Page 1

Operating

G40269 Giant II

Instructions

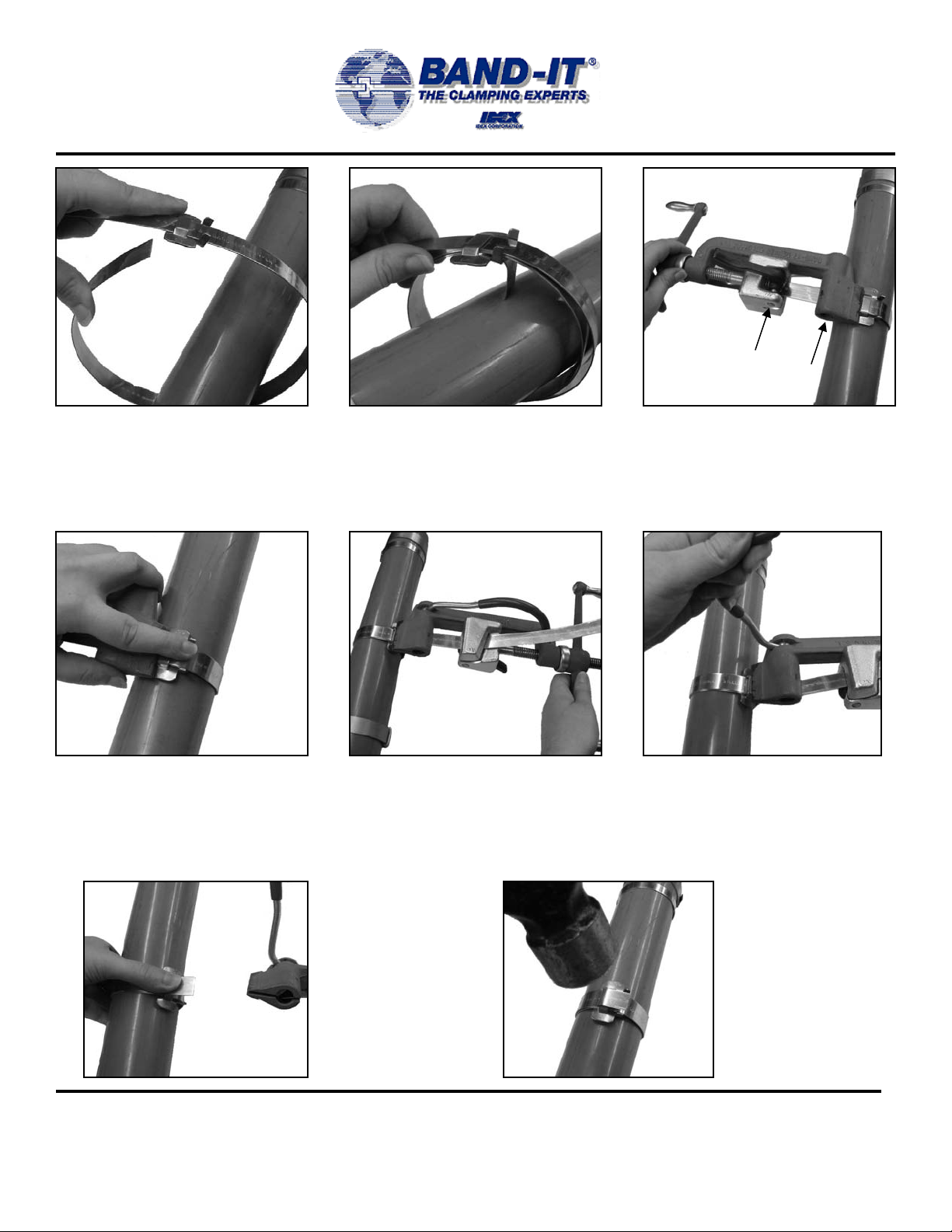

1. Band may be used from bulk roll as this

completely eliminates waste of band. Slide

buckle on band as shown, bringing end of

band around object to be clamped and

again through buckle.

4. Place finger on BAND-IT Band at buckle

bridge while tensioning with tool handle.

