-0758

F: 1-800-624-3925

www.BAND-IT-IDEX.com

Page 3 of 34

Document # S41067 rev. H

© Copyright

BAND-IT-IDEX, Inc. 2010

All rights reserved

Page 4

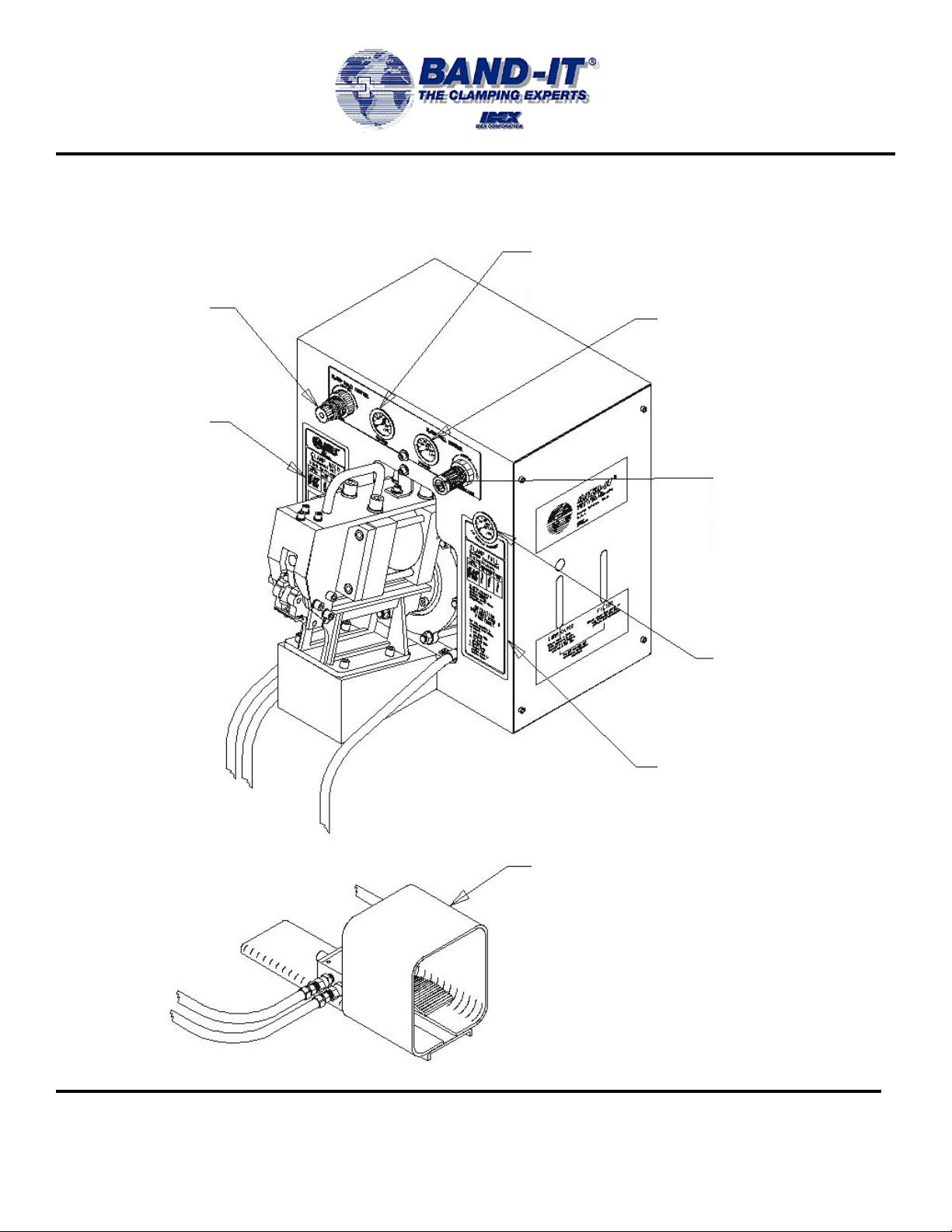

Front Tool

S35099

Controls

CLAMP HOLD

PRESSURE

ADJUSTMENT

KNOB

CHART SHOWS

RECOMMENDED

HOLD PRESSURE

FOR CLAMPS

Automatic Air Tool

CLAMP HOLD

PRESSURE GAUGE

CLAMP PULL

PRESSURE GAUGE

CLAMP PULL

PRESSURE

ADJUSTMENT KNOB

FOOT CONTROL

Figure 1 – Front View

AIR SUPPLY

PRESSURE GAUGE

CHART SHOWS MAX.

RECOMMENDED PULL

PRESSURE FOR CLAMPS

BAND-IT-IDEX, Inc.

A Unit of IDEX Corporation

4799 Dahlia Street

Denver, CO 80216-0307 USA

P: 1-800-525-0758

F: 1-800-624-3925

www.BAND-IT-IDEX.com

Page 4 of 34

Document # S41067 rev. H

© Copyright

BAND-IT-IDEX, Inc. 2010

All rights reserved

Page 5

Specifications

TOOL SIZE

Width 17 Inches (431.8mm)

Height 18.5 Inches (469.9 mm)

Depth (over head) 21.5 Inches (546.1 mm)

Depth (chassis) 11 Inches (279.4 mm)

Weight 135 Lbs (61.2 kg)

TEMPERATURE

Operating ambient +32°F to +125°F (0°C to +51.5°C)

Storage temperature -20°F to +160°F (-28.8°C to +71.1°C)

SUPPLY AIR

Pressure 100-120 psi (7.0-8.4 kg/cm², 689-827 kPa)

Temperature +32°F to +165°F (0°C to +73.8°C)

Consumption/cycle 6.7 cubic feet/minute @ 100 psig

Line size minimum I.D. 3/8" (9.53 mm)

Connection size 1/4 npt .203" (5.156 mm) minimum I.D.

Filter in tool 50 micron sintered bronze

LUBRICANT

Type DTE 24 Hydraulic oil

Quantity 1/3 pint (.157 liter)

PERFORMANCE

Control specifications Foot operated valve with guard

Water drain connection Tube I.D. 1/8" (3.175 mm)

Cycle time 10 seconds

Pull-up clamp 3.5 seconds

Cut-off clamp 1.5 seconds

Eject tail and reset 1.0 seconds

CLAMP TYPE

Tool with S260 head Band-It Jr. and SID Junior Preformed

Width (inches) 1/4, 3/8, 1/2, 5/8, 3/4

Width (mm) 6.35, 9.53, 12.7, 15.88, 19.05

Diameter 3/4"-8" diameter

Materials 201/316 SS and galv. carbon steel

S35099

Automatic Air Tool

Guard meets OSHA part 1910.

Sections 217 and 218, June 1974

Valve meets ANSI B11.1-1971

BAND-IT-IDEX, Inc.

