Page 1

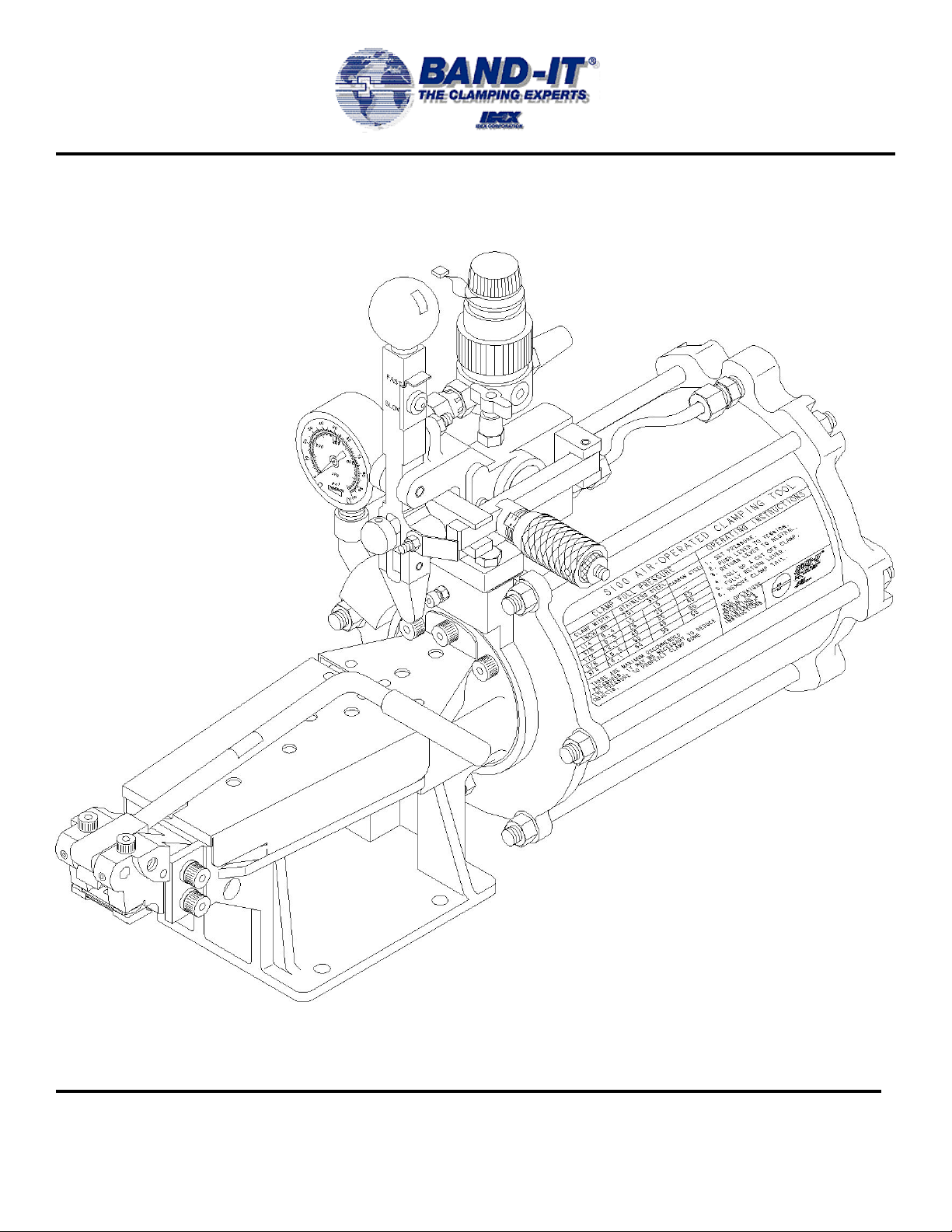

S10099

Classic Air Tool

THE CLASSIC S10099 HAS BEEN

DISCONTINUED AND REPLACED WITH

THE S75099. REPAIR PARTS ARE

LIMITED AND MAY NOT BE AVAILABLE.

CONTACT FACTORY FOR AVAILABILITY.

BAND-IT-IDEX, Inc.

A Unit of IDEX Corporation

4799 Dahlia Street

Denver, CO 80216-3070 USA

P: 1-800-525-0758

F: 1-800-624-3925

www.BAND-IT-IDEX.com

Page 1 of 18

Document # P09287 rev. L

© Copyright

BAND-IT-IDEX, Inc. 2006

All rights reserved

Page 2

Table of Contents

S10099

Classic Air Tool

AIR TOOL SPECIFICATIONS

AIR LINE REQUIREMENTS

SAFETY PROCEDURES 3

INSPECTION AND INSTALLATION 4

MOUNTING TEMPLATE 5

RECOMMENDED OPERATING PRESSURE 6

PULL-UP SPEED CONTROL 7

PRESSURE INDICATOR CALIBRATION 8

HOLDING PRESSURE ADJUSTMENT 9

CLAMP APPLICATION 10

TROUBLESHOOTING 11

3

MAINTENANCE 12

MAINTENANCE CHECK LIST 13

WARRANTY 13

REPAIR PARTS LIST - CYLINDER ASSEMBLY 14

REPAIR PARTS LIST - VALVE ASSEMBLY 15

REPAIR PARTS LIST - JUNIOR CLAMP HEAD 16

OPTION - FILTER/LUBRICATOR 17

OPTION -12° INCLINE BASE 18

BAND-IT-IDEX, Inc.