When you feel BAND-IT Band stop moving

through buckle as you are turning handle,

maximum pressure is being exerted by the

BAND-IT Band around object being

clamped. Stop turning handle.

2. Continue band around object once

more and again through buckle.

Double banding develops a great deal

more radial compression than single

banding. Bend end of band under

buckle.

5. Roll tool over buckle, backing off with

tension handle1- 1½ turns throughout entire

rolling operation. Failure to back off tension

with tension handle throughout entire course

of roll-over may result in breaking of band.

There is no loss of tension as band released

is used up in the bend.

Hand Tool

3. Place band in open of tool nose and

gripper block. Move into slot as far as

possible, to avoid buckle sliding into tool

nose. Apply tension by turning handle of

tool.

6. Pull cutting handle to cut the band.

When applying Giant Band clamps, prior

to cutting off clamp, release band gripper

and push tool nose away from buckle

approx. ¼”.

BAND-IT-IDEX, Inc.

A Unit of IDEX Corporation

4799 Dahlia Street

Denver, CO 80216-3070 USA

P: 1-800-525-0758

F: 1-800-624-3925

7. Remove tool,

holding stub of band

down with thumb.

www.BAND-IT-IDEX.com

Page 1 of 3

8. Hammer

down buckle

ears to complete

BAND-IT clamp.