A Unit of IDEX Corporation

4799 Dahlia Street

Denver, CO 80216-0307 USA

P: 1-800-525-0758

F: 1-800-624-3925

www.BAND-IT-IDEX.com

Page 5 of 34

Document # S41067 rev. H

© Copyright

BAND-IT-IDEX, Inc. 2010

All rights reserved

Page 6

S35099

Installation

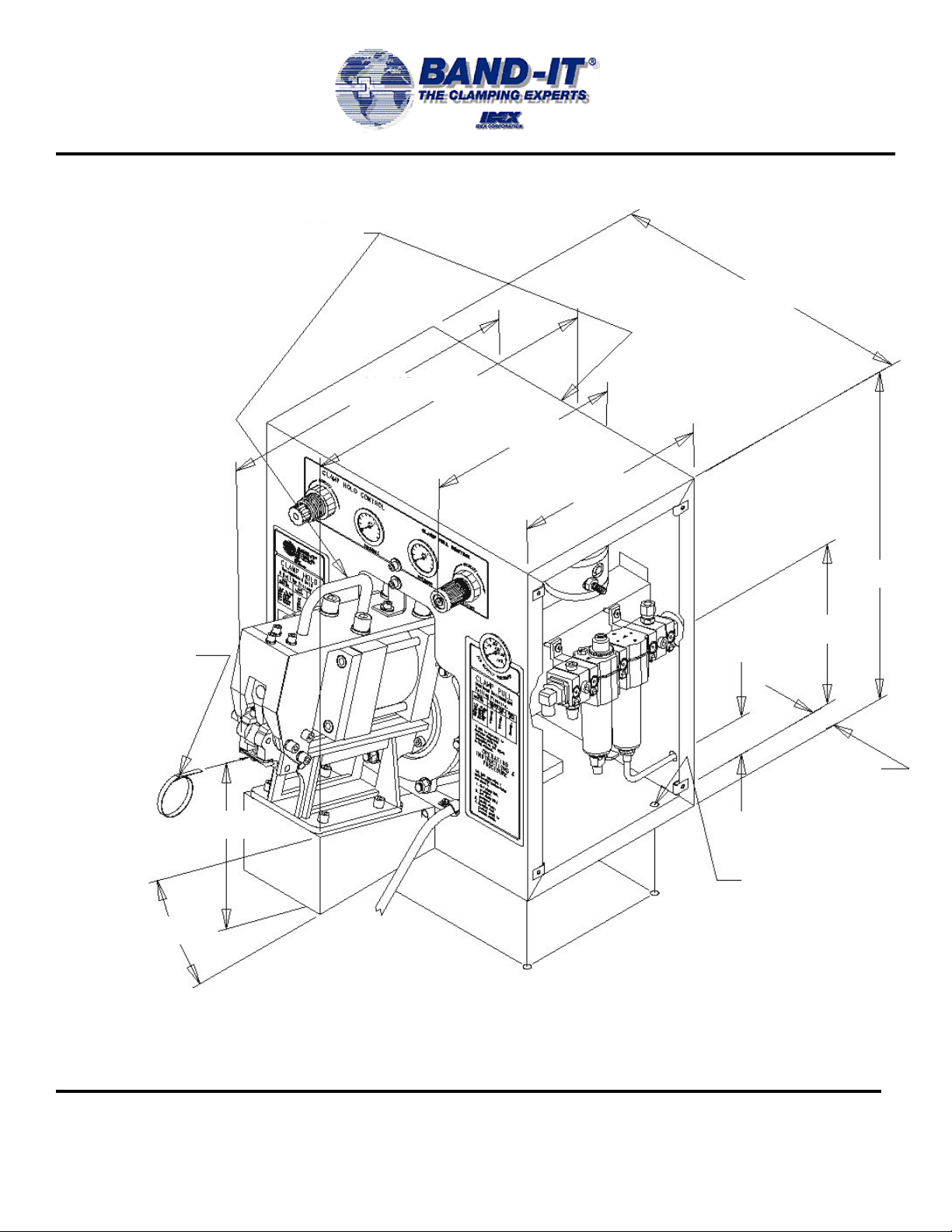

UNPACKING:

1. Lift the outer tube of the packing box. Carefully examine the tool for shipping damage as

evidenced by dents, loose parts, etc. Report any shipping damage found to the carrier that

delivered the tool.

2. Lift out foot control valve and remove protective packing.

3. Remove the side panels (2) of the tool chassis. Keep the screws for reassembly. The tool is

bolted to the bottom base of the shipping carton. Remove these screws.

4. Lift the tool using the hand hole at the rear top of the chassis and the handle on the tool head.

Support the foot control valve and its lines to avoid damage while moving the tool.

5. The shipping carton has been specially prepared to protect the tool. It is recommended to keep

the carton and hardware so the tool can be repacked in it, should it be desirable to ship the tool to

another location or return it to the factory for service.

6. CAUTION: The tool weighs approximately 117 pounds. The aid of a suitable lifting device is

recommended for handling the tool. Use the lift points provided. See figure 2.

MOUNTING:

1. Locate the tool in its desired location, and secure the tool to the mounting surface with 5/16"

diameter bolts (4). Place the foot control valve on the floor. See figure 2 for location of the bolts.

2. A drain tube connected to the pipe connection on the bottom of the filter is supplied so the water,

automatically ejected, can be dumped. This drain line can be connected to a permanent drain

(recommended) or it can drain into a container. This line can be routed through the opening in the

front of the chassis. If alternate routing of the hose is desired, an access hole must be cut through

the chassis at the desired location.

3. Prepare the incoming air line, the supply air should be clean (filtered) and free of moisture.

Recommended air source hook up should be done with a quick-disconnect coupling such as a

Hansen 3000 series 1/4 npt socket and plug, or equivalent. For permanent hook up, use of a

shut-off valve in the air line is recommended to enable shut-off of the incoming air when servicing

the tool. Route the air line through the access hole in the rear of the chassis. Alternate routing of

the supply air can be done through the bottom of the chassis. Connect the air line to the tee fitting

in the inlet port of the filter. See figure 2.

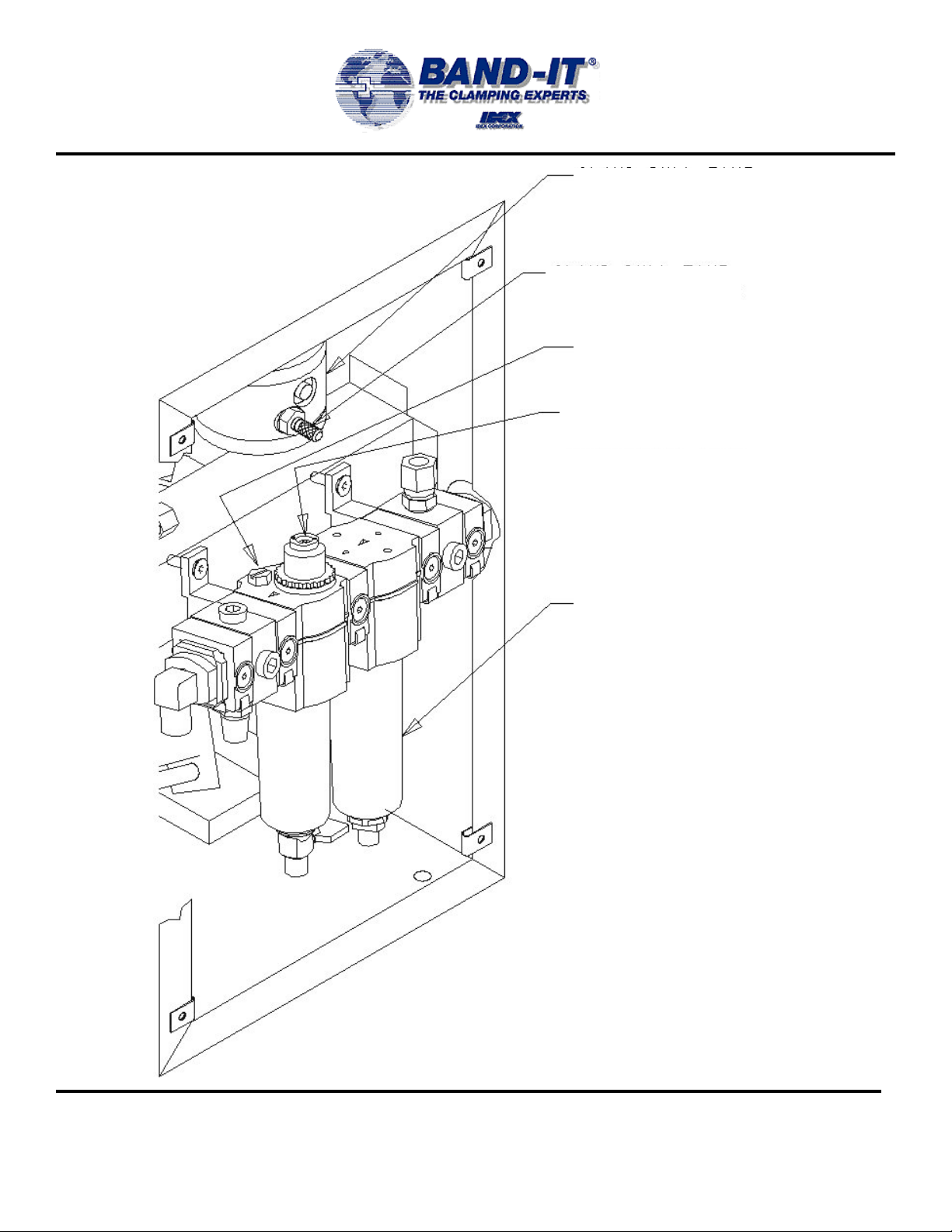

4. Remove the filler plug of the lubricator, see figure 4, and fill the bowl to the fill line with the DTE 24

hydraulic oil supplied with the tool. Note

5. Do not fill past the fill line on the bowl. Reattach filler plug. The tool is ready for preliminary

operation. Do not reassemble the side panels. The lubricator must be checked for proper

operation. Refer to the operating instructions section.

WARNING: This tool is intended for use with industrial compressed air systems. The tool must not

be used where pressure or temperature may exceed the maximum rated operating condition as

stated in the specifications section. The polycarbonate plastic bowls used in this tool could be

damaged and possibly burst if exposed to strong alkali’s, compressor oils containing aromatic

hydrocarbons, synthetic oils, or fumes of these substances in contact with the polycarbonate plastic

bowls, externally or internally.

: The lubricator cannot be filled while tool is pressurized.

Automatic Air Tool

BAND-IT-IDEX, Inc.

A Unit of IDEX Corporation

4799 Dahlia Street

Denver, CO 80216-0307 USA

P: 1-800-525-0758

F: 1-800-624-3925

www.BAND-IT-IDEX.com

Page 6 of 34

Document # S41067 rev. H

© Copyright

BAND-IT-IDEX, Inc. 2010

All rights reserved

Page 7

Installation

LIFT HERE

S35099

Automatic Air Tool

17.077

20.498 18.380

12.850

10.880

POSITION OF ITEM

FOR INSERTION OF

CLAMP INTO TOOL

15°

8.9

18.500

9.50

1.375

2.090

8.50 X 14.50

PARALLEL HOLE

PATTERN

.41 DIA X 4 PLACES

BAND-IT-IDEX, Inc.

A Unit of IDEX Corporation

4799 Dahlia Street

Denver, CO 80216-0307 USA

P: 1-800-525-0758

F: 1-800-624-3925

Figure 2 – Tool Overall Size

www.BAND-IT-IDEX.com

Page 7 of 34

Document # S41067 rev. H

© Copyright

BAND-IT-IDEX, Inc. 2010

All rights reserved

Page 8

Operating

S35099

Instructions

PRELIMINARY

Read air supply pressure gauge (Fig. 1). Air pressure should not be lower than 100 psi and no higher

than 120 psi. Depress the foot control valve pedal and hold the pedal down so the tool operates

through its cycle. When the tool has completed the cycle, release the pedal and the tool will reset for

the next cycle.

