Page 1

Owner’s

Manual

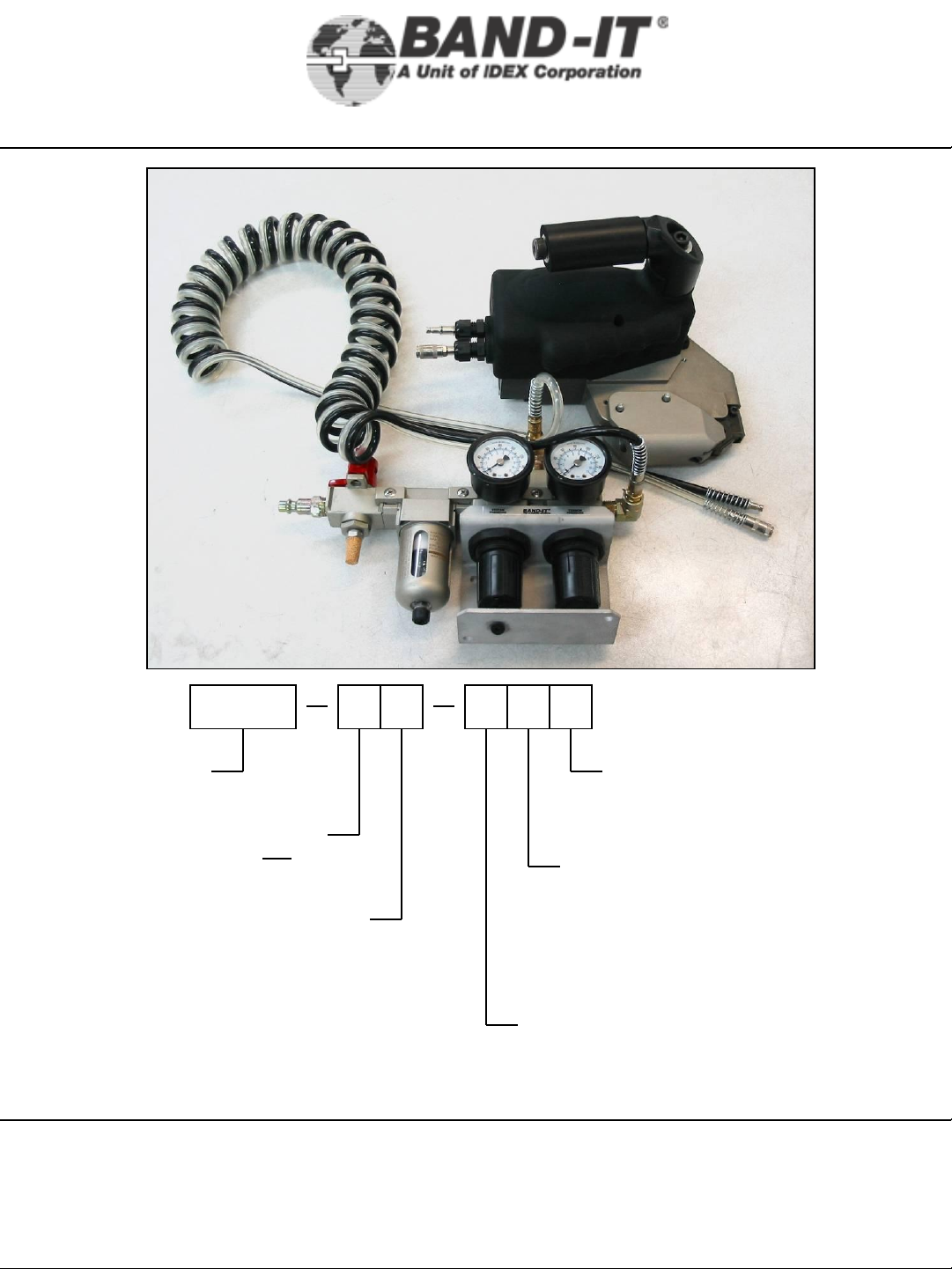

IT4000-AB

5/16” Band-Lok

Tool

IT4000 A B 0 0 0

Base part number

Product level

Revisions are not

compatible

Tool revision

Revisions are

compatible

BAND-IT-IDEX, Inc.

A Unit of IDEX Corporation

4799 Dahlia Street Denver, CO 80216-0307 USA

P: 1-800-525-0758 F: 1-800-624-3925

www.BAND-IT-IDEX.com

1 of 28

Other options:

0 – None (standard)

Trigger options:

0 – Standard thumb trigger

1 – Connection for a remote trigger

(I17490, Foot Control Kit, is

available to purchase separately)

Packaging options:

0 – Tool with all accessories (standard)

1 – Tool only

Document # I17794 Rev D

© Copyright

BAND-IT-IDEX, Inc. 2009

All rights reserved

Page 2

Table of

Contents

Warranty & Safety Guidelines 3

Air System 4-6

Parts Identification 7,22

IT4000-AB

5/16” Band-Lok

Tool

Table of Contents Page

Tool Overview 8

Setup & Assembly Instructions 9-11

Remote Operations & Fixturing Tips 12,13

Operating Tips 14

Operating Instructions 15

Troubleshooting 16-20

Maintenance 21-28

BAND-IT-IDEX, Inc.

A Unit of IDEX Corporation

4799 Dahlia Street Denver, CO 80216-0307 USA

P: 1-800-525-0758 F: 1-800-624-3925

www.BAND-IT-IDEX.com

2 of 28

Document # I17794 Rev D

© Copyright

BAND-IT-IDEX, Inc. 2009

All rights reserved

Page 3

Warranty &

Safety Guidelines

Warranty:

For Warranty information visit the following URL

www.BAND-IT-IDEX.com/Warranty.html

Safety Guidelines

• Read this manual and become familiar with the tool before installing any

clamps.

• Protective eyewear should be worn when connecting and disconnecting

the tool to compressed air sources and during operation.

IT4000-AB

5/16” Band-Lok

Tool

• Wear appropriate gloves for handling steel while operating this tool,

applying stainless steel clamps and removing scrap clamp tail.

• Clamp tensioning can be immediately stopped by releasing the tool

trigger system.

• When applying clamps, care should be taken to insure fingers and loose

clothing are not in the way of the clamp being applied.

• Never attempt to clamp objects which have a potential to burst, shatter

or otherwise cause bodily harm.

• Disconnect air supply and electrical power prior to maintenance and

disassembly of tool components.

• Liquids or lubricants should never be put into the air lines.

BAND-IT-IDEX, Inc.