Document # P36187 Rev. H

© Copyright

BAND-IT-IDEX, Inc. 2007

All rights reserved

Page 2

Cleaning and

G40269 Giant II

Warranty

Hand Tool

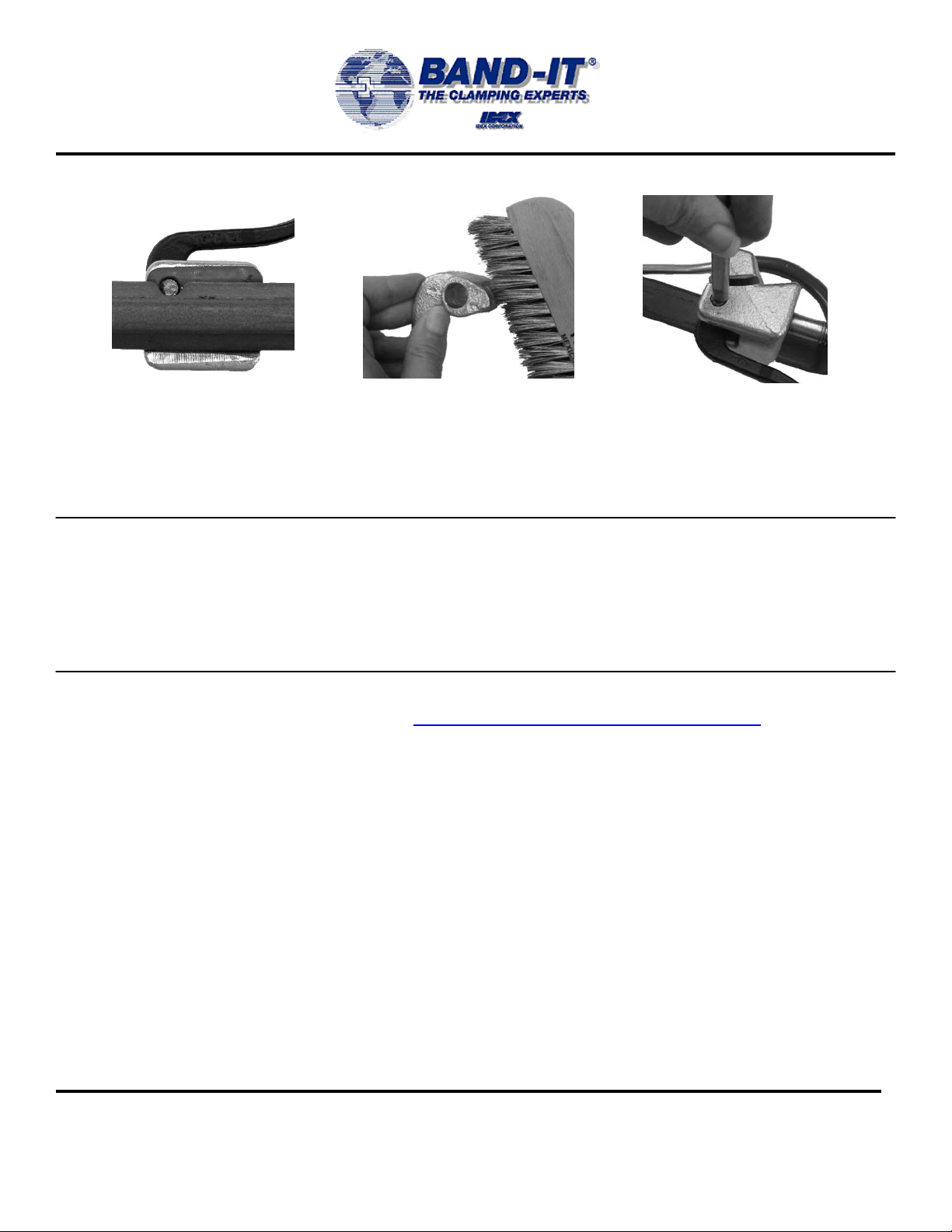

Gripper Cleaning Instructions:

1. Remove gripper. Align gripper pin

hole with notch in tool frame. Using a

punch and hammer, punch pin out of

slide block.

2. Using a wire brush, clean all

foreign matter from teeth.

NOTE: Periodically apply food-grade white lubricant or equivalent to tension screw thread (on

page 3) to prevent excessive wear.

If tool fails to securely grip tail of clamp, follow gripper cleaning instructions above.

3. Replace pin: Align gripper hole with

slide block hole, insert pin in hole and

hammer pin in place.

Refer to website for warranty information: http://www.band-it-idex.com/warranty.html

BAND-IT-IDEX, Inc.

A Unit of IDEX Corporation

4799 Dahlia Street

Denver, CO 80216-3070 USA

P: 1-800-525-0758

F: 1-800-624-3925

www.BAND-IT-IDEX.com

Page 2 of 3

Document # P36187 Rev. H

BAND-IT-IDEX, Inc. 2007

© Copyright

All rights reserved

Page 3

Tool Assembly

G40269 Giant II

Parts List

SET SCREW

CUTTER BAR

TENSION SCREW

CUTTER BAR HANDLE

SLIDE BLOCK

ECCENTRIC LEVER TENSION NUT

Hand Tool

EXTERNAL RETAINING RING

SPIN GRIP

THRUST

BEARING

TENSION HANDLE

TOOL FRAME PIN, ECC. LEVER PIVOT

1. To assist in removing threaded parts,

apply heat to soften locking compound.

2. When connecting the tension screw to

the slide block, clean threads (male and

female) of foreign matter, then apply two

drops of high strength locking compound

(Loctite 271 or equiv.) onto male threads

and connect parts together. Apply 3 oz.

of white lubricant or equiv. to tension

screw thread.

3. When connecting the set screw to the

cutter bar, clean threads (male and

female) of foreign matter, then apply one

drop of medium strength locking

compound (Loctite 242 or equiv.) onto

male thread and connect parts together.

BAND-IT-IDEX, Inc.

A Unit of IDEX Corporation

4799 Dahlia Street

Denver, CO 80216-3070 USA

P: 1-800-525-0758

F: 1-800-624-3925

www.BAND-IT-IDEX.com

REPAIR PARTS LIST FOR G40269

PART # DESCRIPTION

G41387 TOOL FRAME

G40888 THRUST BEARING

SLIDE BLOCK ASSEMBLY

G42487

INCLUDES: SLIDE BLOCK, TENSION SCREW,

TENSION NUT, ECCENTRIC LEVER, AND LEVER

PIVOT PIN

TENSION HANDLE ASSEMBLY

G42087

INCLUDES: TENSION HANDLE, SPIN GRIP AND

EXTERNAL RETAINING RING

CUTTER BAR ASSEMBLY

G42287

INCLUDES: CUTTER BAR HANDLE, CUTTER

BAR, AND SET SCREW (ON FAR SIDE)

Page 3 of 3

Document # P36187 Rev. H

© Copyright

BAND-IT-IDEX, Inc. 2007

All rights reserved

Loading...

Loading...