Cycle the tool three or four times without attempting to apply a clamp and observe the tool as it cycles

to become familiar with the operating sounds and action of the tool. During these cycles, check the air

lines for leaks and observe that the piston rods of the pull cylinder and cut-off cylinder operate freely.

CLAMP PULL PRESSURE GAUGE

Read the pressure shown on the clamp pull pressure gauge (Fig. 1) as the tool goes through the pullup cycle. The pressure to be read is the pressure shown at the time the control valve shifts.

Pressures shown on the gauge after the valve has shifted should be ignored.

CLAMP HOLD PRESSURE GAUGE

Read the pressure shown on the clamp hold pressure gauge (Fig. 1) as the tool goes through that

portion of the cycle. The pressures observed are those to which the tool is set to operate. The

pressure to be read is the pressure shown at the time the cut-off cylinder operates the cam to lock the

clamp and to cut-off clamp tail. Pressures shown on gauge at other times during the cycle are

unimportant and should be ignored. The cycle time, clamp pull pressure and clamp hold pressure

should always be checked as described prior to attempting to apply a clamp on an item.

ADJUSTMENT OF LUBRICATOR

The lubricator adjustment must be checked to determine that the drip rate is one drip per cycle (set

and locked at Band-It, does not need to be adjusted). Locate the drop rate adjustment knob on the

top of the lubricator (Fig. 4). The drip rate adjustment should be made only when there is a constant

flow of air through the lubricator (operate the tool).

Locate the sight dome just below the adjustment knob and observing the oil as it drips downward into

the lubricator. To adjust the drip rate, turn the slotted red rotator in sight feed dome counter-clockwise

to increase drip rate: clockwise to decrease the drip rate. When the proper rate of one drop per cycle

is obtained, stop adjustment. Do not operate the tool at a higher drip rate than recommended as the

larger amount of lubricant could adversely affect the operation of the time-delay valves and also result

in accumulation of lubricant near the air exhaust.

Operation at a lower drip rate can starve the cylinders and valves and reduce their life due to

premature wear.

Automatic Air Tool

BAND-IT-IDEX, Inc.

A Unit of IDEX Corporation

4799 Dahlia Street

Denver, CO 80216-0307 USA

P: 1-800-525-0758

F: 1-800-624-3925

www.BAND-IT-IDEX.com

Page 8 of 34

Document # S41067 rev. H

© Copyright

BAND-IT-IDEX, Inc. 2010

All rights reserved

Page 9

Operating

Instructions

S35099

Automatic Air Tool

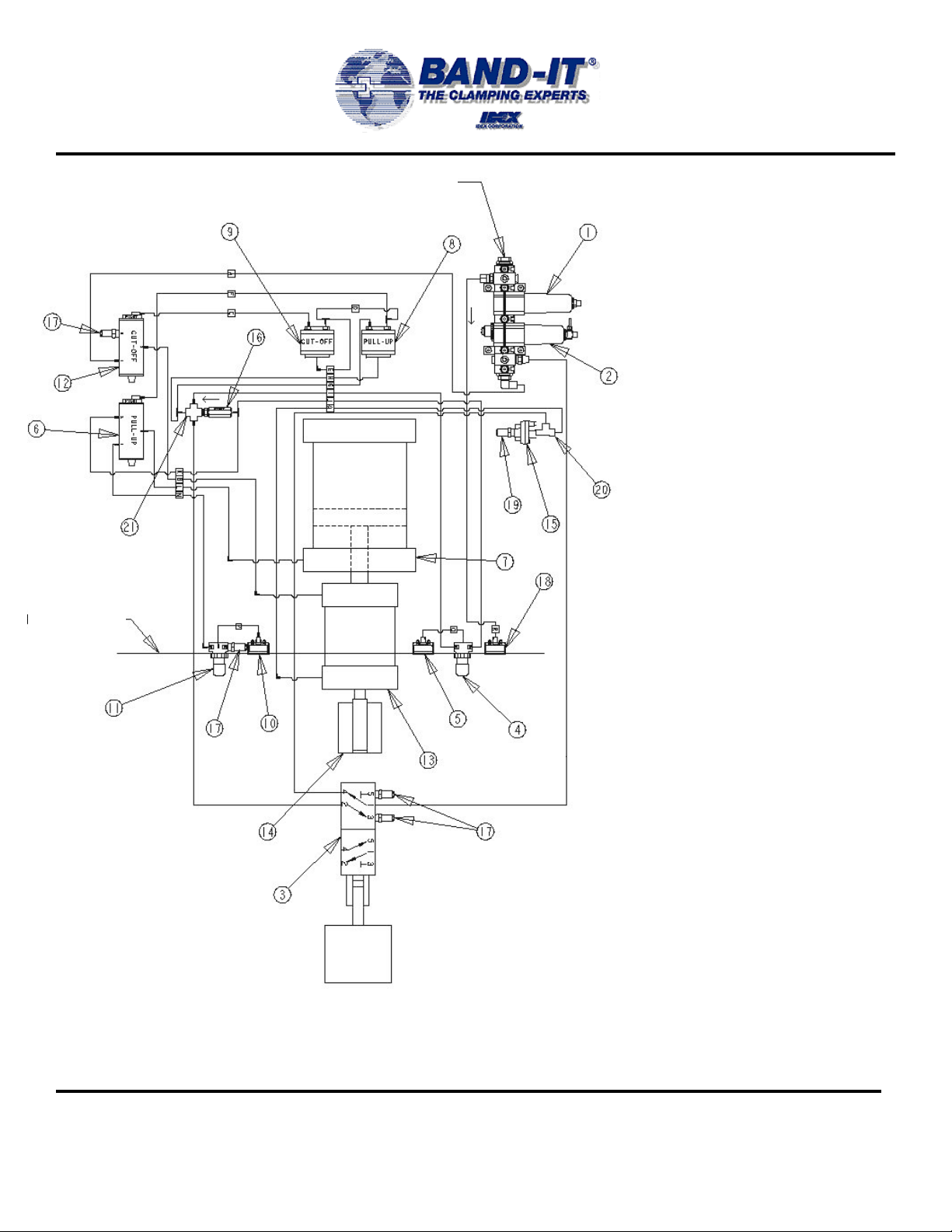

FRONT

PANEL

CLAMP

HOLD

CONTROL

100-120 PSI AIR SUPPLY

CLAMP PULL

CONTROL

LEGEND:

1 FILTER, AIR

2 LUBRICATOR

3 VALVE, FOOT OPERATED

4 VALVE, CLAMP PULL

PRESSURE CONTROL

5 GAUGE, CLAMP PULL

PRESSURE

6 VALVE, PULL-UP CYLINDER

7 CYLINDER, CLAMP PULL

8 VALVE, TIME DELAYED,

PULL-UP CYLINDER

9 VALVE, TIME DELAYED,

CUT-OFF

10 GAUGE, CLAMP HOLD

PRESSURE

11 VALVE, CLMAP HOLD

PRESSURE CONTROL

12 VALVE, CUT-OFF CYLINDER

13 CYLINDER, CLAMP LOCK

AND CUT-OFF

14 HEAD, CLAMP

15 VALVE, QUICK EXHAUST

16 VALVE, CHECK

17 MUFFLER, AIR EXHAUST

18 GAUGE, AIR SUPPLY

PRESSURE

19 MUFFLER, AIR EXHAUST 1/4

20 TEE, STREET 1/4-18 NPT

21 CROSS, BRASS, 1/4 NPTF,

FEMALE

▲ ON TOOLS SERIAL NUMBER 168 AND UP

Figure 3 – Air Control Schematic

BAND-IT-IDEX, Inc.

A Unit of IDEX Corporation

4799 Dahlia Street

Denver, CO 80216-0307 USA

P: 1-800-525-0758

F: 1-800-624-3925

NOTES:

1 SYSTEM SHOWN IN NORMAL (OFF) POSITION.

2 TO START CYCLE, DEPRESS FOOT CONTROL

VALVE 3.

3 KEEP FOOT CONTOL VALVE DEPRESSED TO

COMPLETE CYCLE.

4 RELEASE FOOT CONTROL VALVE WHEN THE

COMPLETE CYCLE IS DONE OR TO STOP THE

TOOL DURING ITS CYCLE.

5

□ REFERS TO IDENTIFICATION LETTERS PLACED

ON EACH AIR LINE.

www.BAND-IT-IDEX.com

Page 9 of 34

Document # S41067 rev. H

© Copyright

BAND-IT-IDEX, Inc. 2010

All rights reserved

Page 10

Operating

S35099

Instructions

ADJUSTMENT OF CYCLE TIME

The cycle time consists of two adjustable time elements. These can be adjusted as desired to: match

the operator’s skill, compensate for the difficulty of the assembly of the item being clamped, increase

or decrease the speed of the tool to allow the tool to tension the clamp, etc. A six second time for a

complete tool cycle is recommended as a reasonable time to make clamp assemblies, avoid operator

fatigue, and obtain a good production rate. The total time to apply a clamp will be increased by the

time to load the clamp on the item being clamped into the tool and removing the item and the spent

tail after clamping. It is not likely that the cycle time will need be adjusted frequently.