A Unit of IDEX Corporation

4799 Dahlia Street

Denver, CO 80216-3070 USA

P: 1-800-525-0758

F: 1-800-624-3925

www.BAND-IT-IDEX.com

Page 2 of 18

Document # P09287 rev. L

© Copyright

BAND-IT-IDEX, Inc. 2006

All rights reserved

Page 3

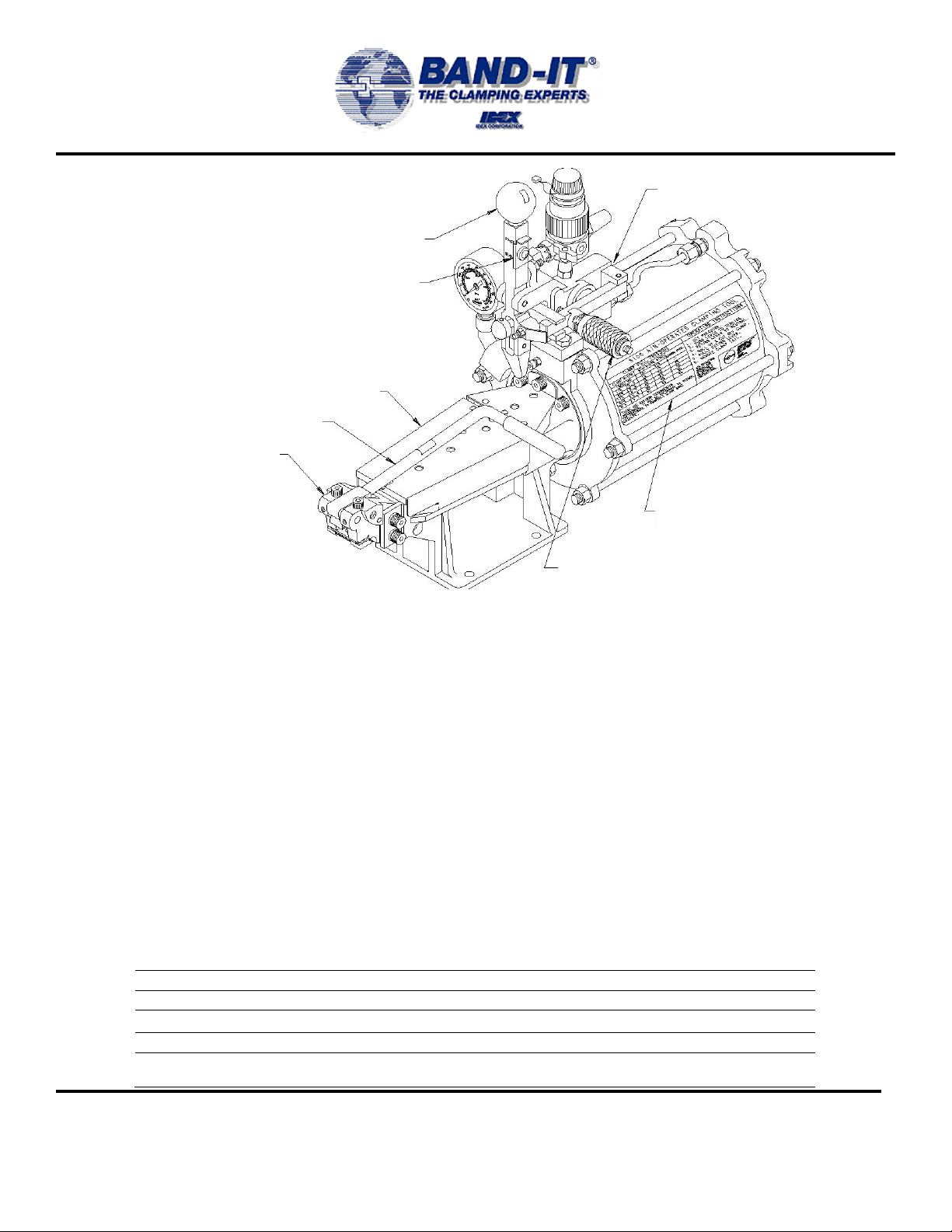

PULL SPEED CONTROL

AIR SUPPLY INLET

Specifications

S10099

and Safety

OVERALL DIMENSIONS: 20 ¼” LONG

9 7/8” WIDE

13 ¼” HIGH

SHIPPING WEIGHT: 42.5 LBS. CONTROL LEVER

SLIDE COVER

CUT OFF HANDLE

JUNIOR CLAMP HEAD

1.

FAMILIARIZE YOURSELF WITH OPERATING

PROCEDURES BEFORE OPERATING THE S10099 AIR

TOOL.

2.

DO NOT OPERATE TOOL WITHOUT SLIDE COVER IN

PLACE.

3.

USE ONLY RECOMMENDED BAND-IT PREFORMED

CLAMPS OR BAND AND BUCKLE WITH THE PROPER

HEAD ASSEMBLY.

4.

DO NOT EXCEED RECOMMENDED PRESSURE SETTINGS.

EXCESS PRESSURE MAY CAUSE SUDDEN CLAMP

FAILURE DURING APPLICATION OR RESULT IN AN

UNSAFE CLAMP. CERTAIN APPLICATIONS MAY REQUIRE

A REDUCED PRESSURE SETTING. SEE PAGE 6 FOR

RECOMMENDED PRESSURE SETTINGS. ALSO SEE PAGE

6 FOR IMPORTANT ADVICE AND WARNINGS.

AIR LINE PRESSURE: 100 PSI MINIMUM, 150 PSI MAXIMUM (7.0 – 10.5 kg/cm2, 689 – 1034 kPa)

CONSUMPTION: 3-5 CFM WITH 20 GALLON TANK MIN.

LINE SIZE: 1/4” ID MINIMUM

CONNECTION: 1/4” NPT

FILTER / LUBRICATOR:

MUST BE ADDED TO AIR SUPPLY. SEE PAGE 18 FOR BAND-IT FILTER /

LUBRICATION KIT

SAFETY PROCEDURES

AIR LINE REQUIREMENTS

5.

ALWAYS KEEP FINGERS CLEAR OF CLAMP DURING

APPLICATION.

6.

DISCONNECT AIR SUPPLY BEFORE SERVICING AIR

TOOL.

7.

TOOL MUST BE FIRMLY MOUNTED (SEE INSTALLATION

INSTRUCTIONS ON PAGE 4).

8.

SAFETY CLASSES OR GOGGLES SHOULD BE WORN

WHEN APPLYING CLAMPS.

9.

ALWAYS KEEP TOOL IN GOOD OPERATING CONDITION.

Classic Air Tool

PRESSURE SETTING

CHART

PRESSURE SETTING CONTROL

BAND-IT-IDEX, Inc.

A Unit of IDEX Corporation

4799 Dahlia Street

Denver, CO 80216-3070 USA

P: 1-800-525-0758

F: 1-800-624-3925

Document # P09287 rev. L

www.BAND-IT-IDEX.com

Page 3 of 18

BAND-IT-IDEX, Inc. 2006

© Copyright

All rights reserved

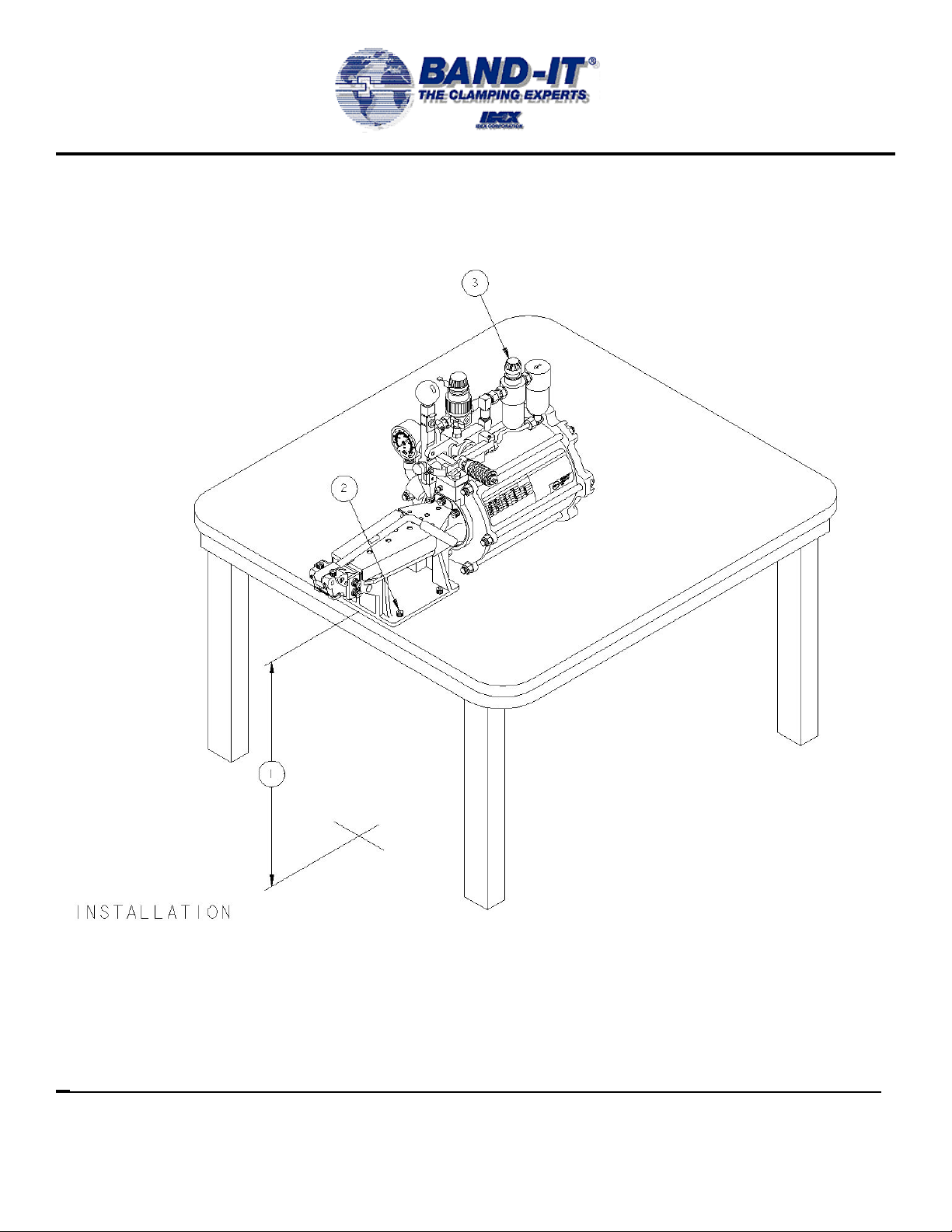

Page 4

Inspection and

S10099

Installation

INSPECTION

WHEN REMOVING AIR TOOL FROM SHIPPING CARTON, CHECK FOR

SHIPPING DAMAGE WHICH SHOULD BE REPORTED TO THE CARRIER.