A Unit of IDEX Corporation

4799 Dahlia Street Denver, CO 80216-0307 USA

P: 1-800-525-0758 F: 1-800-624-3925

www.BAND-IT-IDEX.com

3 of 28

Document # I17794 Rev D

© Copyright

BAND-IT-IDEX, Inc. 2009

All rights reserved

Page 4

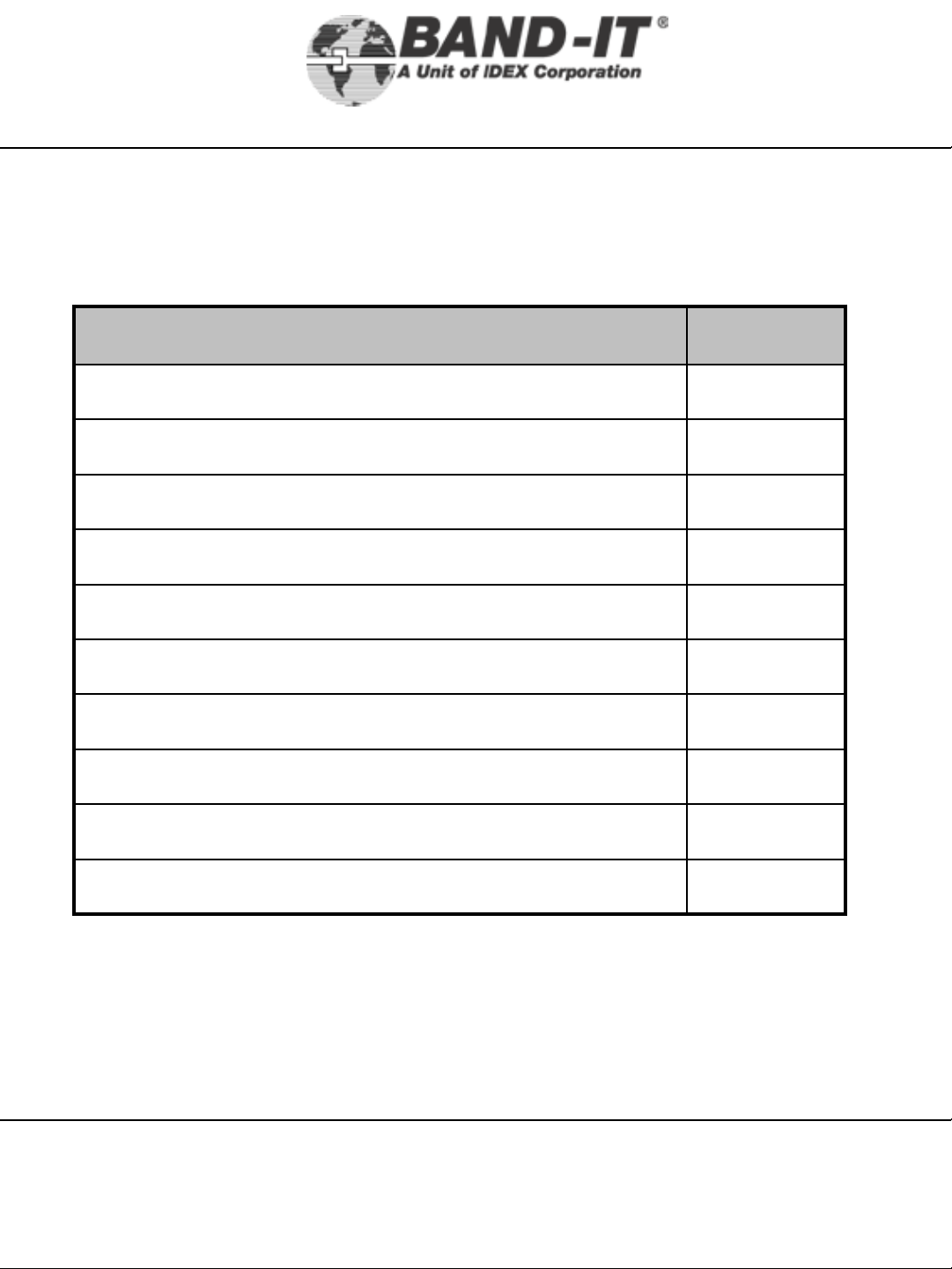

IT4000-AB

Air System

5/16” Band-Lok

The IT4000 is a pneumatic tool that needs a clean and dry air supply. The BAND-IT Air

Controller Module includes a filter to meet these requirements. For proper tool

performance, the air requirements at the inlet to the BAND-IT Air Controller Module of

the IT4000 must be:

Item Min Max

Inlet Supply Pressure (PSI) 100 140

Inlet Supply Air Flow (SCFM) 1.5

Particle Size In Air Supply (microns) 5

Air Moisture Content 20% RH

Tension Pressure Settings (PSI) 50 70

Cut-off Pressure Setting (PSI) 110 115

Tool

Note – An Air Booster Unit is now available to meet air pressure requirements.

Please have tool model and serial #’s available when calling the factory for

service assistance. Contact BAND-IT-IDEX customer service, 303-320-4555.

Caution – Do not exceed a Tension pressure of 70 PSI. Pressures above 70 PSI

may cause premature clamp failure.

Air Controller Module

Inlet air supply

Cut-off Pressure

Regulator

Tension

Pressure

Regulator

BAND-IT-IDEX, Inc.

A Unit of IDEX Corporation

4799 Dahlia Street Denver, CO 80216-0307 USA

P: 1-800-525-0758 F: 1-800-624-3925

www.BAND-IT-IDEX.com

4 of 28

Document # I17794 Rev D

© Copyright

BAND-IT-IDEX, Inc. 2009

All rights reserved

Page 5

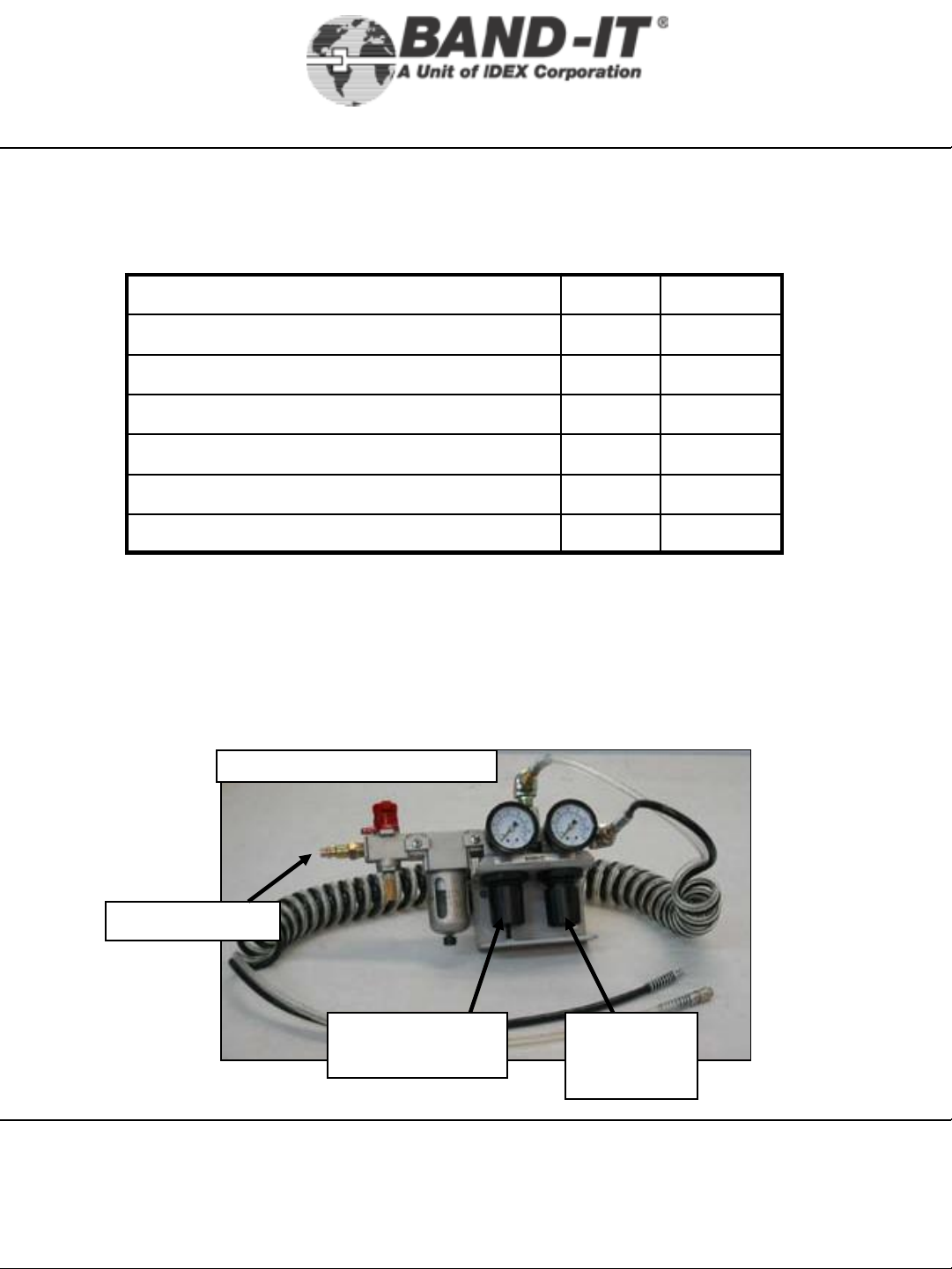

Air System

Inlet Air Supply

Quick Disconnect

Use one of two

quick-disconnects

supplied or remove

and use 1/4” NPT

fitting

Air Shut-Off Valve

IT4000-AB

5/16” Band-Lok

Tool

Air Controller Module

Cut-off

Outlet

Tension

Outlet

Exhaust

Muffler

Cut-off

Pressure

Gauge

Cut-off Pressure

Regulator

Factory set to 110

PSI Do not adjust

Air Filter Environment:

Standard Filters/Regulators

incorporate polycarbonate bowls and/or

observation windows. DO NOT use in

an environment that will expose the

above mentioned components to

synthetic fluids, organic solvents,

chemicals, cutting lubricants, thread

lock solutions or similar materials.

Filter

Fluid Drain

Release

Valve

Tension

Pressure Gauge

Tension Pressure

Regulator

Pull Regulator

Knob and twist to

adjust tension,

push to lock

Mounting Bracket

Unit may be mounted

on wall or bench

Note: Air Controller Module

must be mounted and operated

in a horizontal position.

BAND-IT-IDEX, Inc.

A Unit of IDEX Corporation

4799 Dahlia Street Denver, CO 80216-0307 USA

P: 1-800-525-0758 F: 1-800-624-3925

www.BAND-IT-IDEX.com

5 of 28

Document # I17794 Rev D

© Copyright

BAND-IT-IDEX, Inc. 2009

All rights reserved

Page 6

IT4000-AB

Air System

5/16” Band-Lok

Tool

The standard IT4000 shipping container includes: Air Controller

Module, IT4000 tool body, coiled air line, owner’s manual and tool kit.

