Page 1

Operating

Manual

IT5000-C / IT6000-C

3/8” IT Tool

IT5000-C / IT6000-C

3/8” BAND-IT

®

Pneumatic IT Tools

Patent Pending

BAND-IT-IDEX, Inc.

A Unit of IDEX Corporation

4799 Dahlia Street

Denver, CO 80216-3070 USA

P: 1-800-525-0758

F: 1-800-624-3925

www.BAND-IT-IDEX.com

Page 1 of 36

Document # P48850 Rev. C

© Copyright

BAND-IT-IDEX, Inc. 2015

All rights reserved

Page 2

Operating

Manual

IT5000-C / IT6000-C

3/8” IT Tool

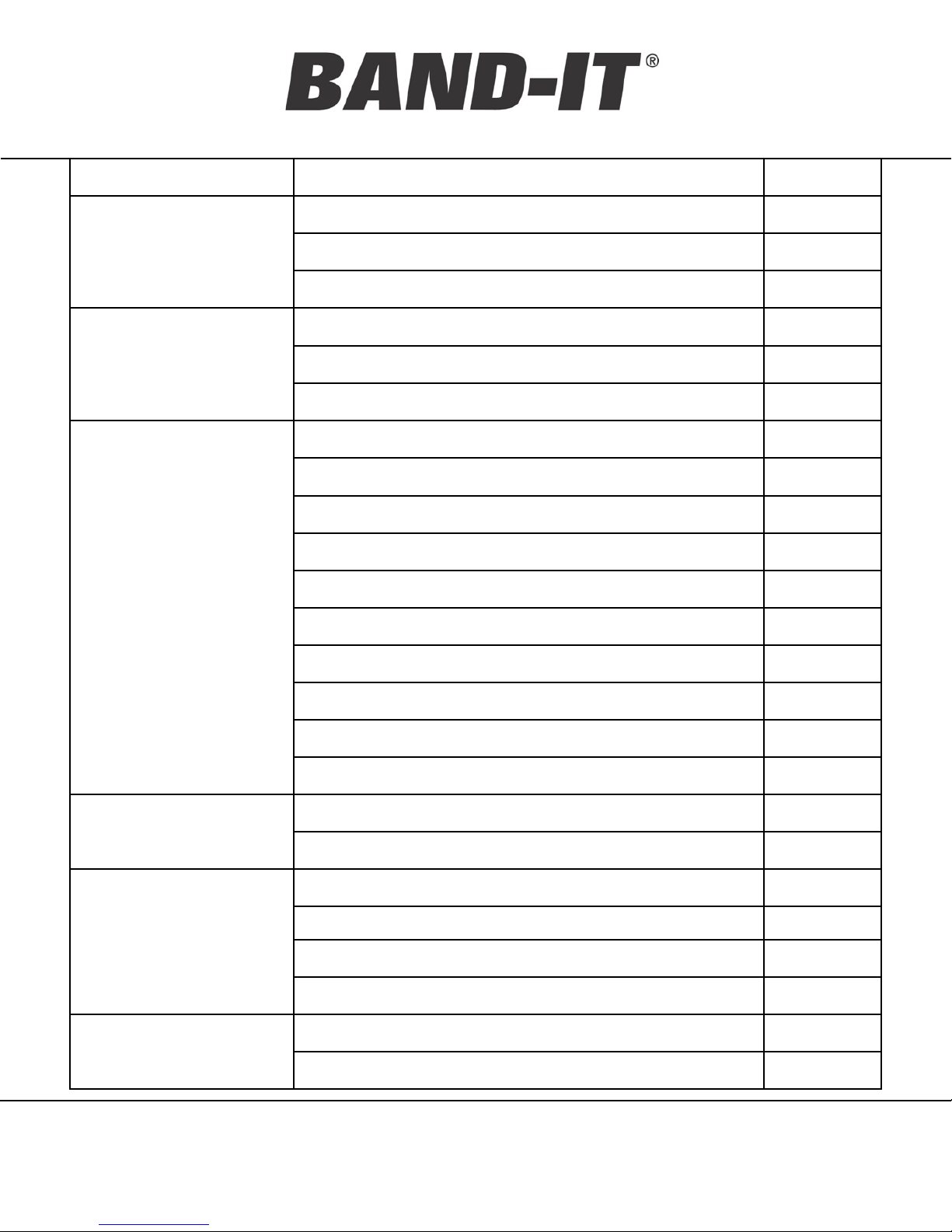

Topic Page Description Page #

Safety Safety Guidelines 3 - 5

Tool Overview 6

Introduction

Air System

Tool Operation

Model Identification & Options Review 6 - 7

Tool / Component Identification 8 - 9

Air System Requirements 10

Air Control Regulator 11-12

Air System Settings 13

Tie / Clamp Installation Procedure 14

IT Tool Orientation Requirements 15

Tie / Clamp Inspection 16

Clamp Placement 17

Dimple Clip 18

Adjustable Support Arm / Handle 19

Tool Clearance Requirements 20

Mounting & Fixturing 21-22

Remote Actuation Configuration 23

Cutoff Signal Option 24

Unable to Achieve Tension 25

Trouble Shooting

Tool Symptoms 26

Preventative Maintenance 27

Replacement Parts 28

Maintenance

Maintenance 29 – 34

Cutoff Timing Adjustment 35

Quality Assurance Test Equipment 36

Quality/Warranty

General Warranty Info 36

BAND-IT-IDEX, Inc.

A Unit of IDEX Corporation

4799 Dahlia Street

Denver, CO 80216-3070 USA

P: 1-800-525-0758

F: 1-800-624-3925

www.BAND-IT-IDEX.com

Page 2 of 36

Document # P48850 Rev. C

© Copyright

BAND-IT-IDEX, Inc. 2015

All rights reserved

Page 3

Operating

IT5000-C / IT6000-C

Manual

Safety Guidelines

This equipment has been tested by BAND-IT-IDEX and is safe to use providing that the

proper safety precautions are observed.

DANGER—Misuse of this equipment may result in serious injury to personnel.

• Only use the equipment for its intended purpose, as described in this manual

• Do not attempt to operate the equipment with covers removed

• Refer to the installation section before installing machine

• Do not operate machine with wet hands

Please read this entire manual before unpacking, setting up or operating this equipment.

Pay attention to all danger and caution statements. Failure to do so could result in serious

injury to the operator or other personnel, or damage to the equipment.

3/8” IT Tool

CAUTION—This equipment generates moderate levels of audible noise when in use.

• Ensure that it is installed in a location where operating noise will not cause disturbance.

Symbols:

Caution – Refer to accompanying documents

Caution – Risk of electric shock

It is the task of the employer to warn his or her staff of risks, to train them on prevention of

accidents, and to provide necessary safety equipment and devices for the operator’s safety.

Before starting to work with the machine, the operator should check the features of the

machine and learn all details of the machine’s operation. The machine should only be

operated by staff members who have read and understand the contents of this manual.

BAND-IT-IDEX, Inc.

A Unit of IDEX Corporation

4799 Dahlia Street

Denver, CO 80216-3070 USA

P: 1-800-525-0758

F: 1-800-624-3925

www.BAND-IT-IDEX.com

Page 3 of 36

Document # P48850 Rev. C

© Copyright

BAND-IT-IDEX, Inc. 2015

All rights reserved

Page 4

Operating

Manual

IT5000-C / IT6000-C

3/8” IT Tool

Directives de sécurité / Garantie

Cet équipement a été examiné par BAND-IT et est sûr pour employer fournir qu'on observe les

mesures de sécurité appropriées.

Danger-Abusez de cet équipement peut avoir comme conséquence des dommages sérieux au

personnel.

•

Utilisez seulement l'équipement pour son but prévu, comme décrit en ce manuel. N'essayez pas

d'actionner l'équipement des couvertures étant coupées

•

Reliez seulement à l'alimentation électrique correcte, comme indiqué de la plaque de contrôle

•

Référez-vous à la section d'installation avant d'installer la machine

•

N'actionnent pas la machine avec les mains humides

Veuillez lire ce manuel entier avant de déballer, installer ou actionner cet équipement. Prêtez l'attention

à tous les rapports de danger et d'attention. Le manque de faire ainsi a pu avoir comme conséquence

les dommages sérieux à l'opérateur, ou tout autre personnel, ou les dommages à l'équipement.

Attention-Cet équipement produit des niveaux modérés du bruit audible en service.

Assurez-vous qu'il est installé dans un endroit où le bruit de fonctionnement ne causera pas la

perturbation.

Symboles :

Attention - référez-vous aux documents d'accompagnement

Attention - risque de décharge électrique

C'est le charger de l'employeur pour avertir son personnel des risques d'accidents, pour les former sur

la prévention des accidents, et de fournir l'équipement et les dispositifs nécessaires de sûreté pour la

sûreté de l'opérateur.

Avant de commencer à travailler avec la machine, l'opérateur devrait vérifier les dispositifs de la

machine et apprendre tous les détails de l'opération de machine. La machine devrait seulement être

actionnée par les membres de personnel qui ont lu et comprendre le contenu de ce manuel.

BAND-IT-IDEX, Inc.