Classic Air Tool

1. RECOMMENDED TABLE HEIGHT IS 34” TO 40”. THIS IS THE OPTIMUM RANGE FOR APPLYING CLAMPS TO MOST ITEMS.

MAKE SURE THE INSIDE CLEARANCE IS ADEQUATE FOR ITEMS TO BE CLAMPED.

2. THE AIR TOOL MUST BE FIRMLY SECURED TO WORK BENCH. USE 5/16” DIAMETER FASTENING HARDWARE (NOT SUPPLIED

WITH AIR TOOL). AIR TOOL MAY BE MOUNTED ON AN OPTIONAL 12° INCLINE BASE (SEE PAGE 18).

INSTALLATION

3. THE INCOMING AIR SUPPLY MUST COME THROUGH A FILTER/LUBRICATOR, LOCATED NO MORE THAN 30” FROM AIR TOOL

(SEE PAGE 17 FOR BAND-IT FILTER / LUBRICATOR KIT).

USE OF THE S10099 AIR TOOL WITHOUT A FILTER / LUBRICATOR VOIDS THE WARRANTY

BAND-IT-IDEX, Inc.

A Unit of IDEX Corporation

4799 Dahlia Street

Denver, CO 80216-3070 USA

P: 1-800-525-0758

F: 1-800-624-3925

www.BAND-IT-IDEX.com

Page 4 of 18

Document # P09287 rev. L

© Copyright

BAND-IT-IDEX, Inc. 2006

All rights reserved

Page 5

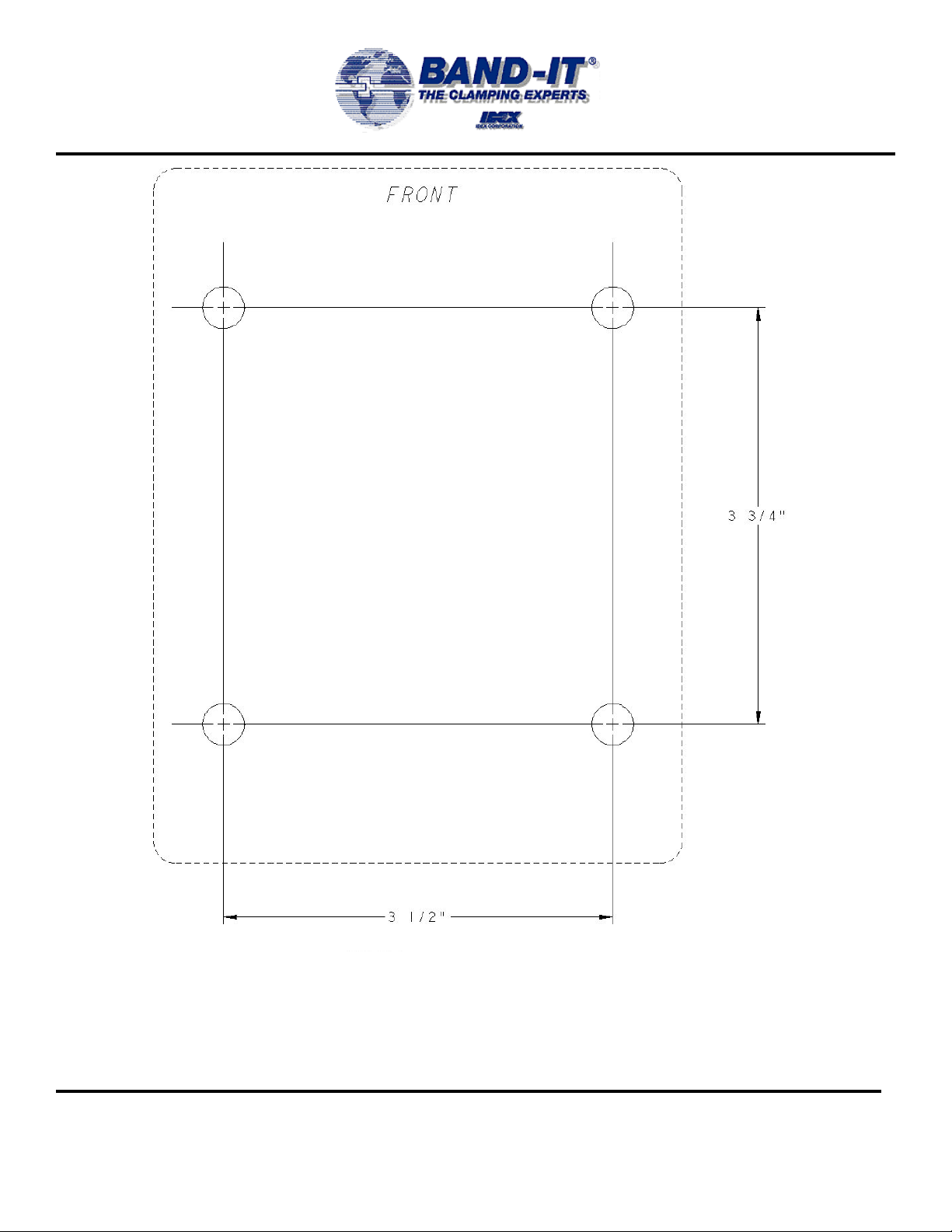

Mounting

S10099

Template

Classic Air Tool

NOTES:

1. AIR TOOL MUST BE FIRMLY SECURED!

2. USE 5/16” FASTENING HARDWARE.

3.

DO NOT USE S10099 AIR TOOL WITHOUT A FILTER / LUBRICATOR

BAND-IT-IDEX, Inc.

A Unit of IDEX Corporation

4799 Dahlia Street

Denver, CO 80216-3070 USA

P: 1-800-525-0758

F: 1-800-624-3925

www.BAND-IT-IDEX.com

Page 5 of 18

Document # P09287 rev. L

BAND-IT-IDEX, Inc. 2006

.