(tools with packaging option 1 include the tool and manual only)

Initial Setup - Pneumatics

• Connect the tool body to the Air Controller Module using the included Coiled Hose

Assembly. The hose assembly includes both a clear and black hose. Each hose

end includes a female and male fitting, arranged to prevent reversing of

connections.

• Connect Air Controller Module to air source (assure air supply meets

requirements on page 4) and turn RED Shut-off Valve counter clockwise to

pressurize tool (supply position).

• Cut-off Pressure: 110 PSI recommended. Make sure the Cut-off Pressure

Gauge located on the left side of the module reads a pressure of 110 PSI min and

115 PSI max..

• Tension Pressure: 70 PSI recommended. The Tension Pressure Gauge

monitors the tension applied to the clamp tail. Recommended air pressure at the

Tension Gauge should be 50-70 PSI for BAND-IT 5/16” Band-Lok ties.

• Caution: Tension pressures above 70 PSI may cause premature clamp failure

and/or tool wear.

Setting the Tool Air Pressure

The tension pressure directly affects the force applied to the clamp.

To correctly set the air pressure from the air controller module going to the tool, hook up

the air supply to the tool. Activate the tool by depressing the trigger for a few seconds. Reread the pressure when the tool is at rest and adjust again if necessary. Repeat until the

desired pressure is shown on the tension pressure gage.

Tension pressure may need to be adjusted depending on the application.

BAND-IT-IDEX, Inc.

A Unit of IDEX Corporation

4799 Dahlia Street Denver, CO 80216-0307 USA

P: 1-800-525-0758 F: 1-800-624-3925

www.BAND-IT-IDEX.com

6 of 28

Document # I17794 Rev D

© Copyright

BAND-IT-IDEX, Inc. 2009

All rights reserved

Page 7

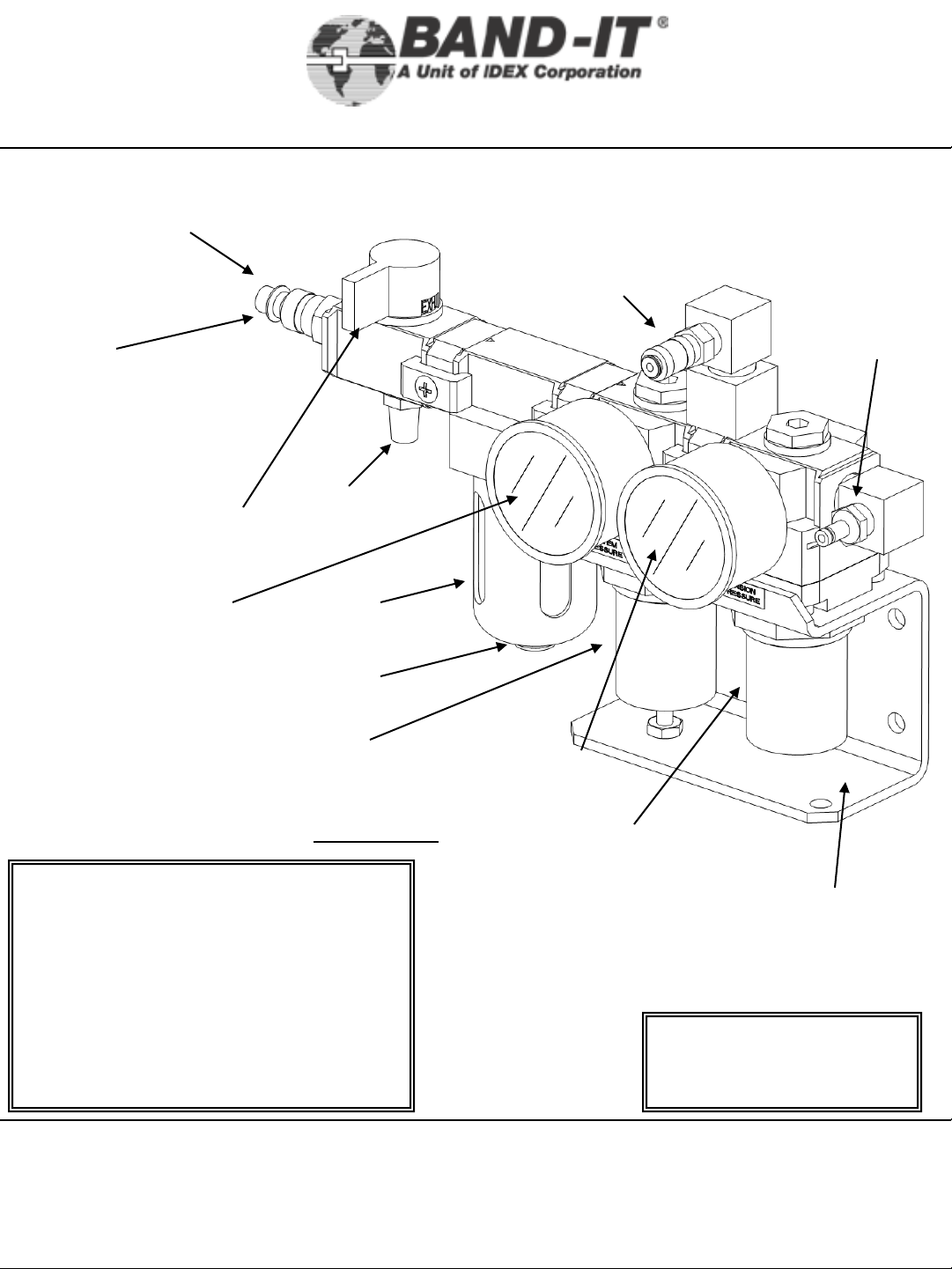

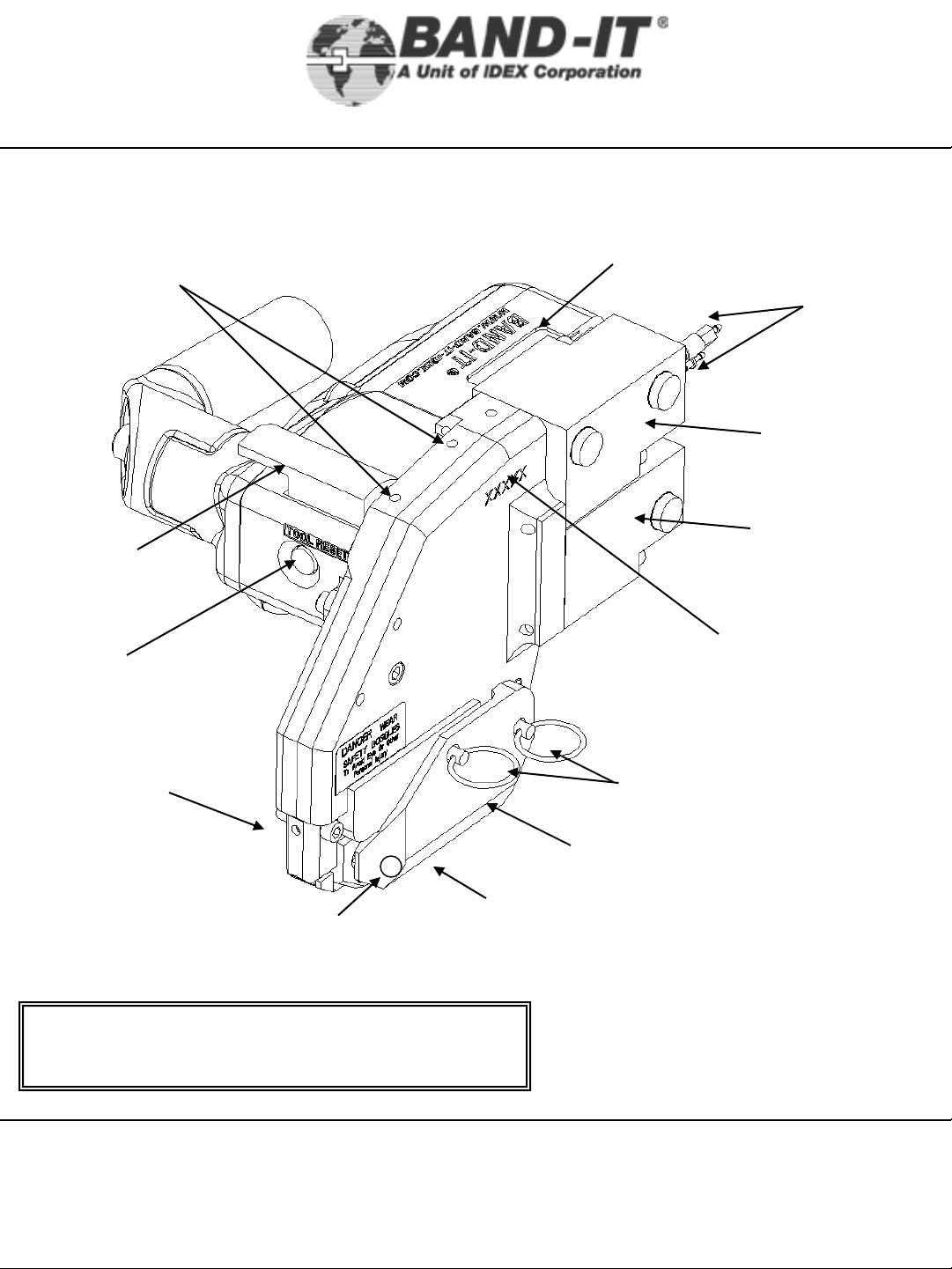

Parts

Identification

IT4000-AB

5/16” Band-Lok

Tool

IT4000-AB Tool Body

Tool Hanger

Mounting

Holes

Operating

Trigger

Reset

Button

Model I.D.