ADJUSTMENT OF CLAMP PULL TIME

This is the time needed to allow the pull cylinder to tighten the clamp and to build air pressure to the

pressure level selected. Pulling clamps with less than 40 psi does not require as much time to

tension the clamp so, if desired, the tool cycle time can be shortened. Conversely, if the tool is used

for clamps requiring pull pressure of 40 psi, or greater, the cycle time will need to be longer. To

adjust this time, remove the right side panel (4 screws) and locate the time delay valve (Fig. 4).

Locate the knurled adjustment knob (secured with a lock nut). Loosen the lock nut with a wrench and

turn the screw clockwise (right hand) to increase the cycle time, turn the screw counter-clockwise (left

hand) to decrease the cycle time. After an adjustment, it is recommended to cycle the tool a few

times to check the time to which the tool has been reset. When satisfied with the time, tighten the

lock nut to secure the adjustment knob and reassemble the side panel. A reasonable elapsed time

for this portion of the cycle is three seconds.

ADJUSTMENT OF CLAMP LOCKING AND CUT-OFF TIME

This is the time required to reduce the pressure in the pull cylinder to the clamp holding pressure and

to actuate the cut-off cylinder which locks the clamp and cuts off the clamp tail. For tools equipped

with the Band-It Jr. preformed clamp head, the operator must have time to roll the clamp up to

position for cut-off. Time required for roll up is dependent upon operator skill, familiarity with the tool,

weight and size of the item being clamped. To adjust this cycle time, remove the left side panel (four

screws) and locate the time control valve (Fig. 5). Locate the knurled adjustment knob (secured with

a lock nut). Loosen the lock nut with a wrench and turn the screw clockwise to increase the cycle

time, counter-clockwise to decrease the cycle time. Cycle the tool a few times to make certain the

cycle time is changed to that desired. Tighten the lock nut to secure the adjustment knob and

reassemble the side panel.

Automatic Air Tool

BAND-IT-IDEX, Inc.

A Unit of IDEX Corporation

4799 Dahlia Street

Denver, CO 80216-0307 USA

P: 1-800-525-0758

F: 1-800-624-3925

www.BAND-IT-IDEX.com

Page 10 of 34

Document # S41067 rev. H

© Copyright

BAND-IT-IDEX, Inc. 2010

All rights reserved

Page 11

Operating

Instructions

S35099

Automatic Air Tool

CLAMP PULL TIME

DELAY VALVE

CLAMP PULL TIME

ADJUSTMENT SCREW

LUBRICATOR FILLER

PLUG

LUBRICATOR DRIP RATE

ADJUSTMENT KNOB

FILTER

Figure 4 – Right Side of Tool

BAND-IT-IDEX, Inc.

A Unit of IDEX Corporation

4799 Dahlia Street

Denver, CO 80216-0307 USA

P: 1-800-525-0758

F: 1-800-624-3925

www.BAND-IT-IDEX.com

Page 11 of 34

Document # S41067 rev. H

© Copyright

BAND-IT-IDEX, Inc. 2010

All rights reserved

Page 12

Operating

Instructions

CLAMP HOLD TIME

DELAY VALVE

CLAMP HOLD TIME

ADJUSTMENT SCREW

CUT-OFF

CONTROL VALVE

S35099

Automatic Air Tool

PULL-UP

CONTROL VALVE

Figure 5 – Left Side of Tool

BAND-IT-IDEX, Inc.

A Unit of IDEX Corporation

4799 Dahlia Street

Denver, CO 80216-0307 USA

P: 1-800-525-0758

F: 1-800-624-3925

www.BAND-IT-IDEX.com

Page 12 of 34

Document # S41067 rev. H

© Copyright

BAND-IT-IDEX, Inc. 2010

All rights reserved

Page 13

Operating

Instructions

ADJUSTMENT OF CLAMP PULL PRESSURE

This adjustment will be required for different materials and construction of the items being clamped.

A convenient chart summarizing the maximum pressures to use for the most commonly used Band-It

clamps is located on the lower right front panel (Fig. 1). Note that this chart shows the maximum

pressure to be used. Pulling clamps to pressures higher than recommended may result in clamp

breakage or improper clamp locking caused by excessive stretching of the clamp band. It is likely

that a pressure setting slightly below this maximum will be satisfactory.

Some testing, by assembling clamps on a test specimen of the item being clamped, may be useful to

determine the desirable pressure setting. To adjust the pressure, locate the clamp pull pressure knob

(Fig. 1) on the front panel. Adjustment is made by a knurled knob secured with a lock ring. Pull the

lock ring out toward the knob so it can be turned. Turn the knob clockwise to increase the pressure

setting; counter-clockwise to decrease the pressure setting. The pressure to which the tool is set is

shown on the gauge beside the knob (Fig. 1). To check the pressure to which the tool is set, cycle

the tool and observe the maximum pressure reading shown on the gauge when the piston is all the

way in. Note that this pressure must be read during the pull cycle only. When the desired pressure is

obtained, push the lock ring in and the knob is locked. Note: It is important to adjust so the pressure

observed on the gauge is regulated to the desired pressure by the time the tool cycles and not

attempt to set the pressure so that it is changing rapidly and merely "passing through" the desired

pressure at the time the tool operates.

The latter condition can result in wide variations of pull pressure as the air pressure fluctuates.

ADJUSTMENT OF CLAMP HOLD PRESSURE

The pressure in the clamp pull cylinder must be reduced to allow the tool to lock the clamp after

pulling and to satisfactorily cut off the clamp tail. This pressure is adjusted by the knurled knob on the

left front panel (Fig. 1). The pressure to which the tool is set is shown on the gauge beside the knob

(Fig. 1). Note that during this cycle, the pressure drops rapidly. The tool must be set so the desired

pressure is shown at the instant the cut-off cylinder moves the cam out to lock the clamp and cut off

the tail. To adjust this pressure, pull the lock ring out and turn the knob clockwise to increase the

pressure; counter-clockwise to decrease the pressure.

A convenient chart summarizing the recommended pressures to use for the most common sizes of

Band-It clamps is located on the lower left front panel. Note that this chart shows only recommended

pressure settings; operation outside these pressure settings will possibly result in poor locks on the

clamps, breaking of the clamp band (pressure too high), or difficulty in cutting off the tail (pressure too

low). The tool should be cycled to check the pressure setting of the tool. When satisfactory, push the

lock ring in to secure the adjustment knob. Note: It is important that the pressure be adjusted so the

pressure is regulated to the desired holding pressure at the time the cut-off cylinder actuates and not

attempt to adjust the tool so the pressure is changing rapidly at the time the cylinder actuates. This

will result in consistent holding pressures.

The tool is ready for Band-It Jr. clamps.

S35099

Automatic Air Tool

BAND-IT-IDEX, Inc.

A Unit of IDEX Corporation

4799 Dahlia Street

Denver, CO 80216-0307 USA

P: 1-800-525-0758

F: 1-800-624-3925

www.BAND-IT-IDEX.com

Page 13 of 34

Document # S41067 rev. H

© Copyright

BAND-IT-IDEX, Inc. 2010

All rights reserved

Page 14

Operating

Instructions

S35099

Automatic Air Tool

APPLYING CLAMPS

The following step-by-step instructions should be followed to successfully tension and lock a clamp.

This information is also summarized on a decal located on the lower left front panel and explained in

further detail in other sections of this manual.

CAUTION! When operating, do not place fingers near or between the clamp band and the item being

clamped as they could be pinched.

1. Set and/or check clamp pull pressure.

2. Slide clamp over object being clamped. Insert tail of clamp into the open slot of the backing

plate of the clamp tool head. Push the clamp tail into the head as far as possible (the clamp

buckle should be almost touching the backing plate of the clamp tool head).

3. Support the item being clamped. The operator should hold the object so the clamp buckle is

essentially level with the tail and should also keep the object horizontal and lift it if necessary

as the weight of the assembly is not held by the clamp.

4. Depress the pedal of the foot control valve and hold the pedal down as the tool operates

through its cycle.

5. Allow the tool to tighten the clamp and observe the pull pressure. The tool will then

automatically cycle and lower the pressure in the pull cylinder to the hold pressure.

6. Roll up hose when clamp hold gauge drops to approximate roll up pressure shown in chart

below. Rotate object being clamped upward and position clamp buckle under shear hook of

machine.

7. Support the object being clamped as the cut-off cylinder automatically pushes the cam outward

to perform and cut-off operation.

Pull-Up Pressure

Clamp Width

(mm)

Stainless Steel

201 SS 316 SS

(psi)

Carbon

Steel

Hold Pressure

(psi)

Roll Up Pressure

(psi)

1/4" (6.35)

3/8" (9.525)

1/2" (12.7)

5/8" (15.875)

3/4" (19.05)

15

25

40

50

60

15

20

35

40

50

25

40

50

60

6-7

6-7

8-9

9-10

10-12

9-10

9-10

11-12

12-14

13-16

STOPPING THE TOOL

Should the occasion arise that the tool operation must be stopped to clear a jammed clamp, the tool

cycle can be stopped by releasing the foot control valve and the tool will reset itself. Should the

control valve again be depressed prior to allowing the tool to reset, erratic cycling will result.

BAND-IT-IDEX, Inc.