© Copyright

All rights reserved

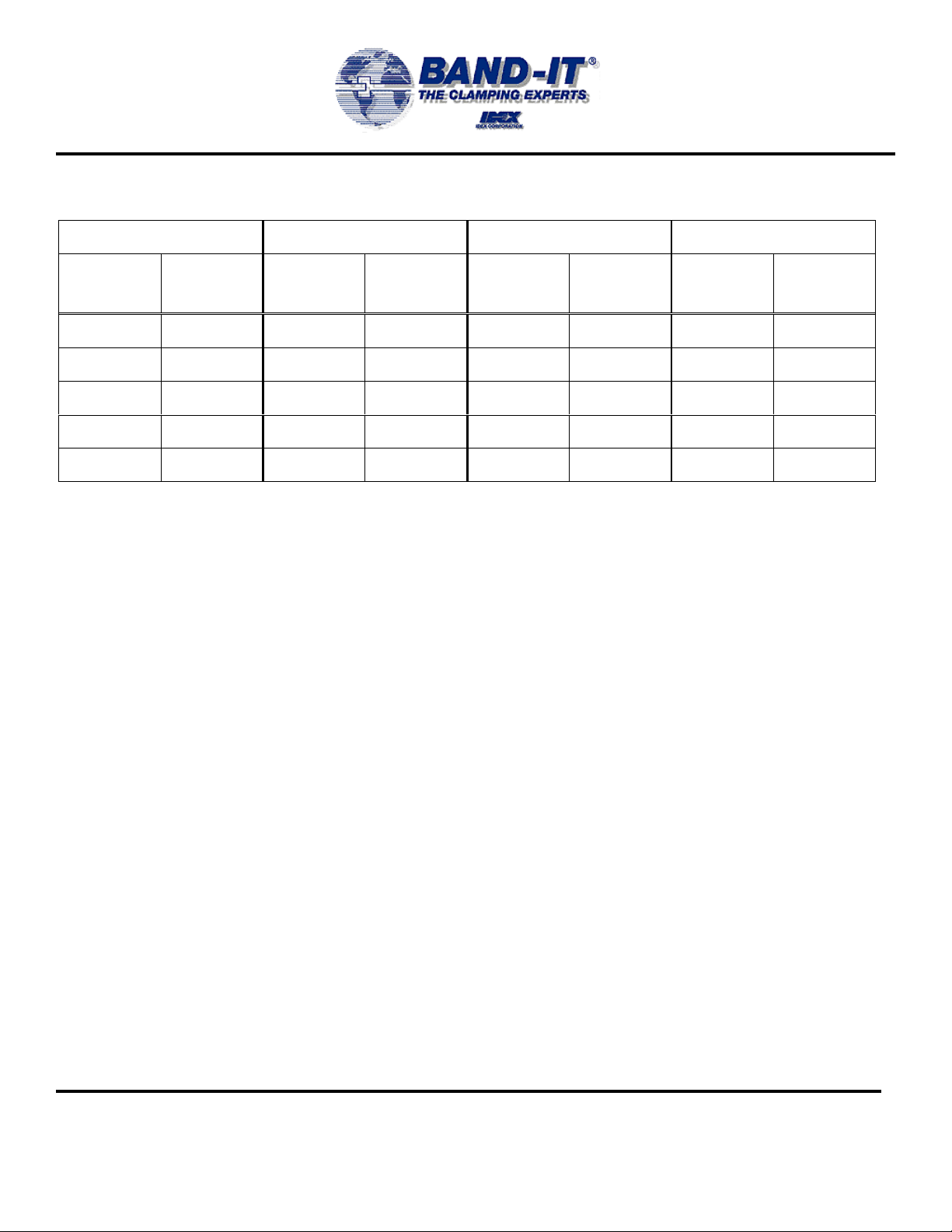

Page 6

Operating

S10099

Pressure

OPERATING PRESSURES SHOWN BELOW ARE IN PSI

CLAMP WIDTH 201 STAINLESS STEEL 316 STAINLESS STEEL CARBON STEEL

INCH mm

1/4” 6.4 15 4 15 4 -- --

3/8” 9.5 25 5 20 5 25 6

1/2” 12.7 40 6 35 6 40 7

5/8” 15.9 50 7 40 7 50 8

3/4” 19.1 60 8 50 8 60 9

NOTES:

THESE ARE RECOMMENDED MAXIMUM PRESSURES FOR BAND-IT JUNIOR® CLAMPS. IT MAY BE NECESSARY TO

REDUCE PRESSURE SETTINGS TO PROPERLY CLAMP SOME OBJECTS.

USE ONLY BAND-IT CLAMPS ON THE AIR TOOL.

PULL UP

PRESSURE

HOLDING

PRESSURE

PULL UP

PRESSURE

HOLDING

PRESSURE

Classic Air Tool

PULL UP

PRESSURE

HOLDING

PRESSURE

IMPORTANT ADVICE AND WARNINGS TO USER.

READ BEFORE APPLYING CLAMPS.

WHEN CLAMPING A HOSE END, REMEMBER THAT A TIGHTER CLAMP KEEPS THE FITTING MORE SECURE, BUT EXCESS

TENSION COULD DAMAGE THE HOSE. FITTING STEM MUST HAVE PROMINENT BARBS FOR PROPER RETENTION INSIDE

THE HOSE, BUT MUST NOT BE SHARP TO PREVENT CUTTING INTO THE HOSE. HOSE, FITTING AND CLAMP MUST BE

COMPATIBLE WITH EACH OTHER AND THE WORKING ENVIRONMENT USED IN. IF IN DOUBT, CONSULT THE HOSE OR

FITTING MANUFACTURER OR CALL BAND-IT.

CLAMPING OBJECTS OTHER THAN HOSE REQUIRE SIMILAR PRECAUTIONS.

CAUTION: IMPROPERLY TIGHTENED CLAMPS MAY RESULT IN DANGEROUS HOSE ASSEMBLIES, WHICH COULD CAUSE

INJURIES OR PROPERTY DAMAGE.

CAUTION: ABUSE OR USE OF A HOSE OUTSIDE THE MANUFACTURER’S RECOMMENDED CONDITIONS MAY CAUSE IT

TO QUICKLY DETERIORATE AND BECOME A SAFETY HAZARD. THIS COULD RESULT IN SERIOUS INJURY OR

PROPERTY DAMAGE. INSPECT AND TEST HOSE ASSEMBLIES FREQUENTLY. REPAIR OR REPLACE AT THE SLIGHTEST

SIGN OF DAMAGE OR DETERIORATION.

BAND-IT-IDEX, Inc.

A Unit of IDEX Corporation

4799 Dahlia Street

Denver, CO 80216-3070 USA

P: 1-800-525-0758

F: 1-800-624-3925

www.BAND-IT-IDEX.com

Page 6 of 18

Document # P09287 rev. L

© Copyright

BAND-IT-IDEX, Inc. 2006

All rights reserved

Page 7

SLOW / FAST SELECTOR

Pull-Up Speed

S10099

Control

VALVE HANDLE

PRESSURE GAUGE

Classic Air Tool

SET SCREW

JAM NUT

BOSS

PULL UP SPEED CALIBRATION

1. START WITH PISTON ROD IN FORWARD POSITION AND SET SCREW WITH JAM NUT ALL THE

WAY BACK (SCREW END FLUSH WITH BOSS). PUT SLOW / FAST SELECTOR ON “SLOW”.

2. SLOWLY PUSH VALVE HANDLE FORWARD UNTIL PISTON GLIDES BACK AND PRESSURE

INDICATES ON THE PRESSURE GAUGE.

3. KEEP HANDLE IN THAT POSITION AND TURN SCREW OUT UNTIL IT CONTACTS THE SURACE OF

THE SLOW / FAST SELECTOR. HOLD SCREW IN POSITION WITH HEX WRENCH AND TIGHTEN

JAM NUT.

4. CHECK CALIBRATION BY CYCLING TOOL ON BOTH SLOW AND FAST PULL UP. OBSERVE THE

DIFFERENCE IN PISTON SPEED.

FOR APPLYING MOST ALL BAND-IT PREFORMED CLAMPS, PULL SPEED CONTROL SHOULD BE IN “UP”

(FAST) POSITION.

CASES WHERE PULL SPEED CONTROL MAY BE USED IN “DOWN” (SLOW) POSITION ARE:

A) WHEN EXACT POSITIONING OF CLAMP IS REQUIRED.

B) FOR APPLYING CLAMPS TO LARGE OR HEAVY AND HARD TO HANDLE HOSE.

C) TRAINING A NEW OPERATOR.

D) IF CLAMPS ARE NOT PULLING SMOOTHLY.

BAND-IT-IDEX, Inc.

A Unit of IDEX Corporation

4799 Dahlia Street

Denver, CO 80216-3070 USA

P: 1-800-525-0758

F: 1-800-624-3925

Document # P09287 rev. L

www.BAND-IT-IDEX.com

Page 7 of 18

BAND-IT-IDEX, Inc. 2006

© Copyright

All rights reserved

Page 8

VALVE HANDLE

ADJUSTING

KNOB

INDICATOR

Pressure Indicator

S10099

Calibration

Classic Air Tool

Figure 1

SLOW / FAST SELECTOR

PRESSURE GAUGE

CALIBRATION SET-UP:

NUMBERS SHOWN ON INDICATOR ARE IN 10 PSI

GRADUATIONS.

EXAMPLE: 7 = 70 PSI 6 = 60 PSI

PRESSURE INDICATOR CALIBRATION SHOULD ALWAYS

BE DONE AT 70 PSI.

USE MIDWAY SPACE BETWEEN EACH GRADUATION

LINE FOR 5 PSI GRADUATION.

WHEN CALIBRATING OR ADJUSTING PRESSURE INDICATOR,

VALVE HANDLE MUST ALWAYS BE IN RETURN POSITION

(PISTON ROD FULLY EXTENDED TO THE FRONT).

SPEED CONTROL SELECTOR MUST BE SET ON “FAST” PULLUP PRIOR TO CALIBRATION (AS SHOWN).

SET SCREW

CALIBRATION PROCEDURE

REFER TO FIGURE 1 FOR IDENTIFICATION OF EACH PART.

LOOSEN SET SCREW AND REMOVE PRESSURE INDICATOR SLEEVE.

TURN ADJUSTING KNOB CLOCKWISE UNTIL THERE IS A 1/8” GAP BETWEEN ADJUSTING KNOB AND INDICATOR AS SHOWN.