A Unit of IDEX Corporation

4799 Dahlia Street

Denver, CO 80216-3070 USA

P: 1-800-525-0758

F: 1-800-624-3925

www.BAND-IT-IDEX.com

Page 4 of 36

Document # P48850 Rev. C

© Copyright

BAND-IT-IDEX, Inc. 2015

All rights reserved

Page 5

Operating

IT5000-C / IT6000-C

Manual

Safety Guidelines

Environmental operating conditions are defined as:

• For Indoor Use ONLY

• Temperature range from 5°C to 40°C

• Max relative humidity 80% for temperatures up to 31°C. Allowable humidity then

decreases linearly to 50% at 40°C

• Conforms to Applicable Rated POLLUTION DEGREE 1

• Correct illumination for safety of operator (ISO 8995-89)

Additional Safety Guidelines:

• Read this manual and become familiar with the tool before installing any clamps.

3/8” IT Tool

• Protective eyewear should be worn when connecting and disconnecting the tool to

compressed air sources and during operation.

• Wear appropriate gloves for handling steel while operating this tool, applying steel

clamps and removing scrap clamp tail.

• Clamp tensioning can be immediately stopped by releasing the tool trigger. If a remote

trigger is used, the system must be connected to allow for immediate disabling of the tool.

• When applying clamps, care should be taken to insure fingers and loose clothing are not

in the way of the clamp being applied.

• Never attempt to clamp objects which have a potential to burst, shatter or otherwise

cause bodily harm.

• Disconnect air supply and electrical power prior to maintenance and disassembly of tool

components.

• Liquids or lubricants should never be put into the air lines.

BAND-IT-IDEX, Inc.

A Unit of IDEX Corporation

4799 Dahlia Street

Denver, CO 80216-3070 USA

P: 1-800-525-0758

F: 1-800-624-3925

www.BAND-IT-IDEX.com

Page 5 of 36

Document # P48850 Rev. C

© Copyright

BAND-IT-IDEX, Inc. 2015

All rights reserved

Page 6

Operating

Manual

IT5000-C / IT6000-C

3/8” IT Tool

Tool Overview

This machine is designed to automatically install clamps with repeatability and control.

• The tool consists of a tension system and a cutting system, both pneumatically controlled.

• The pneumatic system can be adjusted to provide appropriate clamp force for different

applications. As the tension pressure is increased, the output force of the tool increases.

• During the tension cycle, the tool continues to tension the band until the pre-set tension is

achieved. The tool stops tensioning when the pressure in the tension cylinder equals the inlet

tension pressure coming from the air controller module.

• After the tool has achieved the preset tension, a valve switches over to the cutoff cycle.

• The gripping system retains force on the clamp until after the knife is actuated, which forms a

locking feature and cuts the excess clamp tail.

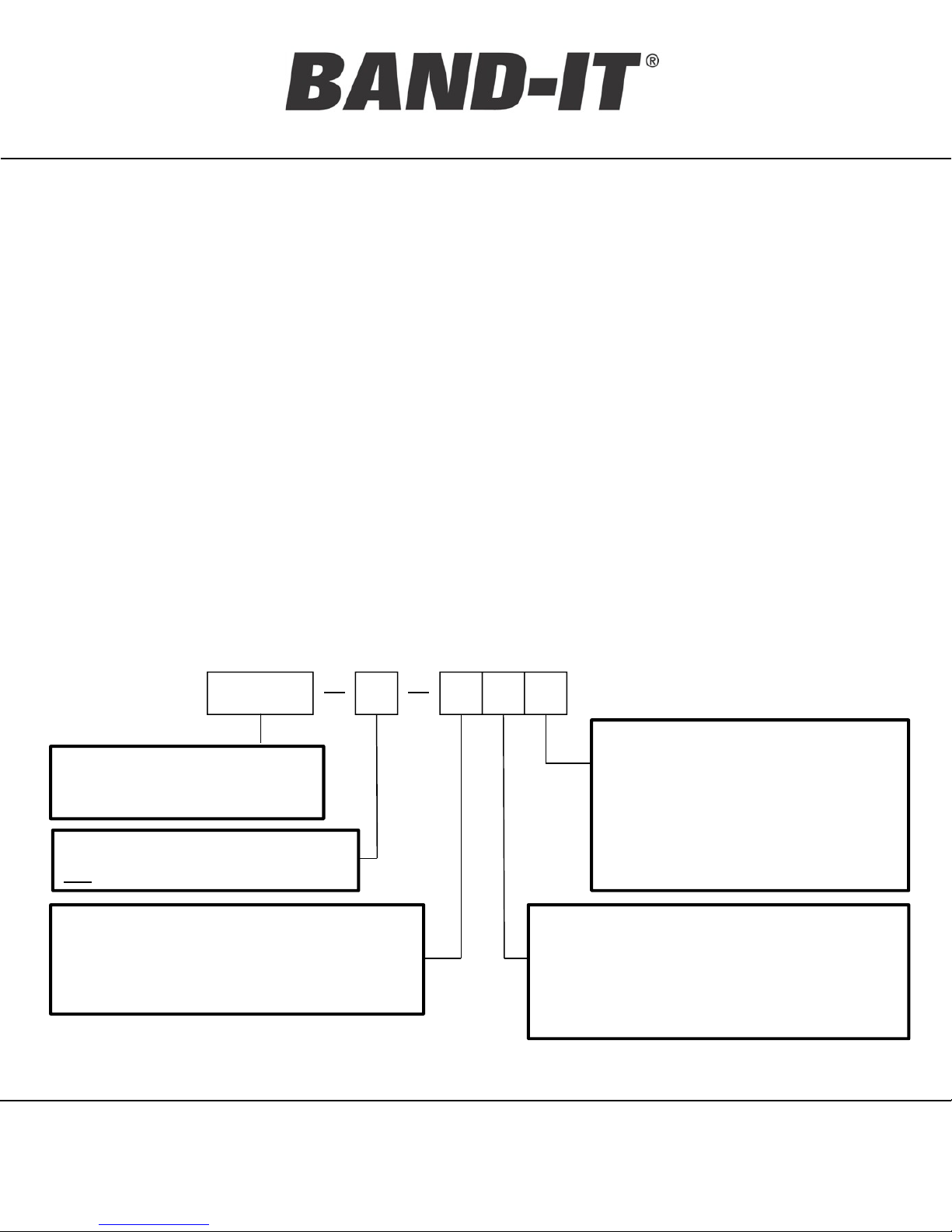

Model Identification

IT6000 C 0 0 0

Feedback options:

IT6000 – 3/8” Tie-Lok®Ties

IT5000 – 3/8” JR®Clamps

Product model: Revisions are

not compatible

Packaging options:

0 – Tool with standard accessories

1 – Tool only

Trigger options:

0 – Standard thumb trigger

1 – Connection for a remote trigger

0 – Standard Tool

1 – Data Feedback System

(obsolete)

2 – Cutoff Signal Sensor

(tool trigger disabled)

BAND-IT-IDEX, Inc.

A Unit of IDEX Corporation

4799 Dahlia Street

Denver, CO 80216-3070 USA

P: 1-800-525-0758

F: 1-800-624-3925

www.BAND-IT-IDEX.com

Page 6 of 36

Document # P48850 Rev. C

© Copyright

BAND-IT-IDEX, Inc. 2015

All rights reserved

Page 7

Operating

Manual

IT5000-C / IT6000-C

3/8” IT Tool

IT Tool Options

• Any IT tool can be ordered as a stand alone tool or with accessories. Accessories

packages all include a pneumatic air flow regulator. Additional accessories vary depending

on the tool options.

• The remote trigger option is a combination of a plumbing modification inside the tool, and a

sold separately foot pedal package. (see pg.19 for additional information)

• I17490 – Foot Pedal Control Kit, IT tools

• I17450 – Manual, Foot Pedal Kit

• The cutoff signal functions by a pneumatic switch set to trigger every cutoff cycle providing

an easy way to confirm and count clamps installed. The accessories option includes an 12ft

extension cord for connecting to the sensor.

• P48960 – Manual, Cutoff Signal

• The data system configuration is no longer available.

• P48950 – Manual, Data Feedback System

BAND-IT-IDEX, Inc.

