Page 1

BAND-IT-IDEX, Inc.

A Unit of IDEX Corporation

4799 Dahlia Street

Denver, CO 80216-0307 USA

P: 1-800-525-0758

F: 1-800-624-3925

Document # P91687 Rev. H

© Copyright

BAND-IT-IDEX, Inc. 2010

All rights reserved

www.BAND-IT-IDEX.com

Page 1 of 4

C00369 Heavy Duty

Hand Tool

Instruction

Manual

Safety Practices:

1. Read this manual and become familiar with the tool before use.

2. Protective eyewear should be worn during use.

3. Wear appropriate gloves for handling steel.

4. When applying clamps, care should be taken to insure fingers are not in contact with

the clamp during installation.

5. Never attempt to clamp objects which have the potential to burst, shatter or

otherwise cause bodily harm.

6. Do not use tool on live electrical sources.

Introduction:

The C00369 Tool installs any BAND-IT Band of .030" thickness or less and 3/4" Giant

Band of .044" thickness.

Table of Contents:

1. Introduction & Safety Practices

2. Operating Instructions

3. Tool Assembly Parts List

4. Cleaning & Warranty

Page 2

BAND-IT-IDEX, Inc.

A Unit of IDEX Corporation

4799 Dahlia Street

Denver, CO 80216-0307 USA

P: 1-800-525-0758

F: 1-800-624-3925

Document # P91687 Rev. H

© Copyright

BAND-IT-IDEX, Inc. 2010

All rights reserved

www.BAND-IT-IDEX.com

Page 2 of 4

C00369 Heavy Duty

Hand Tool

Operating

Instructions

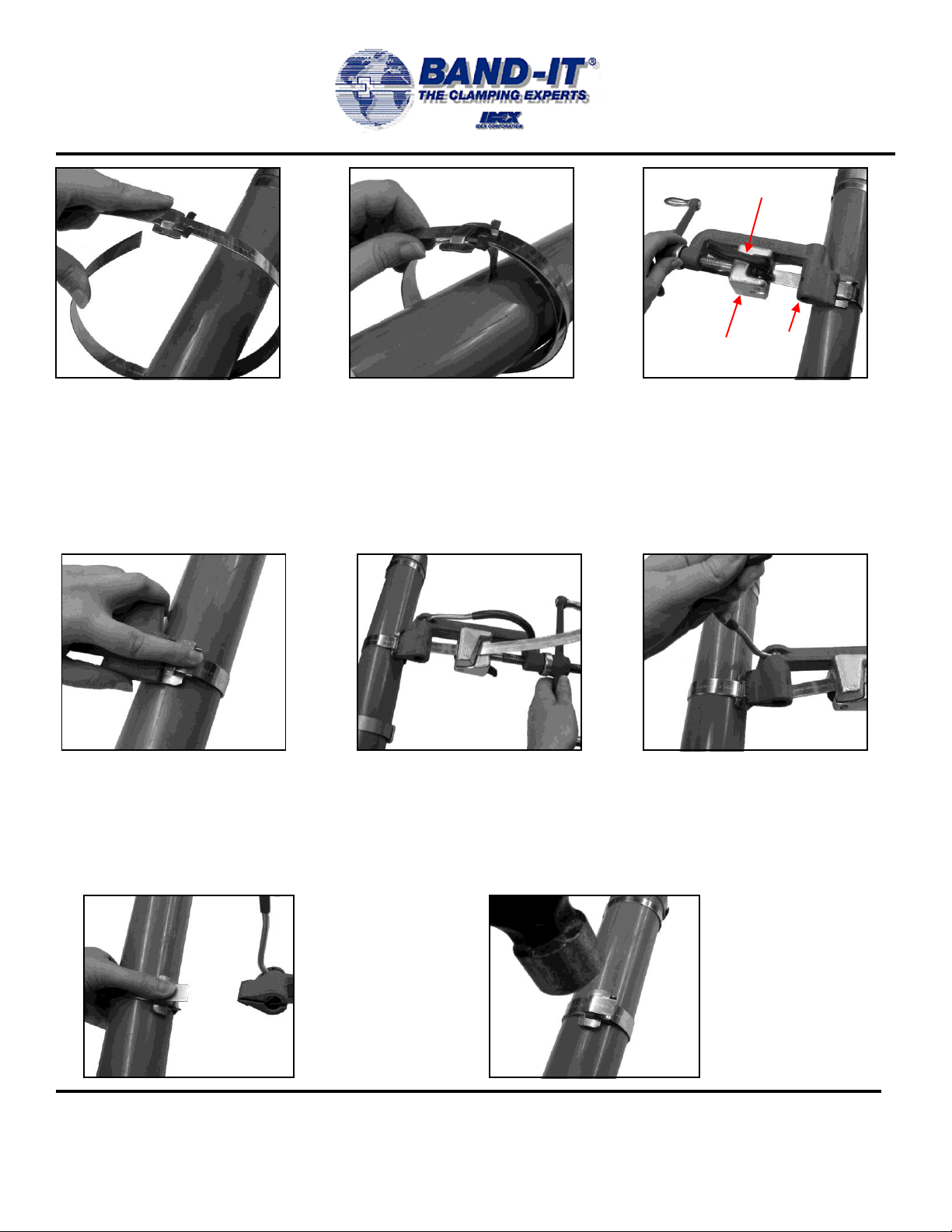

1. Slide buckle on band as shown.

Bring tip of band around workpiece

and again through buckle.