ACTUATE VALVE HANDLE TO THE PULL-UP CYCLE AND OBSERVE PRESSURE GAUGE. PRESSURE SHOULD STOP INCREASING

AT 70 PSI.

PULL VALVE HANDLE BACK TO RETURN CYCLE, TURN ADJUSTING KNOB CLOCKWISE OR COUNTERCLOCKWISE TO FINE TUNE

PRESSURE GAUGE TO 70 PSI. (BE SURE TO PULL VALVE HANDLE BACK TO ITS RETURN CYCLE POSITION BEFORE EACH

ADJUSTMENT IS MADE).

SLIDE PRESSURE INDICATOR SLEEVE BACK OVER ADJUSTING KNOB AND INDICATOR. ALIGN TAPERED FRONT EDGE OF

PRESSURE INDICATOR SLEEVE WITHIN THE NUMBER SEVEN (7) GROOVE AND LOCK IT IN PLACE WITH SET SCREW.

ONCE INDICATOR SLEEVE HAS BEEN LOCKED IN PLACE TO ADJUSTING KNOB, BOTH PARTS CAN BE TURNED

COUNTERCLOCKWISE FOR LOWER PRESSURE SETTINGS OR CLOCKWISE TO INCREASE PRESSURE SETTING. WHEN

INCREASING PRESSURE, TURN KNOB PAST REQUIRED PRESSURE SETTING ONE (1) OR TWO (2) TURNS THEN BACK TO

REQUIRED PRESSURE SETTING.

80 PSI SETTING CAN BE ACCOMPLISHED BY TURNING INDICATOR SLEEVE CLOCKWISE ALL THE WAY UNTIL IT COMES TO A

STOP, THEN BACK OFF TWO COMPLETE TURNS.

:

PRESSURE

INDICATOR

SLEEVE

BAND-IT-IDEX, Inc.

A Unit of IDEX Corporation

4799 Dahlia Street

Denver, CO 80216-3070 USA

P: 1-800-525-0758

F: 1-800-624-3925

Document # P09287 rev. L

www.BAND-IT-IDEX.com

Page 8 of 18

BAND-IT-IDEX, Inc. 2006

© Copyright

All rights reserved

Page 9

ADJUSTMENT KNOB

LOCKING RING

VALVE SEAL

VALVE HANDLE

Holding Pressure

S10099

Adjustment

Classic Air Tool

PRESSURE GAUGE

GENERAL:

THE HOLDING PRESSURE REFERS TO THE CONTROLLED PRESSURE IN THE TOOL THAT OCCURS

AFTER THE CLAMP HAS BEEN TENSIONED AND THE CONTROL LEVER HAS BEEN POSITIONED TO THE

NEUTRAL POSITION. IN THIS POSITION, THE PRESSURE IN THE TOOL BLEEDS DOWN FROM THE

PULL PRESSURE TO THE HOLDING PRESURE CONTROLLED BY THE HOLD PRESSURE CONTROL

VALVE. THESE PRESSURES ARE READ ON THE PRESSURE GAUGE.

FOR GENERAL USE, THESE TOOLS ARE SET AT 7 - 8 PSI AT THE FACTORY AND THE ADJUSTMENT IS

SEALED.

ONCE SET, PULL UP PRESSURE HAS BEEN ACHIEVED AND VALVE HANDLE HAS BEEN PUT IN

NEUTRAL POSITION, THE PRESSURE SHOULD DROP RAPIDLY AND THEN REACH SET HOLDING

PRESSURE AND STOP THERE.

THE HOLDING PRESSURE IS READ ON THE GAUGE AND IS THE PRESSURE WHICH SHOULD BE

SHOWING WHEN A JUNIOR PREFORMED CLAMP IS TO BE ROLLED OVER AND CUT OFF.

ADJUSTMENT OF HOLDING PRESSURE:

TO ADJUST THE HOLDING PRESSURE, REMOVE THE SEAL, RELEASE THE WHITE LOCKING RING TO

UNLOCK THE KNOB AND TURN THE VALVE CONTROL KNOB CLOCKWISE AS FAR AS POSSIBLE. SET

THE PULL PRESSURE AT 40 PSI OR HIGHER AND OPERATE THE TOOL (CLAMP NOT REQUIRED).

ALLOW THE TOOL TO REACH THE PULL PRESSURE THEN MOVE THE CONTROL VALVE TO NEUTRAL

POSITION. NOW, SLOWLY TURN THE ADJUSTMENT KNOB COUNTERCLOCKWISE AND YOU HEAR THE

AIR EXHAUST AND OBSERVE THE HOLDING PRESSURE DROP. TURN THE KNOB AS NEEDED TO GET

THE PRESSURE TO THE RECOMMENDED SETTING (PAGE 6). PUSH THE WHITE LOCKING RING DOWN

TO LOCK THE KNOB, NOW THE TOOL IS READY TO USE. IF THE VALVE DOES NOT HOLD THE

PRESSURE, THE VALVE IS DEFECTIVE AND SHOULD BE REPLACED. IT IS RECOMMENDED TO CYCLE

THE TOOL A FEW TIMES AND OBSERVE THAT PRESSURES ALWAYS REACH THE LEVEL SELECTED.

TO OPTIMIZE CLAMP CUT-OFF AND CLAMP LOCKING, IT IS RECOMMENDED THAT THE CLAMP HOLD

PRESSURES (SHOWN ON PAGE 6) BE USED FOR DIFFERENT CLAMP WIDTHS.

BAND-IT-IDEX, Inc.

A Unit of IDEX Corporation

4799 Dahlia Street

Denver, CO 80216-3070 USA

P: 1-800-525-0758

F: 1-800-624-3925

Document # P09287 rev. L

www.BAND-IT-IDEX.com

Page 9 of 18

BAND-IT-IDEX, Inc. 2006

© Copyright

All rights reserved

Page 10

AND PULL CUT OFF HANDLE.

Clamp

S10099

Application

STEP 1

TURN PRESSURE INDICATOR KNOB UNTIL

INDICATOR COINCIDES WITH THE

PRESSURE REQUIRED FOR THAT

PARTICULAR BAND WIDTH AND MATERIAL

TYPE. SEE PAGE 6 OR RIGHT SIDE OF

TOOL CYLINDER FOR RECOMMENDED

PRESSURE SETTINGS.

STEP 2

INSERT CLAMP TAIL INTO NOSE OF

TOOL WITH BUCKLE UP. PUSH VALVE

HANDLE TO PULL-UP POSITION AS

SHOWN. (SHOULD TOOL FAIL TO

OPERATE, PUSH ON SHUT-OFF VALVE.)

Classic Air Tool

STEP 3

WHEN SHUT-OFF VALVE TRIPS,

RETURN VALVE HANDLE TO NEUTRAL

POSITION (HALF WAY BETWEEN PULLUP AND RETURN POSITIONS).

STEP 4

WHEN PRESSURE BLEEDS TO HOLDING

PRESSURE AS INDICATED ON PRESSURE

GAUGE, ROLL BUCKLE UNDER SHEAR HOOK

BAND-IT-IDEX, Inc.

A Unit of IDEX Corporation

4799 Dahlia Street

Denver, CO 80216-3070 USA

P: 1-800-525-0758

F: 1-800-624-3925

NOTE:

WHEN APPLYING OVERSIZED CLAMPS,

LIFT UP RAIL COVER, BACK OUT SOCKET

HEAD CAP SCREW LOCATED ON TOP OF

PISTON ROD HEAD TO CLEAR BAND PATH

INSIDE PISTON ROD HEAD FOR MORE

THAN ONE GRIP PER CLAMP.

RETURN SCREW BACK TO ITS ORIGINAL

POSITION WHEN MULTIPLE GRIPS ARE

NO LONGER REQUIRED. THREADED END

OF SET SCREW INSIDE PISTON ROD

HEAD IS USED TO EJECT CLAMP TAIL

SCRAP OUT OF FRONT OF JUNIOR HEAD.

SEE PAGE 6 FOR IMPORTANT ADVICE

AND WARNINGS.

STEP 5

PULL VALVE HANDLE TO RETURN

POSITION TO EJECT TAIL.