A Unit of IDEX Corporation

4799 Dahlia Street

Denver, CO 80216-3070 USA

P: 1-800-525-0758

F: 1-800-624-3925

www.BAND-IT-IDEX.com

Page 7 of 36

Document # P48850 Rev. C

© Copyright

BAND-IT-IDEX, Inc. 2015

All rights reserved

Page 8

Operating

Manual

IT5000-C / IT6000-C

3/8” IT Tool

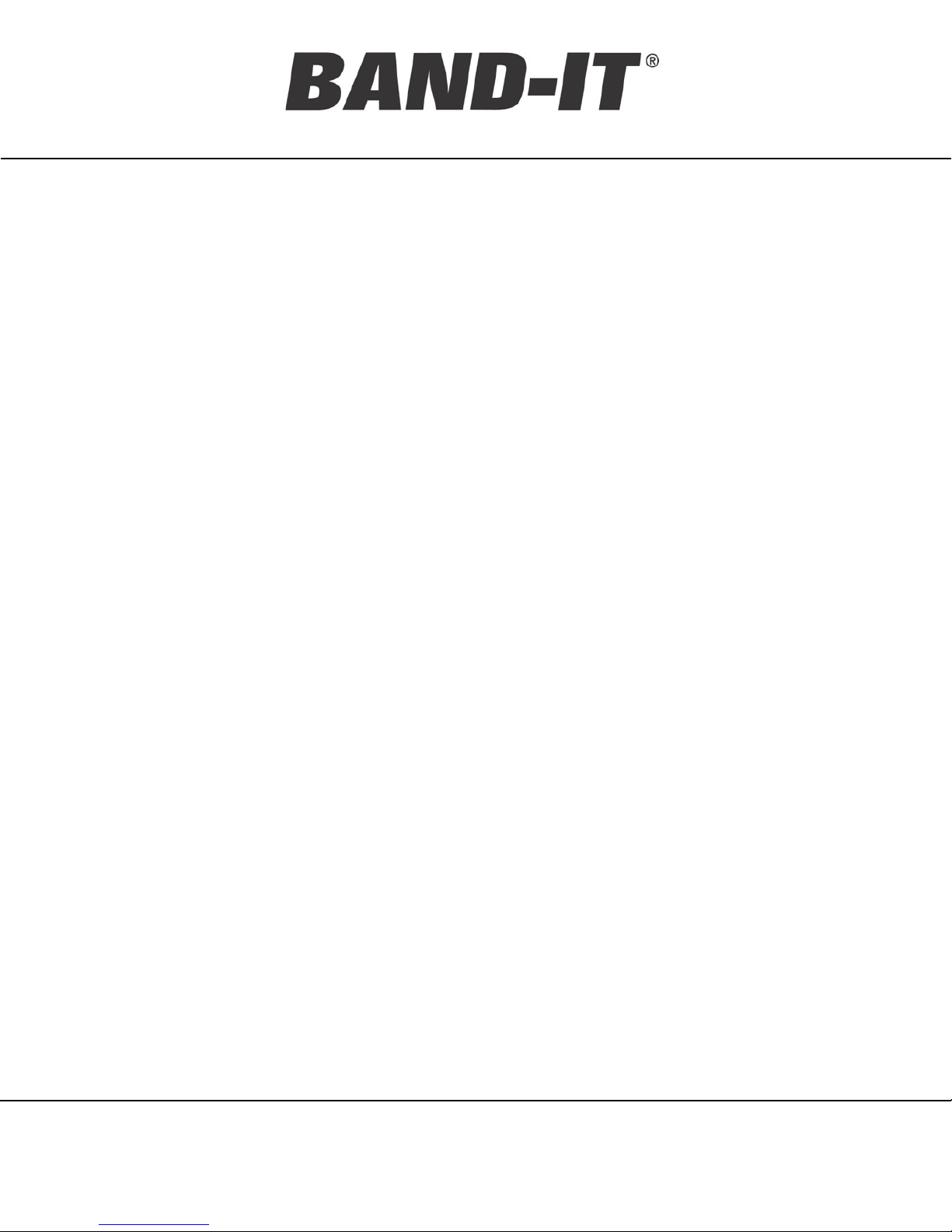

Tool / Component Identification

Operating Trigger

Tool

Reset

Tool

Mounting

Locations

Tool Head with

Knife and Cutter

Blade (see below)

Handle Cover

Handle

Quick Connect Air Couplings

(Do not add lubricants)

Tool Body

and Cover

Maintenance Cover w/

Tension Block Assembly

Tension

Cylinder

Cut-Off

Cylinder

Serial #

Location

IT5000-C / 3/8” JR®Clamps

“JR” on Cutter Blade

No Punch in Knife

3/8” JR Clamp 3/8” Tie-Lok Tie

BAND-IT-IDEX, Inc.

A Unit of IDEX Corporation

4799 Dahlia Street

Denver, CO 80216-3070 USA

P: 1-800-525-0758

F: 1-800-624-3925

IT6000-C / 3/8” Tie-Lok®Ties

www.BAND-IT-IDEX.com

Page 8 of 36

“TL” on Cutter Blade

Punch in Knife

Document # P48850 Rev. C

© Copyright

BAND-IT-IDEX, Inc. 2015

All rights reserved

Page 9

Operating

Manual

IT5000-C / IT6000-C

3/8” IT Tool

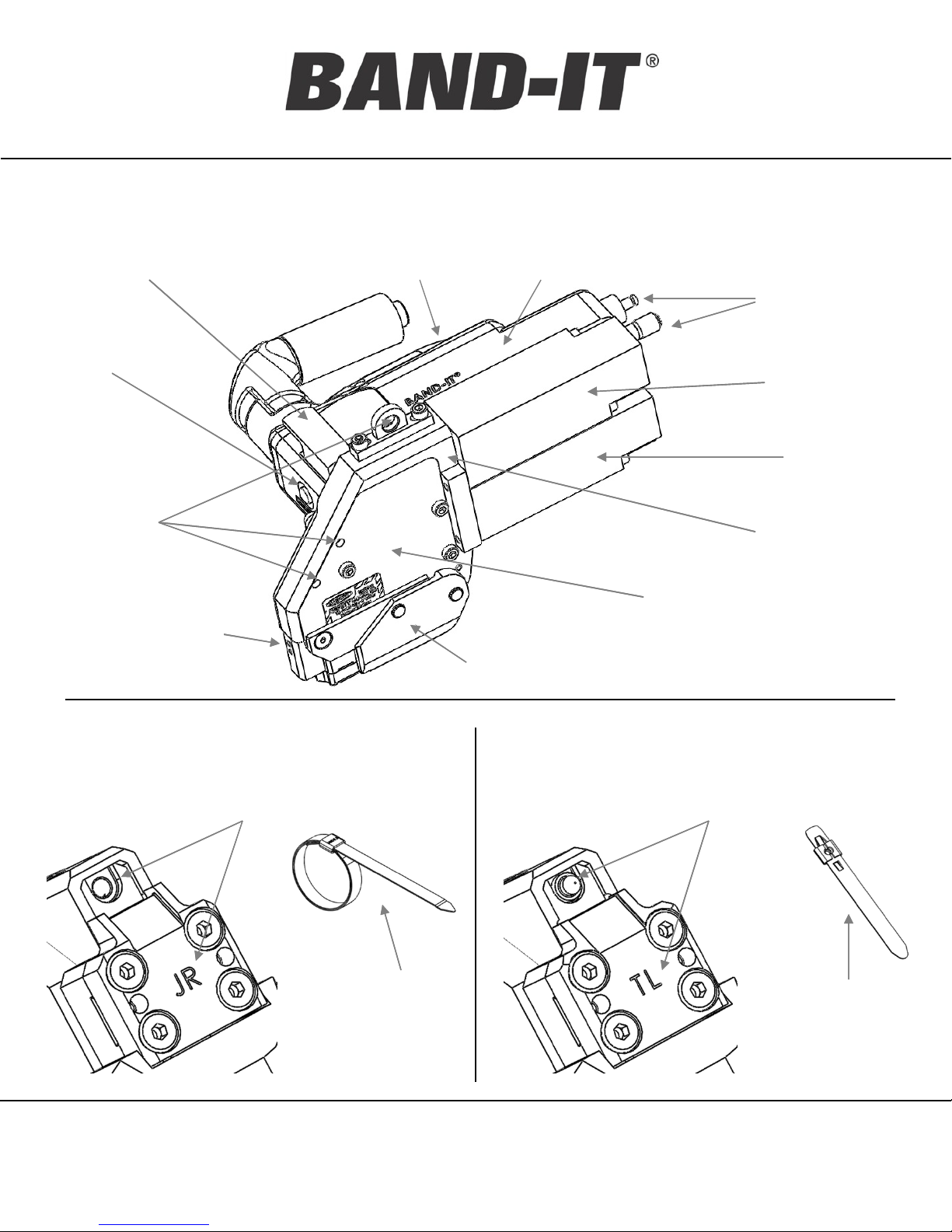

Identification of Standard Accessories

Coiled Air Lines

Packaging Option 0: Box includes IT tool, owners manual, air controller module,

coiled air line, hex keys and fittings

Packaging Option 1: Box includes the IT tool and manual only

BAND-IT-IDEX, Inc.

A Unit of IDEX Corporation

4799 Dahlia Street

Denver, CO 80216-3070 USA

P: 1-800-525-0758

F: 1-800-624-3925

www.BAND-IT-IDEX.com

Page 9 of 36

Air Regulator

Module

Document # P48850 Rev. C

© Copyright

BAND-IT-IDEX, Inc. 2015

All rights reserved

Page 10

Operating

Manual

IT5000-C / IT6000-C

3/8” IT Tool

Air System Requirements

For proper tool performance, the incoming compressed air requirements to the BAND-IT Air

Controller Module of the 3/8” BAND-IT Pneumatic IT Tool must be:

Item Min Max

Inlet Supply Pressure in PSI (kPa) 100 (690) 150 (1,034)

Inlet Supply Air Flow in SCFM (L/min) 1.5 (0.71)

Filtered air particle size (microns) (5)

Air Moisture Content 20% RH

Warning - Failure to follow the below specifications may cause significant damage to

internal tool components.