Plate

Quick Connect

Air Couplings

(Do not add

lubricants)

Tension

Cylinder

Cut-off

Cylinder

Serial #

Location

Tool Head

with Cutter

Knife and

Blade

Flip Cover

Head Screws

Important: Before disassembling tool, be sure to

shut-off air supply on theAir Controller Module.

BAND-IT-IDEX, Inc.

A Unit of IDEX Corporation

4799 Dahlia Street Denver, CO 80216-0307 USA

P: 1-800-525-0758 F: 1-800-624-3925

www.BAND-IT-IDEX.com

Flip Cover

Tightening Screw

7 of 28

Quick Release Pins

Maintenance

Flip Cover

Document # I17794 Rev D

© Copyright

BAND-IT-IDEX, Inc. 2009

All rights reserved

Page 8

IT4000-AB

Tool

5/16” Band-Lok

Overview

Pneumatic System:

The pneumatic valves and cylinders contain seals and o-ring components which can

experience accelerated wear associated with quality of the supply. Worn cylinder o-rings

allow air to bypass the pistons in the cylinders, affecting the performance of the tool and

cause the output force of the tool to drift. Although cylinders are permanently lubricated,

premature wear can be caused by contaminants in the air supply or the presence of water

and oil. The tool’s internal valves can also be affected by contaminants in the air lines

causing a valve malfunction.

BAND-IT recommends the use of an Air Booster System to address the potential problems

associated with low air supply. In addition to filtering and drying the air supply, it will assure

pressure of 110 PSI improving the consistency of tool performance.

Tool

Tool Function:

The IT4000 tool utilizes the conditioned air supply to actuate the mechanical linkage. The

linkage activates a gripping system which tensions BAND-IT Band-Lok clamps. The tension

output of the tool can vary depending upon the air pressure supplied to the tool. If the pressure

is increased, the output force increases.

During the tension cycle, the tool continues to tension the band until the pre-set tension is

achieved. The tool stops tensioning when the pressure in the tension cylinder equals the inlet

tension pressure coming from the air controller module. After the tool has achieved the preset

tension, its valve switches over to the cutoff cycle. The gripping system retains force on the

clamp until a knife is actuated down, forming the lock, and cutting the excess clamp tail.

BAND-IT-IDEX, Inc.

A Unit of IDEX Corporation

4799 Dahlia Street Denver, CO 80216-0307 USA

P: 1-800-525-0758 F: 1-800-624-3925

www.BAND-IT-IDEX.com

8 of 28

Document # I17794 Rev D

© Copyright

BAND-IT-IDEX, Inc. 2009

All rights reserved

Page 9

Setup &

Assembly

Instructions

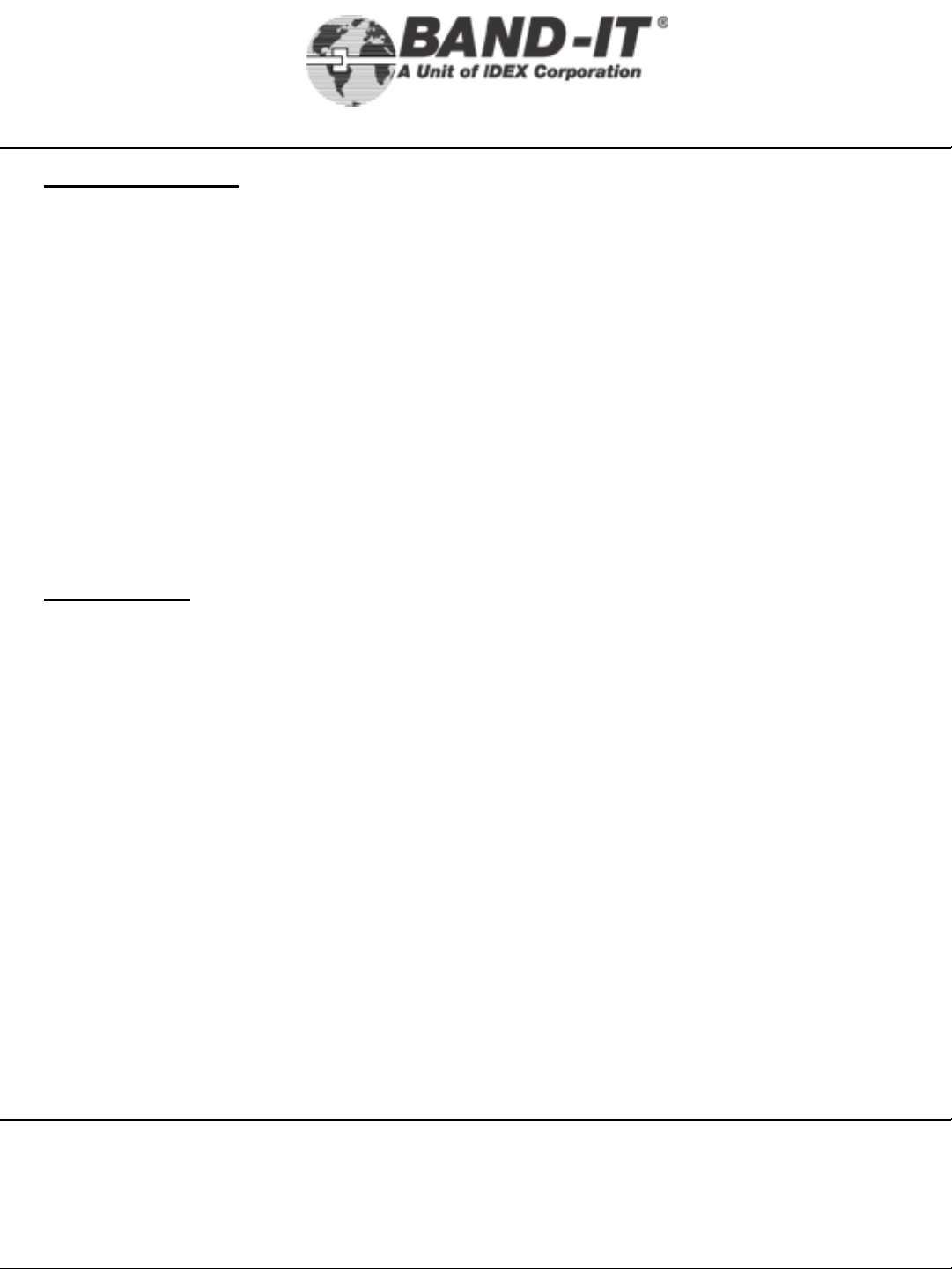

Handle adjustment:

• Using 1/4” hex key (supplied), adjust

the Support Arm/Handle to

ergonomically match the operators

hand.

• Be sure not to adjust the Handle too far

outward (beyond interlocking legs) or

the handle will not function properly or

provide support to the operator.

IT4000-AB

5/16” Band-Lok

Tool

Hanger Support Instructions:

1. An aluminum hanger (accessory)

can be utilized for supporting the

tool.

2. A hanger can be installed (as

shown) into the two threaded holes.

3. Secure the hanger against the tool

body with the two supplied screws.

4. A light application of vibratite is

already included on the screw’s

thread.

Hanger Mount

BAND-IT-IDEX, Inc.