A Unit of IDEX Corporation

4799 Dahlia Street

Denver, CO 80216-0307 USA

P: 1-800-525-0758

F: 1-800-624-3925

www.BAND-IT-IDEX.com

Page 14 of 34

Document # S41067 rev. H

© Copyright

BAND-IT-IDEX, Inc. 2010

All rights reserved

Page 15

Maintenance

S35099

Instructions

VALVES AND GAUGES

No periodic maintenance is required.

AIR LINES

No periodic maintenance is required. However, checking the tube connectors to see that they are

tight when the tool is serviced is recommended.

FILTER

Clean the filter a minimum of every six months or more frequently if dirt particles are observed to be

accumulating in the bowl.

LUBRICATOR

Drain and clean once a year or clean immediately if the lubricator is observed to be discolored or

contaminated. Keep the oil level to the fill line. DO NOT over-fill since this reduces the efficiency of

the lubricator. Discard the oil drained, do not reuse.

Automatic Air Tool

Warning: The lubricator should be refilled with DTE 24 hydraulic oil only. The

use of other oils may cause damage to the system.

CLAMP TAIL GRIPPER PLATE

Remove the clamp tail gripper as shown in figure 6, and remove the right hand side panel. Depress

the pedal of the fool control valve and allow the tool to cycle as though it was pulling a clamp. When

the piston rod is pulled all the way back, disconnect or shut off the air supply. The tool will stop its

action and the plate can be reached at the end of the piston rod. Slide tripper plate out of the piston

rod. Clean to remove any accumulation of dirt, debris, etc. and apply molybdenum disulfide lubricant

such as Molykote type G-n or equivalent to the edges of the plate. Reassemble the plate with

chamfered edge up and toward the front of the tool. Slide the plate all the way into the piston rod.

Reconnect or turn on the air. The tool will complete the cycle and return the piston rod toward the

front of the tool. Reassemble the clamp tail gripper and the tool is ready to use.

CLAMP TAIL GRIPPER

BAND-IT-IDEX, Inc.

A Unit of IDEX Corporation

4799 Dahlia Street

Denver, CO 80216-0307 USA

P: 1-800-525-0758

F: 1-800-624-3925

ACCESS HOLE ON

EITHER SIDE OF BASE

GRIPPER PIVOT PIN

SET SCREW

Figure 6 – Clamp Tail Gripper

www.BAND-IT-IDEX.com

Page 15 of 34

Document # S41067 rev. H

© Copyright

BAND-IT-IDEX, Inc. 2010

All rights reserved

Page 16

Maintenance

S35099

Instructions

Automatic Air Tool

GENERAL

This tool has been designed and constructed to reduce minimum maintenance. Periodic checking of

the tool to check for loose screws and fittings that may have loosened is necessary. A thorough

check for air leaks, wear on the moving parts, etc. is recommended to keep the tool in peak operating

condition.

AIR EXHAUST MUFFLERS

Remove and clean once a year minimum with a degreaser (such as Gunk) to remove accumulated oil

deposits.

CYLINDERS

These cylinders have seals to keep dirt from entering the cylinders but the dirt accumulated at the

seals should be cleaned away a minimum of once a year (more often if used in a very dirty area).

CLAMP TAIL GRIPPER

To remove gripper, loosen set screw in bottom of piston rod head (Figure 6) and tap gripper pivot pin

through access holes in base and remove pin, slide gripper lever off spring loop.

Remove accumulated dirt and debris from the recesses or the teeth with a pointed object or knife

blade. This should be done frequently when pulling plated carbon clamps. Apply Molykote type G-n

or equivalent lubricant to the pivot pin.

JR. CLAMP HEAD

Keep sliding surfaces or the cam and shear hook well lubricated with a thin film of molybdenum

disulfide lubricant such as Molykote G-n lubricant or equivalent.

CUTTER BLADE/BACKING PLATE

Check daily to be certain these are tight. Frequently check both for chipped or broken edges and

replace if these are found. Inspect the lower edge of the cutter blade for sharp edges. If a sharp

edge is found, use a fine grained sharpening or honing stone and lightly stone the lower edges to a

smooth radius (Figure 7).

BAND-IT-IDEX, Inc.

A Unit of IDEX Corporation

4799 Dahlia Street

Denver, CO 80216-0307 USA

P: 1-800-525-0758

F: 1-800-624-3925

Figure 7 – Cutter Blade Edge

www.BAND-IT-IDEX.com

Page 16 of 34

USE A FINE STONE AND WHET

A RADIUS ON THIS EDGE SO IT

DOES NOT SCRAPE

FINGERNAIL

Document # S41067 rev. H

© Copyright

BAND-IT-IDEX, Inc. 2010

All rights reserved

Page 17

Maintenance

S35099

Summary

COMPONENT

Cutter Blade and

Backing Plate

Clamp Tail Gripper

Cam Contact

Surface

Filter 6 months Check for accumulation of dirt.

Lubricator

FREQUENCY

2,000 clamps

2,000 clamps

2,000 clamps

Daily

pulled

pulled

pulled

CHECK

Check to see if blade is loose.

Look for broken or chipped

edge. Feel lower edge for

sharp edge.

Check for build up of foreign

material in teeth.

Observe surface for lubricant.

Check lubricant level. Observe

for contaminated or discolored

lubricant.

Automatic Air Tool

ACTION

Tighten screws and replace

if necessary. With stone,

hone edge of cutter blade

round (figure 7).

Remove and clean with

pointed object or knife blade.

Lubricate with molybdenum

disulfide grease such as

Molykote G-n.

Clean with soap and warm

water.

Refill to fill level with DTE 24

hydraulic oil. If needed, drain

and clean lubricator with

soap and warm water before

refilling.

Air Exhaust Mufflers

(5)

Cylinders (2) Yearly

Cam Roller 6 months

Clamp Head 6 months

Trip Plate 6 months

6 months Look for build up of dirt.

Check for accumulation of dirt

on piston rod cylinders.

Clean surface of roller and

wipe away excess lubricant.

Check for loose mounting

screws.

Clean to remove dirt, debris,

etc.

Remove and clean with nonflammable degreaser such

as Gunk.

Clean with soap and warm

water.

Lubricate with SAE 30 oil.

Tighten mounting screws.

Apply Molykote G-n or

equivalent.

BAND-IT-IDEX, Inc.

A Unit of IDEX Corporation

4799 Dahlia Street

Denver, CO 80216-0307 USA

P: 1-800-525-0758

F: 1-800-624-3925

www.BAND-IT-IDEX.com

Page 17 of 34

Document # S41067 rev. H

© Copyright

BAND-IT-IDEX, Inc. 2010

All rights reserved

Page 18

S35099

Troubleshooting

Automatic Air Tool

GENERAL

This section contains information on problems that may possibly occur and the corrections to be

made to restore the tool to proper operating condition. When using this clamp application tool,

problems can occur with the tool or with the clamp being assembled. The guidelines shown and

attention by the tool operator will result in identifying the problem so a timely correction can be made.

PROBLEM OBSERVATION CORRECTION

1) Clamp tail breaks

during pull up.

2) Clamp pulls

satisfactorily but

does not lock

properly.

3) Foot control

leakage.

- Knife-like edge on tail, edge of band

on clamp is scarred and heavily

scraped, deposits of metal on

underside of tail at buckle edge.

- Tail is broken at 45° angle and/or

section thinned at break.

- Tail breaks during pull-up.

- Band-It Jr. lock is formed but pulls

through buckle.

- Air exhausts through exhaust port

when tool is not being operated.

- Cutter blade broken, replace.

Cutter blade has sharp edge, remove sharp

edge.

- Pull up pressure set too high, reduce

pressure.

- Check hold pressure and reduce to

recommended level. Roll up is being

attempted before pressure has dropped

below recommended PSI. Operator should

wait for pressure to drop or decrease the

holding cycle time (see operating

instructions).

- Check hold pressure and reduce for

maximum level recommended for clamp

width and material

- Clamp may have been rolled up at a higher

pressure than recommended. Operator

should wait for pressure to drop or decrease

the holding cycle time (see operating

instructions).

- Disconnect tubes L and B at cylinder end.

Check each port for any air exhaust or faulty

cylinder seals and repair.

4) Tool operation is

erratic, especially

when tool is

resetting.

BAND-IT-IDEX, Inc.

A Unit of IDEX Corporation

4799 Dahlia Street

Denver, CO 80216-0307 USA

P: 1-800-525-0758

F: 1-800-624-3925

- Pull cylinder is jerky during return.

- Tool makes stuttering noises as air

exhausts from the cylinder(s).

www.BAND-IT-IDEX.com

Page 18 of 34

- Check for debris under foot control valve

pedal, or check to see that the valve is

operated fully when pedal is depressed.

Document # S41067 rev. H

© Copyright

BAND-IT-IDEX, Inc. 2010

All rights reserved

Page 19

S35099

Troubleshooting

PROBLEM

5) Clamp pulls jerky.

Clamp may or

may not lock.

6) Clamp tail slipping

in clamp tail

gripper.

7) Clamp tail cannot

be inserted into

tool.

- Motion during pull up is erratic and

sticky, but the edges of the band on

the clamp are not scarred.

-The object being clamped may be

held in a twist while the clamp is

being tightened.

-The object being clamped is heavy or

has downward pressure on it.

- Clamp pulls and locks satisfactorily

but tail is sliding or scraping in clamp

tail gripper.

- Cycle tool and observe that the

gripper lever tail moves as the piston

rod returns to contact the clamp

head.