Although cylinders are permanently lubricated, premature wear can be caused by

contaminants in the air supply or the presence of water and oil. The tool’s internal

valves can also be affected by contaminants in the air lines causing a valve malfunction.

The BAND-IT Air Controller Module includes a filter to meet particle requirements.

BAND-IT recommends the use of an Air Booster System to address the potential problems

associated with low air supply, including:

•filters and dries the air supply

•assures pressure of 100 PSI (690 kPa)

Contact BAND-IT-IDEX Customer Service at 1-800-525-0758 or 303-320-4555 for more

information.

BAND-IT-IDEX, Inc.

A Unit of IDEX Corporation

4799 Dahlia Street

Denver, CO 80216-3070 USA

P: 1-800-525-0758

F: 1-800-624-3925

www.BAND-IT-IDEX.com

Page 10 of 36

Document # P48850 Rev. C

© Copyright

BAND-IT-IDEX, Inc. 2015

All rights reserved

Page 11

Operating

Manual

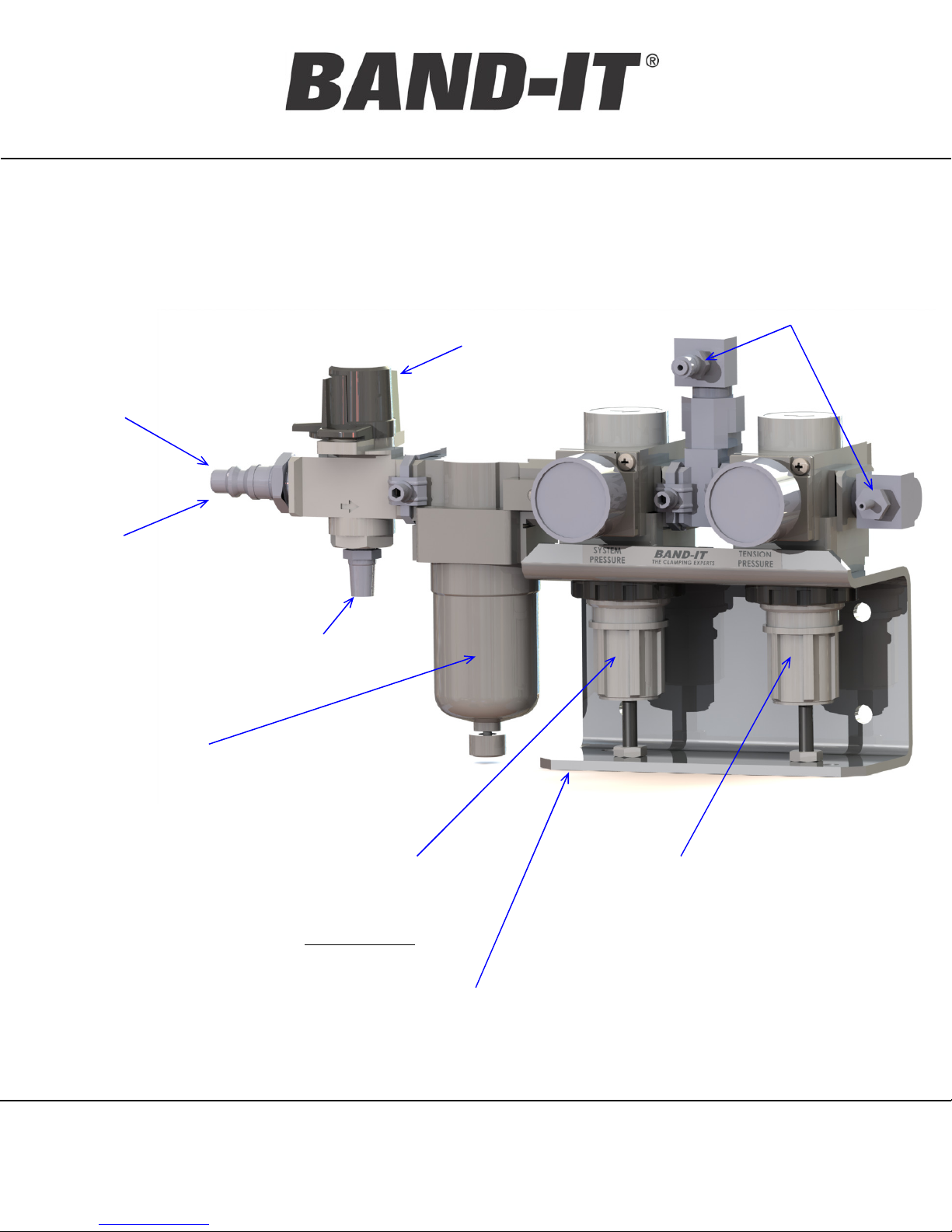

Air Supply

100-150 psi

IT5000-C / IT6000-C

3/8” IT Tool

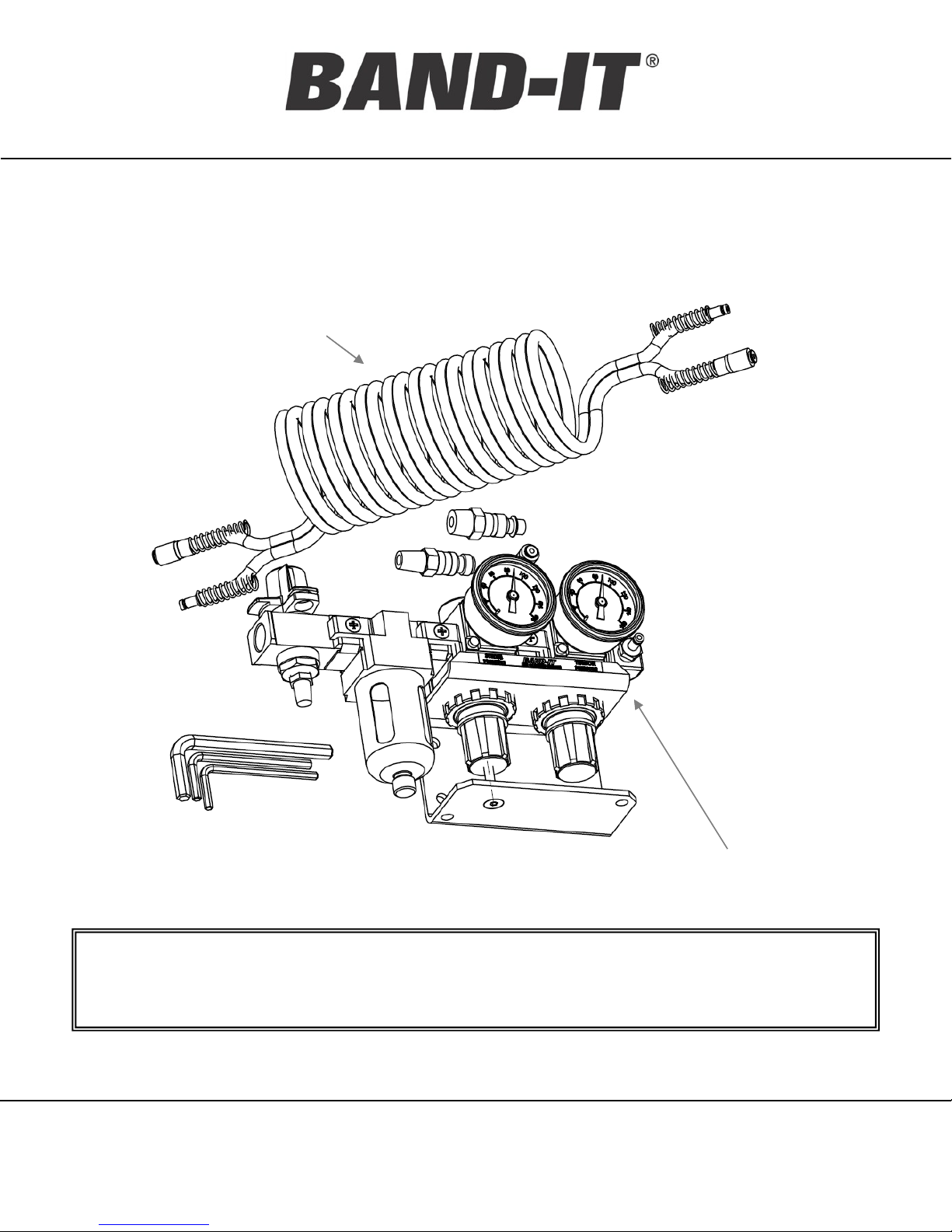

Air Control Regulator Assembly (I56090)

1/8” Quick Disconnects

Connect tool air hoses

Air Shut-Off

Valve

Quick Disconnect

Comes with “Industrial”

installed, also supplied with

Tru-Flate fitting.

Alternatively connect with

any ¼” npt fitting.

Muffler

Air Filter (5 micron)

Standard Filters/Regulators incorporate

polycarbonate bowls and/or observation

windows. Be sure any fluids used near

this assembly are compatible.

System Air Pressure

Regulator with Gauge

Factory set to 105 psi

Do not adjust

Mounting Bracket

Unit may be mounted

on wall or bench

Tension Pressure Regulator

with Gauge

Factory set to 70psi.