Note: Band may be used from bulk roll

as this completely eliminates waste of

band.

2. Insert band around workpiece

again and through buckle. Double

wrapping develops much more radial

compression than single wrapping.

Bend end of band under buckle.

3. Place band in opening of tool nose

and Gripper Block. Move into slot as

far as possible, to avoid buckle sliding

into Tool Nose. Tighten band clamp by

turning the Tension Handle clockwise

while holding Band Gripper tight against

band. NOTE: The spring load of the

band gripper is not intended to secure

and prevent the band from slipping

during tension process.

4. Place finger on BAND-IT Band at

buckle bridge while tensioning. When

you observe the band stops moving

through the buckle, maximum pressure

is being exerted around the workpiece.

Stop turning handle.

5. Roll tool over buckle, backing off

with Tension Handle 1 - 1½ turns

throughout entire rolling operation.

Failure to back off tension with tension

handle throughout roll-over may result

in breaking the band. There is no loss

of tension as band released is used up

in this process.

6. Rotate Cutting Handle forward to cut

the band. When applying Giant Band

clamps, prior to cutting off clamp,

release Band Gripper and push Tool

Nose away from buckle approx. ¼”.

7. Remove tool, holding

stub of band down.

8. Hammer down buckle ears

to complete BAND-IT clamp.

Tool Nose

Gripper Block

Band Gripper

Page 3

BAND-IT-IDEX, Inc.

A Unit of IDEX Corporation

4799 Dahlia Street

Denver, CO 80216-0307 USA

P: 1-800-525-0758

F: 1-800-624-3925

Document # P91687 Rev. H

© Copyright

BAND-IT-IDEX, Inc. 2010

All rights reserved

www.BAND-IT-IDEX.com

Page 3 of 4

C00369 Heavy Duty

Hand Tool

1. To assist in removing threaded parts,

apply heat to soften locking compound.

2. When connecting item 13 (Set Screw)

to item 14 (Cutter Bar), clean threads

(male and female) of foreign matter, then

apply one drop of medium strength

locking compound (Loctite 242 or equiv.)

onto male thread and connect parts

together.

3. Kit # C01899 contains one each Band

Gripper, one Gripper Spring and one Pin.

Replace all parts as a set to maximize

tool performance. Periodic cleaning of

band gripper teeth will improve tool

performance.

C00369 BAND-IT TOOL

REPAIR PARTS LIST

ASSY #

ITEM

DESCRIPTION

QTY

C01899

1

PIN, ECCENTRIC LEVER PIVOT

1 2 BAND GRIPPER

1 3 GRIPPER SPRING

1

C02187

4

TOOL FRAME

1

C04799

5

SPIN GRIP

2 6 EXTERNAL RETAINING RING

2 7 BUSHING, TENSION HANDLE

1 8 TENSION HANDLE

1 9 SET SCREW, HALF DOG

1

C04986

10

TENSION SCREW, 5/8”,

LUBRICANT, FIN

1

C05887

11

CUTTER BAR HANDLE

1

12

VINYL GRIP

1

13

SET SCREW

1

14

CUTTER BAR

1

C07086

15

THRUST BEARING

1

3 4 10 2 11

12

14

15 1 5 6 7 9 8

13

Tool Assembly

Parts List

Page 4

BAND-IT-IDEX, Inc.

A Unit of IDEX Corporation

4799 Dahlia Street

Denver, CO 80216-0307 USA

P: 1-800-525-0758

F: 1-800-624-3925

Document # P91687 Rev. H

© Copyright

BAND-IT-IDEX, Inc. 2010

All rights reserved

www.BAND-IT-IDEX.com

Page 4 of 4

C00369 Heavy Duty

Hand Tool

Cleaning &

Warranty

Gripper Cleaning Instructions:

1. To remove Gripper, align

Gripper Pin hole with notch in

tool frame. Using a punch and

hammer, punch Pin out of

Slide Block.

2. Using a wire brush, clean all

foreign matter from teeth.

3. To replace Pin, Gripper

Spring must be seated in

Tension Screw hole. Align

Gripper hole with Slide Block

hole and insert Pin using a

hammer.

Refer to website for warranty information: http://www.band-it-idex.com/warranty.html

NOTE: Periodically apply food-grade white lubricant or equivalent to Tension Screw thread (item

10 on page 3) to prevent excessive wear.

If tool fails to securely grip tail of clamp, follow Gripper cleaning instructions above.

Loading...

Loading...