OBSERVATION

Automatic Air Tool

CORRECTION

- Check clamp pull pressure and increase

pressure if pull is below maximum

recommended pressure.

- Straighten/support the object and keep as

level as possible. Lift the object or support it

so the buckle is straight with the clamp tail.

- Check to see if the band gripper pin has

loosened and is dragging on the sides of the

base. Relocate and tighten set screw if it is

loose (fig. 6).

- Pull up cylinder may need lubrication.

Check the lubricator for oil and to see if the

lubricator is working properly. Add oil and

correct the setting and cycle the tool a

number of times to lubricate the cylinder

prior to resuming operation.

- Remove the clamp tail gripper and clean the

teeth. Observe for flattened teeth. If found,

gripper should be replaced. Note that

chipped teeth may hold band satisfactorily

and use is not detrimental, but a

replacement gripper should be ordered.

- Tripper plate may be stuck due to dirt or lack

of lubricant. Clean and relubricate the plate.

- Gripper level not opening. Tripper plate may

be broken or binding. Disassemble gripper

lever and/or tripper plate and clean or

replace defective item (fig. 6).

8) Clamp tail is

crumpled or

trapped as the

tool resets.

BAND-IT-IDEX, Inc.

A Unit of IDEX Corporation

4799 Dahlia Street

Denver, CO 80216-0307 USA

P: 1-800-525-0758

F: 1-800-624-3925

- Tail is caught in the tool instead of

being ejected back through or below

the clamp head.

www.BAND-IT-IDEX.com

Page 19 of 34

- Operate the tool and KEEP THE FOOT

CONTROL VALVE PEDAL DEPRESSED.

Reach under piston rod and locate the band

gripper lever. Rotate the lever toward the

clamp head and allow the tail to fall out of

the tool. If the tail does not fall out, use

pliers to grasp the clamp tail and remove it.

Release foot control valve pedal. NEVER

position your fingers anywhere but on the

gripper lever and keep the foot control valve

depressed.

Document # S41067 rev. H

© Copyright

BAND-IT-IDEX, Inc. 2010

All rights reserved

Page 20

S35099

Troubleshooting

PROBLEM

9) Tool doesn’t cut

off clamp.

10) Tool never

reaches the

selected pull

pressure. Tool

operation may

be erratic in this

portion of the

cycle.

11) Tool takes

excessive time

for clamp pullup.

12) Tool does not

tighten clamps

- Cut-off cylinder stalls and does not

cut off clamp tail.

- Clamp tail bends and allows tool to

force buckle past cutter blade edge.

- Pressure observed increases, then

drops rapidly and jumps back up to a

higher pressure.

- Tool cycles to start the clamp holding

cycle before selected pressure is

observed on gauge.

- Tool pulls the clamp and reaches the

selected holding pressure, then the

operator waits before the tool

operates to the holding and cut-off

cycle.

- Selection of higher clamp pull

pressure does not result in tighter

clamps. Excessive amount of air is

exhausting from the quick-exhaust

valve.

OBSERVATION

Automatic Air Tool

CORRECTION

- Check for loose or broken cutter blade.

Tighten screws if loose. Replace cutter

blade if broken.

- Reset clamp hold pressure to recommended

pressure.

- If air line supply pressure is below 100 PSI,

stop operation and correct or allow pressure

to rise above 100 PSI.

- Check cut-off cylinder air cushion valve (fig.

14). It might be screwed in too deep.

- Cut-off cylinder piston seals leak. Loosen

nut off of tube Q. If air is still escaping

remove cylinder and replace seals.

- Cut-off cylinder piston rod may be binding.

Shut off air supply and remove tubes B and

Q and operate piston rod by hand to see if it

moves freely. If not, check back-up roller for

.010” clearance or remove cylinder.

- Lubricate between shear hook and cut-off

cam.

- Increase the clamp pull cycle time to allow

the tool to regulate to the selected pressure.

- Air line pressure may be lower than the

selected pressure. Check and correct.

- Check the system for an air leak.

- Decrease the clamp pull cycle time (fig. 4).

- Check for air system leak. Tighten or

replace defective items.

- Pull cylinder seal may be leaking. Operate

tool to stall the cylinder. Remove tube N and

if air is escaping, disassemble pull cylinder

and repair.

- Check to see if gripper level pin is dragging

on the base. Reposition and retighten the

set screw that retains the pin (fig 6).

BAND-IT-IDEX, Inc.

A Unit of IDEX Corporation

4799 Dahlia Street

Denver, CO 80216-0307 USA

P: 1-800-525-0758

F: 1-800-624-3925

www.BAND-IT-IDEX.com

Page 20 of 34

Document # S41067 rev. H

© Copyright

BAND-IT-IDEX, Inc. 2010

All rights reserved

Page 21

S35099

Troubleshooting

PROBLEM

13) Tool takes

excessive time

prior to actuation

of cut-off cylinder.

14) Tool does not

read clamp hold

pressure

selected.

- Tool reaches clamp hold pressure

selected and operator must wait a

second or more before cut-off cylinder

actuates.

- Cut-off cylinder actuates before the clamp

hold pressure selected shows on the

gauge.

- Pressure drops below desired pressure

and regulates at a lower pressure.

- Pressure never regulates.

OBSERVATION

Automatic Air Tool

CORRECTION

- Decrease the actuation time for the cut-off

cylinder (fig. 5).

- Time delay valve may be clogged. Remove

needle valve and observe. If dirty, remove valve,

disassemble and clean.

- Cut-off valve may be sticking. Remove cut-off

valve, disassemble and clean or replace (fig. 5).

- Increase the actuation time for the cut-off

cylinder.

- Increase the clamp hold pressure.

- Adjust valve. If no response, replace hold

pressure valve.

BAND-IT-IDEX, Inc.

A Unit of IDEX Corporation

4799 Dahlia Street

Denver, CO 80216-0307 USA

P: 1-800-525-0758

F: 1-800-624-3925

www.BAND-IT-IDEX.com

Page 21 of 34

Document # S41067 rev. H

© Copyright

BAND-IT-IDEX, Inc. 2010

All rights reserved

Page 22

S35099

Repair Parts

GENERAL

This tool is designed and manufactured to require minimal maintenance and to have a long life.

However, certain parts may require periodic replacement due to normal wear. Replacement of these

items will enable keeping the tool operating to its peak efficiency. The part lists shows all parts that

may be required to repair the tool.

HOW TO ORDER REPAIR PARTS

This parts list is grouped into major sub-assembly sections of the tool. Components that also can be

repaired are shown in their respective sections. Locate the part needed on the drawings and observe

the number attached to it, match this number with "ITEM" on repair parts list. Order the parts using

the six-digit part number and complete description shown on the repair parts list. Should a serial

number be required, find the serial number of the tool on the nameplate located on the exterior of the

front panel in the lower left-hand corner (Fig. 8). It is recommended that the serial number

information be supplied on all repair part orders. Submit the order to your BAND-IT distributor or

representative for processing. Note that some parts have part numbers marked on the parts, this

information may be helpful in assuring that the correct part is ordered, but always consult the repair

parts list and supply all the information as suggested in this section. It is recommended that items

such as nuts, bolts, etc, be purchased locally.

Automatic Air Tool

BAND-IT-IDEX, Inc.

A Unit of IDEX Corporation

4799 Dahlia Street

Denver, CO 80216-0307 USA

P: 1-800-525-0758

F: 1-800-624-3925

Figure 8 – Tool Serial Number Location

www.BAND-IT-IDEX.com

Page 22 of 34

Document # S41067 rev. H

© Copyright

BAND-IT-IDEX, Inc. 2010

All rights reserved

Page 23

S35099

Repair Parts

Automatic Air Tool

ITEM PART NO. QTY. DESCRIPTION

1 S44479 1 HEAD ASSEMBLY, (FIG. 1)

2 S37889 1 CONTROL AIR ASSEMBLY, (FIG. 10)

3 S34787 1 CHASSIS, WELDED

4 S37987 1 BRACKET, BASE MOUNTING

5 S38087 1 BRACKET, L-TOP

6 S38277 1 DECAL, CLAMP HOLD AND PULL CONTROL

7 S38377 1 DECAL, CLAMP HOLD

8 S38477 1 DECAL, CLAMP PULL

9 S31788 1 DECAL, NAMEPLATE AND SERIAL NO.

10 S38587 1 CLIP, SINGLE HOSE

11 S38687 1 CLIP, SINGLE VALVE

12 S38787 1 CLIP, DOUBLE HOSE

13 H66088 2 SCREW, HEX HD, 1/4-20 X 1.00

14 S32687 4 SCREW, SOC HD, 1/4-20 X 1.75

15 S33787 4 SCREW, SOC HD, 1/4-20 X 2.50

16 J90987 8 SCREW, SOC HD, 5/16-18 X 0.88

17 S25087 3 SCREW, SOC HD, NYLON PATCH, 1/4-20 X 0.63

18 S32887 27 WASHER, FLAT, 0.22 ID X 0.63 OD X 0.06

19 S33987 8 WASHER, FLAT, 0.34 ID X 0.69 OD X 0.06

20 R00622 1 PAD, RUBBER, 2 X 5 X 0.75

21 S26387 11 WASHER, LOCK, 0.25

22 J66587 8 WASHER, LOCK, 0.31

23 A93087 4 SCREW, FLAT HD, SOC #10-32 X 0.75

24 S32787 10 NUT, HEX, 1/4-20

25 G92188 4 NUT, HEX, 5/16-18

26 S26587 4 LOCKNUT, NYLON INSERT #10-32 UNF

27 S27587 2 SCREW, SHEET METAL, #8

28

29 S39079 1 PANEL, SIDE, SLOTTED

30 S36387 8 U-TAP CLIP, #10-24

31 S39087 1 PANEL, SIDE, PLAIN

32 P06486 2 DECAL, BAND-IT LOGO

33 J65387 8 SCREW, SOC. HD, NYLON PATCH, #10-24 X 0.50

34 S26079 1 HEAD ASSEMBLY, JR CLAMP, (FIG. 13)

35 S31589 1 LUBRICATING OIL AND BOTTLE ASSY (NOT SHOWN)

36 S41185 4 NUT, CLIP-ON, 5/16-18

37 S42487 1 DECAL, FILTER-LUBRICATOR

BAND-IT-IDEX, Inc.