(suggested setting for IT6000)

Do not set higher than tool manual

listed maximum pressure. (pg.13)

To adjust, remove screw & nut pull

down on knob and twist. Push back

up and replace screw & nut to lock.

BAND-IT-IDEX, Inc.

A Unit of IDEX Corporation

4799 Dahlia Street

Denver, CO 80216-3070 USA

P: 1-800-525-0758

F: 1-800-624-3925

www.BAND-IT-IDEX.com

Page 11 of 36

Document # P48850 Rev. C

© Copyright

BAND-IT-IDEX, Inc. 2015

All rights reserved

Page 12

Operating

Manual

IT5000-C / IT6000-C

3/8” IT Tool

Regulator Mounting Holes

For proper performance the air control module must be mounted and operated in a horizontal

position as shown on the previous page. Below is the layout for the mounting hole locations

dimensioned in inches.

Hole layout for mounting to a wall

Hole layout for mounting to a bench

BAND-IT-IDEX, Inc.

A Unit of IDEX Corporation

4799 Dahlia Street

Denver, CO 80216-3070 USA

P: 1-800-525-0758

F: 1-800-624-3925

www.BAND-IT-IDEX.com

Page 12 of 36

Document # P48850 Rev. C

© Copyright

BAND-IT-IDEX, Inc. 2015

All rights reserved

Page 13

Operating

IT5000-C / IT6000-C

Manual

Air System Settings

Initial Setup – Pneumatic Settings

Connect the tool body to the Air Controller Module using the included Coiled Hose

Assembly. The hose assembly includes both a clear and black hose. Each hose end

includes a female and male fitting, arranged to prevent reversing of connections.

Connect Air Controller Module to air source (assure air supply meets requirements on “Air

System Requirements” page) and turn RED Shut-off Valve to pressurize tool (supply

position).

IT5000-C / 3/8” JR®Clamps IT6000-C / 3/8” Tie-Lok® Ties

3/8” IT Tool

Minimum

Recommended

Maximum

Cut-Off

Pressure

100 PSI

(690 kPa)

105 PSI

(725 kPa)

110 PSI

(760 kPa)

Tension

Pressure

60 PSI

(410 kPa)

85 PSI

(585 kPa)

90 PSI

(620 kPa)

Cut-Off

Pressure

100 PSI

(690 kPa)

105 PSI

(725 kPa)

110 PSI

(760 kPa)

Tension

Pressure

50 PSI

(345 kPa)

70 PSI

(480 kPa)

75 PSI

(520kPa)

Caution: Tension pressures above the specified settings may cause premature

clamp failure and/or tool wear. Refer to the “Tool / Component Identification” page

to verify the tool model.

Setting the Tool Air Pressure

The tension pressure directly affects the force applied to the clamp.

To correctly set the air pressure from the air controller module going to the tool, connect the

air supply to the tool. Activate the tool by depressing the trigger for a few seconds. Re-read

the pressure when the tool is at rest and adjust again if necessary. Repeat until the desired

pressure is shown on the tension pressure gage.

Tension pressure may need to be adjusted to provide adequate tension for the specific

application.

BAND-IT-IDEX, Inc.

A Unit of IDEX Corporation

4799 Dahlia Street

Denver, CO 80216-3070 USA

P: 1-800-525-0758

F: 1-800-624-3925

www.BAND-IT-IDEX.com

Page 13 of 36

Document # P48850 Rev. C

© Copyright

BAND-IT-IDEX, Inc. 2015

All rights reserved

Page 14

Operating

Manual

Tie-Lok® Tie / Jr®Clamp Installation Procedure

1. (Tie-Lok Tie only) Lace the tie snug around

the assembly and locate the buckle in the

target location.

2. Band should be applied to a uniform solid

surface allowing the buckle adequate support

during the clamp locking and clamp tail cut-off

operation. (pg. 17)

3. Insert the tail of the clamp all the way through

the tool bringing the tool head as close to the

buckle as possible. The tail length extending

into tool must be at least 2.5” (6.4 cm) long.

IT5000-C / IT6000-C

3/8” IT Tool

4. Do not activate tool while inserting clamp tail

because this can cause tie tail to jam in the

Tension Block Assembly.

5. Ensure proper tool orientation. (pg. 15)

6. Begin tensioning by pushing and holding down

operating trigger or by using the remote

trigger system. If the trigger is released, the

tool will cease operation if the desired tension

has not been achieved.

7. While tensioning clamp, allow the tool to move

freely.(pg.15) Continue to hold down operating

trigger until tool completely tensions and cuts

off clamp. Release trigger after cut off.

8. After clamp is completed, clamp tail scrap

must be removed from tool. Clamp tail scrap

is not ejected automatically. Tool is now ready

for next tie/clamp.

Note: Trigger activation requires approximately 3 lbs.f

BAND-IT-IDEX, Inc.

A Unit of IDEX Corporation

4799 Dahlia Street

Denver, CO 80216-3070 USA

P: 1-800-525-0758

F: 1-800-624-3925

www.BAND-IT-IDEX.com

Page 14 of 36

Document # P48850 Rev. C

© Copyright

BAND-IT-IDEX, Inc. 2015

All rights reserved

Page 15

Operating

Manual

IT5000-C / IT6000-C

3/8” IT Tool

IT Tool Orientation Requirements

The BAND-IT Pneumatic IT Tool must be used correctly in order to reliably install a clamp.

Part of ensuring that the tool is producing a strong lock is making sure that it approaches the

application correctly and the fixture configuration allows repeatability of application.

• The tool should approach the assembly in the same orientation that it will finish a clamp

installation. Typically around 20°relative to the surface of the work piece.

• The tool head should come close to the buckle and work piece after inserting the clamp

tail.

• Tie-Lok Ties, have the dimple clip start to engage the buckle.

• JR clamps, stage the tool slightly above the clamp.

• The buckle should be located in the final target area on the assembly.

• Once the tool begins tensioning, allow the band to pull the tool down to the surface.

• As the band is tensioning, the tool may rotate clockwise above the buckle as in direction 1

(Green Arrow).

• During cut-off, the tool must be allowed to rotate counter-clockwise up to 35 degrees in

direction 2 (Blue Arrow).

Typically

20°- 25 °

BAND-IT-IDEX, Inc.

A Unit of IDEX Corporation

4799 Dahlia Street

Denver, CO 80216-3070 USA

P: 1-800-525-0758

F: 1-800-624-3925

1

2

www.BAND-IT-IDEX.com

Page 15 of 36

Document # P48850 Rev. C

© Copyright

BAND-IT-IDEX, Inc. 2015

All rights reserved

Page 16

Operating

Manual

Tie / Clamp Inspection

The IT6000-C forms a locking dimple into

the Tie-Lok tie with the punch and cuts the

remaining tail. When installing a Tie-Lok tie,

a visual check is recommended to verify the

presence of a locking dimple after the tie

has been applied.

Locking Dimple

IT5000-C / IT6000-C

3/8” IT Tool

The IT5000-C forms a locking lip on the

preformed JR clamp and cuts the remaining

tail. When installing a JR clamp, a visual

check is recommended to verify the

presence of the locking lip after the clamp

has been applied.

Locking Lip

By controlling and monitoring the items that are needed to form a good lock, an operator

can help ensure that the clamp will be applied correctly without having to inspect every

assembly. The key issues are:

• Adequate air pressure and volume (Pg.10)

• Appropriately setting the tension and cutoff air pressure for the application (Pg.13)

• Angle of approach (Pg.15)

• Operator Handling Ergonomics (Pg.19)

• Mounting the tool on a weight balancer or custom fixture (Pg.21)

• Following the recommended Preventative Maintenance schedule (Pg.25)

BAND-IT-IDEX, Inc.

A Unit of IDEX Corporation

4799 Dahlia Street

Denver, CO 80216-3070 USA

P: 1-800-525-0758

F: 1-800-624-3925

www.BAND-IT-IDEX.com

Page 16 of 36

Document # P48850 Rev. C

© Copyright

BAND-IT-IDEX, Inc. 2015

All rights reserved

Page 17

Operating

Manual

IT5000-C / IT6000-C

3/8” IT Tool

Clamp Placement

Buckle location is critical to clamp performance. Use the following guidelines as a reference.

• Band target area must be wider that the band and tool head with some additional

clearance for variation side to side.

• Do not install clamps at an angle

• Buckle locations cannot be over air gaps

• Avoid installing buckles on flat surfaces when possible

• On large oval shapes locate buckle on smaller

radius.

• Do not install clamps around square corners

• Do not install clamps on tapered surfaces or on tube bends

• Tie-Lok & JR Clamp advised min installed diameter is 1”

For specific questions contact BAND-IT-IDEX Customer Service at 1-800-525-0758 or

303-320-4555 for more information.

BAND-IT-IDEX, Inc.

A Unit of IDEX Corporation

4799 Dahlia Street

Denver, CO 80216-3070 USA

P: 1-800-525-0758

F: 1-800-624-3925

www.BAND-IT-IDEX.com

Page 17 of 36

Document # P48850 Rev. C

© Copyright

BAND-IT-IDEX, Inc. 2015

All rights reserved

Page 18

Operating

Manual

IT5000-C / IT6000-C

3/8” IT Tool

Dimple Clip Guide (IT6000 only)

• The dimple clip is designed to eliminate the occurrence of undetectable loose ties.