A Unit of IDEX Corporation

4799 Dahlia Street Denver, CO 80216-0307 USA

P: 1-800-525-0758 F: 1-800-624-3925

www.BAND-IT-IDEX.com

9 of 28

Document # I17794 Rev D

© Copyright

BAND-IT-IDEX, Inc. 2009

All rights reserved

Page 10

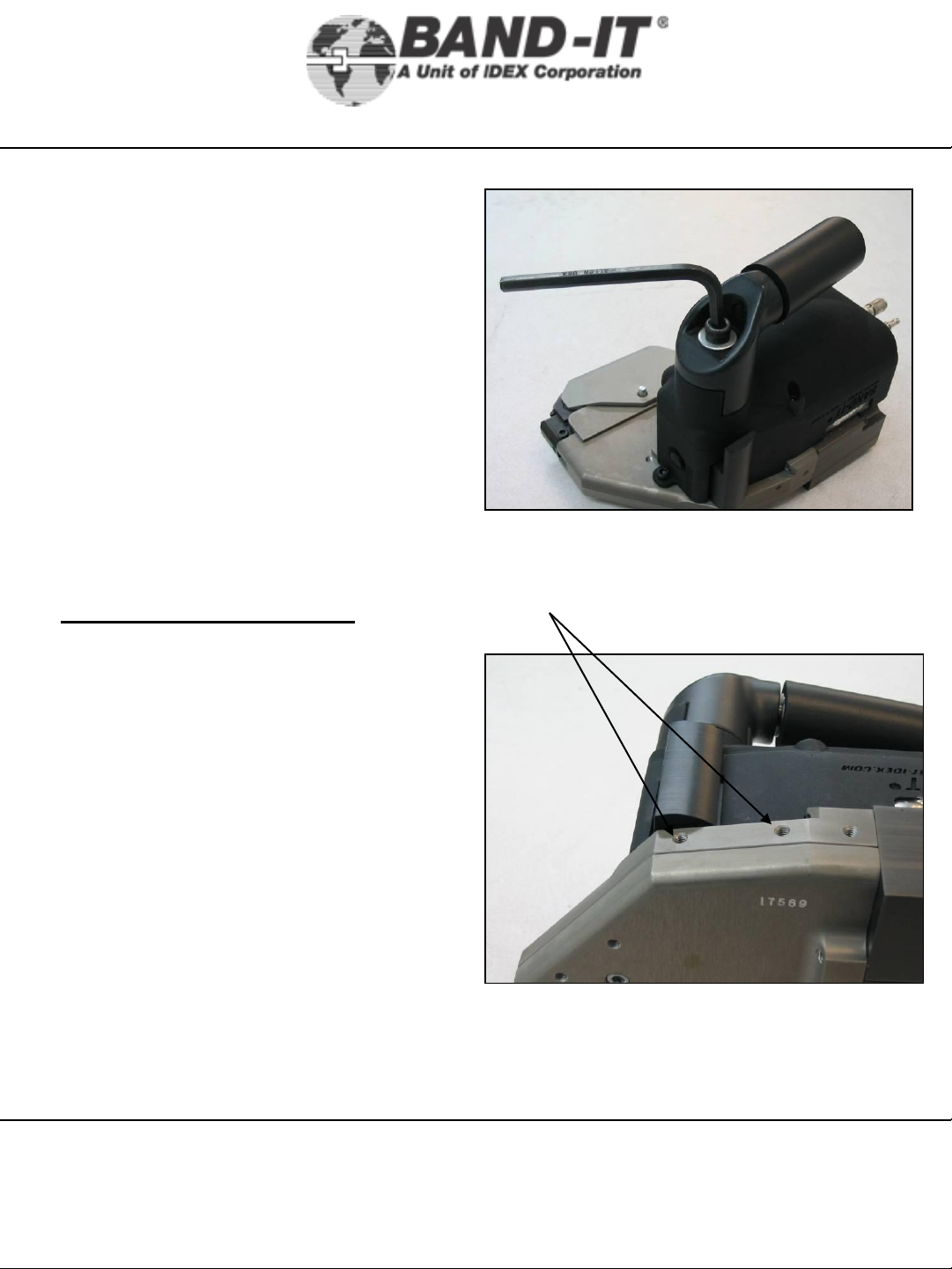

Setup &

Assembly

Instructions

Three additional fixture mounting holes are available

to assist with mounting the IT4000. Thread size is

#10-32 for each of the holes. Usable thread depth is

.400” for two of the three fixture holes. One hole is

utilized to attach and lock the tool body halves

together. This hole may also be used for fixturing,

provided the #10-32 cap screw is replaced with a

similar threaded screw with appropriate thread

length secure the two halves together in addition to

fixturing.

IT4000-AB

5/16” Band-Lok

Tool

Fixture Mounting LocationsFixture Locating Points

BAND-IT-IDEX, Inc.

A Unit of IDEX Corporation

4799 Dahlia Street Denver, CO 80216-0307 USA

P: 1-800-525-0758 F: 1-800-624-3925

www.BAND-IT-IDEX.com

10 of 28

Note: Hole locations

are .750” to

centerline of holes

and edge of tool as

indicated by the

detail to the left.

Document # I17794 Rev D

© Copyright

BAND-IT-IDEX, Inc. 2009

All rights reserved

Page 11

Setup &

Assembly

Instructions

Part of insuring that the tool is producing a strong lock is making sure that it approaches

the application correctly and is fixtured to allow repeatability of application. The tool

should approach the surface tangent to where the buckle of the band is to be applied.

The tool should be allowed to float 1/8” – 1/4” above the surface to allow the buckle to

move to the proper position for cut-off. Once the tool begins tensioning, the band will

pull the tool down to the surface.

IT4000-AB

5/16” Band-Lok

Tool

1/8” – 1/4”

Buckle LocationPivot Point

As the band is tensioning, the tool may rotate clockwise up to 5 degrees about the pivot

point (Green Arrow). During the cut-off cycle, the tool must be allowed to rotate counterclockwise up to 35 degrees (Blue Arrow). Because of this movement, BAND-IT

recommends that the tool be mounted in a fixture that will provide adequate

rotation during both cycles.

BAND-IT-IDEX, Inc.

A Unit of IDEX Corporation

4799 Dahlia Street Denver, CO 80216-0307 USA

P: 1-800-525-0758 F: 1-800-624-3925

www.BAND-IT-IDEX.com

11 of 28

Document # I17794 Rev D

BAND-IT-IDEX, Inc. 2009

© Copyright

All rights reserved

Page 12

Remote Operation

& Fixturing Tips

IT4000 Orientation Requirements:

• The IT4000 tool has a number of Tool/Clamp/Object Being Clamped

orientation requirements that must be followed in order to reach an acceptable

end result.

• In concept, the fixture maker should attempt to replicate the natural human

wrist/elbow/shoulder motions that would occur when operating the tool in the

hand-held configuration, allowing the tool to float along a plane through the

entire Tension (pull-up) and Cut-Off (lock) process.

The tool MUST:

• Contact the object being clamped without restricting or forcing.

IT4000-AB

5/16” Band-Lok

Tool

Suggestions Include:

• The tool fixture should be able to accommodate some longitudinal rotational

movement, i.e. “wrist like”, at the final moment of applied tension. The

purpose being, to allow the tool freedom of movement to orient itself in its best

natural orientation as relates to the clamp and the object-being-clamped.

• A home or neutral position should be established at the optimal final position

with +/- 10-12½ degrees of rotational freedom being allowed from the pivot

point.

• The tool fixture should be able to accommodate some extensive movement,

i.e. “elbow like”, during the tension phase to allow the tool to be “pulled” up to

the object being clamped.

• Deviations from accommodating the natural inclination of the tool/clamp/object

being clamped, may negatively impact the integrity of the final assembly. The

clamp should fully rest upon the object being clamped at the time of final

tension and cut-off. If the tool can not reach the object being clamped and

attempts to cut-off, the clamp and/or lock may not form optimally.

BAND-IT-IDEX, Inc.

A Unit of IDEX Corporation

4799 Dahlia Street Denver, CO 80216-0307 USA

P: 1-800-525-0758 F: 1-800-624-3925

www.BAND-IT-IDEX.com

12 of 28

Document # I17794 Rev D

© Copyright

BAND-IT-IDEX, Inc. 2009

All rights reserved

Page 13

IT4000-AB

Remote Operation

& Fixturing Tips

IT4000 Configured for Remote Actuation:

• The IT4000 with trigger option 1 and is a modified version of the base unit. A tool with trigger option 0 is

manually operated via the incorporated thumb actuation lever. A tool with trigger option 1 is configured to

allow remote operation via palm button or other device permitting the tool to be incorporated into the

customer’s fixture or assembly process. Band-It offers a Foot Control Kit (I17490) for this purpose.

• The modification consists of deactivating the thumb lever actuation switch and installing two 6-ft X 1/8”

O.D. hoses to accomplish the same task via the use of a remote actuation device such as a palm button

or other device that can provide a pneumatic signal to pilot the tension control valve.

• Various actuation devices can be incorporated based upon end user requirements. Basic schematic for 2-

way & 3-way valves included below. The valve should be set up in the normally closed mode and upon

opening the circuit a supply of air is provided.