Document # P09287 rev. L

www.BAND-IT-IDEX.com

Page 10 of 18

BAND-IT-IDEX, Inc. 2006

© Copyright

All rights reserved

Page 11

NOTE: IF PROBLEM PERSISTS OR CANNOT BE IDENTIFIED, CALL BAND

-

IT, 303

-

320-4555.

Troubleshooting

PROBLEM PROBABLE CAUSE CORRECTION

SHARP OR SCARRED EDGES ON CLAMP.

METAL DEPOSITS ON UNDERSIDE OF TAIL

AT BUCKLE EDGE. CLAMP TAIL BREAKING

BEFORE CLAMPING OPERATION

COMPLETED.

TAIL IS BROKEN AT APPROXIMATELY 45°

CLAMP MATERIAL STRETCHED OR

THINNED AT BREAK.

CLAMP TAIL BREAKS DURING ROLL-UP.

LOOSE OR BROKEN CUTTER BLADE /

BACKING PLATE. SHARP EDGE ON

CUTTER BLADE DUE TO WEAR.

PULL-UP PRESSURE SET HIGHER THAN

RECOMMENDED.

HOLDING PRESSURE SET HIGHER THAN

RECOMMENDED. ROLL-UP IS ATTEMPTED

BEFORE PRESSURE HAS DROPPED TO

APPROPRIATE LEVEL.

PULL-UP PRESSURE SET LOWER THAN

RECOMMENDED.

MAKE CERTAIN ALL FASTENERS ARE

TIGHT. REPLACE ANY BROKEN OR

CHIPPED BLADES. HONE SHARP EDGE TO

A SMOOTH RADIUS.

REDUCE PULL-UP PRESSURE TO THE

RECOMMENDED MAXIMUM OR SLIGHTLY

LOWER. APPLY CLAMP AND ADJUST IT IF

NECESSARY.

REDUCE HOLDING RESSURE TO THE

RECOMMENDED MAXIMUM OR SLIGHTLY

LOWER. APPLY CLAMP AND ADJUST IF

NECESSARY. WAIT WITH ROLL-UP UNTIL

GAUGE REACHES REQUIRED HOLDING

PRESSURE.

INCREASE PULL-UP PRESSURE.

Classic Air Tool

S10099

CLAMP PULLS IN A JERKY MANNER.

CLAMP PULLS BUT DOES NOT LOCK.

CLAMP TAIL SLIPS IN BAND GRIPPER

LEVER.

CLAMP TAIL CATCHES AS TOOL RESETS.

TOOL DOES NOT CUT OFF CLAMP.

TOOL TAKES EXCESSIVE TIME FOR CLAMP

PULL-UP.

CLAMP TAIL CANNOT BE INSERTED INTO

TOOL.

CLAMP NOT INSERTED PROPERLY.

BAND GRIPPER PIN LOOSE. TIGHTEN SET SCREW.

PULL-UP CYLINDER NEEDS LUBRICATION.

HOLDING PRESSURE SET HIGHER THAN

RECOMMENDED.

BROKEN OR WORN TEETH ON BAND

GRIPPER LEVER.

SPRING STRETCHED OUT. REPLACE SPRING.

TRIPPER PLATE STUCK DUE TO DIRT OR

LACK OF LUBRICATION.

CLAMP TAIL DOES NOT ALIGN PROPERLY

DURING RESET.

LOOSE OR BROKEN CUTTER BLADE. TIGHTEN OR REPLACE CUTTER BLADE.

IMPROPER HOLDING PRESSURE

NO OR LOWER THAN RECOMMENDED

HOLDING PRESSURE.

AIR LEAK FROM LOOSE CONNECTION OR

WORN PARTS.

TRIPPER PLATE MAY BE BROKEN OR

BINDING.

MAKE SURE CLAMP IS STRAIGHT AND

LEVEL WHEN INSERTING.

CHECK FILTER / LUBRICATION AND ADD

OIL IF NECESSARY.

REDUCE HOLDING PRESSURE TO THE

RECOMMENDED MAXIMUM OR SLIGHTLY

LOWER. APPLY CLAMP AND ADJUST IF

NECESSARY.

REPLACE BAND GRIPPER LEVER.

CLEAN AND/OR RE-LUBRICATE.

MOVE VALVE HANDLE TO PULL-UP

POSITION. REACH UNDER PISTON ROD

AND LOCATE BAND GRIPPER LEVER.

ROTATE LEVER TOWARD CLAMP HEAD

AND ALLOW TAIL TO FALL FROM TOOL. IF

TAIL REMAINS STUCK, USE PLIERS TO

GRASP TAIL AND CAREFULLY REMOVE.

NEVER POSITION FINGERS ANYWHERE

BUT ON GRIPPER LEVER AND KEEP VALVE

HANDLE IN PULL-UP POSITION.

ADJUST HOLDING PRESSURE TO

RECOMMENDED LEVEL.

ADJUST CHECK VALVE TO

RECOMMENDED HOLDING PRESSURE.

TIGHTEN LOOSE CONNECTION AND / OR

REPLACE WORN PARTS.

ADJUST OR REPLACE TRIPPER PLATE.

BAND-IT-IDEX, Inc.

A Unit of IDEX Corporation

4799 Dahlia Street

Denver, CO 80216-3070 USA

P: 1-800-525-0758

F: 1-800-624-3925

www.BAND-IT-IDEX.com

Page 11 of 18

Document # P09287 rev. L

© Copyright

BAND-IT-IDEX, Inc. 2006

All rights reserved

Page 12

Maintenance

1. FOR BEST RESULTS AND PROPER FUNCTIONING OF THE AIR

TOOL, A FILTER / LUBRICATOR MUST BE USED ON THE AIR

SUPPLY OR IN LINE WITHIN 30 INCHES OF THE AIR TOOL.

THE WARRANTY IS VOIDED IF A FILTER / LUBRICATOR IS

NOT USED.

2. BEFORE USING AIR TOOL, CHECK TO SEE THAT THE

CUTTER BLADE AND BACKING PLATE ARE FULLY

TIGHTENED. LOOSE BOLTS CAN EASILY CAUSE BREAKAGE

OF BLADE AND BACKING PLATE.

3. CLEAN GRIPPER OCCASIONALLY. PARTICLES AND DIRT ON

THE GRIPPER LEVER CAN CAUSE IT TO SLIP OFF THE

CLAMP TAIL. TO REMOVE GRIPPER LEVER, SLACKEN OFF

SET SCREW AND TAP OUT PIN.

4. CUTTER BLADE AND BACKING PLATE EDGES MUST BE KEPT

CLEAN AND FREE OF METAL SHAVINGS. HONE SMOOTH AT

FIRST SIGN OF CLAMP GOUGING.

S10099

Classic Air Tool

CUTTER BLADE

BACKING PLATE

BAND GRIPPER

THE BAND-IT S10099 AIR TOOL, ALTHOUGH DURABLE, DOES NEED PERIODIC MAINTENANCE AND

REPAIR. IF THIS TOOL NEEDS MINOR REPAIR OR COMPLETE OVERHAUL (LIST BELOW), IT SHOULD BE

RETURNED TO BAND-IT IN DENVER, COLORADO.

MINOR REPAIR:

1. TEST AND INSPECT TOOL TO DETERMINE SOURCE OF PROBLEM.

2. CLEAN EXTERIOR OF TOOL.

3. REPLACE WORN OR DAMAGED, EXTERNAL EXPENDABLE PARTS.

4. ADJUST, TEST AND INSPECT.

REPLACE CUTTER BLADE AND BACKING PLATE AS KIT J93099.

REPLACE GRIPPER CLOSING SPRING AND BAND GRIPPER AS KIT S45199.

PARTS REPLACED ARE INVOICED AT CURRENT PART PRICES.

OVERHAUL:

1. TOTALLY DISMANTLE TOOL AND CLEAN ALL PARTS.

2. REFINISH EXTERNAL PARTS SUCH AS CASTINGS, CYLINDER, ETC.

3. INSPECT ALL PARTS FOR WEAR AND DAMAGE. REPLACE AS NEEDED.

4. REPLACE ALL EXPENDABLE PARTS SUCH AS GASKETS AND O-RINGS.

5. REASSEMBLE, ADJUST, TEST AND INSPECT.

EXPENDABLE PARTS REPLACED AT NO EXTRA CHARGE.