A Unit of IDEX Corporation

4799 Dahlia Street

Denver, CO 80216-0307 USA

P: 1-800-525-0758

F: 1-800-624-3925

www.BAND-IT-IDEX.com

Page 23 of 34

Document # S41067 rev. H

© Copyright

BAND-IT-IDEX, Inc. 2010

All rights reserved

Page 24

S35099

Repair Parts

Automatic Air Tool

BAND-IT-IDEX, Inc.

A Unit of IDEX Corporation

4799 Dahlia Street

Denver, CO 80216-0307 USA

P: 1-800-525-0758

F: 1-800-624-3925

Figure 9 – Tool Assembly

www.BAND-IT-IDEX.com

Page 24 of 34

Document # S41067 rev. H

© Copyright

BAND-IT-IDEX, Inc. 2010

All rights reserved

Page 25

Repair Parts

S35099

Automatic Air Tool

BAND-IT-IDEX, Inc.

A Unit of IDEX Corporation

4799 Dahlia Street

Denver, CO 80216-0307 USA

P: 1-800-525-0758

F: 1-800-624-3925

Figure 9 – Tool Assembly (cont.)

www.BAND-IT-IDEX.com

Page 25 of 34

Document # S41067 rev. H

© Copyright

BAND-IT-IDEX, Inc. 2010

All rights reserved

Page 26

Repair Parts

S35099

Automatic Air Tool

ITEM PART NO. QTY DESCRIPTION

1 S31689 1 FILTER/LUBRICATOR ASSEMBLY

1 *FILTER

1 *LUBRICATOR

2 *QUIKCLAMP WALL MOUNT

3 *QUIKCLAMP

2 *1/4” PIPE ADAPTOR

2 *PORTING BLOCK

4 *PLUG

2 S35587 1 VALVE, FOOT OPERATED

1 *BODY KIT (SPOOL O-RINGS,

BUMPERS, PILOT O-RINGS,

MANIFOLD O-RINGS)

3 S35687 1 GUARD, FOOT

4 S28787 2 VALVE, TIME DELAY

1 *SERVICE KIT (AIR CAP GASKET,

VALVE HEAD GASKET, BLOCK

REPACKING, ADJ SCREW ORINGS, 2 END PLUG O-RINGS, 4

PISTON O-RINGS)

5 S35787 2 VALVE, AIR OPERATED

6 S35887 1 VALVE, PULL/TENSION

REGULATOR

7 S10287 1 VALVE, HOLD TENSION RELIEF

8 S35987 2 NUT, RING PANEL MOUNT

9 S36087 1 VALVE, CHECK

10 S41799 1 QUICK EXHAUST VALVE AND

MUFFLER KIT

11 S36287 2 GAUGE, PRESSURE, 0-100 PSI

12 S36487 3 CONNECTOR, FEMALE

13 S36587 2 CONNECTOR, MALE

14 S36687 9 CONNECTOR, MALE

15 S36787 2 ELBOW, MALE 90°

16 S36887 6 ELBOW, MALE 90°

17 S36987 1 ELBOW, MALE 90°

18 S37087 2 ELBOW, MALE 90°

19 S37187 1 TEE, MALE RUN

20 S37287 3 TEE, MALE BRANCH

* For replacement of these items and their

component parts, purchase directly from the

manufacturer or its distributor(s).

** Individual tubes do not have unique part

numbers. These tubes may be cut to length

shown from a bulk roll of tubing. The part

number to be ordered is shown as item 46.

Customers must order the number of feet

desired. A 29-foot roll is required to replace all

the tubing in one tool.

ITEM PART NO. QTY DESCRIPTION

21 S37387 2 NIPPLE, HEX

22

23 S37587 1 CROSS, FITTING

24 S11787 4 MUFFLER AIR EXHAUST

26 S37689 3 HOSE ASSY., FOOT OPERATED

VALVE

27 S30587 2 LETTER, TUBE I.D. (CARD W/

ALL LETTERS REQUIRED)

28 NSS** 1 TUBE “A” 3/8 OD X 28” LONG

29 NSS** 1 TUBE “B” 3/8 OD X 28” LONG

30 NSS** 1 TUBE “C” 3/8 OD X 15” LONG

31 NSS** 1 TUBE “D” 3/8 OD X 18” LONG

32 NSS** 1 TUBE “E” 3/8 OD X 12” LONG

33 NSS** 1 TUBE “F” 3/8 OD X 19” LONG

34 NSS** 1 TUBE “G” 3/8 OD X 19” LONG

35 NSS** 1 TUBE “H” 3/8 OD X 28” LONG

36 NSS** 1 TUBE “I” 3/8 OD X 19” LONG

37 NSS** 1 TUBE “J” 3/8 OD X 19” LONG

38 NSS** 1 TUBE “K” 3/8 OD X 15” LONG

39 NSS** 1 TUBE “L” 3/8 OD X 33” LONG

40 NSS** 1 TUBE “M” 3/8 OD X 33” LONG

41 NSS** 1 TUBE “O” 3/8 OD X 18” LONG

42 NSS** 1 TUBE “P” 3/8 OD X 18” LONG

43 NSS** 1 TUBE “Q” 3/8 OD X 10” LONG

44 NSS† --- COMPOUND, TELFLON FIL.

SEALANT

45 NSS‡ --- COMPOUND, MED. LOCKING

(BLUE)

46 S37787** 1 TUBE, POLYETHYLENE 3/8 OD

47 S39687 1 TEE, MALE BRANCH, 1/4 NPT

48 S41987 1 GAUGE PRESSURE PANEL

MOUNT

49 S40787 1 ASSEMBLY, DRAIN TUBE

50 NSS** 1 TUBE “R”, 3/8 OD X 12” LONG

51 S25487 1 ELBOW, 90° STREET, 1/4 NPT

52 G00689 4 SWIVEL UNION, 1/4” M X F

† Use Teflon filled sealant such as Loctite 592 or

equivalent, manufactured by Loctite Corp.,

Newington, Connecticut, 06111. Purchase locally.

‡ Use a medium strength sealing compound such as

Loctite 242 or equivalent, manufactured by Loctite

Corp., Newington, Connecticut, 06111. Purchase

locally.

NSS – Items not sold separately for repair.

BAND-IT-IDEX, Inc.

A Unit of IDEX Corporation

4799 Dahlia Street

Denver, CO 80216-0307 USA

P: 1-800-525-0758

F: 1-800-624-3925

www.BAND-IT-IDEX.com

Page 26 of 34

Document # S41067 rev. H

© Copyright

BAND-IT-IDEX, Inc. 2010

All rights reserved

Page 27

Repair Parts

S35099

Automatic Air Tool

BAND-IT-IDEX, Inc.

A Unit of IDEX Corporation

4799 Dahlia Street

Denver, CO 80216-0307 USA

P: 1-800-525-0758

F: 1-800-624-3925

Figure 10 – Control Air System

www.BAND-IT-IDEX.com

Page 27 of 34

Document # S41067 rev. H

© Copyright

BAND-IT-IDEX, Inc. 2010

All rights reserved

Page 28

Repair Parts

ITEM PART NO. QTY DESCRIPTION

1 S45479 1 CYLINDER ASSEMBLY, PULL-UP

(SEE PULL-UP CYLINDER PARTS LIST)

2 S22687 1 SPACER, MOUNTING BRACKET

3 J66587 2 WASHER, LOCK, 5/16 I.D.

4 S24787 2 SCREW, CAP, SOC. HD, 5/16-18 X 3-1/2

5 S26287 4 WASHER, LOCK, 1/2 I.D.

6 S25287 4 SCREW, CAP, SOC HD, 1/2-13 X 1

7 S43687 1 BRACKET, MOUNTING, MACHINED

8 S22487 1 CYLINDER, CUT-OFF

(SEE CUT-OFF CYLINDER PARTS LIST)

9 S52488 1 CAM, CUT-OFF

10 S22878 1 BLOCK, SUPPORT, CAM ROLLER

11 S43387 3 SCREW, CAP, SOC. HD, 1/4-20 X 1

12 S26387 3 WASHER, LOCK, 1/4 I.D.

13 S44187 1 COVER, FRONT

14 S23987 - SHIM, CAM ROLLER (QTY MAY VARY)

15 S22787 1 ROLLER CAM

16 S22987 1 PIN, CAM ROLLER

17 NSS * LUBRICANT, MOLYBDENUM DISULFIDE

18 S34987 1 HANDLE, CARRYING

19 S18387 2 WASHER, LOCK, #10

20 J91587 2 WASHER, FLAT, 7/32 X 1/2 X 1/16

21 J64987 2 SCREW, CAP. SOC. HD, #10-32 X 3/4

22 S42987 - SHIM, CAM ROLLER (QTY MAY VARY)

S35099

Automatic Air Tool

* Use a multi-purpose, heavy-duty lubricant

paste such as Molykote G-n paste as

manufactured by Dow Corning Corporation,

Midland, Michigan 48640, or equivalent.