• The customer is responsible for incorporating this tool into their process, BAND-IT is available to provide

advice and recommendations.

5/16” Band-Lok

Tool

Remote trigger: 2-way valve

Hose from tool

(male quick disconnect)

Actuate

to stop

tool

Supply Hose from

tool 90-120 PSI

(female quick disconnect)

Multiple Triggers

Hose from tool

(male)

If more than one trigger is used,

connect in series. All need to be

actuated to run the tool.

Supply Hose from

tool 90-120 PSI

(female)

Actuate

to start

tool

Remote trigger: 3-way valve

Hose from

tool (male)

Actuate to

stop tool

Supply Hose from

tool 90-120 PSI

(female)

Connect the 2 hoses extending

from the tool to the ports of the

valve. As the hoses are not

marked, they may need to have

their connection on the valve

reversed if the remote trigger

does not start the tool.

Actuate to

start tool

BAND-IT-IDEX, Inc.

A Unit of IDEX Corporation

4799 Dahlia Street Denver, CO 80216-0307 USA

P: 1-800-525-0758 F: 1-800-624-3925

www.BAND-IT-IDEX.com

13 of 28

Document # I17794 Rev D

© Copyright

BAND-IT-IDEX, Inc. 2009

All rights reserved

Page 14

IT4000-AB

Operating Tips

5/16” Band-Lok

Tool

Clamp Installation:

When installing a clamp, a random visual check to verify the presence of a locking lip

after the clamp has been applied is recommended. The lip is the locking element of

an installed band. The IT4000 forms a dimple into the band at the buckle edge with

the knife. By controlling and monitoring the items that are needed to form a good

lock, an operator can help insure that the clamp will be applied correctly without

having to inspect every assembly.

These items are:

• Adequate air pressure and volume (see page 4, 6)

• Setting the tool air pressure (see page 4, 6)

• Following recommended PM Schedule (see page 21)

• Fixture mounting the tool properly (see page 10-13 )

For best performance and to extend tool life:

• Follow preventative maintenance and parts replacement instructions

(page 21) at appropriate service intervals.

• Do not remove factory applied lubrication from inside tool unless performing a

thorough maintenance procedure and then replacing with fresh lubricant

immediately.

• Do not use degreaser in the tool body.

• Do not spray any lubricant or cleaner into the Quick Connect Air Couplings.

• Use nominal recommended tension setting (listed on page 4, 6). Higher pressure

may not result in a tighter clamp, but increases the likelihood of clamp tail jamming

and premature worn parts.

• Do not over-tighten Knife Pin access screws. Over tightening of these screws may

result in stripping screw threads.

• For maintenance beyond what is described in this manual, consult BAND-IT.

BAND-IT-IDEX, Inc.

A Unit of IDEX Corporation

4799 Dahlia Street Denver, CO 80216-0307 USA

P: 1-800-525-0758 F: 1-800-624-3925

www.BAND-IT-IDEX.com

14 of 28

Document # I17794 Rev D

© Copyright

BAND-IT-IDEX, Inc. 2009

All rights reserved

Page 15

Operating

Instructions

IT4000-AB

5/16” Band-Lok

Tool

2.5”

1. Insert clamp tail into tool as shown. Clamp tail length

extending into tool must be at least 2.5” (6.4 cm) long. The

head of the tool should rest against the buckle. Note - Do not

activate tool while inserting clamp tail. This can cause

clamp tail to jam in the Tension Block Assembly.

2. Begin tensioning clamp by pushing and holding down

operating trigger

3. Band should be applied to a uniform solid surface allowing

the buckle adequate support during the clamp locking and

clamp tail cut-off operation.

4. While tensioning clamp, hold tool slightly tipped forward.

This will assist proper clamp installation. Continue to hold

down operating trigger until tool completely tensions and

cuts off clamp. Release trigger after cut off.

5. After clamp is completed, clamp tail scrap must be

removed from tool. Clamp tail scrap is not ejected

automatically. Tool is now ready for next clamp.

BAND-IT-IDEX, Inc.

A Unit of IDEX Corporation

4799 Dahlia Street Denver, CO 80216-0307 USA

P: 1-800-525-0758 F: 1-800-624-3925

www.BAND-IT-IDEX.com

15 of 28

Document # I17794 Rev D

© Copyright

BAND-IT-IDEX, Inc. 2009

All rights reserved

Page 16

IT4000-AB

Troubleshooting

5/16” Band-Lok

Tool

Tool fails to fully tension clamp:

Failure to fully tension the clamp can be caused by a variety of factors. The two most

common factors are: incorrect tension pressure and problems in the Tension Block

Assembly.

Check tension pressure setting on Tension Pressure Gauge of Air Controller Module.

Adjust pressure per the settings in the Setup & Assembly Instructions section found on

(pages 9-11).

After air pressure settings are verified or corrected, if failure to fully tension clamps

continues, evaluate the clamp tail dimple pattern. If elongated dimples are present, the

problem may be with the Tension Block.

Normal clamp tail

dimple pattern.

If a problem is indicated, follow the instructions on page 24 to remove the tension block

assembly.

Examine the Tension Block components for excess lubrication. Refer to lubrication

instructions on pages 24, 27.

If dirt or debris is visible, follow the cleaning instructions on page 24.

Examine the Tension Block and Gripper for wear (see below).

If excessive wear is determined, follow the instructions on page 24 to replace the worn

parts.

BAND-IT-IDEX, Inc.

A Unit of IDEX Corporation

www.BAND-IT-IDEX.com

Clamp tail dimple pattern indicates

problem in the tension block

assembly.

Document # I17794 Rev D

© Copyright

4799 Dahlia Street Denver, CO 80216-0307 USA

P: 1-800-525-0758 F: 1-800-624-3925

16 of 28

BAND-IT-IDEX, Inc. 2009

All rights reserved

Page 17

IT4000-AB

Troubleshooting

5/16” Band-Lok

Tool

Tool fails to cut off clamp tail:

• The Inlet Air Pressure may be low. Check air supply to Air Controller Module. Cut-off

Pressure Gauge should indicate 105 PSI minimum, 110 PSI maximum. See pages 4 - 6 for

air supply requirements.

• The scrap clamp tail from the previous clamp may not have been removed. Press the Reset

Button to release the tension on the clamp and remove the scrap clamp tail.

• The Cutter Blade or Knife may be worn. See below for Cutter Blade inspection and

replacement.

• Note: The Flip Cover Tightening Screw and Flip Cover Head Screws are factory tensioned

and will need to have thread locking compound reapplied and be re-tensioned after the quick

release pins are reinstalled upon completion of maintenance.

Cutter Blade inspection and replacement:

1. Loosen the Flip

Cover Tightening

Screw and Flip Cover

Head Screws (see

note above) to remove

both Quick Release

Pins as shown.

3. Remove the Cutter

Blade Pin and Cutter

Blade.

2. Remove Flip

Cover and

Tension Block

Assembly for

cleaning and

lubrication.

4. When installing

the Cutter Blade

Pin, use a small

screwdriver to

push the front

gripper toward the

back of the tool.

BAND-IT-IDEX, Inc.

A Unit of IDEX Corporation

4799 Dahlia Street Denver, CO 80216-0307 USA

P: 1-800-525-0758 F: 1-800-624-3925

www.BAND-IT-IDEX.com

17 of 28

Document # I17794 Rev D

© Copyright

BAND-IT-IDEX, Inc. 2009

All rights reserved

Page 18

Symptom Probable cause Recommended Fix Page

Rear tension block slipping,

therefore tool does not

reach cut off tension.

Remove and inspect gripper block assembly. Replace as

required.

24

Front gripper slipping

Remove and inspect front gripper and gripper guide arm.

Replace if worn.

*

Dirty front and rear gripper

interfaces

Remove and clean contact surfaces surrounding grippers. 24

Air leaks when trigger is not

activated

Listen for air leaks. Check red valve , Air lines, and

replace as required. No air leaks allowed. Remove and

replace as required or contact BAND-IT.

28

Worn flip cover and tool

body

Inspect inside of flip cover and bottom of tool body for

excessive wear. Replace flip cover as required. For tool

body wear contact BAND-IT for evaluation.

28

Water or oil in pneumatic

lines.

Purge pneumatic lines and red four way valve assembly.

Install a desiccant air dryer or similar which meets tool set

up requirements.

*

Tool cutting before full

tension applied.

Verify cut-off timing. If required, remove right side body

and adjust timing valve. Replace if damaged.

28

Premature release of trigger Hold trigger down until tool completes cut off cycle 15

Fluctuating facility air

pressure

Verify if facility air pressure meets tool set up

requirements (see manual). Air booster system may be

4-8

Worn knife/blade

Remove and replace knife and blade. Refer to

maintenance schedule.