ALL OTHER PARTS REPLACED ARE INVOICED AT CURRENT PART PRICES.

BAND-IT-IDEX, Inc.

A Unit of IDEX Corporation

4799 Dahlia Street

Denver, CO 80216-3070 USA

P: 1-800-525-0758

F: 1-800-624-3925

www.BAND-IT-IDEX.com

Page 12 of 18

Document # P09287 rev. L

© Copyright

BAND-IT-IDEX, Inc. 2006

All rights reserved

Page 13

S10099

Maintenance List

Classic Air Tool

Warranty

MAINTENANCE CHECK LIST

COMPONENT CHECK ACTION FREQUENCY

CLAMP HEAD

CUTTER BLADE AND

BACKING PLATE

FILTER / LUBRICATOR

ECCENTRIC LEVER

CYLINDER

TRIPPER PLATE

AIR EXHAUST

MUFFLERS

Refer to website for warranty information: http://www.band-it-idex.com/warranty.html

CHECK FOR LOOSE

MOUNTING SCREWS.

CHECK TO SEE IF BLADE

IS LOOSE OR HAS ANY

BROKEN OR CHIPPED

EDGES.

CHECK FOR BUILD-UP OF

DIRT, ETC. CHECK FOR

LOW, CONTAMINATED OR

DISCOLORED LUBRICANT.

CHECK FOR BUILD-UP OF

DIRT, ETC., IN TEETH.

CHECK FOR BUILD-UP OF

DIRT, CONTAMINANTS ON

PISTON ROD SEALS.

CHECK FOR BUILD-UP OF

DIRT, CONTAMINANTS,

ETC.

CHECK FOR BUILD-UP OF

DIRT, CONTAMINANTS,

ETC.

TIGHTEN ALL SCREWS AND

FASTENERS.

TIGHTEN ALL SCREWS AND

FASTENERS. REPLACE IF

NECESSARY.

DRAIN AND CLEAN WITH SOAP

AND WATER. REFILL WITH

DTE 24 HYDRAULIC OIL.

REMOVE AND CLEAN WITH

SMALL POINTED OBJECT,

KNIFE BLADE, WIRE BRUSH.

CLEAN WITH SOAP AND WARM

WATER.

CLEAN AND APPLY TYPE G-N

LUBRICANT OR EQUIVALENT.

REMOVE AND CLEAN WITH

NON-FLAMMABLE

DEGREASER.

DAILY

DAILY

EVERY 2000 CLAMPS

EVERY 2000 CLAMPS

6 MONTHS

6 MONTHS

6 MONTHS

BAND-IT-IDEX, Inc.

A Unit of IDEX Corporation

4799 Dahlia Street

Denver, CO 80216-3070 USA

P: 1-800-525-0758

F: 1-800-624-3925

www.BAND-IT-IDEX.com

Page 13 of 18

Document # P09287 rev. L

© Copyright

BAND-IT-IDEX, Inc. 2006

All rights reserved

Page 14

Repair Parts List

S10099

Cylinder Assembly

Classic Air Tool

ITEM PART NO. DECRIPTION QTY.

1 J65687 SCREW, SOC. HEAD CAP #10-32 X 1/2 1

2 J65087 NUT, HEX, #10-32 1

3 S14487 GAUGE, LIQUID 0-100 PSI ¼ NPT 1

4 J63387 O-RING, .188 ID X .062 THICK 1

5 J61587 CONTROL PLUNGER 1

6 J66687 GASKET, CYLINDER 2

7 J63287 O-RING, 5.437 ID X .295 THICK 1

8 S44887 SPACER, STROKE LIMITING 1

9 S45587 O-RING, .437 ID X .103 THICK 1

10 S44687 PISTON 1

11 J60767 CYLINDER 1

12 J92687 DECAL, CAUTION 1

13 S14887 TUBING, COPPER, ¼ OD 1

14 S11687 FITTING, COPPER TUBE ¼ X ¼ NPT 1

15 S47988 COVER, REAR CYLINDER 1

16 J67687 NUT, HEX, 3/8-24 12

17 S60287 DECAL, MAXIMUM SETTINGS 1

18 S44987 BOLT, HEX HEAD, ½-13 X 2.5 LG. 1

19 S45687 WASHER, FLAT 17/32 ID X 1-1/16 OD 1

20 J62187 CYLINDER BOLT 6

21 J90187 COVER, FRONT CYLINDER 1

22 J92187 DRAIN COCK, 1/8 NPT 1

23 J63187 O-RING, .750 ID X .125 THICK 1

BAND-IT-IDEX, Inc.

A Unit of IDEX Corporation

4799 Dahlia Street

Denver, CO 80216-3070 USA

P: 1-800-525-0758

F: 1-800-624-3925

www.BAND-IT-IDEX.com

Page 14 of 18

ITEM PART NO. DESCRIPTION

24 S10487

25 J66587 WASHER, LOCK, 5/16 ID 4

26 S21789 BASE 1

27 S45888 SLIDE COVER 1

28 S45087 TRIPPER PLATE, BAND GRIPPER 1

29 J65487 SCREW, SET. 5/16-24 X 3/8 LONG 1

30 J61967 PLATE, ROD GUIDE 1

31 S48087 SCREW, BUTTON HEAD, #10-32 X 3/8 2

32 J67287 SCREW, SOC. HEAD CAP, ¼-28 X ½ 1

33 S44787 PISTON ROD 1

34 J66487 PIN, ECCENTRIC LEVER BACK-UP 1

35 S21587 PIN, PIVOT, BAND GRIPPER 1

36 J61187 PIN SPRING, 1/8 X 1 3/8 LONG 1

38 S45199 BAND GRIPPER KIT 1

39 J90987 SCREW, SOC. HEAD CAP, 5/16-18X7/8 6

40 J68187 SCREW, SET, #8-32 X 1/8 LONG 1

41 S25787 LUBRICANT, MOLY PASTE 42 C00387 LOCKING COMPOUND, HIGH STRENGTH 43 S25687

44 S39787

45 S25587

46 S11287

SCREW, SOC. HEAD CAP, 5/16-18X5/8

LOCKING COMPOUND, MEDIUM STRENGTH

GASKET AND JOINT SEALANT

COMPOUND, TEFLON SEALANT

FITTING, 45ْ, ¼ X ¼ NPT

Document # P09287 rev. L

© Copyright

BAND-IT-IDEX, Inc. 2006

All rights reserved

QTY

4

-

-

-

1

Page 15

WITHOUT RETURNING THE ENTIRE TOOL.

Repair Parts List

S10099

Valve Assembly

NOTE:

ENTIRE VALVE ASSEMBLY CAN BE REMOVED AS

A UNIT. THE VALVE ASSEMBLY CAN BE SENT TO

BAND-IT FOR SERVICING OR OVERHAUL

Classic Air Tool

ITEM PART NO. DESCRIPTION QTY.

1 J67887 SCREW, SET, #10-32 X 1-1/4 1

2 J65087 NUT, HEX, #10-32 3

3 J91687 BRACKET, COCKING 1

4 S10687 CUP, SHUT OFF VALVE 1

5 J64887 SCREW, SET, #10-32 X 3/8 2

6 S19187 HANDLE, VALVE 1

7 J92587 HANDLE, PLASTIC BALL 1

8 J61487 LINK, CONTROL VALVE 1

9 S10587 VALVE STEM 1

10 S10887 O-RING, .737 ID X .103 THICK 1

11 J63587 VALVE CUP 2

12 J61387 WASHER, VALVE SPACER 2

13 J64987

14 J64587

15 J60187

16 S37387

17 S48387

18 S10487

19 G00689

20 S10287

21 S11387

22 S11787

23 J92187

24 J64687

25 J64487

26 J63387

27 J64787

SCREW, SOC. HEAD CAP, #10-32 X ¾

PIN, SPRING, ¼ X 1-1/8 LONG

VALVE HEAD

NIPPLE, HEX, ¼ NPT

ELBOW, 90ْ 1/4 NPT

SCREW, SOC. HEAD CAP, 5/16-18 X 5/8

FITTING, SWIVEL, ¼ X ¼ NPT

VALVE, RELIEF, ¼ NPT

CHECK VALVE SEAL

MUFFLER, AIR EXHAUST, ¼ NPT

DRAIN COCK, 1/8 NPT

NUT, HEX, ¼-28

PIN, SPRING, 3/16 X 1” LONG

O-RING, .188 ID X .062 THICK

SCREW, SET, ¼-28 X 1”

BAND-IT-IDEX, Inc.