Purchase locally.

NSS – Items not sold separately for repair.

BAND-IT-IDEX, Inc.

A Unit of IDEX Corporation

4799 Dahlia Street

Denver, CO 80216-0307 USA

P: 1-800-525-0758

F: 1-800-624-3925

www.BAND-IT-IDEX.com

Page 28 of 34

Document # S41067 rev. H

© Copyright

BAND-IT-IDEX, Inc. 2010

All rights reserved

Page 29

Repair Parts

S35099

Automatic Air Tool

BAND-IT-IDEX, Inc.

A Unit of IDEX Corporation

4799 Dahlia Street

Denver, CO 80216-0307 USA

P: 1-800-525-0758

F: 1-800-624-3925

Figure 11 – Tool Head Assembly

www.BAND-IT-IDEX.com

Page 29 of 34

Document # S41067 rev. H

© Copyright

BAND-IT-IDEX, Inc. 2010

All rights reserved

Page 30

Repair Parts

ITEM PART NO. QTY DESCRIPTION

1 J67687 12 NUT, HEX, 3/8-24

2 NSS * COMPOUND, HIGH STRENGTH

3 S47987 1 COVER ASSEMBLY, REAR

4 S44987 1 BOLT, HEX HD, 1/2-13 X 2-1/2

5** S45587 1 O-RING, 1/2 DIA

6 S44687 1 PISTON, CYLINDER

7 J63287 1 O-RING, PISTON

8 J60787 1 TUBE, CYLINDER

9 J62187 6 BOLT, CYLINDER TIE

10 J63187 1 O-RING, PISTON ROD

11 S21877 1 HEAD, FRONT PULL-UP CYLINDER

12 J66687 2 GASKET, CYLINDER

13 S45687 1 WASHER, FLAT, 17/32 ID X 1-1/16

14 J90987 6 SCREW, CAP. SOC. HD, 5/16-18 X

15 S45389 1 PISTON ROD ASSY (USES ITEMS

16 S44887 1 SPACER, STROKE LIMITING

(RED)

CYLINDER

OD

7/8

27 THRU 30)

S35099

Automatic Air Tool

ITEM PART NO. QTY DESCRIPTION

17 S21587 1 PIN, CLAMP TAIL GRIPPER

18 S45087 1 PLATE, CLAMP TAIL GRIPPER

19 S45186 1 GRIPPER, CLAMP TAIL

20 S21789 1 BASE, TOOL

21 S52687 1 SPRING, CLAMP TAIL GRIPPER

22 J64887 1 SCREW, SET, SOC HD, #10-32 X

23 NSS † LUBRICANT, MOLY PASTE

24 S44787 1 ROD, PISTON

25 NSS †† COMPOUND, MEDUIM LOCKING,

26 NSS †††

27 J66487 1 PIN, CLAMP TAIL GRIPPER

28 J65487 1

29 J61187 1 PIN, 1/8 X 1 3/8 SPRING

30 J67287 1 SCREW, CAP. SOC. HD. 1/4-28 X

31 J61967 1 PLATE, ROD GUIDE

32 S69587 2 SCREW, BUTTON HD, #10-32 X

TRIP

RETURN

3/16

(BLUE)

COMPOUND, GASKET AND

SEALING (BOTH SIDES OF

GASKET)

BACKUP

SCREW, SET, SOC. HS, 5/16-24 X

3/8

1/2

3/8

For replacement of these items and their component parts, purchase directly from the

manufacturer or its distributor(s).

* Use a high strength compound such as Loctite 271 or equivalent, manufactured by Loctite

Corp., Newington, Connecticut, 06111. Purchase locally.

** Denotes components of S795 Seal Kit.

† Use a multi-purpose, heavy-duty lubricant paste such as Molykote G-n paste as

manufactured by Dow Corning Corporation, Midland, Michigan 48640, or equivalent.

Purchase locally.

†† Use a medium strength sealing compound such as Loctite 242 or equivalent, manufactured

by Loctite Corp., Newington, Connecticut, 06111. Purchase locally.

††† Use a pliable non-hardening paste type compound such as Permatex Form-A-Gasket #2

or equivalent, manufactured my Permatex Company, Inc. Kansas City, Kansas, 66115.

Purchase locally.

NSS – Items not sold separately for repair.

BAND-IT-IDEX, Inc.

A Unit of IDEX Corporation

4799 Dahlia Street

Denver, CO 80216-0307 USA

P: 1-800-525-0758

F: 1-800-624-3925

www.BAND-IT-IDEX.com

Page 30 of 34

Document # S41067 rev. H

© Copyright

BAND-IT-IDEX, Inc. 2010

All rights reserved

Page 31

Repair Parts

S35099

Automatic Air Tool

Figure 12 – Pull-Up Cylinder Assembly

BAND-IT-IDEX, Inc.

A Unit of IDEX Corporation

4799 Dahlia Street

Denver, CO 80216-0307 USA

P: 1-800-525-0758

F: 1-800-624-3925

www.BAND-IT-IDEX.com

Page 31 of 34

Document # S41067 rev. H

© Copyright

BAND-IT-IDEX, Inc. 2010

All rights reserved

Page 32

Repair Parts

S35099

Automatic Air Tool

ITEM PART NO. QTY DESCRIPTION

1 S51287 1 HEAD, FINISHED, JR. AIR TOOL

*2 J85785 1 BLADE, CUTTER FINISHED

*3 J85688 1 PLATE, BACKING, FINISHED

4 S25887 1 SHEAR HOOK, FINISHED, JR.

AIR TOOL

5 S43987 2 KEY, SUPPORT, FIN. JR. AIR

TOOL

6 S43887 1 PLATE, SUPPORT, FIN. RIGHT

7 S43797 1 PLATE, SUPPORT, FIN. LEFT

*Order J93099 cutter blade kit. Not

available separately.

ITEM PART NO. QTY DESCRIPTION

8 S17287 1 SPRING, COMP, .240 DIA X .688

9 J90887 1 PIN, PIVOT, FINISHED

10 S24987 6 SCREW, CAP, 5/16-18 X 1-1/4

11 J66587 6 WASHER, LOCK, 5/16 ID

12 S39487 2 NUT, HEX JAM, 5/16-18

*13 S44087 2 SCREW, CAP, ¼-28 X 2

14 S44387 --- SHIM, MOUNTING, FINISHED (EST 6

REQ.)

BAND-IT-IDEX, Inc.

A Unit of IDEX Corporation

4799 Dahlia Street

Denver, CO 80216-0307 USA

P: 1-800-525-0758

F: 1-800-624-3925

www.BAND-IT-IDEX.com

Page 32 of 34

Document # S41067 rev. H

© Copyright

BAND-IT-IDEX, Inc. 2010

All rights reserved

Page 33

Repair Parts

S35099

Automatic Air Tool

ITEM PART NO. QTY DESCRIPTION

1 G92189 4 NUT, HEX, 5/16-18

3 J66587 4 WASHER, LOCK, 5/16 ID

6 S33987 4 WASHER, FLAT, .341 ID X .69 OD X .06 THICK

7 S35089 1 TOOL ASSEMBLY, AUTOMATIC AIR

8 S38987 1 BOX, S350 SHIPPING ASSEMBLED

9 S39587 4 BOLT, ROUND HEAD, SQ. NECK, 5/16-18

With side panels of item 7 removed, mount baseboard from item 8 onto the base of item 7

using items 1,3,6,9 (see DETAIL A).

Mount side panels onto item 7.

Place item 7 and the baseboard assembly into bottom lid of item 8. Place the sides and

dividers of the item 8 around item 7 as shown.

Place foot control assembly of item 7 in right front side pocket with pedal end down and base

facing outward. Put rubber hose to the side and front of air tool, between divider and side

box.

BASE BOARD

NYLON

STRAP

DETAIL A

ENLARGED

BAND-IT-IDEX, Inc.

A Unit of IDEX Corporation

4799 Dahlia Street

Denver, CO 80216-0307 USA

P: 1-800-525-0758

F: 1-800-624-3925

www.BAND-IT-IDEX.com

Page 33 of 34

Document # S41067 rev. H

© Copyright

BAND-IT-IDEX, Inc. 2010

All rights reserved

Page 34

Repair Parts

S35099

Automatic Air Tool

SEE

DETAIL A

BAND-IT-IDEX, Inc.

A Unit of IDEX Corporation

4799 Dahlia Street

Denver, CO 80216-0307 USA

P: 1-800-525-0758

F: 1-800-624-3925

Figure 14 – Boxed Tool Assembly

www.BAND-IT-IDEX.com

Page 34 of 34

Document # S41067 rev. H

© Copyright

BAND-IT-IDEX, Inc. 2010

All rights reserved

Loading...

Loading...