21,22

Timing valve adjustment

Verify timing. If required, remove right side body and

adjust timing valve. Replace if damaged.

28

Rear tension block slipping,

therefore tool does not

reach cut off tension.

Remove and inspect gripper block assembly. Replace as

required.

24

Coiled hose line has air leak

Verify no air leaks in coiled hose assembly. Remove and

replace as required.

4-8

Front gripper slipping

Remove and inspect front gripper and gripper guide arm.

Replace if worn.

*

Red four way valve

malfunction

Remove clean and inspect. Replace as required. *

Worn blade pin or housing

Remove and replace blade pin and/or Maintenance Flip

Cover

23

Tool will not

tension

properly (i.e.

slipping, slow

etc.)

Tool will not

cut off clamp

tail

Troubleshooting

Matrix

IT4000-AB

5/16” Band-Lok

Tool

BAND-IT-IDEX, Inc.

A Unit of IDEX Corporation

4799 Dahlia Street Denver, CO 80216-0307 USA

P: 1-800-525-0758 F: 1-800-624-3925

www.BAND-IT-IDEX.com

18 of 28

Document # I17794 Rev D

BAND-IT-IDEX, Inc. 2009

All rights reserved

© Copyright

Page 19

Symptom Probable cause Recommended Fix Page

Linkage components

damaged, causing

interference

Remove tool left side body and verify linkage mechanism.

Remove and replace damage as required or contact BANDIT.

27

Cut-off cylinder seal

damaged or leaking

Remove left side tool body and verify seal integrity *

Cut off pneumatic air leak

Verify Coiled Hose Assembly is free of air leaks. Remove

handle cover and inspect for leaks on gray anodized valve

assembly and red valve assembly. Inspect for leaks in

pneumatic system.

*

Water or oil in pneumatic

lines.

Purge pneumatic lines and red four way valve assembly.

Install a desiccant air dryer or similar equipment which meets

tool requirements).

4

Screws holding Cutter Knife

Pin too long or loose

Verify proper length screws and Cutter Knife Pin seated

properly.

23

Coiled hose line is reversed

(i.e. cut off pressure is

actually going to tension

cylinder.

Verify coiled hose air line from right side of control module

enters bottom fitting on tool.

4,5,7

Improper tool use Verify operator properly trained and familiar with tool manual. 5,7,8,14

Tension setting too low Adjust Air Controller Module's tension setting per instructions. 4

Improper buckle location or

application

Locate buckle on smallest radius area. Buckle must be

supported underneath during application. Contact BAND-IT

for application verification / recommendation.

15

Tool cuts clamp tail before

reaching full tension.

Verify timing. If required remove right side handle and adjust

Timing Valve. Replace if damaged.

28

Worn Cutter Knife/ Cutter

Blade

Remove and replace Cutter Knife and Cutter Blade. Refer to

maintenance schedule.

17

Air leaks when trigger is not

activated

Listen for air leaks. Check red valve, Air lines, and replace as

required. No air leaks allowed. Remove and replace as

required or contact BAND-IT.

Contact BAND-

IT for

assistance

Control Module air pressure

valve is in "off" position.

Rotate Control Module valve to open position. Verify gauges

read air pressure.

5

Pinched coil hose line

Loosen fitting on coiled hose assembly where it enters tool

body.

4,7

Kinked or pinched air line

Remove right side handle and inspect air lines. Remove and

replace as required.

28

Tension piston interference

with hanger screw holes.

Loosen Hanger Screw on top of tool. Thread engagement

cannot exceed .125 in.

11

Quick disconnect fittings

not positively engaged.

Disconnect and firmly reconnect. 5,8

Tool will not

operate when

trigger is

depressed

Loose clamp

after cut-off

Tool will not cut

off clamp tail -

Continued.

Troubleshooting

Matrix

IT4000-AB

5/16” Band-Lok

Tool

BAND-IT-IDEX, Inc.

A Unit of IDEX Corporation

4799 Dahlia Street Denver, CO 80216-0307 USA

P: 1-800-525-0758 F: 1-800-624-3925

www.BAND-IT-IDEX.com

19 of 28

Document # I17794 Rev D

BAND-IT-IDEX, Inc. 2009

All rights reserved

© Copyright

Page 20

Symptom Probable cause Recommended Fix Page

Control Module air pressure

valve is in "off" position.

Rotate Control Module valve to open position. Verify

gauges read air pressure and check all air

connections.

5

Clamp tail inside tool

Remove clamp tail, if jammed remove

maintenance/flip cover and remove clamp material.

15,17

Knife is in down position.

Remove or replace knife. Verify missing and or

damaged linkage.23Wrong clamp type for tool Verify proper tool for selected clamp. cover

Handle will not

adjust

Handle nut is

damaged/misaligned.

Remove handle assembly and inspect nut/housing for

damage. Replace as required.

9

Clamp will not

insert into tool

Troubleshooting

Matrix

* = for additional assistance, contact BAND-IT

IT4000-AB

5/16” Band-Lok

Tool

BAND-IT-IDEX, Inc.

A Unit of IDEX Corporation

4799 Dahlia Street Denver, CO 80216-0307 USA

P: 1-800-525-0758 F: 1-800-624-3925

www.BAND-IT-IDEX.com

20 of 28

Document # I17794 Rev D

BAND-IT-IDEX, Inc. 2009

All rights reserved

© Copyright

Page 21

IT4000-AB

Maintenance

5/16” Band-Lok

Tool

Tool Preventative Maintenance:

The tool has some wear components that must be checked and replaced on a certain

schedule. BAND-IT has developed a Preventative Maintenance (PM) schedule to help

facilitate these requirements. If tools are experiencing difficulties during function or there

audible air leaks coming from inside the handle, the tool should be returned to BAND-ITIDEX, Inc. for servicing.

BAND-IT recommends that the tool be sent in for general overhaul every 100,000 clamps

installed.

Preventative Maintenance Schedule

Clamps

Installed

Every 12,500 Tension Block Assembly Clean & Re-Lubricate

Every 25,000 Mechanical Linkage Clean & Re-Lubricate

Every 50,000 Blade, Blade pin, Knife

Maintenance

Item

Flip Cover Clean & Re-Lubricate

Tool Head Clean & Re-Lubricate

Cut-off Blade Replace

Cut-off Knife Replace

Front Gripper Clean & Re-Lubricate

and Knife pin

Tension Block Assembly Replace Assembly

Front Gripper Replace Gripper

Maintenance

Action

Replace

BAND-IT-IDEX, Inc.

A Unit of IDEX Corporation

4799 Dahlia Street Denver, CO 80216-0307 USA

P: 1-800-525-0758 F: 1-800-624-3925

www.BAND-IT-IDEX.com

21 of 28

Document # I17794 Rev D

© Copyright

BAND-IT-IDEX, Inc. 2009

All rights reserved

Page 22

IT4000-AB

Maintenance

5/16” Band-Lok

Tool

Production tools will experience wear of specific parts. Preventative maintenance, including

regular cleaning and lubrication, will reduce the replacement frequency of these parts. To

maximize life, use synthetic gel lubricant containing Teflon. See (pages 22-28) for tool

maintenance. When repairing tools, threaded fasteners should be secured using a small

amount of Loctite, Blue - Medium strength being careful to apply sparingly.

Replacement Parts

Part #

I16087 Knife 1

I13887 Knife pin 1

I17687 Knife mounting screws 2

I16187 Blade 1

I13987 Blade pin 1

I30187 Tension block 1

I30190 Tension Block Assembly (Includes I30187,

I10388, I10888, and 2 A38487)

I24199 Flip Cover Assembly (Includes assembled flip

cover and 2 quick release pins)

I16387 Lubricant (synthetic gel lubricant containing

Teflon)

Description

Quantity per

Tool

1

1

Note –Please have tool model and serial #’s available when calling the factory for

service or assistance. Contact BAND-IT-IDEX customer service, 800-525-0758.

Part numbers are subject to change.

BAND-IT-IDEX, Inc.

A Unit of IDEX Corporation

4799 Dahlia Street Denver, CO 80216-0307 USA

P: 1-800-525-0758 F: 1-800-624-3925

www.BAND-IT-IDEX.com

22 of 28

Document # I17794 Rev D

© Copyright

BAND-IT-IDEX, Inc. 2009

All rights reserved

Page 23

Maintenance

Knife Assembly Replacement:

IT4000-AB

5/16” Band-Lok

Tool

A) Remove Cutter Blade as described on page 17.

B) Remove the 2 Knife Pin access screws. These

are special length screws.

Important: When repairing tools, threaded fasteners

should be secured using Loctite, Blue - Medium

strength.