This provides a positive visual indicator to identify good vs. bad tie installation.

• Installing the clip

– Step 1: Locate clip on front of tool head

– Step 2: Install M4x5 screw to hold clip in place. Do not exceed 6 newton meters

(N-m) torque. [ 53 inch pounds (in-lb) ] Over tightening will cause the screw thread

to strip.

• Tool orientation is critical to proper function. The tool must be aligned so the clip is

contacting the work piece while the clamp is being tensioned in order to make sure

the buckle locates inside clip during assembly.

• If the blade is not contacting the work piece during clamp tensioning, the clip will

overshoot the buckle. When the buckle slides under the clip, the dimple lock

cannot form and the tie will be loose. There will also be a sharp edge after cutoff.

CORRECTINCORRECT

BAND-IT-IDEX, Inc.

A Unit of IDEX Corporation

4799 Dahlia Street

Denver, CO 80216-3070 USA

P: 1-800-525-0758

F: 1-800-624-3925

www.BAND-IT-IDEX.com

Page 18 of 36

Document # P48850 Rev. C

© Copyright

BAND-IT-IDEX, Inc. 2015

All rights reserved

Page 19

Operating

IT5000-C / IT6000-C

Manual

Adjustable Support Arm / Handle for Hand Use

• Using a hex key (supplied), adjust the Support Arm/Handle to ergonomically match

the operators hand.

• Be sure not to adjust the Handle too far

outward (beyond interlocking legs) or the

handle will not function properly or

provide support to the operator.

3/8” IT Tool

Hex Key

Tool Ergonomics

• Tool weight – 7 Pounds (3.2 Kg)

• A Neutral wrist position is recommended

• A bent wrist can cause operator fatigue, and tool misuse

• Any fixture design should attempt to replicate the natural

human wrist / elbow / shoulder motions that would occur

when operating the tool in the hand-held configuration,

allowing the tool to float along a plane through the entire

Tension (pull-up) and Cut-Off (lock) process.

BAND-IT-IDEX, Inc.

A Unit of IDEX Corporation

4799 Dahlia Street

Denver, CO 80216-3070 USA

P: 1-800-525-0758

F: 1-800-624-3925

www.BAND-IT-IDEX.com

Page 19 of 36

Document # P48850 Rev. C

© Copyright

BAND-IT-IDEX, Inc. 2015

All rights reserved

Page 20

Operating

Manual

IT Tool Clearance Requirements

There are three common considerations for tool clearance

1. Channel Flat width (D)

• Must be wider than the blade (A) 0.96” [24.4mm]

2. Raised width (E)

• Must be wider than flip cover (B) 1.38” [35.1mm]

when between 0.23” - 1.5” [5.8 - 38.1mm] tall

• Must be wider than the pins (C) when taller than

1.5” [38.1mm]

3. Shoulder height (F) depends on tool orientation

• When under the handle, must be less than 2”

• When away from handle, width must increase to

give clearance to air cylinders, but no height

limitation.

IT5000-C / IT6000-C

3/8” IT Tool

Front

View

A. Blade width

• 0.96” [24.4mm]

B. Flip cover width

• 1.38” [35.1mm]

C. Pin

D. Flat width

• > 0.96” [24.4mm]

E. Channel width

• > 1.38” [35.1mm]

F. Shoulder height

• < 2” [50.8mm]

C

B

D

A

F

E

BAND-IT-IDEX, Inc.

A Unit of IDEX Corporation

4799 Dahlia Street

Denver, CO 80216-3070 USA

P: 1-800-525-0758

F: 1-800-624-3925

www.BAND-IT-IDEX.com

Page 20 of 36

Document # P48850 Rev. C

© Copyright

BAND-IT-IDEX, Inc. 2015

All rights reserved

Page 21

Operating

Manual

IT5000-C / IT6000-C

3/8” IT Tool

Fixture Hanger

At a minimum BAND-IT recommends that the tool be connected to a weight balancer

or be mounted in a fixture that will provide adequate rotation during operation.

• Support boom & Balancer

• 4 axis of movement

to locate tool directly

over target clamp

location.

• The balancer must

support a tool weight

of approximately 7 lb.

Swing Arm

Weight

Balancer

IT Tool

The tool comes with a hanger loop installed on the top face to mount to a weight balancer.

When removed, there are four M5 threads that can be used to secure the tool to a fixture. The

included tool hanger may be attached to any of the mounting holes as shown below.

Caution: do not allow screws to extend deeper than 7/16” (0.438”) into the tool

body. Longer screws will interfere with the internal components of the tool and

cause tool to jam.

BAND-IT-IDEX, Inc.

A Unit of IDEX Corporation

4799 Dahlia Street

Denver, CO 80216-3070 USA

P: 1-800-525-0758

F: 1-800-624-3925

www.BAND-IT-IDEX.com

Page 21 of 36

Document # P48850 Rev. C

© Copyright

BAND-IT-IDEX, Inc. 2015

All rights reserved

Page 22

Operating

Manual

Three additional fixture

mounting holes are available

to assist with mounting the

tool. Thread size is M5 for all

holes.

One hole is utilized to attach

and lock the tool body cover

to the tool body. This hole

may also be used for a fixture,

provided the M5 cap screw is

replaced with a similar screw

with appropriate thread

length.

IT5000-C / IT6000-C

3/8” IT Tool

Fixture Mounting Holes

Fixture guide for Tie-Lok®Ties

The center block should allow for the buckle to pass around the work piece

This will allow the tie to be threaded from either end

Clamp guild material should be

heat treated tool steel

BAND-IT-IDEX, Inc.

A Unit of IDEX Corporation

4799 Dahlia Street

Denver, CO 80216-3070 USA

P: 1-800-525-0758

F: 1-800-624-3925

www.BAND-IT-IDEX.com

Page 22 of 36

Document # P48850 Rev. C

© Copyright

BAND-IT-IDEX, Inc. 2015

All rights reserved

Page 23

Operating

Manual

IT5000-C / IT6000-C

3/8” IT Tool

Remote Actuation Configuration

• A tool with trigger option 0 is manually operated via the thumb button. A tool with trigger

option 1 is configured to allow remote operation via palm button or other device permitting

the tool to be incorporated into the customer’s fixture or assembly process.

• The modification consists of deactivating the thumb lever actuation switch and installing two

6-ft X 1/8” O.D. hoses with quick disconnects. These lines can be connected to any valve

used as a remote actuation device. Examples include palm buttons, foot control pedals,

and others.

• Various actuation devices can be incorporated based upon end user requirements. Basic

schematic for 2-way & 3-way valves included below. The valve should be set up in the

normally closed mode and upon opening the circuit a supply of air is provided.

• The customer is responsible for incorporating this tool into their process. BAND-IT-IDEX is

available to provide advice and recommendations.

Remote trigger: 2-way valve

Hose from tool

(male quick disconnect)

Actuate to

stop tool

Supply Hose from

tool (female quick disconnect)

Remote trigger: 3-way valve

Hose from

tool (male)

Actuate to

stop tool

Actuate to

start tool

Actuate to

start tool

Multiple Triggers

Hose from tool

(male)

If more than one trigger is used,

connect in series. All need to be

actuated to run the tool.

Supply Hose from

tool (female)

Supply Hose from

tool (female)

BAND-IT-IDEX, Inc.

A Unit of IDEX Corporation

4799 Dahlia Street

Denver, CO 80216-3070 USA

P: 1-800-525-0758

F: 1-800-624-3925

www.BAND-IT-IDEX.com

Page 23 of 36

Document # P48850 Rev. C

© Copyright

BAND-IT-IDEX, Inc. 2015

All rights reserved

Page 24

Operating

Manual

IT5000-C / IT6000-C

3/8” IT Tool

Cutoff Signal Option

The cut-off signal option provides a signal from the tool that indicates the completion of a

clamp installation. Pressurization of the cut-off cylinder activates a pressure switch when

the tool switches from the tension cycle to the cut-off cycle. The pressure switch is

“normally open” and closes to complete a circuit when cut-off cylinder pressure exceeds

45±15 psi during cutoff cycle. The signal can be transmitted to a data collection device,

such as a PLC, via the 12-foot extension cable and used as a counter to track the number

of clamps applied by the tool. The switch has a maximum voltage rating of 42V.

The -002 and -012 configurations are tool

systems that also come with a 12-foot

extension cable (I60387), female receptacle

(I60487) and electric panel lock nut (I61187)

for mounting to a PLC or other control box. The

polarity of the 2 wire leads from the receptacle

is not critical.

An IT Tool with configurations -102 and -112

contain the pressure switch and 2 pole Micro

AC series male receptacle.

Mounting Hole:

½”-14 NPT

Or

.85” diameter clearance hole for ½”-14 lock nut

Contact BAND-IT IDEX Customer Service at 1-800-525-0758 or 303-320-4555 for

any questions not addressed above.

BAND-IT-IDEX, Inc.