A Unit of IDEX Corporation

4799 Dahlia Street

Denver, CO 80216-3070 USA

P: 1-800-525-0758

F: 1-800-624-3925

ITEM PART NO. DESCRIPTION QTY.

28 S10787 STEM, SHUT-OFF VALVE 1

29 J63787 SPRING, COMP, .531 DIAM X 1.25 LG 1

30 J66887 BUSHING, BRASS ¼ NPT 1

31 S42387 PLUG, PLASTIC CAP, ¼ NPT 1

32 S11887 FITTING, COPPER TUBE, ¼ X 1/8 NPT 1

33 J63487 WASHER, NEOPRENE 1

34 J92387 BOLT, HEX, 5/16-18 X 1” LONG 1

35 J63187 O-RING, .750 ID X .125 THICK 1

36 J61687 VALVE HOOK 1

37 S23387 INDICATOR, PRESSURE SETTING 1

38 S23087 SPRING, COMP. ½ DIA X 2.31 LONG 1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

39 S23287

40 J62787

41 S23487

42 J68187

43 S23187

44 J62887

45 J66787

46 J61787

47 J61287

48 J63687

49 J64387

50 J90487

51 J91487

52 J91387

53 J64287

54 S25587

www.BAND-IT-IDEX.com

Page 15 of 18

KNOB, ADJUST PRESSURE INDICATOR 1

LOCKING KNOB, PRESSURE IND. 1

SLEEVE, PRESSURE INDICATOR 1

SCREW, SET, #8-32 X 1/8 2

POST, PRESSURE INDICATOR 1

TRIP PISTON 1

GASKET, VALVE HEAD 1

VALVE ARM 1

WASHER, VALVE CUP 1

SPACER, CONTROL VALVE 1

PIN, SPRING, 3/16 X 5/8 LONG 1

SHIFT SLIDE, SLOW AND FAST PULL 1

WASHER, NEOPRENE AND STEEL 1

SCREW, BUTTON HEAD, #10-32 X ½ 1

PIN, SPRING, 3/16 X 7/8 LONG 1

COMPOUND, TEFLON SEALANT -

Document # P09287 rev. L

© Copyright

BAND-IT-IDEX, Inc. 2006

All rights reserved

Page 16

SHEAR HOOK PIVOT PIN TO BE RETAINED BY USING MEDIUM STRENGTH

Repair Parts List

S10099

Junior Clamp Head

Classic Air Tool

INSTALLATION INSTRUCTIONS FOR CUTTER BLADE

AND BACKING PLATE

1. REMOVE OLD CUTTER BLADE SCREWS, CUTTER BLADE

AND BACKING PLATE.

2. INSERT NEW SCREWS AND PUT ON NEW BACKING

PLATE WITH WORD “TOP” FACING UP (EITHER

DIRECTION) AS SHOWN.

3. PUT NEW CUTTER BLADE ON WITH SLOT FACING UP AS

SHOWN AND TIGHTEN SCREWS.

4. ALWAYS REPLACE ALL PARTS AS A KIT.

ITEM PART NO. DESCRIPTION QTY.

1 J93099 CUTTER / BLADE KIT 1

3 S18787 SCREW, SOC. HEAD CAP, ¼-28 X 1.75 2

4 S51287 HEAD, JR. PREFORMED CLAMP 1

6 J64887 SCREW, SET, #10-32 X 3/16 2

7 J00587 SHEAR HOOK 1

8 S11589 HANDLE ASSEMBLY 1

9 S18487 GRIP, HANDLE COVER 1

10 S52987 PIN, PIVOT, CAM 1

*11 J90887 PIN, PIVOT, SHEAR HOOK 1

12 S18687 DECAL, WARNING 1

KITS

-

*

BLUE LOCTITE COMPOUND 242 OR EQUIVALENT.

BAND-IT-IDEX, Inc.

A Unit of IDEX Corporation

4799 Dahlia Street

Denver, CO 80216-3070 USA

P: 1-800-525-0758

F: 1-800-624-3925

J93099

STANDARD CUTTER BLADE/ BACKING PLATE

www.BAND-IT-IDEX.com

Page 16 of 18

-

Document # P09287 rev. L

© Copyright

BAND-IT-IDEX, Inc. 2006

All rights reserved

Page 17

AIR FILTER

Filter/Lubricator

S10099

Classic Air Tool

LUBRICATOR

¼” NPT PLUG

90° ELBOW

SWIVEL FITTING

HEX NIPPLE

FILLER PORT

LONG NIPPLE

90° ELBOW

AIR SUPPLY “IN” PORT

INSTRUCTIONS

1. REMOVE ¼” NPT PLUG FROM AIR SUPPLY “IN” PORT.

2. ASSEMBLE 90° ELBOW MALE END INTO FEMALE END OF AIR SUPPLY “IN” PORT. BE SURE FEMALE END

OF 90° ELBOW IS IN DIRECTION SHOWN AFTER ASSEMBLY.

3. USE OPEN FACE WRENCH ON 90° ELBOW TO ASSEMBLE MALE END OF LONG NIPPLE SUB-ASSEMBLY

INTO ASSEMBLED 90° ELBOW FEMALE PORT. BE SURE MALE END OF 90° ELBOW IS FACING STRAIGHT

BACK IN CENTER LINE OF PULL-UP CYLINDER AS SHOWN.

4. ASSEMBLE SWIVEL FITTING OF FILTER / LUBRICATOR SUB-ASSEMBLY SHOWN TO MALE END OF

ASSEMBLED 90° ELBOW. BE SURE THAT FILTER AND LUBRICATOR ARE STRAIGHT UP AND DOWN.

NOTE:

FILTER AND LUBRICATOR SUB-ASSEMBLY MAY BE ASSEMBLED AWAY FROM TOOL, NO MORE THAN 30”

FROM AIR SUPPLY “IN” PORT. FILTER AND LUBRICATOR MUST BE IN DIRECT LINE WITH TOOL, NO OTHER

HOOKUPS ALLOWED BETWEEN FILTER / LUBRICATOR AND TOOL.

PRIOR TO HOOKING UP AIR SUPPLY TO TOOL, UNSCREW THE TWO FILLER PORT SCREWS ON OPPOSITE

SIDE OF EACH OTHER AND FILL BOWL HALF WAY WITH DTE 24 HYDRAULIC OIL PROVIDED WITH KIT.

ADJUST DRIP RATE TO ONE DROP FOR EVERY 6 TO 7 CYCLES.

TO DRAIN AIR FILTER, TURN KNURLED KNOB COUNTERCLOCKWISE (IN).

USE OF THE S10099 AIR TOOL WITHOUT A FILTER / LUBRICATOR VOIDS THE WARRANTY.

BAND-IT-IDEX, Inc.

A Unit of IDEX Corporation

4799 Dahlia Street

Denver, CO 80216-3070 USA

P: 1-800-525-0758

F: 1-800-624-3925

www.BAND-IT-IDEX.com

Page 17 of 18

Document # P09287 rev. L

BAND-IT-IDEX, Inc. 2006

© Copyright

All rights reserved

Page 18

12° Incline Base

S10099 AIR TOOL

S10099

Classic Air Tool

12° INCLINE BASE

2 REQUIRED PER TOOL

NOTES:

INCLINE BASE MUST BE FIRMLY SECURED TO WORK BENCH.

USE 5/16” DIAMETER FASTENING HARDWARE (NOT SUPPLIED WITH BASE).

USE MOUNTING TEMPLATE (PAGE 5) FOR HOLE LOCATIONS.

BAND-IT-IDEX, Inc.

A Unit of IDEX Corporation

4799 Dahlia Street

Denver, CO 80216-3070 USA

P: 1-800-525-0758

F: 1-800-624-3925

www.BAND-IT-IDEX.com

Page 18 of 18

Document # P09287 rev. L

© Copyright

BAND-IT-IDEX, Inc. 2006

All rights reserved

Loading...

Loading...