To remove Cutter Knife Pin the Knife Assembly

must be in its uppermost position indicated by the

Cutter Knife Pin in line with the access hole. If not

aligned, connect the tool to the Air Controller

Module. Open the Air Shut-off Valve to

momentarily pressurize the tool. Close the valve

and disconnect the tool from the Air Controller

Module. Then push out the Cutter Knife Pin with

a piece of wire (for example, a bent paper clip).

BAND-IT-IDEX, Inc.

A Unit of IDEX Corporation

4799 Dahlia Street Denver, CO 80216-0307 USA

P: 1-800-525-0758 F: 1-800-624-3925

www.BAND-IT-IDEX.com

Note the orientation of the knife prior to removal.

Once the pin is removed, grasp the Knife

Assembly with a pair of needle-nose pliers and

pull out of tool head. Examine for wear and

replace if needed.

Re-install all parts in reverse order. After the

Maintenance Flip Cover is installed and Quick

Release Pins are in place, apply tension to the

Flip Cover Tightening Screw and Flip Cover

Head Screws.

Document # I17794 Rev D

© Copyright

23 of 28

BAND-IT-IDEX, Inc. 2009

All rights reserved

Page 24

IT4000-AB

Maintenance

5/16” Band-Lok

Tool

Tension Block Assembly Maintenance:

Remove the Maintenance Flip Cover by loosening the Maintenance Cover Tightening Screw and Flip Cover

Screws on the Maintenance Flip Cover and removing both Quick Release Pins as shown on page 17.

Tension Block

Assembly

Tension

Gripper

Tension Block Assembly

Compression Spring - 2

Tension Block

Tension Block Assembly, inspection and parts replacement:

Disassembly:

• Lift and remove the Tension Block Assembly from the notch on the Tension Arm.

• Push out the Gripper. remove the loose Gripper Springs.

• Push out the Gripper Pin.

Inspection:

• Inspect and replace the Tension Block if worn.

• Inspect and replace the Tension Gripper if worn.

• Inspect and replace the Gripper Pin if worn.

Reassembly:

• Lubricate the Gripper surfaces as shown on page 27.

• Install the Gripper in the Tension Block.

• Lubricate the Tension Pin surfaces as shown on page 27.

• Install the Gripper Pin in the Tension Block.

• Reinstall the Gripper Springs.

• Reinstall the Tension Block Assembly. Be sure to engage

the Tension Block Pin with the notch on the Tension Arm.

• Lubricate the Maintenance Flip Cover as described on page 27.

• Reinstall the Maintenance Flip Cover and insert Quick Release Pins.

• Tension the Flip Cover Tightening Screw and Flip Cover Head

Screws to complete reassembly.

Tension Block Pin

Tension Gripper

BAND-IT-IDEX, Inc.

A Unit of IDEX Corporation

4799 Dahlia Street Denver, CO 80216-0307 USA

P: 1-800-525-0758 F: 1-800-624-3925

www.BAND-IT-IDEX.com

24 of 28

Document # I17794 Rev D

© Copyright

BAND-IT-IDEX, Inc. 2009

All rights reserved

Page 25

IT4000-AB

Maintenance

5/16” Band-Lok

Tool

• Remove the Maintenance Flip Cover. Examine all moving parts and linkages for wear.

• Using an air nozzle, gently clean the parts of any dirt and metal filings in the tensioning

cavity.

• Using cotton swabs or a short bristled brush, continue to wipe away any foreign debris and

purge once again with the air nozzle.

• After thoroughly cleaning all moving parts, re-lubricate all surfaces. Following are lubrication

instructions.

• For mechanical parts lubrication use a synthetic gel lubricant containing Teflon.

Procedure for disassembly to clean and lubricate the

mechanical linkage points

1) Remove the two screws located at the back of the

cylinders. Remove third screw holding the side

bodies together. Holding the tool in place, gently

lift the side cover exposing the mechanical linkage.

This side cover is a close fit and may require a

slight rocking motion to separate the cover from

the tool.

2) Examine the linkage for over-all condition such as

dirt, metal filings, liquid contamination and

lubrication.

3) Examine the upper cylinder (tension cylinder), for

evidence of air leaks, noted by residue around the

piston.

4) Clean tool cavity, including tool body, linkage, and

already removed tool cover.

BAND-IT-IDEX, Inc.

A Unit of IDEX Corporation

4799 Dahlia Street Denver, CO 80216-0307 USA

P: 1-800-525-0758 F: 1-800-624-3925

www.BAND-IT-IDEX.com

25 of 28

Document # I17794 Rev D

© Copyright

BAND-IT-IDEX, Inc. 2009

All rights reserved

Page 26

Maintenance

IT4000-AB

5/16” Band-Lok

Tool

4) Lubricate the removed cover as shown with red arrows above. Also,

lubricate the tool body, linkage and Tension Block Assembly as shown on page 27.

5) Inspect all mechanical linkage for lubrication, proper placement and refit cover.

6) Secure the tool side cover by inserting and tightening (2) #10 – 32 X 4”

length cap screws through the Cylinder Housing and into the Cover. Apply

a light dab of Blue Loctite to one or two threads to prevent loosening during

operation.

BAND-IT-IDEX, Inc.

A Unit of IDEX Corporation

4799 Dahlia Street Denver, CO 80216-0307 USA

P: 1-800-525-0758 F: 1-800-624-3925

www.BAND-IT-IDEX.com

26 of 28

Document # I17794 Rev D

© Copyright

BAND-IT-IDEX, Inc. 2009

All rights reserved

Page 27

IT4000-AB

Maintenance

5/16” Band-Lok

Tool

Lubrication – Follow recommended intervals – Use a synthetic gel lubricant containing

Teflon for the internal parts as shown and described. Lubricate all pivot points and internal

surfaces of maintenance flip cover with a light coating of the lubricant.

Caution – Excessive amounts of lubricant may result in gripper slippage, requiring a

full repeat of cleaning process.

Lightly lubricate all

points indicated with

Maintenance Flip Cover

every 12,500 cycles

red arrows.

Tool mechanics

every 25,000 cycles

After the Maintenance

Flip Cover is cleaned,

lubricated, installed and

Quick Release Pins are

in place, apply tension to

the Flip Cover

Tightening Screw and

Flip Cover Head Screws.

Refer to pages 7, 17.

BAND-IT-IDEX, Inc.

A Unit of IDEX Corporation

4799 Dahlia Street Denver, CO 80216-0307 USA

P: 1-800-525-0758 F: 1-800-624-3925

www.BAND-IT-IDEX.com

27 of 28

Tension Block Assembly

every 12,500 cycles

Note: Ensure no

lubrication is present in

the center of Gripper.

(indicated by the blue

circle)

Document # I17794 Rev D

© Copyright

BAND-IT-IDEX, Inc. 2009

All rights reserved

Page 28

Maintenance

Procedure to adjust the timing of the clamp tail cut-off:

Bottom airline

IT4000-AB

5/16” Band-Lok

Tool

The Timing Valve will be affected over time by

contaminants in the air system. Moisture, dirt

particles, oil and solvents can cause blockage or

fluctuations in the tool performance.

Cycle should be .5 – 1.0 seconds.

Cut-off timing set too short will not allow the clamp to

achieve the desired tension before switching to the

cut-off function causing a loose clamp. Clamping on

softer objects requires a longer timing.

Cut-off timing set too long may slow production and

cause operator to twist the tool during application.

This may damage tool.

Procedure:

1) Remove the two cap screws in the Handle Cover with

a 9/64” hex key. Remove cover and lay aside during

their removal. The Brass Needle Valve used to adjust

timing is highlighted in view to the left.

BAND-IT-IDEX, Inc.

A Unit of IDEX Corporation

2) To adjust: Hold the valve in position being careful not

to kink tubing inside tool. Start by gently turning the

Adjusting Valve Screw clockwise until snug. Back out

the Adjusting Screw counterclockwise 1 1/2 turns.

This should be the proper setting, yielding a .5-1.0

second delay.

3) To test and verify proper adjustment: Connect the tool

to the Air Control Module, then turn supply valve on.

Gently kink the coiled air supply tube connected to the

bottom Quick Connect Air Coupling (top photo), then

activate the Tool Trigger. This action causes the tool

to cut off, allowing the timing to be reviewed. Adjusting

the Timing Screw in by ½ turn will slow the tool’s cutoff action. Adjusting the Timing Screw out by a half

turn increases the speed of the cut-off activation.

Repeat this entire step until timing is set at a .5 – 1.0

second delay. Caution: Setting timing to less than

.5 may result in loose clamps.

www.BAND-IT-IDEX.com

Document # I17794 Rev D

© Copyright

4799 Dahlia Street Denver, CO 80216-0307 USA

P: 1-800-525-0758 F: 1-800-624-3925

28 of 28

BAND-IT-IDEX, Inc. 2009

All rights reserved

Loading...

Loading...