A Unit of IDEX Corporation

4799 Dahlia Street

Denver, CO 80216-3070 USA

P: 1-800-525-0758

F: 1-800-624-3925

www.BAND-IT-IDEX.com

Page 24 of 36

Document # P48850 Rev. C

© Copyright

BAND-IT-IDEX, Inc. 2015

All rights reserved

Page 25

Operating

IT5000-C / IT6000-C

Manual

Trouble Shooting Guide: Unable to Achieve Tension

If the tool fails to fully tension the clamp:

Failure to fully tension the clamp can be caused by a variety of factors. The two

most common factors are incorrect tension pressure and problems with the grippers.

• Check tension pressure setting on Tension Pressure Gauge of Air Controller Module.

Adjust pressure per the settings found in the “Air System Settings” page.

• Evaluate the clamp tail dimple pattern. If elongated dimples are present, the problem

may be with the Tension Block or Front Gripper.

Front Gripper Tension Block

3/8” IT Tool

Normal clamp tail dimple

pattern.

Clamp tail dimple pattern

indicates a problem

• If a problem is indicated, follow the instructions in the “Maintenance” section to remove

and inspect the tension block assembly and the front gripper.

• Examine the Tension Block and Tension Gripper for damage or wear.

• Examine the Front Gripper area for foreign debris and/ or buildup of metal shavings.

• Ensure that the four cutter blade screws are tightened.

• If excessive damage or wear is determined, replace the worn parts.

A worn out tension block:

Edge is no longer sharp, or is chipped

BAND-IT-IDEX, Inc.

A Unit of IDEX Corporation

4799 Dahlia Street

Denver, CO 80216-3070 USA

P: 1-800-525-0758

F: 1-800-624-3925

A worn out tension gripper:

Ridges are worn off in some sections

www.BAND-IT-IDEX.com

Page 25 of 36

Document # P48850 Rev. C

© Copyright

BAND-IT-IDEX, Inc. 2015

All rights reserved

Page 26

Operating

Manual

Symptom Items to check Suggested fix

IT5000-C / IT6000-C

3/8” IT Tool

Trouble Shooting Guide: Tool Symptoms

Difficulty inserting

clamp tail into tool

Tool does not cycle

when the trigger is

pressed

Tool tightens clamp,

but cutoff does not

activate

Tool attempts to cutoff

and lock the clamp

before it is tight

Is there a clamp tail already in

Remove previous clamp tail

the tool?

Do the gages on the control

module show pressure?

Do the gages on the control

module show pressure?

Check incoming supply pressure.

Turn the air regulator valve ON.

Check incoming supply pressure.

Turn the air regulator valve ON.

Check for pinched air lines under

the handle cover.

After the tool stalls, does

nothing further happen? (no

Check for pinched air lines.

Check cutoff timing.

sound of the cylinder moving)

Does the cylinder sound as

though it moves, but the knife

does not extend?

Remove the side body and verify all

links are present and connected.

Verify there is a knife installed.

Is the cutoff timing too short? Adjust cutoff timing.

Is the tool struggling to pull up

the clamp?

Increase tension pressure.

Lubricate the tool.

Tool fails to cut or

lock clamp.

Check tension and cutoff

pressures

(Press reset button to

release tool from

clamp if stalled)

Check knife and blade for

excessive wear or chips on

the cutting edges.

Contact BAND-IT-IDEX Customer Service at 1-800-525-0758 or 303-320-4555 for

repair on any issues not addressed above.

BAND-IT-IDEX, Inc.

A Unit of IDEX Corporation

4799 Dahlia Street

Denver, CO 80216-3070 USA

P: 1-800-525-0758

F: 1-800-624-3925

Adjust pressure regulators if not set

at specification. Verify that the hose

from the tension regulator enters the

bottom port of the tool.

Replace as necessary.

www.BAND-IT-IDEX.com

Page 26 of 36

Document # P48850 Rev. C

© Copyright

BAND-IT-IDEX, Inc. 2015

All rights reserved

Page 27

Operating

Manual

IT5000-C / IT6000-C

3/8” IT Tool

Preventative Maintenance

The tool has components that must be checked and/or replaced on a regular schedule. If

tools are experiencing difficulties during function or there are audible air leaks coming from

inside the handle, the tool should be returned to BAND-IT for service. Pneumatic components

must be serviced by BAND-IT in order to assure proper tool performance after a repair.

Clamps

Installed

Maintenance

Item

Maintenance

Action

Maintenance Cover (pg. 27) Clean & Re-Lubricate

Tension Block and Gripper (pg. 28) Inspect, Clean, Re-Lubricate

Every 25,000

Front Gripper (pg. 29) Clean & Re-Lubricate

Cutter Blade & Blade Screws (pg. 29)

Inspect & Replace if necessary

Tool Cavity, Tool Head, Linkages (pg. 30) Clean & Re-Lubricate

Every 50,000

Knife and Dimple Punch (pg. 31) Inspect & Replace if necessary

Every 100,000

Head Pin and Front Cutoff Lever Inspect & Replace if necessary

Some applications and environments may require maintenance intervals to be adjusted.

Consult BAND-IT-IDEX for more information.

For best performance and to extend tool life:

• Follow preventative maintenance and parts replacement instructions at appropriate service

intervals.

• Do not remove factory applied lubrication from inside tool unless performing a thorough

maintenance procedure and then replacing with fresh lubricant immediately.

• Do not use degreaser in the tool body.

• Do not spray any lubricant or cleaner into the Quick Connect Air Couplings.

• Use nominal recommended tension setting (see “Air System Settings” page). Tension

pressures above the specified settings may cause premature clamp failure and/or tool wear.

• For maintenance beyond what is described in this manual, consult BAND-IT-IDEX Customer

Service at 1-800-525-0758 or 303-320-4555 .

BAND-IT-IDEX, Inc.

A Unit of IDEX Corporation

4799 Dahlia Street

Denver, CO 80216-3070 USA

P: 1-800-525-0758

F: 1-800-624-3925

www.BAND-IT-IDEX.com

Page 27 of 36

Document # P48850 Rev. C

BAND-IT-IDEX, Inc. 2015

All rights reserved

© Copyright

Page 28

Operating

Manual

IT5000-C / IT6000-C

3/8” IT Tool

Maintenance: Replacement Parts

Production tools will experience wear of specific parts. High cycle tools may experience a

component failure that is not considered a wear part. Preventative maintenance, including

regular cleaning and lubrication will reduce the replacement frequency of these parts. Threaded

fasteners may be replaced by off the shelf parts, but they must be an identical replacement or

tool function may be affected.

Part # Description

I51065

I51066

I51069

I51067

I51004

I51057

I40087

I51064

M24187

I14387

Maintenance Cover Assembly: includes assembled maintenance cover,

two clevis pins, two retaining rings (pg. 27)

Tension Block Assembly: includes tension block, tension gripper,

tension pin, and 2 springs (pg. 28)

IT6000-C Cutter Blade with four screws (pg. 29)

IT6000-C Knife Assembly Kit: includes assembled knife, dimple punch,

and spring pin (pg. 31)

IT5000-C Knife (pg. 31)

IT5000-C Cutter Blade (pg. 29)

Hanger bracket; for attaching tool balancer (seen on pg. 7)

Front gripper ball (pg.29)

Front cutoff lever (pg.31, step 5, attached to knife)

Head pin (pg.31, pin retaining M24187 to head)

Socket head cap screws M5 x 10mm; for balancer bracket & cover plate

Lubricant, Chevron Rykotac Grease EP (or equivalent)

Several fasteners require Loctite, Blue - Medium strength.

Please have both the tool model and serial numbers available when calling the factory for

service or assistance. Contact BAND-IT-IDEX Customer Service at 1-800-525-0758 or

303-320-4555 for more information. Part numbers are subject to change.

BAND-IT-IDEX, Inc.

A Unit of IDEX Corporation

4799 Dahlia Street

Denver, CO 80216-3070 USA

P: 1-800-525-0758

F: 1-800-624-3925

www.BAND-IT-IDEX.com

Page 28 of 36

Document # P48850 Rev. C

© Copyright

BAND-IT-IDEX, Inc. 2015

All rights reserved

Page 29

Operating

Manual

Maintenance: Maintenance Cover

Important: Before disassembling tool, be sure to shut-off air supply on the

Control Module.

Note: This tool uses metric fasteners.

1) Remove the two e-style

retaining rings and two clevis

pins. Remove the

maintenance cover.

2) Remove the tension block

assembly by lifting it out of

tension arm slot. Tension block

may come out with

maintenance cover.

IT5000-C / IT6000-C

3/8” IT Tool

3) Fully clean and lubricate inside

of maintenance cover as

shown.

Lightly lubricate all

points indicated

with red arrows.

Maintenance Cover

***Continued on next page***

Tension

Block

Assembly

BAND-IT-IDEX, Inc.

A Unit of IDEX Corporation

4799 Dahlia Street

Denver, CO 80216-3070 USA

P: 1-800-525-0758

F: 1-800-624-3925

www.BAND-IT-IDEX.com

Page 29 of 36

Document # P48850 Rev. C

© Copyright

BAND-IT-IDEX, Inc. 2015

All rights reserved

Page 30

Operating

Manual

IT5000-C / IT6000-C

3/8” IT Tool

Maintenance: Tension Block Inspection & Replacement

Disassembly & Inspection:

1) Remove the two Compression Springs.

2) Remove Tension Gripper and Tension Block pin from the Tension Block.

3) Tension Gripper — Look for worn spots or other damage.

4) Tension Block — Look for damaged edge on insert or other damage. See the “Trouble

Shooting Guide: Unable to Achieve Tension” page 24 for details.

Reassembly:

1) Thoroughly clean out any accumulated debris from inside the Tension Block

2) Lubricate the surfaces shown with red arrows

3) Install the Tension Gripper and Tension Block Pin in the Tension Block.

4) Reinstall the Compression Springs

Tension Gripper

Clean out any

accumulated debris

from the slot in the

Tension Block

Compression SpringsTension Block

Tension Block Pin

Lightly lubricate all outside surfaces

of tension block and surfaces

indicated with red arrows.

Insert

Note: Ensure no lubrication is present in

the center of Tension Gripper (indicated

by the circled area)

BAND-IT-IDEX, Inc.

A Unit of IDEX Corporation

4799 Dahlia Street

Denver, CO 80216-3070 USA

P: 1-800-525-0758

F: 1-800-624-3925

www.BAND-IT-IDEX.com

Page 30 of 36

Document # P48850 Rev. C

© Copyright

BAND-IT-IDEX, Inc. 2015

All rights reserved

Page 31

Operating

Manual

Maintenance: Cutter Blade Inspection & Replacement

Removal & Installation:

1) Remove the four M4 screws with a 3mm hex

key. This can occur with the tool fully

assembled.

2) Pull the cutter blade off of the two alignment pins

in the tool head.

3) Inspect cutter blade for chips and excessive

wear on cutting edge. Replace if blade is

causing unacceptable clamp cut-off. Clean any

shavings or debris that have built up on cutter

blade.

IT5000-C / IT6000-C

3/8” IT Tool

Cutter Blade

4) Remove all accumulated shavings and debris

from inside the front gripper where the ball

bearing is inserted. The part can be pulled back

and out of the tool head slot.

5) Lubricate ball bearing after cleaning.

6) To re-install cutter blade, use alignment pins and

install the four M4 screws with blue Loctite.

Ball

Bearing

Front Gripper

BAND-IT-IDEX, Inc.

A Unit of IDEX Corporation

4799 Dahlia Street

Denver, CO 80216-3070 USA

P: 1-800-525-0758

F: 1-800-624-3925

www.BAND-IT-IDEX.com

Page 31 of 36

Document # P48850 Rev. C

© Copyright

BAND-IT-IDEX, Inc. 2015

All rights reserved

Page 32

Operating

Manual

IT5000-C / IT6000-C

3/8” IT Tool

Maintenance: Tool Body and Linkages

1) Remove the three cap screws (4mm hex) and the one flat head screw (3mm hex) as

shown.

2) Remove the side cover after screws are removed. The side cover is a close fit and may

require a screwdriver to pry off near the tension arm.

3) Examine the mechanical linkages for over-all condition such as dirt, metal filings, liquid

contamination and lubrication.

Pry Here

BAND-IT-IDEX, Inc.

A Unit of IDEX Corporation

4799 Dahlia Street

Denver, CO 80216-3070 USA

P: 1-800-525-0758

F: 1-800-624-3925

www.BAND-IT-IDEX.com

Page 32 of 36

Document # P48850 Rev. C

© Copyright

BAND-IT-IDEX, Inc. 2015

All rights reserved

Page 33

Operating

Manual

IT5000-C / IT6000-C

3/8” IT Tool

Maintenance: Knife Inspection & Replacement

1) Remove the one cutoff link and two pins shown

2) Remove the tool head by removing one flat head screw (3mm hex) on opposite side

3) Remove tool head assembly by sliding it along keyway in tool body

4) Lift cutter arm and knife assembly out of tool head

5) Push the pin out of knife assembly to remove the cutter arm

6) Inspect cutting edge for chips and excessive wear. Make sure knife is well lubricated.

7) For IT6000-C only: the Dimple Pin height should be 0.120” minimum. Inspect dimple pin

for excessive wear.

Note: Be careful not to let ball bearing fall out of gripper guide. Further cleaning of the gripper

guide and ball bearing can occur here if necessary.

Step 1

Step 4

Lightly lubricate all

sides of cutting knife.

Step 5

Front

Cutoff

Lever

Cutting Edge

Step 3

BAND-IT-IDEX, Inc.

A Unit of IDEX Corporation

4799 Dahlia Street

Denver, CO 80216-3070 USA

P: 1-800-525-0758

F: 1-800-624-3925

Head Pin

Dimple Pin Height

0.120” Minimum

www.BAND-IT-IDEX.com

Page 33 of 36

Document # P48850 Rev. C

© Copyright

BAND-IT-IDEX, Inc. 2015

All rights reserved

Page 34

Operating

Manual

IT5000-C / IT6000-C

3/8” IT Tool

Maintenance: Lubrication

Important: Before disassembling tool, be sure to shut-off air supply on the

Control Module.

Note: This tool uses metric fasteners.

The recommended lubricant is Chevron Rykotac Grease EP.

1) Lubricate tool cavity as shown with red arrows below. Also, lubricate the inside surfaces of

the maintenance cover (shown below).

2) BAND-IT recommends lubrication every 25,000 clamps. Dirty environments may require

more frequent intervals.

3) Inspect all mechanical linkages for lubrication and proper placement. Refit cover.

4) Secure the tool side cover by inserting and tightening the screws to 20-30 in-lbs removed

on the previous page’s steps. Apply medium strength blue Loctite to the 3 cap screws and

high strength red Loctite to the one flat head screw.

Tool Cavity

Lightly lubricate all points

indicated with red arrows.

BAND-IT-IDEX, Inc.

A Unit of IDEX Corporation

4799 Dahlia Street

Denver, CO 80216-3070 USA

P: 1-800-525-0758

F: 1-800-624-3925

www.BAND-IT-IDEX.com

Page 34 of 36

Document # P48850 Rev. C

© Copyright

BAND-IT-IDEX, Inc. 2015

All rights reserved

Page 35

Operating

Manual

IT5000-C / IT6000-C

3/8” IT Tool

Maintenance: Cutoff Timing Adjustment

1) Remove the two cap screws in the Handle Cover with a 4mm hex key. Remove cover and

lay aside during their removal.

2) The valve used to adjust timing is highlighted in the picture below.

3) To adjust: Loosen jam nut, and turn adjustment screw clockwise to increase the cutoff delay

and counter-clockwise to decrease the cutoff delay. Once the delay is set, tighten the jam

nut against the adjustment screw.

4) To test and verify proper adjustment: Connect the tool to the Air Control Module, then turn

supply valve on. Gently kink the coiled air supply tube connected to the bottom Quick

Connect Air Coupling, then activate the Tool Trigger. This action causes the tool to cut off,

allowing the timing to be reviewed. Adjusting the Timing Screw in by ½ turn will slow the

tool’s cut-off action. Adjusting the Timing Screw out by a half turn increases the speed of

the cut-off activation. Repeat this entire step until timing is set at a 0.5 – 1.0 second delay.

Caution: Setting timing to less than 0.5s may result in loose clamps.

Cutoff Timing

Valve

Notes:

-Cut-off timing set too short will not allow the clamp to achieve the desired tension before

switching to the cut-off function causing a loose clamp. Clamping on softer objects requires

a longer timing.

-Cut-off timing set too long may slow production and cause operator to twist the tool during

application. This may damage tool and/or clamp.

BAND-IT-IDEX, Inc.

A Unit of IDEX Corporation

4799 Dahlia Street

Denver, CO 80216-3070 USA

P: 1-800-525-0758

F: 1-800-624-3925

www.BAND-IT-IDEX.com

Page 35 of 36

Document # P48850 Rev. C

© Copyright

BAND-IT-IDEX, Inc. 2015

All rights reserved

Page 36

Operating

Manual

Quality assurance testing equipment

• BAND-IT offers a calibration device M38090

• Manual # M28050

• Use to verify tool tension output.

IT5000-C / IT6000-C

3/8” IT Tool

Warranty

• Individual tool warranty terms and conditions are included with the tool quote. Refer to

quote documentation for specific details.

• Tool sales may include up to 12 month limited warranty. Limited meaning that wear parts

are not included, such as blades and grippers.

• BAND-IT must be given the opportunity to physically examine all warranty claims.

• Tools found with severe abuse or unapproved modifications may void warranty upon

BAND-IT’s discretion.

Additional warranty information, up-to-date literature, and all tool instructions, are

available online at: http://www.BAND-IT -IDEX.com/

Or call Customer Service at 1-800-525-0758 or 303-320-4555

BAND-IT-IDEX, Inc.

A Unit of IDEX Corporation

4799 Dahlia Street

Denver, CO 80216-3070 USA

P: 1-800-525-0758

F: 1-800-624-3925

www.BAND-IT-IDEX.com

Page 36 of 36

Document # P48850 Rev. C

BAND-IT-IDEX, Inc. 2015

© Copyright

All rights reserved

Loading...

Loading...